Do you have to deal with annoying defects in your plastic parts, such as sink marks, warpage, or short shots? In most cases, all these frustrating phenomena have to do with one key factor: the wrong temperature profile. If temperatures are off, it results in wasted material, lost production time, and poor quality of parts. What if you could finally dial in the perfect settings for your barrel, nozzle, and mold to achieve consistent high-quality results every single time?

A perfect temperature profile in injection molding process should be an accurate balance between the heat settings across the barrel, the nozzle, and the mold, considering the plastic material being processed. This will result in uniform melting of resin, easy flow into the mold cavity, and controlled cooling. This is the key to preventing defects, optimizing cycle times, and producing consistent, high-quality parts that meet specifications.

Getting the overall concept is one thing, but the real secrets are in the details. The temperature profile isn’t just one number; it’s a series of carefully controlled zones, each with its own vital role. I’ve spent years in factories, tweaking these settings to solve production headaches. To truly master this, you need to understand how each component works together. Let’s break down each part of the process, starting with the heart of it all: the injection barrel.

What Is Temperature Profile in Injection Molding?

The temperature of injection molding refers to the temperature of heat applied to plastic pellets in the injection molding process to a form of molten plastic.

This is with a number of important temperature controls: barrel temperature, nozzle temperature, and mold temperature.

Barrel temperature is the amount of heat in the barrel of the injection molding machine where the plastic pellets are melted into a liquid form whereby plasticization will have been done.

Nozzle temperature refers to the heat that is applied on the nozzle wherein the molten plastic is injected into the mold. It must be slightly so that it does not drool, below the front barrel temperature.

Mold temperature is the temperature of the mold cavity surface which is very important in the rate of cooling and the final product appearance.

These temperatures should be well adjusted with consideration of the nature of plastic material, the form and size of a product, and the form of a mold.

A smooth injection molding is achieved by ensuring that the temperature remains in place. Changes in temperature may result in changes in the quality of products hence it is important to monitor and closely regulate temperatures during production. Knowledge of these components of temperatures and their functions can assist in a successful result in injection molding.

Temperature Settings for an Injection Molding Machine: Some Essentials Tips

Injection molding is a very accurate method of production, where temperature settings for the injection molding machine are really important to guarantee the quality and efficiency of the final product. Proper temperature control ensures that the plastic material melts correctly, flows uniformly into the mold, and cools properly to achieve the proper characteristics. Herein is a comprehensive guide to the key temperature settings you need to manage for optimal injection molding.

1. Barrel Temperature Profile in Injection Molding

What it is: It refers to the temperature applied to the plastic material inside an injection machine’s barrel. It is usually divided into several zones, with each set at a specific temperature.

Why It Matters: Each zone in the barrel has a specific function of melting, mixing, and conveying the plastic. Setting the temperatures correctly in each zone ensures that the plastic melts and mixes properly before injection.

Typical Settings: The set ranges for barrel temperatures are usually from 150°C to 300°C (300°F-570°F), depending on the type of plastic. For example:

ABS: 200°C – 240°C (392°F – 464°F)

Polypropylene: 220°C – 250°C (428°F – 482°F)

Polyethylene: 180°C – 230°C (356°F – 446°F)

2. Mold Temperature

What it is: Mold temperature relates to the temperature of the mold cavity where plastic is injected and solidified.

Why It Matters: Mold temperature governs the rate of cooling for the plastic, the surface finish, and the dimensional accuracy of the part. Proper mold temperature control aids in achieving uniform quality in parts and reducing cycle times.

Typical Settings: Mold temperatures typically range from 20°C to 120°C (68°F to 248°F), depending on the material and the complexity of the part. Examples would be:

ABS: 60°C – 80°C (140°F – 176°F)

Polypropylene: 30°C – 60°C (86°F – 140°F)

Engineering Plastics (e.g., Nylon): 80°C – 120°C (176°F – 248°F)

3. Nozzle Temperature

What it is: it’s the temperature applied to the nozzle, through which the molten plastic injects into the mold.

Why It Matters: Nozzle temperature controls the flow and ease of plastic injection into the mold cavity. Proper setting of the nozzle temperature helps prevent problems such as stringing, drips, and less desirable flow characteristics.

Typical Settings: The nozzle temperature ranges from 200°C to 280°C (392°F to 536°F), dependent on the material being used. For example:

ABS: 220°C – 260°C (428°F – 500°F)

Polypropylene: 230°C – 270°C (446°F – 518°F)

4. Temperature of the Heating Band

What it is: Some injection molding machines have additional heating bands along the barrel to give more precise control over the temperature of the plastic.

