Designing a perfect plastic part is a huge challenge. But the real trouble often starts when you try to manufacture it. Unexpected defects can completely derail your project, leading to expensive mold rework, wasted materials, and frustrating delays that push back your launch date. What if you could see inside the mold and predict these problems before you ever cut a piece of steel?

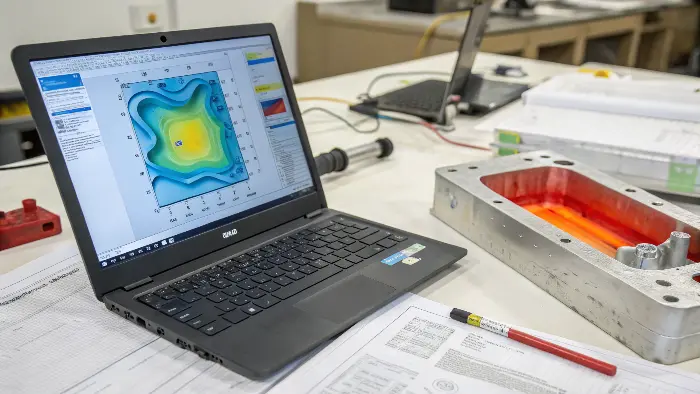

Mold flow analysis saves you time and money by simulating how melted plastic fills a mold. This digital test run identifies potential problems like air traps, weak spots, or warping before you build the physical tool. By fixing these issues in the design phase, you avoid expensive mold modifications, reduce material waste, and get your product to market faster with fewer defects. It’s a proactive approach that prevents costly surprises.

That’s the big picture, but the real value is in the details. This simulation isn’t just a pretty picture; it’s a powerful engineering tool that provides concrete data to make better decisions. It gives you the confidence that your design is not just possible, but optimized for manufacturing. Let’s break down exactly what this analysis is and how it delivers these powerful benefits to your projects.

So, What Exactly Is Mold Flow Analysis?

Have you ever launched a brand new mold only to discover ugly sink marks or weak weld lines on the very first parts? It’s a designer’s nightmare. It forces you back to the drawing board after you’ve already spent a fortune on tooling. This cycle of trial-and-error manufacturing is incredibly expensive and slow. But there is a way to predict these issues and design them out from the very beginning.

Mold flow analysis, often just called mold analysis, is a computer simulation that predicts how molten plastic will flow and fill an injection mold cavity. It visualizes the entire process, showing pressure, temperature, and cooling patterns. This allows designers and engineers to foresee manufacturing defects and optimize the part design, mold design, and processing parameters before any physical tooling is created, ensuring a smoother production run.

Think of it as a virtual prototype for the injection molding process. Before you commit tens of thousands of dollars to a steel mold, you can run dozens of tests on your computer. I remember a project early in my career for a medical device housing. We skipped the analysis to save a little money upfront. The result? A nightmare of warpage that made the parts unusable. We spent six weeks and over $20,000 modifying the tool. A two-day simulation would have caught the issue and saved all of that. The analysis essentially breaks the process down into key stages.

Key Stages of Simulation

-

Fill Analysis: This is the most basic part of the simulation. It shows how the plastic material fills the empty space in the mold. It helps you spot potential "short shots," where the mold doesn’t fill completely. It also clearly shows where weld lines (where two flow fronts meet) and air traps (where air gets trapped by plastic) will form.

-

Pack Analysis: After the mold is filled, extra plastic is "packed" in under pressure to compensate for shrinkage as it cools. This analysis simulates that stage. It’s crucial for identifying the root cause of sink marks and internal voids.

-

Cool Analysis: The cooling stage often takes up the majority of the injection molding cycle time. This simulation analyzes the efficiency of the mold’s cooling channels. It helps you design a cooling system that cools the part evenly, which is key to preventing warpage and reducing the overall cycle time.

-

Warp Analysis: This final simulation takes data from the fill, pack, and cool stages to predict the final shape of the part after it’s ejected from the mold. It shows you exactly how and how much the part is likely to bend or twist. This is incredibly valuable for parts that need to fit together perfectly in an assembly.

What Are the Real-World Benefits of Mold Flow Analysis?

