What Are the Hidden Gremlins Causing Your Plastic Parts to Deform, and How Can We Banish Them?

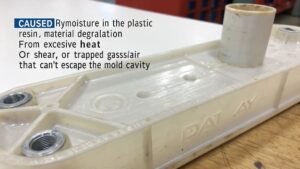

Seeing your freshly molded plastic parts warp, twist, or sink is incredibly frustrating, right? It means wasted material, production delays, and unhappy customers. It eats into your profits. Diagnosing plastic part deformation starts with identifying the type of defect—like warpage, sink marks, or bowing. Then, we systematically investigate material properties,