Are you struggling with defects like burn marks, flash, or incomplete parts in your injection molding process? You’ve adjusted the temperature and material, but the problems persist. It’s frustrating when you can’t pinpoint the exact cause, leading to wasted time and materials. These issues often stem from an imbalance between three critical, interconnected factors.

The quality of your molded parts is directly tied to the relationship between injection speed, injection pressure, and venting efficiency. Injection speed controls how fast the mold fills, pressure ensures the cavity is packed correctly, and venting allows trapped air to escape. A proper balance prevents defects, ensures consistent part dimensions, and optimizes cycle times. Getting this relationship right is fundamental to successful, high-quality production.

Understanding this trio is the first step toward mastering your molding process. Many people I talk to treat these settings as separate dials to turn, but they work together like a team. A change in one directly impacts the others. If you turn up the speed, you have to consider how pressure builds and whether the air has enough time and space to get out. It’s this dynamic relationship that we need to explore to truly solve those nagging quality issues. Let’s break down each element to see how they connect and influence your final product.

Influence of Injection Speed on Product Defects

Flash

Speed at the end of injection can be controlled to prevent or reduce defects such as flash, scorch, and gassing. Allowing the end of filling to decelerate can also help prevent over packing into the cavity which in turn reduces flash and residual strain. Poor venting at the end of the mold flow path or filling can also lead to trapped air, and it is therefore desirable to minimize venting speed (especially at the end of injection).

Jetting mark

The injection speed setting must guarantee quick runner area filling and then gradual gate passing in order to avoid jetting. Identifying this speed transition point is essential. Too late can result in jetting due to excessive flow inertia; too early will result in an excessive increase in fill time. The lower the melt viscosity and the higher the barrel temperature, the more intense the tendency for jetting. Small gates need high-speed, high-pressure injection, which is a major contributor to flow problems.

Short shots

Too slow speeds at the gate or localized flow restriction create Short shots owing to solidification of the melt. This issue can be resolved by increasing the injection speed immediately after passing the gate or in areas with localized flow obstruction. Defects such as flow marks, burn marks at the gate, and delamination in heat-sensitive materials are due to excessive shear when passing through the gate.

Sink mark

The sink mark can be reduced by increasing pressure transfer and decreasing the pressure drop. Low mold temperature and low screw advance speed significantly reduce the flow length, which must be offset by high injection speed. High-speed flow minimizes heat loss and, because of the shear heat generated by friction, it also raises the melt temperature, thus reducing the rate at which the outer layers of the part thicken.

What is the difference between injection speed and injection pressure?

Are you confused about when to adjust speed versus pressure? It’s a common point of uncertainty. You might think they do the same thing: push plastic into the mold. This misunderstanding can lead to a trial-and-error approach that wastes time and produces scrap. Getting them mixed up means you’re not truly in control of the molding process.

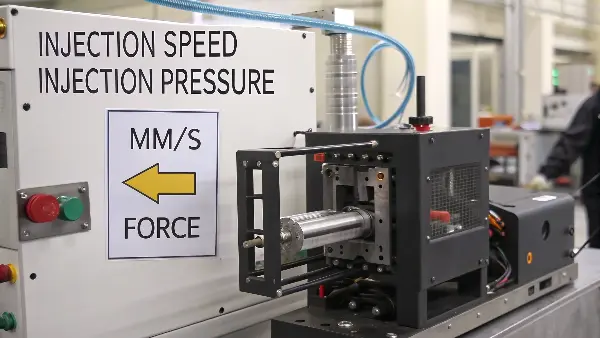

Injection speed is the rate at which the screw moves forward to push molten plastic into the mold, measured in mm/s. It’s about how fast the cavity fills. Injection pressure is the force applied to the plastic to overcome resistance and pack the mold completely. It’s about how hard you push. Typically, the process is speed-controlled during filling and then switches to pressure control during the packing and holding phase.

