Choosing the wrong injection mold base can lead to production nightmares and hidden costs. It feels complex, but getting it right is crucial for efficient, high-quality molding. Let our CKMOLD engineers guide you through the key decisions.

Wise mold base selection1 involves carefully considering the required size based on your part and press, understanding the function of key components, choosing the right material for performance and longevity, adhering to relevant standards like DME or HASCO2, and avoiding common pitfalls.

Selecting a mold base isn’t just picking a block of steel; it’s laying the foundation for your entire molding operation. As someone who’s built a business (CKMOLD) around molds, I’ve seen firsthand how crucial this step is, especially for designers like Jacky who need precision and reliability. Let’s break down the essential factors our engineers always consider.

How Do I Determine the Correct Mold Base Size for My Mold?

Picking a mold base that’s too small is a recipe for disaster, unable to fit your parts or function correctly. Go too large, and you’re wasting money on steel and potentially limiting which presses you can use. How do you hit the sweet spot?

Determine the correct mold base size by calculating the space needed for the cavity and core inserts, ensuring sufficient steel around them, accommodating the required ejector stroke3, confirming compatibility with your injection molding press4 (tie bars, platen size), and leaving room for any necessary features like cooling or side actions.

Getting the size right is fundamental. It’s not just about barely fitting the mold inserts. You need to think about several interacting factors:

- ### Cavity, Core, and Layout: Start with the dimensions of your cavity and core blocks. How many cavities will there be? You need adequate steel surrounding these inserts for strength and to accommodate cooling channels. Don’t forget space for the runner system and gate location. A common rule of thumb is to have at least 2-3 inches (50-75mm) of steel from the cavity/core edge to the mold base edge, but this varies.

- ### Ejector Stroke Requirements: How deep is your part? The ejector system needs enough travel (stroke) to push the part completely off the core. This dictates the height of the ejector box (risers) and influences the overall mold base height (shut height). Ensure the distance between the ejector plate and the B-plate allows for full ejection plus some clearance.

- ### Press Compatibility: This is critical. The mold base must fit your intended injection molding machine. Check these key specs:

- Tie Bar Spacing: Can the base physically fit between the press tie bars?

- Platen Size: Does the base fit on the machine platens? Are the clamping slots compatible?

- Minimum/Maximum Mold Height: Can the press accommodate the base’s overall height when closed?

- Clamp Tonnage: Is the base robust enough (and the projected area suitable) for the press’s clamping force?

-

### Space for Features: Do you need side actions (cams or slides)? Lifters? A hot runner system? These require additional space within the mold base footprint or height, which must be factored into the overall size calculation. Consider cooling line placement as well; they need adequate wall thickness. Sizing Factor Key Consideration Why It Matters Cavity/Core Size Dimensions & Number of Cavities Determines minimum internal base area needed Steel Surround Strength, Cooling Channels, Runner Space Prevents mold flex, ensures proper cooling/filling Ejector Stroke Part Depth + Clearance Ensures part can be fully ejected Press Tie Bars Physical Clearance Base must fit horizontally in the press Press Platen Size Mounting Surface Area & Clamp Slots Base must mount securely Press Mold Height Min/Max Shut Height Base must fit vertically in the press range Added Features Space for Slides, Lifters, Hot Runners, Cooling etc. Allocates room for necessary mechanisms What Are the Key Components of an Injection Mold Base?

You hear terms like "A-Plate," "B-Plate," "Ejector Pins," but what do they actually do? Specifying or discussing a mold base without knowing its parts can lead to confusion and costly errors. Let’s clarify the essential building blocks.

Key mold base components include the stationary A-side (Top Clamping Plate, A-Plate/Cavity Plate, Locating Ring, Sprue Bushing) and the moving B-side (B-Plate/Core Plate, Support Plate(s), Ejector Box/Risers, Ejector Retainer Plate, Ejector Plate, Ejector Pins), plus alignment elements (Leader Pins/Bushings, Return Pins).

Think of a mold base as having two main halves that separate, plus the system to push the part out. Here’s a breakdown:

- ### Stationary Side (A-Side): This half mounts to the stationary platen of the injection molding machine.

- Top Clamping Plate: Secures the mold to the press platen.

