Injection Mould Manufacturing and Design Guide

From Concept to Precision – Your Partner in Custom Plastic Injection Molding

🔧 Injection Mold Making Service by CKMOLD

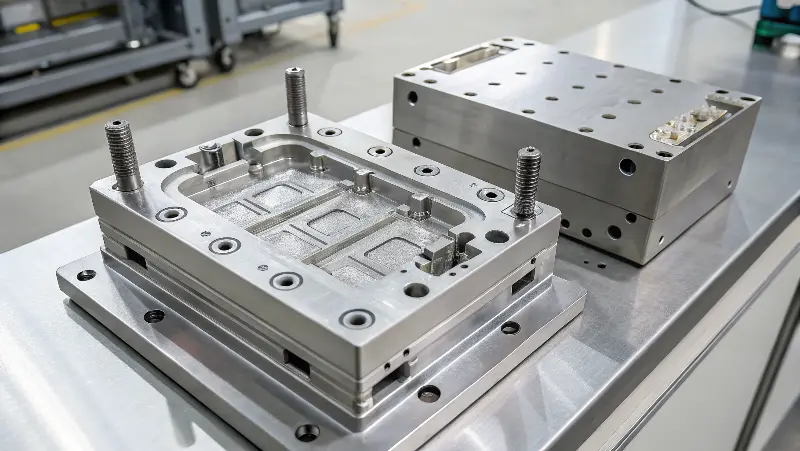

At CKMOLD, we provide complete injection mold making services with a strong focus on precision, efficiency, and customization. With our fully in-house tooling workshop, we are able to respond quickly to your urgent needs and bring your project to market faster.

Backed by decades of experience, our skilled mold makers are capable of meeting a wide range of custom specifications. Whether your project requires high-polish SPI finishes, VDI textures, or specialized mold technologies for complex geometries, CKMOLD ensures that every detail is built to perform — and built to last.

🔩 Injection Mold Solutions by CKMOLD

Find the Perfect Mold Steel for Your Project

At CKMOLD, we help you select the most suitable mold steel to ensure durability, precision, and cost-efficiency in every injection molding project. From high-volume production to complex engineering-grade parts, we provide tailored solutions to meet your exact requirements.

🎯 Achieve Outstanding Results with the Right Material – Every Time.

📚 CKMOLD Resources: Injection Mold Steel Guide

What Are Plastic Mold Steels?

What Type of Steel Is Used for Injection Molds?

Which Tool Steel Is Right for Your Mold?

What Are Plastic Mold Steels?

Plastic mold steels are specialized tool steels designed to withstand the high pressure, temperature, and wear involved in the injection molding process. At CKMOLD, we select mold steels based on your part’s geometry, volume, and surface finish requirements to ensure long-term performance and dimensional stability.

🛠️ CKMOLD Insights: Key Characteristics of Plastic Mold Steels

At CKMOLD, we carefully evaluate mold steel properties to ensure every tool delivers consistent performance throughout its production lifecycle. Here are the essential characteristics we prioritize when selecting mold steels:

🔹 High Hardness

To ensure long service life and dimensional stability, our selected steels provide excellent resistance to wear, abrasion, and deformation — even under high-pressure molding conditions.

🔹 Excellent Thermal Conductivity

Efficient heat dissipation is critical in reducing cycle times and avoiding thermal stress. We choose steels that offer high thermal conductivity to support optimal cooling and maintain part quality.

🔹 Strong Corrosion Resistance

Injection molds often come into contact with corrosive plastic resins, mold release agents, and cleaning fluids. CKMOLD uses steels with strong corrosion resistance to extend tool life and reduce maintenance costs.

🔹 Low Thermal Expansion

To minimize dimensional changes and warping caused by rapid temperature shifts, we select steels with low thermal expansion coefficients — ensuring the mold retains its accuracy across every production run.

🧩 CKMOLD Guide: Key Factors in Selecting the Right Injection Mold Steel

Choosing the appropriate mold steel is critical to ensuring both performance and cost-effectiveness. At CKMOLD, our engineering team evaluates the following key factors to recommend the optimal material for your mold:

🔧 Mold Size and Complexity

Larger or more intricate molds may require steels with excellent machinability and dimensional stability to support fine details and maintain tolerances.

🔁 Production Volume & Tool Life Expectations

High-volume production demands steels with superior hardness and wear resistance, while lower-volume or prototype molds may allow for more economical options.

🧪 Type of Plastic Resin Used

Certain plastics — such as glass-filled, flame-retardant, or corrosive resins — require mold steels that can resist chemical attack, erosion, or high abrasion.

✨ Desired Surface Finish and Precision

If your part requires high-gloss, optical clarity, or textured finishes, we recommend steels like S136 or NAK80 that support mirror polishing and fine surface definition.

💰 Budget and Cost Efficiency

Every project has unique cost constraints. We help you strike the right balance between steel performance and overall project budget — without compromising on quality.

What Type of Steel Is Used for Injection Molds?

For plastic injection molds that do not involve abrasive fillers (like glass fiber) or corrosive additives, P20 steel remains the most widely used material. It offers a reliable balance between machinability, hardness, and cost-efficiency, making it an ideal choice for many general-purpose molding applications.

At CKMOLD, we work with a wide range of industry-standard mold steels to meet various project requirements — whether you need high-gloss surfaces, extended tool life, or resistance to harsh materials.