Let’s dive a little deeper into this distinction because it’s fundamental. Think of it like filling a water balloon. The speed at which you open the tap is the injection speed. If you open it too fast, the balloon might burst before it’s full. Too slow, and it takes forever. The pressure you apply by squeezing the balloon after it’s mostly full to make it firm is like the packing pressure. You’re no longer focused on filling speed but on compacting the contents.

In injection molding, we separate the process into phases to manage this.

Filling Phase (Speed Control)

During this initial stage, the primary goal is to fill about 95-99% of the mold cavity as efficiently as possible.

- What it controls: The machine focuses on maintaining a set screw velocity (speed).

- Why it’s important: Speed affects the material’s viscosity due to shear heating, the appearance of the part surface, and the potential for trapping air.

- Pressure’s Role: Pressure is still present, but it’s a secondary factor. The machine will use whatever pressure is necessary (up to a set limit) to achieve the target speed.

Packing/Holding Phase (Pressure Control)

Once the mold is nearly full, the process switches from speed control to pressure control.

- What it controls: The machine now focuses on maintaining a set pressure for a specific duration.

- Why it’s important: This phase compensates for material shrinkage as it cools, ensuring the part matches the mold’s geometry and doesn’t have sinks or voids.

- Speed’s Role: Speed is no longer the primary command. The screw moves very little, just enough to pack more material in as the plastic cools and contracts.

Here’s a simple breakdown:

| Control Parameter | Dominant Phase | Primary Goal | Analogy |

|---|---|---|---|

| Injection Speed | Filling | Fill the mold cavity quickly and evenly. | Opening the water tap. |

| Injection Pressure | Packing/Holding | Compensate for shrinkage and define final details. | Squeezing the balloon. |

Understanding this switch-over point, often called the V/P (velocity/pressure) transfer, is one of the most critical skills for a process technician. Setting it correctly ensures you get the benefits of both speed and pressure control exactly when you need them.

Why is injection speed so critical in injection molding?

Have you ever faced issues like weld lines or a dull finish on your parts and couldn’t figure out why? You might be overlooking the powerful effect of injection speed. Simply focusing on temperature and pressure isn’t enough. If the speed isn’t optimized, the plastic may cool down too quickly as it flows, leading to visible defects and weak points in the final product.

Injection speed is critical because it directly influences the molten plastic’s viscosity, the surface finish of the part, and the formation of defects. A faster speed generates more shear heat, reducing viscosity and helping the plastic flow more easily into thin sections. This can improve surface appearance and weld line strength. However, excessive speed can cause material degradation or trap air, leading to burn marks.

When I started in this industry, I thought slower was always safer. But I quickly learned that for many materials, especially those with crystalline structures, a faster fill is actually better. The key is finding the "sweet spot." The injection speed determines how the melt front advances through the cavity, and this has a huge impact on both the aesthetics and the structural integrity of the part.

Let’s break down the specific effects of injection speed.

Impact on Material Viscosity

This is the most important concept to grasp. As you push plastic through a narrow gate and into the mold channels at high speed, you create friction, or "shear." This shear generates heat, a phenomenon known as shear heating.

- Higher Speed: More shear, more heat. This lowers the plastic’s viscosity (makes it thinner), allowing it to flow more easily and fill complex or thin-walled sections of the mold.

- Lower Speed: Less shear, less heat. The plastic remains more viscous, which might be necessary for thick-walled parts to prevent jetting, but it can cause short shots (incomplete filling) in thin sections.

Influence on Part Appearance

The speed of the melt front has a direct effect on what the final part looks like.

- Gloss: A faster fill speed often results in a higher gloss finish because the plastic stays molten as it contacts the cold mold wall, perfectly replicating the polished surface. A slow fill allows a skin to form prematurely, resulting in a dull or hazy appearance.

- Weld Lines: When two melt fronts meet, they form a weld line. If the melt fronts have cooled too much (due to a slow injection speed), they won’t fuse together properly, creating a weak and very visible line. A faster speed keeps the fronts hotter, leading to a stronger, less noticeable weld.