- Locating Ring: Centers the mold base relative to the machine nozzle.

- Sprue Bushing: Channels molten plastic from the machine nozzle to the runner system.

- A-Plate (Cavity Plate): Typically holds the cavity inserts (the "female" half forming the exterior of the part).

- ### Moving Side (B-Side): This half mounts to the moving platen of the press and opens/closes.

- B-Plate (Core Plate): Typically holds the core inserts (the "male" half forming the interior of the part).

- Support Plate(s): Provide structural support behind the B-plate to prevent flexing under injection pressure, especially important for larger molds or high-pressure applications. Sometimes integrated with the B-plate.

- Ejector Housing (Spacer Blocks/Risers): Creates space for the ejector system to move.

- Ejector Retainer Plate: Holds the heads of the ejector pins.

- Ejector Plate: Pushes the Ejector Retainer Plate (and thus the pins) forward to eject the part. Connected to the machine’s ejector system.

- ### Alignment & Ejection Components:

- Leader Pins & Bushings: Ensure precise alignment between the A and B halves as the mold closes. Critical for part quality and preventing mold damage.

- Return Pins: Push the ejector system back to its starting position as the mold closes.

- Ejector Pins (and Sleeves/Blades): Directly push the solidified plastic part off the core.

-

### Optional/Integrated Components: Things like stripper plates (for ejecting thin-walled parts), slide assemblies (for undercuts), and lifters are often integrated within the standard base structure. Component Group Key Parts Primary Function A-Side (Fixed) Top Clamp Plate, Locating Ring, Sprue Bushing, A-Plate (Cavity) Mounts mold, locates nozzle, holds cavity B-Side (Moving) B-Plate (Core), Support Plate(s), Ejector Housing (Risers) Holds core, provides support, houses ejector system Ejector System Ejector Retainer Plate, Ejector Plate, Ejector Pins, Return Pins Holds pins, pushes pins forward, returns system back Alignment Leader Pins, Bushings Ensures precise mating of mold halves How Does Material Choice Impact Mold Base Performance and Cost?

Choosing the cheapest steel seems like an easy way to save money, right? But the material your mold base is made from profoundly affects its lifespan, how much maintenance it needs, and even your part quality. How do you pick the right steel grade?

Mold base material choice significantly impacts durability5 (hardness/wear resistance), corrosion resistance6, thermal conductivity (affecting cycle time), and overall cost. Common P20 steel offers a balance, while stainless steel prevents rust, and harder tool steels combat abrasive materials, each influencing performance and long-term value.

The steel grade isn’t just a detail; it’s a core decision affecting the mold’s entire lifecycle. Here’s what our engineers consider:

- ### Common Mold Base Steels:

- P20 (Pre-hardened): The workhorse. Good machinability, reasonable hardness (~30-34 HRC), cost-effective. Suitable for many general-purpose applications and moderate production volumes. It’s the default for many standard bases.

- 1045 / S50C (Mild/Medium Carbon Steel): Cheaper than P20 but significantly softer (~10-20 HRC). Prone to wear, dents, and damage. Generally only suitable for very low volume runs or prototypes where longevity isn’t a primary concern. We rarely recommend it for production tools.

- 420 Stainless Steel (or similar grades like Stavax): Offers excellent corrosion resistance. Essential for medical applications (sterilization), food-grade parts, or when molding corrosive resins like PVC. Significantly more expensive than P20 (material cost and machining time). It also has lower thermal conductivity, potentially affecting cycle times if not managed.

- H13 / Other Tool Steels: Sometimes used for specific plates (like cavity/core plates, though less common for the entire base) or inserts within the base when extreme hardness (~48-52 HRC), wear resistance (e.g., for glass-filled materials), or high polishability is needed. Higher cost and different machining considerations.

- ### Performance Implications:

- Hardness & Wear Resistance: Harder steels resist wear from abrasive fillers in plastic and reduce damage/denting over time, extending mold life and maintaining tolerances.

- Corrosion Resistance: Critical for preventing rust in humid environments, during storage, with certain materials, or when water cooling channels are extensive. Rust = contamination and surface defects.