Below is an overview of the most common injection mold steels and their characteristics:

🔍 Comparison of Common Mold Steels (Used by CKMOLD)

| Mold Steel | Hardness (HRC) | Key Properties | Typical Applications | Suitable Plastic Materials |

|---|---|---|---|---|

| S50C | 19–22 HRC | Medium carbon steel with good wear resistance; reduced ductility | Mold bases, trial molds, low-volume production | PP, PE, ABS, rubber, soft plastics |

| P20 | 30–36 HRC | Excellent machinability, good polishability, affordable | Injection molds, blow molds, extrusion tools | PP, PE, ABS, PS, PA, rubber |

| 2738 | 29–33 HRC | Good polishability and processing stability | Polished surface molds | PP, PE, ABS, PS, PA |

| 718H | 34–38 HRC | Pre-hardened; excellent polishability and wear resistance | High-finish part molds, blow molds | PA, POM, PS, PE, PP, ABS, PBT |

| NAK80 | 37–43 HRC | Good for high-gloss and transparent parts; easy to machine | Transparent molds, mirror-polished tools | PC, PMMA (acrylic), optical plastics |

| 2083 | 48–52 HRC | Corrosion-resistant, wear-resistant, good machinability | Corrosive material injection molds | PVC, POM |

| 2344 (H13 equivalent) | 48–52 HRC | Excellent toughness, heat resistance, polishability | Engineering plastics, inserts for PA+GF/CF | PA+GF, PA+CF |

| H13 | 50–54 HRC | Hot-work die steel; wear and heat resistant | High-temp molding, die casting, inserts | PAI, PEEK, LCP, PEI, PPSU |

| S136 | 48–54 HRC | Premium polishability, high corrosion resistance | Transparent parts, corrosive resins | PC, PMMA, POM, PVC, medical-grade resins |

💡 Notes from CKMOLD Experts:

Need mirror finish? Choose NAK80 or S136.

Handling corrosive plastics? Go with 2083 or S136.

Molding glass-filled or high-temp plastics? We recommend 2344 or H13.

Working with large molds or high output? P20 and 718H offer excellent cost-performance ratio.

🧠 CKMOLD Guide: How to Choose the Right Tool Steel for Your Injection Mold

Selecting the ideal tool steel for your injection mold is a critical step in ensuring durability, precision, and overall cost-effectiveness. At CKMOLD, we evaluate multiple factors, including:

The type of plastic material used

Mold design complexity

Surface finish and dimensional accuracy requirements

Expected production volume

Cycle time and thermal demands

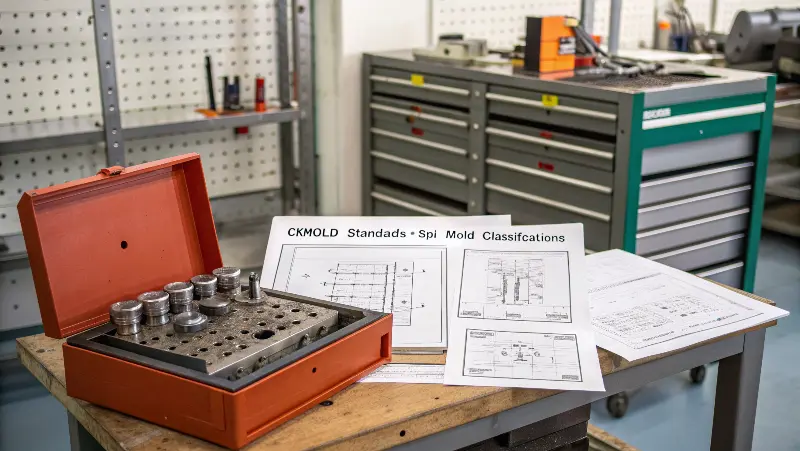

To assist with mold classification and tooling standards, the Society of the Plastics Industry (SPI) developed a system that divides injection molds into five classes — from Class 101 (for high-volume production) to Class 105 (for prototypes and short runs).

🔍 SPI Mold Classification (Used at CKMOLD)

| Class | Lifetime Cycles | Production Volume | Steel Hardness (HRC) | Wear Resistance | Thermal Conductivity | Recommended Cavity Steel |

|---|---|---|---|---|---|---|

| Class 101 | 1,000,000+ | Very High | 50–54 HRC | Very High | High | S7, H13 |

| Class 102 | ≤ 1,000,000 | High | 48–52 HRC | High | Moderate | S136, 2344 |

| Class 103 | ≤ 500,000 | Medium | 38–42 HRC | Moderate | Moderate | 2738, 718, 718H, NAK80 |

| Class 104 | ≤ 100,000 | Low | 15–25 HRC | Low | Low | S50C, P20 |

| Class 105 | ≤ 500 | Prototype / R&D | ≤ 15 HRC | Very Low | Very Low | Aluminum |

🧩 CKMOLD Breakdown of Each SPI Class

🔹 Class 101 — Ultra High Volume

Used for mass production of millions of parts. Built from premium hardened tool steels like H13 or S7. Maximum durability, longer maintenance intervals, and tight tolerances.

🔹 Class 102 — High Volume

For large-scale production where some corrosion resistance and wear life is necessary. Suitable for tools using S136 or 2344 (H13 equivalent) steel.