Risk of Defects

While speed can solve problems, it can also create them if it’s not managed properly.

| Injection Speed | Potential Benefits | Potential Risks |

|---|---|---|

| Fast | Better surface gloss, stronger weld lines, fills thin walls. | Gas traps (burn marks), flash, material degradation, jetting. |

| Slow | Reduces risk of flash and gas traps, better for thick parts. | Short shots, weak weld lines, poor surface finish, flow marks. |

The best approach is often to use a profiled injection speed. This means you vary the speed during the fill. You might start slow as the plastic passes through the gate to prevent jetting, speed up significantly to fill the main body of the part, and then slow down again at the very end to allow air to vent and prevent flash. Mastering speed profiles is what separates the novices from the experts.

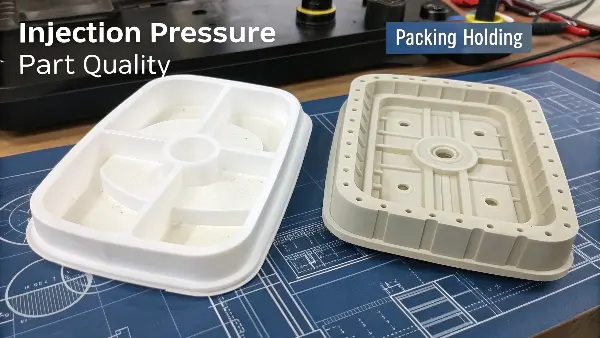

How does injection pressure impact part quality?

Are your parts coming out with sink marks, or are their dimensions inconsistent from shot to shot? You might be using the right material and mold temperature, but the problem could lie in your pressure settings. Insufficient or excessive pressure during the packing phase can ruin an otherwise perfect part, leading to high rejection rates and wasted costs.

Injection pressure, especially during the packing and holding phase, is crucial for compensating for material shrinkage as it cools. Correct packing pressure ensures the part is dense, free of voids and sink marks, and dimensionally accurate. Too little pressure results in under-packed parts with sinks, while too much pressure can cause flash, part sticking, or high internal stress, making parts brittle.

Think of packing pressure as the final step that defines the part’s quality. The filling phase gets the material into the mold, but the packing phase perfects it. I remember working on a project for a medical device where a few microns of dimensional variation was a major failure. We traced the problem back to a very slight inconsistency in our holding pressure. It seems small, but it makes all the difference for high-precision components.

Let’s look at how pressure in different phases affects the final outcome.

First Stage Pressure (Filling)

During the fill, the machine uses pressure as a driving force to achieve the set injection speed. We usually set a pressure limit here.

- Purpose: The pressure limit acts as a safety cap. It ensures that if there’s a blockage or the material suddenly gets stiff, the machine doesn’t generate extreme pressures that could damage the mold or the press.

- Effect on Quality: It’s an indirect effect. If the pressure limit is set too low, the screw may not be able to reach the target injection speed, leading to a "pressure-limited" fill. This can cause the same defects as a slow injection speed, like short shots or poor weld lines.

Second Stage Pressure (Packing & Holding)

This is where pressure takes center stage. After the mold is nearly full, the machine switches to maintaining a set pressure.

- Packing Pressure: A higher pressure applied for a short time to force more material into the cavity and start compensating for shrinkage.

- Holding Pressure: A slightly lower pressure held for a longer duration as the gate freezes off. This continues to feed material to counteract shrinkage as the part solidifies.

The effects of getting this wrong are very clear:

| Pressure Setting | Resulting Defect | Why it Happens |

|---|---|---|

| Too Low | Sink marks, voids, short shots, poor surface detail, dimensional instability. | Not enough material is packed in to compensate for the volume reduction during cooling. |

| Too High | Flash (material seeping out of mold), part sticking, high internal stress (warpage/brittleness), overpacking. | The pressure is high enough to force the mold halves apart or stress the material molecules. |

The key is to apply just enough pressure, for just enough time, to produce a dense, stable part without creating other problems. This depends heavily on the material’s shrinkage rate, the part’s wall thickness, and the gate location and size. Optimizing packing and holding pressure is a delicate balancing act that is essential for producing high-quality, consistent plastic parts.