- Thermal Conductivity: Affects how quickly heat can be removed from the mold, influencing cooling time and overall cycle efficiency. Different steels conduct heat differently.

-

### Cost vs. Total Cost of Ownership (TCO): While stainless or tool steels have a higher upfront cost, they can be cheaper in the long run for demanding applications by reducing maintenance, downtime, and extending the mold’s useful life. Choosing solely on initial price is often a false economy. Steel Type Typical Hardness Corrosion Resistance Relative Cost Key Benefit Key Drawback 1045 / S50C Low (~15 HRC) Poor Lowest Very Inexpensive Poor durability, easily damaged P20 Medium (~32 HRC) Fair Medium Good balance of cost, machinability, durability Can rust, moderate wear resistance 420 Stainless Med-High (~50 HRC Post-HT) Excellent High Resists rust, good for medical/PVC Expensive, lower thermal conductivity H13 (Tool Steel) High (~50 HRC) Fair (can rust) High Excellent wear/heat resistance Expensive, requires heat treatment Why Do Mold Base Standards (Like DME or HASCO) Matter?

You see catalog numbers like DME #2 or HASCO K-series. Are these just brand names, or is there more to it? Ignoring mold base standards can complicate everything from design to maintenance down the road. Why pay attention to them?

Mold base standards (e.g., DME – Imperial, HASCO – Metric) define standardized dimensions, tolerances, and component styles. This ensures interchangeability of parts (pins, bushings), simplifies design integration, allows for predictable quality, and makes global sourcing of replacement components much easier.

Adhering to established standards offers significant practical advantages throughout the mold’s life:

- ### What are Standards? Companies like DME (originating in the US, primarily Imperial sizes) and HASCO (originating in Europe, primarily Metric sizes), along with others like LKM, MISUMI, Progressive Components, etc., publish specifications for common mold base configurations. These specs detail plate thicknesses, overall dimensions, the location and size of leader pins, bushings, screws, sprue bushings, locating rings, and ejector system components for various standard base sizes and styles (e.g., A-series, T-series, K-series).

- ### Interchangeability is Key: This is perhaps the biggest benefit. If you have a DME standard mold base, you can typically order replacement DME standard ejector pins, leader pins, or bushings, and they should fit correctly (within tolerance). This dramatically simplifies maintenance and repairs. Trying to source a non-standard, uniquely sized component can be time-consuming and expensive, especially if the original supplier is unknown or unavailable.

- ### Design and Integration: Designers like Jacky can work with confidence using standard base dimensions. They know the component locations, overall size, and mounting patterns, making it easier to integrate the mold design with the intended press and any automation. CAD libraries for standard bases are readily available.

- ### Predictable Quality: While quality can still vary between manufacturers even within a standard, reputable standard bases generally adhere to expected material grades (like P20 for standard) and manufacturing tolerances for features like plate parallelism, squareness, and bore locations. Non-standard or "no-name" bases may have wider variations.

-

### Global Sourcing: Using a widely adopted standard (like DME or HASCO) makes it easier to find compatible components or even similar bases internationally. If you build a tool in one region using a standard and need service in another, finding parts is much simpler.

While custom mold bases are sometimes necessary for unique applications, they often still try to incorporate standard components wherever possible to retain some of these benefits. The slight potential cost premium for a standard base is usually well worth the long-term convenience and reliability.Feature Standardized Mold Base Non-Standard / Custom Base Implication Components Interchangeable (e.g., pins, bushings) Often Unique Dimensions Easier/Cheaper maintenance for standard Dimensions Predictable, Published Specs Specific to the Design Easier design integration for standard Sourcing Multiple Suppliers, Global Availability Potentially Limited to Original Maker Easier replacement sourcing for standard Quality Generally Meets Industry Norms Variable, Depends Heavily on Manufacturer More predictable baseline quality with standard Design Files CAD Libraries Readily Available Requires Custom Modeling Faster design start with standard What Common Mistakes Should I Avoid When Selecting a Mold Base?