🔹 Class 103 — Medium Volume

A widely used option for medium-duty projects. Balances cost and performance using materials such as NAK80, 718H, or 2738.

🔹 Class 104 — Low Volume

Used for short production runs or less demanding applications. P20 or S50C steels offer good value for pilot tools or bridge production.

🔹 Class 105 — Prototype / R&D

Typically used for initial design validation or functional testing. Soft materials like aluminum are common for fast turnaround and easy modification.

📌 CKMOLD Expert Tips:

Not all molds fit strictly into a single class — our engineers will guide you based on your functional needs and ROI targets.

When molding abrasive or high-temperature plastics, we recommend corrosion- or heat-resistant grades, regardless of SPI class.

Always match cavity steel hardness with production volume to avoid premature wear or overengineering.

🛠️ CKMOLD Standards: Design Requirements for SPI Mold Classifications

At CKMOLD, we build all molds to internationally recognized SPI mold classifications, from prototype tools to full-scale production molds. Below is an overview of the design and material standards we follow for each SPI mold class.

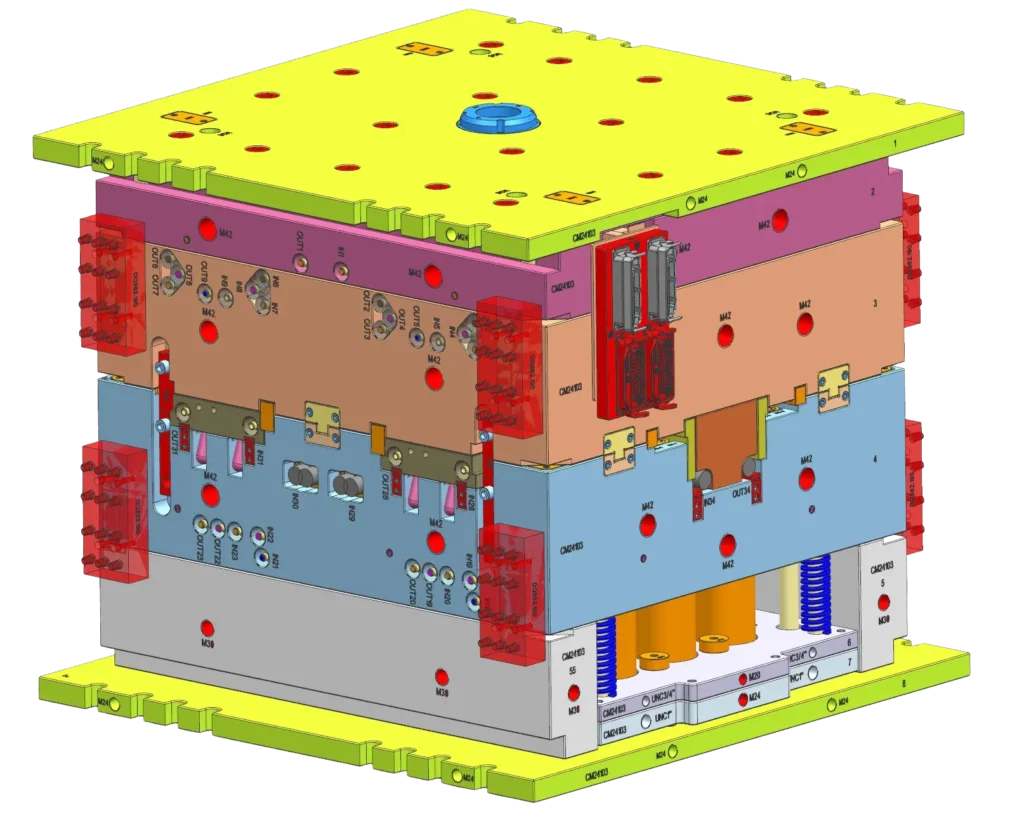

🥇 Class 101 Mold – Ultra High Volume (1,000,000+ cycles)

CKMOLD High-Performance Tooling for 24/7 Production

Complete 3D/2D mold structure drawings required

Mold base: Minimum hardness of 28 HRC

Cavity and core: Minimum hardness of 52 HRC (e.g., H13, S7)

All moving and wear components (ejector pins, lifters, slides, etc.) must be hardened

Guided ejection system required

Slides must include wear plates or inserts

Positive parting line locks to ensure alignment during high-speed production

Comprehensive cooling systems designed into cavities, cores, and slides

Components exposed to cooling water should use stainless materials (e.g., S136) or have anti-corrosion treatment to prevent rust and reduce maintenance

🥈 Class 102 Mold – High Volume (≤ 1,000,000 cycles)

Built for durability, moderate complexity, and long service life

Full mold structure drawings required

Mold base: Minimum hardness 28 HRC

Cavities/cores: At least 48 HRC

All wear-prone areas must be properly heat treated

Efficient cooling lines should be embedded in all plastic-contact areas

Parting line locks recommended for mold alignment and life extension

🥉 Class 103 Mold – Medium Volume (≤ 500,000 cycles)

Cost-effective tooling for mid-range production

Mold structure drawings required

Mold base: Minimum 15 HRC

Cavities/cores: Minimum 38 HRC

Wear components optional depending on application and part tolerance requirements

Suitable for consumer products and non-cosmetic parts with moderate lifespan

🔹 Class 104 Mold – Low Volume (≤ 100,000 cycles)

Pilot or low-volume tooling at minimized investment

Basic mold drawings required

Mold base can be made from mild steel

Cavities/cores: Minimum 15 HRC, usually pre-hardened steels like P20

Suitable for pre-production runs, marketing samples, or secondary part development

🔸 Class 105 Mold – Prototype Use (≤ 500 cycles)

Rapid tool for concept validation or fit-testing

Constructed using low-cost materials such as aluminum, cast metal, or epoxy

Not suitable for production; intended for short-term use only

Quick turnaround, low tooling cost — ideal for design verification

📩 Need help selecting the right SPI mold class for your project? Talk to CKMOLD’s Engineering Team — we’ll recommend the best solution based on your part geometry, plastic type, and production targets.