Why It Matters: Heating bands work to maintain consistent temperatures in certain locations of the barrel, especially when materials or processes call for fine-tuning temperature.

Typical Settings: These temperatures are usually set in relation to the barrel temperature settings and, for most processes, will again be in the range of 200°C to 250°C (392°F to 482°F).

5. Cooling System Temperature

What it is: Cooling systems regulate the temperature of the mold affecting the cooling rate of the injected plastic.

Why It Matters: Proper cooling is necessary to solidify the plastic part effectively, allowing the part to retain its intended dimensions and properties. Inadequate cooling will result in defects or longer cycle times.

Typical Settings: The cooling temperatures are usually not set independently but are controlled by the temperature of cooling water or other cooling media. The temperature of cooling water ranges between 15°C to 25°C, or 59°F to 77°F.

Principle Of Molding Temperature Control

Molding temperature control is a paramount concept in injection molding process that directly influences the quality, outlook, and the accuracy of a molded part. It refers to the fact that the mold is kept at a stable and optimal temperature during the production cycle so that there is continuity in the material flow, correct cooling of the mold and uniform solidification. The idea is to match melt viscosity and cooling time with part shrinkage in a bid to obtain accurate outcomes of part molding.

The idea of the principle is thermal equilibrium the fact that the mold must hit and hold a consistent temperature prior to and during production.

When the temperature of the mold is too low, the molten plastic can solidify too fast resulting in a defect, such as warping, sink marks, or inferior surface finish. On the other hand, when the mold is excessive hot it may increase cooling and cause flashing or dimensional instability.

Mold temperature controllers (chillers or heaters) are used to provide effective temperature control, circulating water or oil over the channels in the mold. These mechanisms are used to maintain the temperature of moulds at a very close range, evenly distributing the heat. The appropriate temperature parameters are dependent on the nature of the plastic resin, shape of the part as well as the preferred surface finish.

To describe the main points, it is important to state the following principle: in order to have high-quality parts with correct dimensions, smooth surfaces, and minimum internal stress, it is important to have a uniform and consistent thermal condition within the mold. Effective temperature control enhances productivity, scrap rate and reliability of injection molding process.

How Do You Set the Right Barrel Temperature Profile?

Ever wondered why your parts have black specks or inconsistent textures? The issue begins long before the plastic touches the mold. A poorly set barrel temperature profile is all it takes to degrade material or incompletely melt it, if at all, and create a host of symptoms downstream that are tough to root out. The feeling is like chasing ghosts, but the culprit is in plain sight in your barrel’s heat zones.

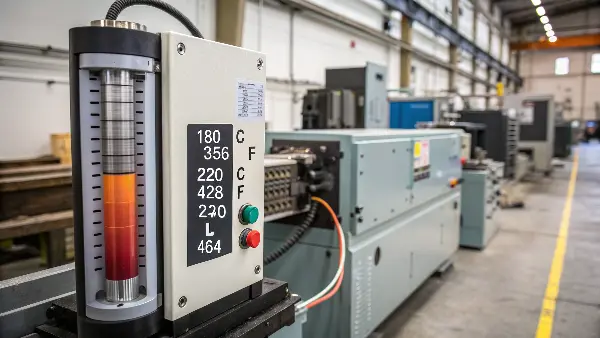

The right barrel temperature profile is a gradient, being cooler at the back-e.g., feed zone-and hot at the front, metering zone. A common material like ABS, for instance, could be at 180°C or 356°F at the back, rise through 220°C or 428°F in the middle, and reach 240°C or 464°F at the front. This gradual rise ensures that the plastic melts evenly without burning, preparing a consistent, homogenous melt for injection into the mold.

To truly dial in your barrel temperature, you need to think of it as a journey for the plastic pellets. The barrel is typically divided into three or more zones, and each one has a specific job to do. I remember a client who was getting terrible results with a polycarbonate part. We discovered they were using a flat temperature profile, which was cooking the material before it was even ready. By setting a proper gradient, we solved the issue in a single afternoon. Let’s break down these zones and their functions.

The Three Key Barrel Zones

The screw inside the barrel moves the plastic pellets forward, and as it does, the material passes through distinct heating zones. Setting the temperature for each zone correctly is critical for a homogenous melt.

-

Rear (Feed) Zone: This is where the plastic pellets first enter the barrel from the hopper. The temperature here should be the lowest in the profile. Its main purpose is to preheat the material and allow air to escape. If this zone is too hot, the pellets can melt prematurely and bridge, blocking new material from feeding in. If it’s too cold, you can put excessive strain on the screw motor.

