Choosing the correct plastic for your application is often a challenging compromise. You might need the ultimate strength and heat deflection of Polycarbonate (PC) along with easy processing and impact durability of ABS. Guess incorrectly, and cracked parts, distorted products, and expensive downtime will be yours. That’s where a robust alternative, PC/ABS alloy, bridges that middle ground, giving you both materials’ best strengths.

You need PC/ABS alloy when your end use needs a combination of high impact strength, especially at low temperatures, good heat resistance, and excellent processability. Ordinary PC is very strong, but it is difficult to shape and has poor chemical resistance. PC/ABS provides a much more balanced set of characteristics, appropriate in automotive interior, electronic housing, and medical equipment products wherein ruggedness and ease of manufacture are critical. This is what to get when PC by itself or ABS by itself won’t do.

At the beginning of my career in the industry of making molds, I experienced a scenario where many clients had problems with choice of the material. They would come up with a perfect part on paper and it would not work in the real world. An aspect which had to be strong would turn too brittle. One of the components had to be easy to shape and would be bent during heat. This back-and-forth taught me an important lesson the design is just as important as is the material. The secret of transforming an excellent design into an effective product is the knowledge of the functioning of the materials such as PC/ABS. Now let us take a closer look as to why this alloy is special.

What Are The Properties Of PC-ABS Materials?

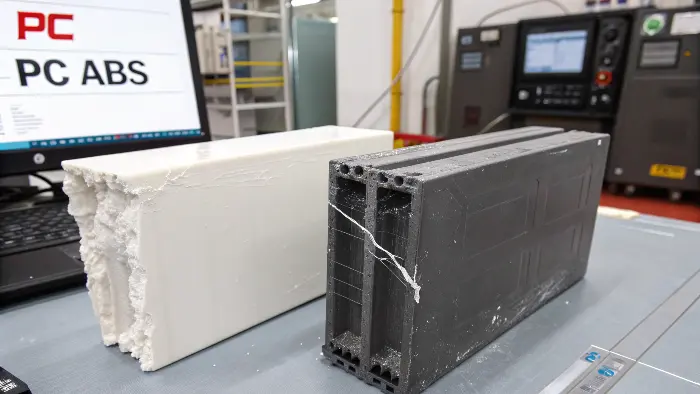

PC-ABS (Polycarbonate Acrylonitrile Butadiene Styrene) is a compound engineering thermoplastic produced by fusion of polycarbonate (PC) and acrylonitrile butadiene styrene (ABS). This combination maximizes the capabilities of the two materials so as to produce an all-purpose and highly durable plastic that has the following main characteristics:

High Impact Resistance: PC-ABS has the impact strength of ABS and the toughness of polycarbonate, which provides it with high impact resistance to shocks and drops. It does well in other applications that demand shock absorbing and durable materials.

Good Tensile Strength and Modulus: The tensile strength of PC-ABS is normally approximately 5900 psi (41 Mpa), higher than ABS alone, but somewhat lesser than pure polycarbonate. The composite is well balanced in the stiffness and the elasticity being flexible and does not lose its shape when under strain.

Heat Resistance: PC provides better thermal stability to the mix so that PC-ABS can retain its stable performance at elevated temperatures as compared to pure ABS. This is why it is appropriate in the conditions that demand a moderate heat resistance.

Chemical and Environmental Resistance: ABS is made with chemical resistance and rigidity, and polycarbonate is made with resistance to UV radiation and other environmental elements. The mixture enhances the general reliability under a wide range of circumstances.

Processability: PC-ABS can be readily injection molded or processed using common plastic machinery, which has the advantage of the ease with which ABS itself can be processed and the performance of polycarbonate.

Balanced Mechanical Properties: The combination has an excellent balance of hardness, toughness and ductile because of the percentages of the polycarbonate and ABS which can be adjusted according to the needs in application.

Overall, PC-ABS is a tough, heat stable, chemically resistant, easily processable and well balanced mechanical plastic, which is best used in engineering designs that require toughness and durability.

Is PC-ABS stronger than PC?