💰 Injection Mold Pricing

Delivering High-Precision, Cost-Effective Tooling — Built to Perform, Priced to Compete

📚 CKMOLD Resources: Understanding Injection Mold Pricing

💰 How Much Does It Cost to Make an Injection Mold with CKMOLD?

📐 How to Request an Accurate Injection Mold Quote from CKMOLD?

🎯 What’s a Reasonable Price for a Custom Plastic Injection Mold?

🏗️ Why Are Injection Molds a Significant Investment? CKMOLD Explains

How Much Does It Cost to Have an Injection Mold Made?

At CKMOLD, injection mold pricing varies depending on the mold complexity, size, and production volume requirements.

A simple, single-cavity mold designed for low-volume production typically ranges from $1,000 to $3,000.

More complex molds for larger parts or multi-cavity designs can cost $10,000 or more.

On average, a standard mold producing a straightforward part roughly the size of a handheld item usually costs around $5,000.

Understanding these estimates highlights the importance of early design planning and optimization, which can significantly reduce tooling costs and accelerate your time to market.

Factors That Influence Injection Mold Costs

The price of an injection mold can range from $1,000 to over $10,000, depending on multiple important factors. we consider these key elements when preparing your mold quotation:

| Factor | Impact on Cost |

|---|---|

| Mold Size & Complexity | Larger and more intricate molds require more materials and labor, increasing overall costs. |

| Mold Steel Material | Higher-grade steels (e.g., hardened tool steels) cost more than mild steel or aluminum alternatives. |

| Mold Design | Number of cavities, gate locations, ejector pins, and complexity of design all affect pricing. |

| Production Volume | High-volume molds are engineered for durability and longevity, resulting in higher upfront costs but lower cost per part. |

| Manufacturing Location & Supplier | Labor and material costs vary by region; molds produced in China typically offer competitive pricing without compromising quality. |

| Additional Features | Hot runner systems, advanced temperature controls, and automation increase mold complexity and cost. |

Providing detailed and accurate information about your project and working closely with CKMOLD’s experienced team helps us deliver precise, fair, and competitive mold pricing tailored to your needs.

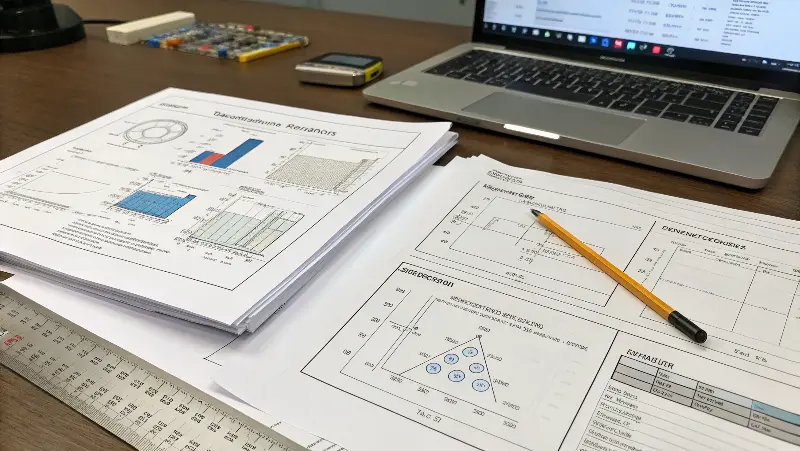

🔍 How to Get an Accurate Injection Mold Quote from CKMOLD

To ensure you receive a fast, accurate, and cost-effective mold quotation from CKMOLD, please follow the steps below:

1. 📄 Provide Detailed Part Specifications

Clearly describe your part:

Function and usage scenario

Overall dimensions and geometry

Material to be used (e.g., PP, ABS, PC)

Target quantity and delivery schedule

2. 🛠 Clearly Define Mold Requirements

Let us know your mold preferences:

Mold type: Hardened steel, Pre-hardened steel, or Aluminum

Surface finish: Polished, Textured, Etched, etc.

Special features: Cooling channels, Hot runner, Ejector system, etc.

3. 📊 Share Your Expected Production Volume & Timeline

Inform us about:

Estimated annual production volume

Mold lifespan expectations

Any production milestones or deadlines

4. 🧩 Submit Mold Design Files

Provide 3D CAD files (preferably in STEP/STP, IGS, or X_T format)

If available, include 2D drawings with tolerances

Let us know your preferred design software, if applicable

5. 📏 Provide Accurate Part Dimensions and Tolerances

Include any critical tolerances or assembly requirements

Inform us of shrinkage factors, insert areas, and undercuts

6. 💬 Request a Comprehensive Quote

We will provide a detailed quotation that includes:

Mold design and manufacturing cost

Tooling components (e.g., inserts, sliders, ejector system)

Sample or T1 part cost

Optional extras (e.g., texturing, special steel, shipping, maintenance plans)

7. 🧾 Review and Clarify the Quote

Ensure all requested items are covered

Ask if anything is unclear—we’re here to help

8. 🧪 Request a Prototype or Sample (Optional)

We can offer rapid prototypes or T1 samples to validate your design before mass production.