-

Center (Transition/Compression) Zone: This middle section is where the real melting happens. The temperature rises significantly here. The screw’s design in this area compresses the material, forcing out any remaining air and creating friction. This frictional heat, along with the heater bands, works to create a uniform melt. This is often the zone where you have the most direct control over the melting process.

-

Front (Metering) Zone: This is the final stop before the nozzle. The temperature here is typically the highest, ensuring the plastic is fully molten, at the right viscosity, and homogenous. This zone acts as a reservoir, holding the precise amount of molten plastic (the "shot") ready for injection. The temperature must be spot-on to achieve the desired flow characteristics.

Here is a simplified table showing a starting point for setting barrel temperatures for different materials. Always check your material supplier’s datasheet for their specific recommendations.

| Material | Rear Zone Temp (°C) | Center Zone Temp (°C) | Front Zone Temp (°C) |

|---|---|---|---|

| ABS | 180 – 210 | 200 – 230 | 220 – 240 |

| Polycarbonate (PC) | 240 – 260 | 260 – 290 | 280 – 310 |

| Polypropylene (PP) | 170 – 190 | 190 – 220 | 200 – 230 |

| Nylon 6 (PA6) | 220 – 240 | 230 – 260 | 250 – 280 |

Remember, these are just starting points. The final settings depend on your specific machine, mold design, and cycle time.

Why is Nozzle Temperature So Critical in Injection Molding?

You have your barrel temperatures tuned to perfection, the melt is homogenous, everything seems right. Then you inject the shot and get stringing, drooling, or a cold slug at the gate. The stringing, drooling, and other frustrating and costly defects so often point to one little, yet mighty, component: the nozzle. Even a few degrees off on nozzle temperature can ruin an otherwise perfect setup, serving as that final, frustrating bottleneck in your process.

The nozzle temperature is critical because it’s the final gate controlling the condition of the plastic before it enters the mold. It must be hot enough not to freeze the material off, causing short shots, yet not so hot as to cause drooling or material degradation. Typically, the nozzle should be set to, or slightly below, the front zone temperature of the barrel to maintain melt consistency and prevent defects like stringing or cold slugs.

The nozzle is the last chance you have to influence the melt before it enters the mold. I learned this the hard way early in my career. We were running a high-precision part, and we kept getting flow lines. We checked everything-barrel temps, injection speed, pressure-but nothing worked. Finally, an old-timer on the floor suggested bumping the nozzle temp up by 5 degrees. It was like magic; the flow lines vanished. That tiny change made all the difference. The nozzle temperature is not just another setting; it is a fine-tuning instrument.

Common Nozzle Temperature Problems and Solutions

The nozzle’s job is to maintain the melt temperature right up to the point of injection. Getting it wrong leads to some very specific, and very common, problems.

-

Problem: Cold Slug

A cold slug is a small, semi-solid piece of plastic that forms at the tip of the nozzle between shots. When injected, it can block the gate or cause cosmetic defects like flow marks on the part.- Cause: The nozzle temperature is too low, or there’s too much cooling at the point where the nozzle touches the cold mold.

- Solution: Increase the nozzle temperature slightly. Ensure the sprue-break function (if used) minimizes contact time between the nozzle and the cold mold. Sometimes, a nozzle design with a better heating profile is needed.

-

Problem: Stringing or Drooling

This is when molten plastic oozes or creates fine threads from the nozzle tip after injection. It’s messy, wastes material, and can interfere with the mold closing on the next cycle.- Cause: The nozzle temperature is too high, or the decompression (suck back) setting is insufficient.

- Solution: Lower the nozzle temperature in small increments. Increase the decompression distance or speed to pull the melt back from the nozzle tip after the screw recovers.

Here is a quick reference table for setting your nozzle temperature based on your front barrel zone setting.

| Material Type | Recommended Nozzle Temperature | Potential Issues if Not Followed |

|---|---|---|

| General Purpose (ABS, PP) | Set 5-10°C below the front barrel zone. | Too high: Drooling, stringing. Too low: Cold slug, gate freeze-off. |

| Heat Sensitive (PVC, PC) | Set it equal to or slightly below the front zone. | Too high: Severe material degradation (burning), black specks. Too low: High injection pressure needed, flow marks. |

| Crystalline (Nylon, PET) | Set it 5-10°C above the front barrel zone. | Too low: Prone to freezing off quickly at the small nozzle orifice, causing short shots. Too high: Can have less effect, but still risks drooling. |

Fine-tuning the nozzle temperature is a delicate balance, but once you get it right, a whole range of problems simply disappear.