You’re looking for the strongest material available to yield a new part. You’ve heard that polycarbonates (PC) are super strong, so now you’re curious about PC/ABS. Making PC always the strongest option can cause unwarranted failure. A part may appear strong but could break with a sudden blow or in low-temperature conditions. Knowing PC/ABS’s particular strengths shows that it frequently offers better impact, so it’s "stronger" in terms of what counts most to durability.

Practically, in terms of impact strength and toughness, PC/ABS is also stronger compared to standard PC. Although pure PC possesses extremely high tensile strength, it tends to be notch-sensitive, so it will crack readily after encountering a sharp corner scratch. PC/ABS alloy incorporates ABS’s ductility, contributing much to its ability to resist cracking upon impact, particularly at low temperatures. That will make PC/ABS a sturdier and more tolerant raw material in everyday use, wherein parts will be liable to being hit, stressed, as well as being dropped.

Dive Deeper: The True Meaning of Strength

When we talk about whether one plastic is "stronger" than another, it’s not a simple yes or no answer. Strength can mean many different things. We need to break it down to see where each material truly shines.

A Tale of Two Strengths: Impact vs. Tensile

The difference between tensile strength and impact strength is the first thing to know. Tensile strength is a measure of the ability of a material to resist slow weakening. Pure PC tends to be the winner in this category. It is so rigid and does not stretch. Strength of impact on the other hand measures the ability of a material to withstand a sudden shock or collusion. Here is a definite weakness of PC/ABS.

I recall that one of my clients was coming up with a handheld scanner to be used in warehouses. To begin with, they decided to use pure PC as the housing material due to its high tensile strength. All the static lab tests were passed with prototypes. However, when workers began operating them on a cold warehouse floor, the scanners would break should they be dropped on accident. The thing was that PC, all its rigidity notwithstanding, is brittle. We have changed the material to PC/ABS blend. The new housings were equally hard to use on a daily basis, however, the ductility that was introduced because of the ABS component was able to absorb the impact of being dropped. The cracking issue was totally eliminated.

The Role of Temperature in Performance

Temperature plays a huge role in how plastics behave. Many materials that are tough at room temperature can become brittle when they get cold. This is known as the ductile-to-brittle transition temperature (DBTT). Pure PC has a higher DBTT than PC/ABS. This means that as the temperature drops, PC becomes brittle sooner than the alloy does.

| Property | Standard PC | PC/ABS Alloy |

|---|---|---|

| Impact Strength (Room Temp) | Good | Excellent |

| Impact Strength (Low Temp, e.g., -20°C) | Poor / Brittle | Good / Ductile |

| Ductile-to-Brittle Transition | Higher Temperature | Lower Temperature |

This makes PC/ABS a much safer choice for products that will be used in a variety of climates, like automotive parts or outdoor electronics.

Notch Sensitivity: A Hidden Weakness

Finally, we have to consider notch sensitivity. This refers to how a material behaves when it has a "notch"—a sharp corner, a scratch, or a small design flaw. These spots concentrate stress. Pure PC is very notch-sensitive. A small imperfection can become the starting point for a major crack under stress. The ABS in a PC/ABS alloy helps to stop cracks from spreading. It makes the material more forgiving of the small imperfections that are almost unavoidable in mass production. This added toughness gives you a wider margin of error in both design and use.

What is the ratio of PC to ABS material?

You’ve chosen PC/ABS alloy as suitable for your project. That’s good. But now again, you are in a predicament: you notice that there are different grades, offering varying proportions of PC to ABS. The wrong ratio can totally transform the qualities of the material. You can end up with too much heat resistance but low moldability, and so forth, at the cost of your end-product. If you understand how that ratio works, then you can choose that ideal combination suitable for your purpose.