9. 🤝 Negotiate Terms (if needed)

We’re flexible and open to discussing pricing terms, delivery schedules, or technical adjustments.

10. ✅ Evaluate CKMOLD as Your Manufacturing Partner

CKMOLD has over 20 years of experience in custom injection mold making

Proven track record with OEMs, engineering firms, and product developers globally

Expertise in a wide range of materials, tolerances, and international quality standards

✅ 6 Key Details CKMOLD Needs for an Accurate Injection Mold Quote

To receive a fast and highly accurate mold quotation from CKMOLD, please make sure to prepare the following information. The more complete and detailed your input, the more precise and reliable our quote will be.

| 🔍 Quote Accuracy | 📐 Drawing | 🧱 Material | 📦 Production Volume | 🎨 Color | ✨ Surface Treatment |

|---|---|---|---|---|---|

| 100% | Complete 3D product model or mold design drawing | Exact resin and grade (e.g., Zytel® 70G33L NC010) | Specific quantity (e.g., 500,000 pcs/year) | Exact Pantone or RAL color code | Clearly defined finish: VDI, SPI, MT, or YS standards |

| 100% | Physical sample part provided | Physical reference sample (actual material) | Annual or batch quantity confirmed | Use sample as color reference | Use sample as finish reference |

| 90% | Multiple angle photos of sample | General resin type (e.g., ABS) | Per order quantity (e.g., 2,000 pcs) | Sample photo for reference | Sample photo for reference |

| 80% | Product sketch or concept drawing | Exact resin and grade | Per order quantity (e.g., 1,000 pcs) | Pantone or RAL color code provided | Surface standard (VDI, SPI, MT, YS) indicated |

📌 Important Tip from CKMOLD

Providing 3D CAD files + clear material and production info will significantly reduce lead time and ensure your tooling is engineered correctly from the beginning. If you’re unsure about any information, our team is happy to guide you step by step.

📤 Ready to get started? Send your files and specifications to CKMOLD now — let’s bring your project to life with precision and reliability.

💡 What Is a Reasonable Cost for a Plastic Injection Mold? — CKMOLD Insight

The cost of a plastic injection mold can vary significantly depending on multiple factors such as part complexity, mold size, steel grade, and production volume.

At CKMOLD, here’s a general price range to help guide your expectations:

Simple molds (single-cavity, basic geometry): $1,000 – $3,000 USD

Standard molds (multi-cavity, moderate complexity): $5,000 – $8,000 USD

High-precision molds (tight tolerance, complex parting lines, hardened steel): $10,000+ USD

💡 Tip: If you’re new to the industry or unsure about pricing, it’s always wise to get multiple quotes and compare based on quality, not just price. At CKMOLD, we’re happy to walk you through that process — transparently and professionally.

✅ How to Choose the Right Injection Mold Manufacturer — CKMOLD Guide

To ensure your mold investment is optimized for both performance and budget, follow this proven selection process:

🧾 Step 1: Collect Detailed Project Information

Before contacting suppliers, prepare:

2D drawings / 3D CAD files of your part

Target resin material, color, and surface finish

Estimated production volume and timeline

Any specific requirements: e.g., FDA, CE, UL, etc.

🌍 Step 2: Compare Multiple Suppliers (Including CKMOLD)

Reach out to mold makers from different regions (China, SE Asia, India)

CKMOLD is based in Dongguan, China, and has served over 300 international clients

Always request the supplier sign an NDA before sharing project files

📊 Step 3: Analyze and Standardize Quotations

Once you’ve received the quotes:

Compare items like mold material, number of cavities, dimensions

Create a unified spec sheet and ask suppliers to update their quotes accordingly

This levels the playing field for an apples-to-apples comparison

🏭 Step 4: Evaluate Mold Makers (Like CKMOLD)

After harmonizing the specs, do the following:

Remove the highest and lowest price quotes to focus on quality options

Ask CKMOLD or other candidates for:

Factory images/videos

Certifications (ISO9001, ISO14001, ISO45001)

Customer references

Review their websites, social media, testimonials, etc.

For critical projects, consider third-party audits or factory visits — CKMOLD welcomes both

✍️ Step 5: Finalize Order & Start Production

Negotiate payment terms

Sign the mold contract

Confirm lead time and project milestones

With CKMOLD’s transparent process and experienced engineering team, you can confidently achieve the best balance between quality and cost for your injection mold project.

📤 Ready for a quote? Contact CKMOLD now and get expert support from our team within 24 hours.

Why Are Injection Molds So Expensive?

Injection molds are pricey because they require extreme precision, expert engineering, and a multi-step production process. Every stage — from design to final validation — demands time, skill, and high-quality materials, all of which add up.

Let’s break it down.

What Drives the Cost of an Injection Mold?