You’ve designed a great product, but can it be manufactured efficiently? The gap between a beautiful CAD model and a high-quality physical part can be huge. This gap is often filled with unexpected costs and frustrating delays. This uncertainty can put your entire project budget and timeline at risk. Imagine having the confidence that your design is ready for manufacturing from day one.

The primary benefits are significant cost and time savings. By identifying and fixing potential defects like sink marks, weld lines, and warpage in the digital phase, you eliminate expensive and time-consuming mold rework. It also helps optimize gate locations, reduce material waste, and shorten cycle times. This leads to a higher quality product, a faster time-to-market, and a much more predictable manufacturing process.

The benefits touch every part of the product development cycle, from the initial design concept to the final production run. It’s not just about avoiding problems; it’s about actively optimizing for success. By using simulation, you are essentially front-loading your problem-solving, tackling issues when they are cheapest to fix—when they are just pixels on a screen. Let’s look at the specific advantages in more detail.

Early Defect Detection and Prevention

This is the most obvious benefit. The simulation acts like an x-ray, revealing problems that are invisible in a CAD model. A study by Plastic-IT Ltd once showed that this kind of early prevention can cut production costs by up to 30%. You can see exactly where a weld line will form and predict if it will be strong enough. You can see if a thick section will cause a sink mark. By seeing these problems early, you can make simple changes to the part geometry or gate location to solve them before they become expensive, real-world headaches.

Design and Material Optimization

Mold flow analysis isn’t just a pass/fail test. It’s an optimization tool. It helps you find the best place to put the gate, ensuring the cavity fills smoothly and evenly. It helps you design the runner system—the channels that carry the plastic to the part—to be as efficient as possible, which reduces material waste with every single shot. It can also help you choose the right material. You can run simulations with different types of plastic to see which one performs best for your specific application, balancing factors like strength, shrinkage, and cost.

Streamlined Production and Lower Costs

A well-analyzed mold runs better. By optimizing the cooling channels, you can significantly shorten the cycle time, which means you can produce more parts per hour. This directly increases your production efficiency and lowers the cost per part. Because you’ve eliminated most of the guesswork, the initial mold trials are much smoother and faster. This shortens your overall development timeline and gets your product to market quicker, giving you a competitive edge. The visual nature of the simulation reports also makes it easier for everyone—designers, toolmakers, and production managers—to get on the same page.

| Benefit Category | How Mold Flow Analysis Helps | Direct Impact |

|---|---|---|

| Design Phase | Identifies flaws before tooling | Avoids costly mold rework and delays |

| Material Usage | Optimizes runner systems & part thickness | Reduces plastic waste & material cost |

| Production Cycle | Optimizes cooling channels for faster cycles | Shortens cycle time, increases output |

| Product Quality | Predicts warpage, stress, and weak spots | Results in stronger, more reliable parts |

How Does This Analysis Directly Reduce Mold Rework Time?

Nothing kills a project’s momentum like having to pull a big, heavy mold from the press for modifications. Each time you have to do this, it means production downtime, skilled labor costs, and sometimes even shipping fees. It’s a reactive, stressful, and expensive process. What if you could get the mold design right the first time, almost every time?

Mold flow analysis drastically reduces mold change time by serving as a virtual trial run. It allows you to test and perfect the mold design on a computer, catching issues that would normally require physical rework. By optimizing gate locations, runner balance, and cooling layouts digitally, you prevent the need for welding, re-machining, or polishing the steel tool after the first shots. This "right-the-first-time" approach is the key to minimizing costly mold changes.

The core idea is moving from a reactive to a proactive mindset. The traditional method of mold making often involves a lot of "trial and error." You build the tool based on experience and best guesses, run some samples, and then fix the problems you find. Mold flow analysis flips this script entirely.

From Reactive Guesswork to Proactive Engineering

Without simulation, when a part comes out of the mold with a defect, you have to start a difficult investigation. Is the sink mark caused by a wall that’s too thick? Is the cooling inadequate? Is the packing pressure too low? You might have to change one thing at a time, putting the mold back in the press after each change, until you find the solution. This is incredibly time-consuming. With analysis, the simulation doesn’t just tell you that you will have a sink mark; it shows you why. The software can isolate the cause, showing you if it’s a thermal issue or a pressure issue, so you know exactly what to fix in the design.