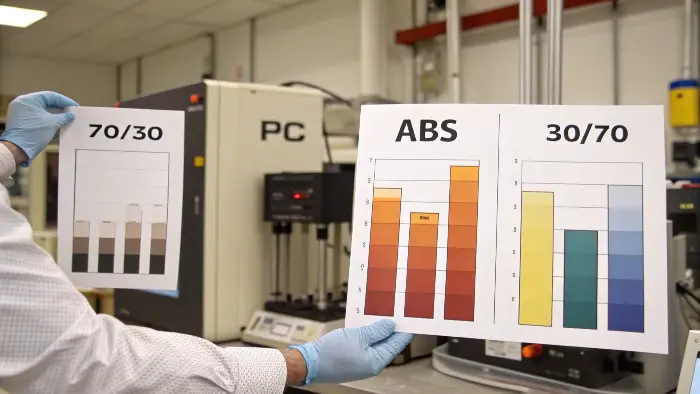

There is no absolute, fixed ratio of PC and ABS; it’s optimized as necessary to attainment of desired properties. Most commercial grades are in the 70/30 to 30/70 ratio of PC/ABS. A ratio with higher PC (e.g., 70/30) will have higher heat resistance and stiffness, approaching that of pure PC. A ratio with higher ABS (e.g., 40/60) will have much Improved flow, with better ease of injection molding as well as higher low-temperature toughness. The best ratio is a compromise based upon needs of your part and application design.

Dive Deeper: Dialing in the Perfect Blend

Think of the PC/ABS ratio like a recipe. By changing the amount of each ingredient, you can create a material perfectly suited for your specific product. The material manufacturer carefully adjusts this ratio to create different grades for different industries.

How Ratios Dictate Performance

The balance between PC and ABS directly impacts the final properties of the plastic. More PC generally means more strength and heat resistance, while more ABS means better flow and ductility. Let’s look at how this plays out in a typical scenario.

| Property | High PC (e.g., 70/30) | Balanced (e.g., 50/50) | High ABS (e.g., 30/70) |

|---|---|---|---|

| Heat Deflection Temp | Highest | Medium | Lower |

| Impact Strength | Very High | High | Good |

| Melt Flow Rate (MFR) | Lower (harder to mold) | Medium | Higher (easier to mold) |

| Surface Finish | Good | Very Good | Excellent |

| Cost | Higher | Medium | Lower |

As you can see, there’s always a trade-off. If you need a part to survive high temperatures inside a car, you would lean toward a high-PC blend. If you are molding a very complex part with thin walls, a high-ABS blend would be better because its higher melt flow rate will fill the mold more easily.

Common Ratios and Their Applications

Different industries have gravitated toward certain ratios that meet their typical needs.

- High-PC Blends (70/30 or 60/40): These are common in automotive and electronics. Think of laptop housings, monitor frames, and automotive instrument panels. These parts need to be strong and resist the heat from electronics or from sitting in a hot car.

- Balanced Blends (50/50): This is a great general-purpose grade. It offers a good mix of all properties and is often used for things like power tool housings, printer casings, and other consumer goods that need to be durable but don’t have extreme temperature requirements.

- High-ABS Blends (40/60): These grades are chosen when processability is the most important factor. If a part has very intricate details or long, thin sections, the excellent flow of a high-ABS blend is necessary to ensure the mold fills completely without defects.

Beyond the Ratio: The Secret Ingredient

There is no easy way to make a mixture of melted PC and ABS. The two polymers are inherently immiscible e.g. oil and water. They would divide and produce a weak insincere material. To overcome this, the material scientists insert a minor portion of a third material known as a compatibilizer. The given special molecule is a bridge the PC and ABS bind at the molecular level. This makes the alloy strong and stable and will guarantee you the good performance you require. That is one of the main reasons why it is so important to use the materials of a reputable supplier who has mastered this science.

Alternative Materials to Polycarbonate and ABS

Substitutes to Polycarbonate and ABS.

Polycarbonate (PC) and ABS have potential substitute materials. These are:.

Acrylonitrile Styrene Acrylate (ASA):

ASA (acrylonitrile styrene acrylate) shares some characteristics with ABS. It is very powerful in impact and works very well under a wide range of temperatures. It is also exceptionally strong against ultraviolet light, minimal water uptake (depending on grades) and can face the elements without issue. Then, when you need an excellent automotive exterior material, ASA is likely to be the solution.

Polymethyl Methacrylate (PMMA):

PMMA is an abbreviated term of polymethyl methacrylate or acrylic or Perspex. It is like PC, but it is optically clear, more so in sheet form. The negative is that PMMA is more fragile and might crack in case it finds itself in a scenario where it is likely to be subjected to high impact.