Several key factors contribute to the high cost of building an injection mold. Here’s a breakdown with estimated percentage shares:

| Cost Factor | What It Involves | Estimated Share |

|---|---|---|

| Mold Material | High-grade tool steels (like hardened steel, stainless steel, or aluminum) are essential for durability and precision — but they’re not cheap. | 20% |

| Design & Engineering | Skilled engineers create CAD files, mold flow simulations, and tooling layouts. It’s a high-expertise process. | 10% |

| Manufacturing Process | CNC machining, EDM, polishing, and heat treating are time- and equipment-intensive. | 20% |

| Skilled Labor | Toolmakers and technicians are needed throughout — from machining to mold assembly and fine-tuning. | 5% |

| Testing & Validation | Each mold must be tested for accuracy and reliability, which takes time and resources. | 5% |

| Mold Complexity | Multi-cavity designs, tight tolerances, and advanced features (like lifters or slides) add difficulty and cost. | 20% |

| Lead Time Pressure | Rush jobs mean overtime, faster shipping, and priority on machines — all of which raise the cost. | 5% |

| Quality Control | Ensuring dimensional accuracy, surface finish, and part consistency requires multiple QA checks. | 5% |

| Manufacturer Margin | Like any business, mold shops add a profit margin to stay sustainable. | 10% |

Can These Costs Be Reduced?

Yes — but it takes smart planning. Here’s how you can manage costs effectively:

Simplify your part design where possible

Reduce cavity count for lower-volume runs

Extend lead time to avoid rush charges

Work with an experienced partner like CKMOLD to optimize mold construction without sacrificing quality

💡 At CKMOLD, we help clients reduce unnecessary costs while still building molds that perform and last.

💰 Injection Mold Manufacturing

Bring Your Ideas to Life with CKMOLD’s Precision Mold Making Expertise

📚 CKMOLD Resources for Injection Mold Manufacturing

How to Find a Reliable Injection Mold Manufacturer in China

How Long Does It Take to Manufacture a Plastic Injection Mold?

What Is the Process of Making an Injection Mold?

How Long Can an Injection Mold Last?

How to Source a Plastic Injection Mold Maker in China ?

If you’re looking for a reliable injection mold supplier in China, it’s essential to understand the geographic distribution and strengths of China’s mold manufacturing industry. At CKMOLD, we’re based in Shenzhen, Guangdong — right in the heart of one of China’s most advanced mold-making regions.

Here’s an overview of the major mold-producing regions in China, including the pros, price levels, and their industrial focus:

| Region | Quality | Cost | Key Characteristics | Industry Share |

|---|---|---|---|---|

| Guangdong | ★★★★★ | $$$$ | The birthplace of China’s mold industry. Known for high-precision tooling and advanced technology. Ideal for export-level projects. Home of CKMOLD. | 25% |

| Shanghai | ★★★★★ | $$$$ | Home to many large-scale mold shops, especially in the automotive and electronics sectors. A popular location for multinational clients. | 15% |

| Jiangsu | ★★★★★ | $$$$ | A growing hub for high-end tooling, especially for medical, electronics, and automotive parts. Many factories relocated from Shanghai. | 20% |

| Zhejiang | ★★★☆☆ | $$ | Known for general-purpose molds, such as household items, bins, and chairs. Many medium-sized manufacturers with flexible pricing. | 25% |

| Fujian | ★★★☆☆ | $$ | Smaller mold shops with experience in basic tooling. Not yet industrially consolidated. Prices and quality similar to Zhejiang. | 10% |

| Hebei | ★★☆☆☆ | $ | Industry still developing. Less infrastructure and specialization. Some growth driven by automotive demand near FAW-Volkswagen. | 5% |

Why Choose CKMOLD?

Located in Shenzhen, Guangdong, CKMOLD delivers high-precision molds with global export standards. We combine the engineering expertise of China’s most experienced mold region with cost-efficient solutions tailored for clients in Europe, North America, and beyond.

Looking for the right mold partner in China? Let CKMOLD simplify your sourcing process.

How to Find a Reliable Injection Mold Factory

Finding the right injection mold manufacturer is critical to your project’s success. At CKMOLD, we believe in transparency and efficiency — and we’re here to guide you through the most effective ways to connect with qualified mold factories in China.

Where to Look

Based on current trends in China’s injection mold industry:

60% of mold factories operate through B2B online platforms.

30% have their own official websites and social media presence.

10% attend trade shows and industry exhibitions.

Common Channels to Find Trusted Mold Suppliers:

📌 B2B Online Directories

These platforms are widely used and offer supplier ratings, company profiles, and RFQ tools:

Alibaba

Made-in-China

Global Sources

🔍 Google Keyword Search

Use search terms like “custom injection mold manufacturer in China” or “plastic tooling supplier Shenzhen” to find vetted websites like CKMOLD.

📱 Social Media Platforms

Some mold manufacturers share their production capabilities and customer projects through:

YouTube

Facebook

LinkedIn

Pinterest

Quora

These platforms can give you a sense of the factory’s communication style and quality standards.

🌐 Company Official Websites

A factory’s official website is often the most complete source of information. At CKMOLD.com, we provide:

Engineering capabilities

Tooling lead times

Customer success stories

Certifications

Contact information

🏢 Industry Associations & Trade Shows

Attending exhibitions or consulting industry bodies can help you verify factory legitimacy:

China Plastics Machinery Industry Association (CPMIA)

China International Mould & Tooling Expo (CIMTE)

🎯 CKMOLD Tip: Looking for a mold maker that speaks your language (literally and technically)? Contact us for a fast, free consultation — we ship worldwide and specialize in high-precision plastic tooling.