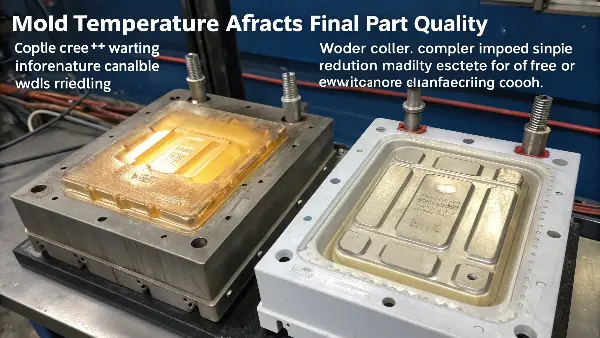

How Does Mold Temperature Affect Final Part Quality?

You have mastered the barrel and nozzle, and the molten plastic flows perfectly into the mold. Yet, the final parts are warped, have sink marks, or lack the glossy finish you promised the client. The problem is no longer about melting the plastic, but how it cools. The mold temperature is one of the most powerful tools you have for controlling the final properties of your part, yet it’s too often the most overlooked.

Mold temperature directly controls the cooling rate of the plastic, which fundamentally impacts the part’s final dimensions, appearance, and structural integrity. The warmer the mold, the better the plastic packs out, avoiding sink marks and providing a good surface finish. The cooler the mold, the faster the cycle time, but there is a risk of increasing internal stress and warpage. The ideal mold temperature has to balance part quality and production efficiency and must be determined with the specific material in mind.

I once worked with a team producing a large, flat panel out of ABS. The parts kept coming out warped like a potato chip. They had tried everything, from adjusting packing pressure to changing gate locations. The problem was their mold temperature. They were running it too cold to shorten the cycle time. By increasing the mold temperature by 15°C, we allowed the stresses to relax before ejection. The parts came out perfectly flat. It added a few seconds to the cycle time, but it saved them from scrapping thousands of parts. The mold isn’t just a cavity; it’s a thermal control chamber.

The Duel Between Amorphous and Crystalline Materials

How you set your mold temperature depends heavily on the type of plastic you’re using. Plastics fall into two main families, and they behave very differently as they cool.

-

Amorphous Plastics (e.g., ABS, PC, Polystyrene)

These materials have a random, jumbled molecular structure. They soften gradually over a wide temperature range.- Mold Temperature Goal: The mold temperature for amorphous plastics is typically set below the material’s Heat Deflection Temperature (HDT). The goal is to cool the part enough so it’s rigid and can be ejected without deforming. A warmer mold can improve surface finish and reduce molded-in stress, but setting it too high will dramatically increase the cooling time.

-

Semi-Crystalline Plastics (e.g., Nylon, PP, PET)

These materials have an ordered, crystalline molecular structure. They have a distinct melting point and tend to shrink much more than amorphous plastics.- Mold Temperature Goal: For these materials, mold temperature is critical for controlling the level of crystallinity. A warmer mold allows more time for the crystals to form, which increases stiffness, hardness, and chemical resistance. A colder mold "freezes" the amorphous structure, resulting in a tougher but less stiff part. Not allowing enough crystallinity to form is a primary cause of post-mold warpage and shrinkage.

This table highlights the different approaches required for these two material types:

| Feature | Amorphous Plastics (ABS, PC) | Semi-Crystalline Plastics (Nylon, PP) |

|---|---|---|

| Primary Goal | Cool the part until it’s solid enough for ejection. | Control the rate and amount of crystal growth. |

| Typical Mold Temp | Set below the Heat Deflection Temperature (HDT). | Set high enough to promote crystal formation, often just below the crystallization temp. |

| Effect of Hot Mold | Improves surface finish, reduces stress, increases cycle time. | Increases crystallinity, stiffness, and dimensional stability. |

| Effect of Cold Mold | Reduces cycle time, can increase stress and warpage. | Reduces crystallinity, can cause unpredictable shrinkage later. |

Ultimately, controlling the mold temperature is about controlling the final properties of your part. It is the key to turning a well-injected shot of plastic into a high-quality finished product.

Conclusion

Mastering the temperature profile in injection molding is a balancing act. It means that the plastic should be perfectly melted in the barrel, flow perfectly through the nozzle, and solidify correctly inside the mold. You will be able to avoid defects, improve the quality of your parts, and run a more efficient and stable production process by setting and fine-tuning the temperatures of each zone from the rear of the barrel to the mold itself.