What are the disadvantages of ABS plastic?

ABS is a wonderful, versatile plastic. It’s inexpensive, rugged, and easy to shape, so it would appear to be an ideal material for a wide range of projects. But ABS in the wrong place can cause big headaches. An ABS part might distort in a hot automobile, crack and discolor in sunlight, or be destroyed by everyday chemicals. Knowing about such limitations helps you appreciate definitively why it’s so much better to mix it up with PC when it’s being used in challenging work.

Standard ABS plastic has several big handicaps in that it has fairly low heat resistance, low UV radiation resistance, and it is vulnerable to some chemicals. ABS will also start to soften at temperatures over 80°C (176°F) and will not be good in high-heat conditions. Direct sunlight will break it down, yellowing and becoming brittle. It will also be undermined by solvents such as acetone and by other industrial chemicals. Those liabilities are directly overcome by introducing PC to make a PC/ABS alloy.

Dive Deeper: Why ABS Alone Isn’t Always Enough

ABS (Acrylonitrile Butadiene Styrene) is one of the most common thermoplastics in the world for good reason. It hits a sweet spot of cost and performance. But it’s not invincible. Knowing its weaknesses helps you appreciate why alloys like PC/ABS were invented.

The Heat Problem: Thermal Limitations

The biggest disadvantage of ABS is that it has a very restricted capacity to process heat. It has a low Heat Deflection Temperature (HDT). This implies that at temperatures that can be easily achieved in most common scenarios, it will begin to soften and deform under load.

The best example is an interior component in a car. In several decades, there were some manufactures who attempted to use standard ABS to manufacture some dashboard parts. A closed car could get terribly hot on a sunny hot day. There would be warping and deformation of their dashboard components by the customers. That is why nowadays almost all the car interior components that come into direct sunlight are produced out of PC/ABS or other high-temperature plastics. The introduction of PC significantly increases the HDT and the material becomes stable to survive.

Fading in the Sun: Poor UV Resistance

In ABS, B represents Butadiene, a polymer that is rubber like which makes ABS tough. It is regrettable that butadiene is highly highly prone to degradation by the ultraviolet (UV) radiations in the sunlight. ABS of standard will be changing chemically when it is subjected to the sun over a long period. You will find this in the form of yellowing of color, loss of the surface finish of glossy surface and most importantly; the material becomes brittle.

I have once been consulted in a project concerning the outdoor security cameras housing. The initial prototypes were designed of a normal white ABS. They were impressive in the office but in real field tests after only a few months, they were horrible. They were chalky, yellowed and easily broken. It was necessary to migrate to a UV-stabilized grade of PC/ABS. The PC material is more resistant to UV and additives to the alloy grade made it long lasting in the outdoors.

Chemical Susceptibility

While ABS holds up well against things like water and weak acids, it can be easily attacked by a range of common organic solvents. Things like acetone (nail polish remover), certain oils, greases, and esters will cause it to soften, swell, or even dissolve. This is a critical factor for any part that might be exposed to industrial fluids or need to be cleaned with harsh chemicals. For example, in a medical setting, devices are constantly wiped down with strong disinfectants. Standard ABS might not survive this repeated chemical exposure. The PC component in a PC/ABS alloy provides an essential layer of chemical resistance, making the alloy a much safer choice for these types of environments.

What is the difference between PC-ABS and ABS-PC?