What is venting in injection molding, and why does it matter?

Ever seen small, dark burn marks on the edges of your plastic parts? That’s not scorched plastic; it’s a sign of a critical problem you might be ignoring. The root cause is trapped, super-heated air that has nowhere to go. This happens when your mold can’t "breathe," and it directly relates to the speed and pressure you’re using.

Venting in injection molding is the process of allowing the air and gases inside the mold cavity to escape as molten plastic rushes in. This is achieved through tiny channels cut into the mold’s parting line. Proper venting is essential because if air is trapped, it gets compressed and super-heated, causing burn marks, incomplete filling (short shots), and poor weld lines. It is the crucial third factor that ties speed and pressure together.

Now we bring it all together. You can have the perfect speed and pressure profiles, but if the air in the cavity can’t get out of the way, you’ll never get a good part. The faster your injection speed, the faster the air needs to escape. The higher your pressure, the more forcefully that air is compressed. This is where venting becomes the hero of the process. I’ve seen countless molding problems solved not by tweaking the machine, but by adding or improving the vents in the mold.

The Science of Trapped Air

When you inject plastic at high speed, you are essentially turning the mold cavity into a piston chamber, with the melt front acting as the piston head.

- Compression: The air ahead of the plastic gets compressed into the last-to-fill areas of the mold.

- Diesel Effect: According to the ideal gas law, when you compress a gas rapidly, its temperature skyrockets. This can raise the air temperature high enough to ignite the gases released from the plastic, causing characteristic burn marks on the part.

- Back Pressure: This compressed air also creates back pressure, which resists the flow of the plastic. This can prevent the cavity from filling completely, even with high injection pressure.

How Proper Venting Solves Problems

Vents are very shallow channels (typically 0.01-0.03mm deep) that are deep enough to let air out but too shallow for the viscous molten plastic to flow into.

- Prevents Burn Marks: By giving the hot, compressed air an escape route, you prevent the diesel effect from happening.

- Enables Complete Filling: Removing the back pressure allows the plastic to fill every corner of the cavity easily, preventing short shots.

- Improves Weld Lines: When two melt fronts meet, trapped air can prevent them from fusing properly. Vents placed at weld line locations help evacuate this air, resulting in a stronger, less visible bond.

The relationship between all three parameters is now clear:

| Parameter | Interaction with Venting |

|---|---|

| Injection Speed | High speed requires excellent venting. The faster you fill, the faster air must be evacuated. |

| Injection Pressure | Inadequate venting creates back pressure, forcing you to use higher injection pressure to fill the part, which can lead to other defects like flash. |

If you are increasing speed and pressure to solve one problem but are suddenly seeing burn marks, the first place I would look is the mold’s venting. Effective venting allows you to use optimal speed and pressure settings without creating new issues. It’s the enabling factor for a fast and efficient process.

Conclusion

In injection molding, speed, pressure, and venting are not isolated settings; they are a deeply connected system. Mastering the balance between how fast you fill (speed), how hard you pack (pressure), and how well the mold breathes (venting) is the true key to producing high-quality parts consistently. By understanding their relationship, you can diagnose problems effectively and unlock your process’s full potential.

FAQs

How does injection speed influence part quality?

How rapidly molten plastic fills the mold is determined by the injection speed. If the speed is too low, the material may cool early and generate flow lines or short shots. High internal stress and burn marks can result at an excessively high level.

What makes injection pressure crucial to molding?

Injection pressure ensures the mold cavity fills completely. Excessive pressure can result in flash, distortion, or overpacking of the part, whereas low pressure can result in weak weld lines or incomplete filling.

How do pressure, speed, and venting interact?

These three factors must be balanced. Higher pressure and improved venting may be necessary at high speeds to prevent flaws. Poor venting may compel molders to reduce speed or pressure.