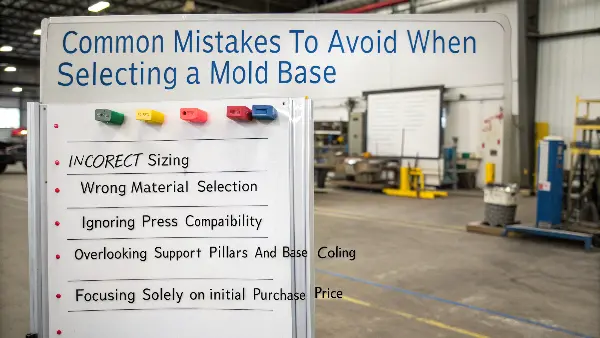

Choosing the right mold base involves balancing many factors. It’s easy to make a mistake, especially under pressure. What are the frequent errors our CKMOLD engineers see that lead to problems later on? Knowing the pitfalls helps you avoid them.

Common mistakes include incorrect sizing (often too small), selecting the wrong material for the plastic or production volume, ignoring press compatibility until it’s too late, overlooking the importance of adequate support pillars and base cooling, and focusing solely on the initial purchase price.

Based on decades of combined experience in mold design, manufacturing, and troubleshooting, here are the mistakes we see most often:

- ### Incorrect Sizing: Usually, this means choosing a base that’s too small to adequately support the cavity/core, provide robust cooling, or fit necessary mechanisms like slides. Less common, but still costly, is choosing one far too large, wasting material and potentially limiting press options. Double-check calculations for insert size, steel surround, stroke, and feature space.

- ### Material Mismatch: This is a big one. Using standard P20 for a high-volume run with glass-filled nylon will lead to premature wear. Using carbon steel (like 1045) for anything other than a prototype is asking for trouble. Forgetting stainless steel when molding PVC or for medical parts leads to corrosion. Always match the base material to the resin’s properties (abrasiveness, corrosiveness) and the expected production life.

- ### Ignoring Press Compatibility: Designing or ordering a base without confirming it fits the target molding machine(s) is a costly oversight. Always verify tie bar spacing, platen dimensions, min/max mold height, and clamping slot compatibility before finalizing the base selection. Assuming it will fit often leads to expensive rework or needing a different press.

- ### Neglecting Support and Cooling in the Base: Proper support pillars under the B-plate are crucial to prevent flexing, especially in larger molds. Don’t rely solely on the machine platens. Also, consider if cooling channels within the base plates themselves (not just in the cavity/core inserts) are needed to help manage overall mold temperature and optimize cycle times.

-

### The Lowest Price Trap: Choosing the absolute cheapest available mold base without considering the factors above (material quality, tolerances, standard vs. non-standard) is often a false economy. The Total Cost of Ownership (TCO) includes maintenance, downtime, scrap rates, and potential early replacement. A slightly more expensive, higher-quality base frequently provides better long-term value. Mistake Consequence How to Avoid Incorrect Sizing Can’t fit components, mold failure, press incompatibility Thoroughly calculate space for inserts, stroke, features, press fit Wrong Material Premature wear, corrosion, short mold life Match steel grade to resin properties & production volume Ignoring Press Fit Mold won’t fit/mount in the intended machine Verify tie bars, platen size, mold height BEFORE ordering Insufficient Support/Base Cooling Mold flex, part defects, inconsistent cycles Add adequate support pillars; consider base cooling channels Choosing Only on Price Higher TCO due to maintenance, downtime, short life Evaluate quality, materials, standards relative to application needs Conclusion

Selecting the right injection mold base requires careful thought about size, components, material, standards, and press compatibility. Avoid common mistakes by looking beyond the initial price. A well-chosen base is foundational to efficient production and high-quality parts. CKMOLD is here to share knowledge and help you succeed.

-

Understanding the best practices for mold base selection can significantly enhance your production efficiency and quality. ↩

-

Exploring DME and HASCO standards will ensure your mold base meets industry requirements for quality and performance. ↩

-

The ejector stroke is a key aspect of mold design that affects part quality and production efficiency. Learn more about optimizing this feature. ↩

-

Ensuring compatibility with your injection molding press is vital for successful operations. This resource will guide you through the necessary considerations. ↩

-

Understanding the impact of mold base materials on durability can help you make informed decisions for better performance and longevity. ↩

-

Learning about corrosion resistance in mold materials is crucial for ensuring longevity and reducing maintenance costs. ↩