How to Evaluate Injection Mold Manufacturers

The precision and reliability of your injection mold have a direct impact on your product quality, production efficiency, and long-term manufacturing success. Choosing the right mold maker can help reduce downtime, minimize maintenance issues, and ensure consistent, high-quality parts.

Here are the key factors to consider when evaluating an injection mold manufacturer:

💰 Pricing & Overall Cost

Don’t just look at the total quote — break it down. Compare pricing from multiple suppliers and pay attention to what’s included:

Material costs (e.g. steel grade)

Labor rates

Tool design fees

Shipping and after-sales support

Smaller factories may offer competitive pricing on simple tools, while larger manufacturers often provide stronger technical support for complex projects. Choose based on project scope, complexity, and long-term value — not just the cheapest option.

✅ Quality Control & Assurance

Make sure the supplier has strict quality control procedures in place. You can ask for:

A list of inspection equipment (e.g. CMM, hardness testers, optical projectors)

An overview of their QC process: Incoming material checks, in-process inspections, and final mold validation

Documentation such as ISO certifications or internal inspection reports

Reliable manufacturers will be transparent about their quality standards and happy to share proof of their process.

Want help evaluating a supplier? Or prefer a shortcut to a proven one?

Contact CKMOLD — our factory is ISO-certified, detail-oriented, and export-ready.

🏭 Experience & Industry Reputation

Look for mold manufacturers with a proven track record in your specific industry or similar applications. Experience matters — it means fewer mistakes, better design insights, and faster turnaround.

Ask for examples of past projects similar to yours.

Check customer testimonials, Google reviews, or LinkedIn endorsements.

Verify their standing through industry associations or trade directories.

A reputable supplier will be transparent and proud to showcase their work.

🧾 Certifications & Compliance

Certifications reflect a company’s commitment to quality, safety, and environmental responsibility. Look for mold makers with credentials such as:

ISO 9001 (Quality Management Systems)

ISO 14001 (Environmental Management)

ISO 45001 (Occupational Health and Safety)

These accreditations show the factory is serious about standards — and reliable for long-term cooperation.

⚙️ Production Capacity & Lead Time

Ask for a full list of the factory’s mold-making equipment to evaluate their true capabilities. Look for:

CNC machining centers

EDM (Electrical Discharge Machining)

Grinding machines

High-speed milling and more

Ensure the supplier has enough machines and staff to meet your deadlines — especially if your project requires tight lead times or volume scalability.

🤝 Communication & Team Support

Strong communication is key to a smooth project. A good supplier should:

Respond quickly and clearly to your messages

Have at least two English-speaking sales reps

Employ multiple in-house engineers who can support your technical questions

This avoids delays caused by language gaps or technical misunderstandings — especially in the design and DFM (Design for Manufacturability) stages.

📌 Pro Tip: At CKMOLD, our English-speaking team and seasoned engineers work closely with you to ensure smooth communication and efficient project execution — from concept to delivery.

How Long Does It Take to Make a Plastic Mold?

Typically, producing a plastic injection mold takes 2 to 8 weeks, depending on several factors like mold complexity, material choice, and the manufacturer’s capabilities. Simple molds can be completed in as little as 2–3 weeks, while highly complex or large production molds may require up to 8 weeks or more.

Typical 30-Day Mold Production Timeline

| Process Step | Estimated Time |

|---|---|

| Mold Design | 3 days |

| Procurement of Mold Steel & Accessories | 3 days |

| Mold Manufacturing & Quality Inspection | 18 days |

| Hardening & Surface Treatment | 3 days |

| Assembly, Fitting & Testing | 3 days |

Note: These are general estimates. Actual times may vary based on the manufacturer, mold design complexity, and materials used. Always consult your manufacturer for a tailored timeline based on your project.

Four Key Factors Impacting Injection Mold Lead Times

1. Mold Design Complexity

The more detailed and precise your mold design is — with fine features, tight tolerances, or multiple cavities — the longer it will take. Complex molds require extra time in CAD design, CNC machining, EDM, polishing, and finishing. Skilled craftsmanship is essential for these demanding projects.

2. Managing Design Changes

Design iterations are common in mold development. Testing prototypes often reveals tweaks needed to achieve desired quality. Every design change means revisiting CAD models, reprogramming machines, and sometimes remaking parts — all of which add to the timeline.

3. Material Selection

Material choice directly affects machining time and mold durability. Hardened steel molds offer exceptional longevity but take longer to machine due to their hardness. Mild steel molds are faster and easier to machine but have a shorter lifespan, which might be fine for lower volume runs.

4. Manufacturer’s Expertise & Capacity

An experienced mold maker with a well-equipped facility can significantly reduce lead times. Advanced CNC machines, EDM equipment, and streamlined workflows enable faster turnaround without sacrificing quality. Smaller or less-equipped shops may face bottlenecks, extending delivery times.

At CKMOLD, we combine skilled engineers, advanced equipment, and efficient production processes to deliver molds on time — meeting your quality standards and project deadlines.

