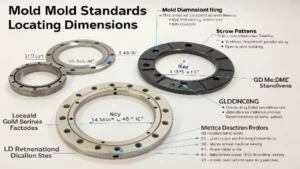

Step-by-Step Guide: How Do You Properly Install Injection Mold Locating Rings?

Struggling with mold setup times or mysterious plastic leaks? An improperly installed locating ring could be the culprit, causing misalignment and frustration. Getting this simple step right is crucial. Properly installing an injection mold locating ring1 involves meticulously cleaning mating surfaces, correctly orienting the ring, carefully inserting and hand-tightening screws,