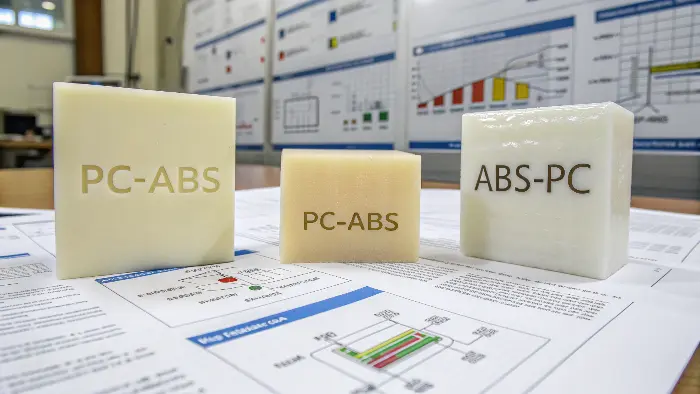

When you read about materials, you may see two terms: PC-ABS and ABS-PC. They appear very similar, so it is tempting to think that they are simply alternate names. But treating them as such can be a misstep. In polymer science, at times, the order of the terms of a name can be a little signal about what is primarily in the material and what kind of performance it should satisfy. Knowing this little tidbit makes it possible to translate the lingua of materials engineers.

Technically, the convention of naming in polymer blends frequently includes the major material as first. Thus, "PC-ABS" would mean it is a blend in which Polycarbonate is the primary, emphasizing heat resistance and strength. "ABS-PC" would mean ABS is the key polymer, emphasizing good mold flow and ductility. Practically, in daily commercial application, "PC/ABS" is used across almost every blend. Hence, never assume by name alone; always verify by checking the technical data sheet of exact properties.

Dive Deeper: Reading Between the Lines

While the distinction between PC-ABS and ABS-PC is subtle, it points to a much more important practice: always verifying a material’s properties with data. The name is just a starting point.

The Naming Convention Explained

In a formal, academic setting, the order matters. The first polymer listed is the "matrix," or the primary component, and the second is the modifier.

- PC-ABS: This suggests a PC-rich blend. You would expect properties closer to pure PC: very high impact strength, high stiffness, and a high heat deflection temperature. This is the material you’d choose when performance under stress is the top priority.

- ABS-PC: This suggests an ABS-rich blend. You would expect properties closer to pure ABS: excellent melt flow for easy molding of complex parts, a superior surface finish, and better ductility at low temperatures, likely at a lower cost.

Commercial Reality vs. Technical Theory

The crucial part is that in the actual world where buying and selling plastics are involved, this rule of naming is not strictly observed. The standard commercial name of the entire category of these alloys, irrespective of the exact ratio, has become PC-ABS (or PC/ABS). Marketing is easier and it has been adopted as the industry name.

This was my personal experience when a junior engineer under me was procuring material to be used on a new project. He must have a substance that had good flow to fill a difficult mold, and he found a supplier that quoted ABS-PC. He supposed that it would contain a high percentage of ABS and improve its flow. It came in as a standard and high impact PC-ABS grade. It happened that the supplier was referring to the same line of products by two different terms. Fortunately, the material was still applicable to the application but it was a valuable experience to our team. The truth is only given by the source number of the parts and the data sheet.

How to Read a Technical Data Sheet (TDS)

The name on the bag is just a label. The truth is inside the Technical Data Sheet (TDS). This one-page document provides the certified, tested properties of that specific grade of plastic. When evaluating a PC/ABS blend, here are the key numbers to look for:

- Melt Flow Index (MFI) or Melt Flow Rate (MFR): This tells you how easily the plastic flows when melted. A higher number means better flow, which is good for complex parts with thin walls. An ABS-rich blend will have a higher MFI.

- Heat Deflection Temperature (HDT): This tells you the temperature at which the material starts to deform under a specific load. A higher number means better heat resistance. A PC-rich blend will have a higher HDT.

- Notched Izod Impact Strength: This measures toughness. It tells you how much energy the material can absorb from a sudden impact before it cracks. This is where the synergy of the blend really shines.

- Tensile Modulus: This is a measure of the material’s stiffness. A higher number means the material is more rigid. Pure PC is stiffer than most PC/ABS blends.

Never choose a material based on its name. Always ask for the TDS and compare the actual data to the requirements of your project.

Conclusion

Ultimately, it is not the case of standard PC versus PC/ABS alloy, but rather which one to use on your work. PC/ABS is a potent alloy which addresses the major flaws of its elements. It imparts to it an excellent impact strength and better processability that PC lacks, but the heat and UV resistance that ABS does not possess. With the knowledge of the blend ratios and strict adherence to the data sheet, you are able to choose a material that is not going to fail.