A Real-World Example

I once worked on a complex housing for an industrial sensor. The part had a very intricate shape, and we had to use multiple gates to fill it properly. Without analysis, we would have spent weeks in the tool shop trying to "balance" the flow from the gates by manually adjusting their sizes. Instead, we ran a simulation. The analysis report clearly showed that one gate was filling its section much faster than the others, which was causing high stress and potential warpage. We adjusted the gate size in the CAD file in just a couple of hours, re-ran the simulation to confirm the fix, and then sent the final design to the toolmaker. That two-hour digital fix saved us what would have easily been a week of physical tool adjustments and trials. That is the power of getting it right before you cut steel.

Beyond Autodesk Moldflow, What Are Your Other Options?

So, you’re sold on the idea of mold flow analysis. But when you start looking into it, you see one big name everywhere: Autodesk Moldflow. Relying on a single software brand can feel limiting, and you might wonder if there are other tools that could be a better fit for your team’s budget or workflow. Are you missing out on other powerful options that could help you?

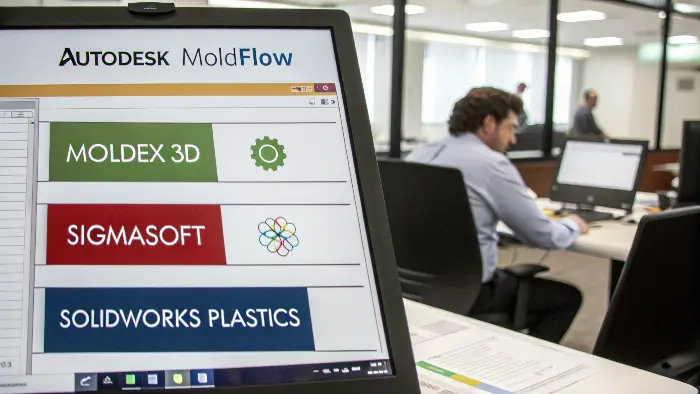

While Autodesk Moldflow is the industry pioneer and a powerful standard, several strong competitors exist. Key alternatives include Moldex3D, which is known for its highly accurate 3D mesh technology, and SIGMASOFT®, which uniquely simulates the entire mold system. Other options like SOLIDWORKS Plastics offer great integration for designers already in that ecosystem. The best choice depends on your specific needs for accuracy, integration, and budget.

The market for simulation software has grown a lot over the years, which is great news for us as users. More competition means more innovation, better features, and more pricing options. While Moldflow established the category, other players have emerged with different strengths and philosophies. Choosing the right one depends on what you value most.

The Main Players in Simulation

It’s not a one-size-fits-all situation. Some tools are built for the expert analyst who needs the highest possible degree of accuracy. Others are designed for the product designer who needs quick, easy-to-understand feedback directly within their CAD environment.

Comparing the Tools

Here’s a quick breakdown of the most common alternatives and where they shine.

| Software | Key Strength | Best For |

|---|---|---|

| Autodesk Moldflow | Industry standard, comprehensive features | Companies needing a robust, widely-recognized tool for deep analysis. |

| Moldex3D | High-accuracy 3D analysis, detailed results | Engineers requiring the highest level of precision for complex parts. |

| SIGMASOFT® | Simulates the entire mold system (holistic) | Optimizing the complete process, including mold temperature control. |

| SOLIDWORKS Plastics | Seamless integration with SOLIDWORKS CAD | Designers who want an easy-to-use, integrated analysis tool. |

| Simpoe-Mold | Part of the Dassault Systèmes ecosystem | Users of CATIA or other Dassault products who need integration. |

How to Choose the Right Tool

For my clients and my own projects, the choice often depends on the stage of the project. For initial design checks, a tool that’s integrated into our CAD software, like SOLIDWORKS Plastics, is fantastic. It’s fast and easy, and it helps us catch 80% of the potential problems right away. For a really high-stakes, complex part, or one made from an exotic material, we might bring in a specialist who uses a high-end tool like Moldflow or Moldex3D for a final, deep-dive validation. It’s not about finding the one "best" tool, but about building a workflow that uses the right tool for the right job.

Conclusion

In short, mold flow analysis is no longer a luxury; it’s a fundamental tool for modern manufacturing. By investing a little time and money in simulation upfront, you save enormous amounts of time, money, and frustration down the line. It transforms mold making from a game of chance into a precise science. It’s a critical step in our mission to help you master molding right.