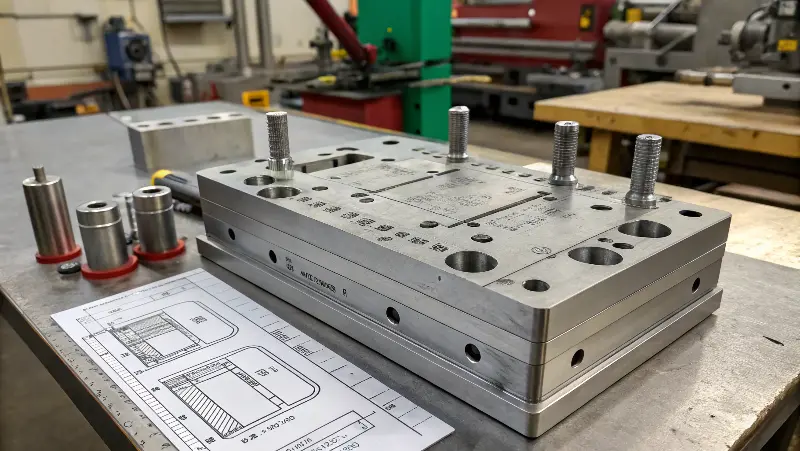

What Is the Injection Mold-Making Process?

The injection mold-making process covers everything from initial design and prototyping to final mold finishing — preparing it for production or shipment to the customer.

At CKMOLD, we closely manage the entire process with a detailed Mold Production Schedule to ensure every step stays on track and meets deadlines.

Step-by-Step Injection Mold-Making Overview

1. Design & Prototyping

Develop a precise 3D mold and part design using industry-leading CAD software like UG or PROE.

Produce a prototype part to validate function and fit, allowing for any necessary design revisions early on.

2. Mold Design

Create detailed mold designs that include all internal features — cavities, cores, cooling channels, and ejector pins.

Ensure the design meets your exact tolerances, production volume, and performance requirements.

3. Material Selection

Choose the optimal mold material based on your part needs and production volume. Options include hardened steel for long runs or mild steel for lower volumes.

Consider durability, corrosion resistance, and thermal conductivity to maximize mold lifespan and efficiency.

4. Precision Machining

Use CNC machining, EDM, and other advanced techniques to craft the mold components with high precision.

Manufacture the mold’s cavities, cores, and all intricate details exactly to specification.

5. Assembly & Installation

Assemble mold components including inserts, cores, and ejector systems.

Verify perfect fit and function to prevent any interference during molding.

6. Inspection & Testing

Conduct thorough inspections to ensure the mold meets all quality and dimensional standards.

Perform trial runs to validate the ejection system, cooling channels, and final part quality.

7. Quality Control

Run comprehensive quality checks covering part consistency, dimensional accuracy, and surface finish.

Make any necessary fine-tuning adjustments before final approval.

8. Packaging & Shipping

Carefully package the mold to protect it during transport.

Arrange shipping directly to your facility or designated destination.

Additional Services During Mold Production

Surface Treatment: Apply treatments like chrome plating or nitriding to improve hardness and corrosion resistance.

Coatings: Use release agents or lubricants to enhance mold release and reduce wear.

Mold Maintenance Guidance: Provide detailed instructions on mold care to maximize durability and performance over time.

How Long Does an Injection Mold Last?

On average, a properly maintained injection mold can have the following lifespan based on production volume:

High-volume production (100,000–500,000 pcs/year): 1 to 3 years

Moderate-volume production (50,000–100,000 pcs/year): 3 to 5 years

Low-volume production (10,000–50,000 pcs/year): 5 to 10 years or more

Key Factors That Impact Injection Mold Lifespan

Mold Design and Build Quality: Precision engineering and high-grade materials result in molds that last longer and perform consistently.

Production Volume & Usage: The more parts produced, the faster the mold wears out. High-cycle molds naturally have shorter lifespans.

Material Selection: Hardened steel molds outlast those made from softer materials like aluminum or copper. Material choice affects durability and maintenance frequency.

Maintenance & Cleaning: Regular upkeep and cleaning extend mold life by preventing buildup, corrosion, and mechanical wear.

Operating Conditions: Extreme temperatures, high injection pressures, and corrosive environments can accelerate mold wear and reduce lifespan.

4 Proven Ways to Extend Your Injection Mold Life

1. Maintain Regular Cleaning and Upkeep

Keep your molds spotless and well-maintained. Use high-quality cleaning agents to remove residue and prevent buildup. Clean molds produce consistent, defect-free parts and last significantly longer.

2. Optimize Your Cooling System

Proper cooling is critical. Effective cooling not only solidifies the part quickly but also protects the mold from heat-related damage. Insufficient cooling can cause warping and reduce mold durability.

3. Use High-Quality Mold Steel

Investing in premium mold steel pays off in the long run. Cheap steel may reduce upfront costs but leads to faster wear and more frequent mold replacements. High-quality steel molds deliver better performance and longevity.

4. Invest in Automation

Automated molding systems reduce human error and improve consistency, which helps prevent premature mold damage. For high-volume or repetitive production, automation keeps molds in better condition and extends their usable life.

Free Optimization Solutions from CKMOLD

Expert Design Review & Feedback

Receive professional guidance to refine your mold design for better performance and manufacturability.Structural Optimization to Cut Mold Costs

We help streamline your mold structure to reduce complexity and lower overall production expenses.Direct One-on-One Consultations with Our Engineers

Collaborate closely with our technical team to address your specific needs and get tailored solutions.