To locate a reliable mold manufacturing company in China for your project but concerned about quality, communication, or unexpected costs, don’t miss it if you are looking for solution. I’ll introduce my experience to assist you in determining important characteristics of a reliable partner to guarantee the success of your project.

Some of the key features you should look at in this respect are:

- Highlight their Technical Competency

- Communication skills

- Service quality,

- Understanding your personal needs

- Open procedures

- List of successful accomplishments

I’ve come to understand that all these are much greater than simply the original price quote for a successful long-term result.

Finding the right partner is crucial, and I know it can feel overwhelming. Many people ask similar questions when they start looking. Let’s break down some common concerns to give you a clearer picture and help you make an informed decision.

What is a mold manufacturer, really?

Do you find the term "mold manufacturer" a bit vague? Unsure what services and expertise they truly offer? This lack of clarity can make it hard to assess if a supplier meets your specific project needs. Let me explain what a good mold manufacturer does, so you know exactly what to look for.

A mold manufacturer, especially a reliable one in China, is more than just a factory. They are partners who design, engineer, and produce high-precision molds, typically for plastic injection molding. They should offer services from DFM analysis to mold trials and sometimes even initial production runs, acting as a key part of your supply chain.

A mold manufacturer is a specialized company that creates the tools, known as molds or dies, used in mass production processes like injection molding, die casting, or blow molding. When I first started in this industry, I thought it was just about cutting steel. But it’s so much more. A truly reliable mold maker is an engineering partner.

A good mold manufacturer offers a comprehensive range of services:

- Design for Manufacturability (DFM): They analyze your product design. They suggest modifications to make it easier and more cost-effective to mold. This is a critical step I always emphasize with my clients. It saves headaches later.

- Mold Design: They use specialized CAD/CAM software. They design the intricate details of the mold itself. This includes cavities, cores, cooling channels, runner systems, and ejection systems.

- Material Selection (Mold Steel): They advise on the best steel for the mold. For example, P20, H13, or S136. This choice depends on production volume, the plastic material being molded, and the desired mold life.

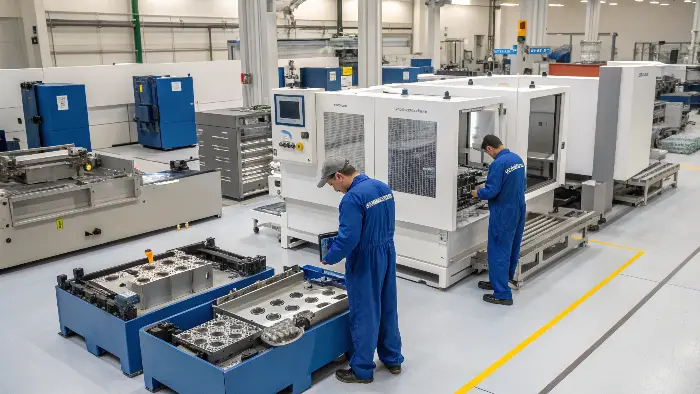

- Precision Machining: They use advanced machinery and includes CNC milling machines, EDM, wire cutting, and precision grinding to create the mold components with very tight tolerances.

- Assembly and Fitting: Skilled mold technicians assemble all the machined components and the use of fitting and assembly ensure everything fits perfectly and functions smoothly.

- Mold Trials (T0, T1, etc.): They test the completed mold. They do this by injecting plastic to produce sample parts. Then, they inspect these parts and fine-tune the mold until the parts meet all specifications.

- After-Sales Service: This includes ongoing support like mold maintenance, repair, and sometimes even modifications if your product design changes in the future.

Here’s a simple breakdown of their core functions and why they matter to a designer like Jacky:

| Core Function | Description | Why it’s important for you (Jacky) |

|---|---|---|

| Consultation & DFM | Reviewing your part design for moldability, suggesting improvements. | Optimizes your design for efficient production, reduces potential costs, and avoids future manufacturing issues. |

| Mold Engineering | Designing the actual mold tool based on the approved part design. | Ensures the mold functions correctly, produces quality parts consistently, and meets lifespan requirements. |

| Mold Fabrication | Machining, heat treating, finishing, and assembling the mold components. | The physical creation of your critical production tool to exact specifications. |

| Testing & Iteration | Running mold trials, inspecting sample parts, and making necessary adjustments. | Guarantees the mold produces parts that meet your precise quality standards and functional requirements. |

| Support & Maintenance | Providing maintenance schedules, repairs, and sometimes production assistance. | Ensures long-term usability and reliability of the mold, protecting your investment. |

Understanding these aspects helps you evaluate the comprehensive capabilities of the company you need for sourcing for your projects. It’s not just about having machines; it’s about the engineering expertise, quality processes, and service they are offering.

How much does it cost to manufacture a mold in China?

Worried about the investment needed for a new mold? Are Chinese prices truly competitive, or are there hidden traps you should be aware of? Budgeting for molds can be tricky, and unexpected costs can derail your project’s financial viability if not managed carefully. I’ll break down the key factors influencing mold costs in China, so you can get a clearer estimate.

Cost to create a mold in China will be quite volatile, typically between a few thousand to over a hundred thousand US dollars. A few of the key variables include the size and complexity of the mold, the part design complexity, the steel, number of cavities, tolerances needed, and lifespan to be gained from the mold. It’s not a fee that is one-size-fits-all.

When I get quotes for molds, I see a wide range. It’s essential to understand what drives these costs to make fair comparisons. Let’s look at the main elements:

- Part Complexity and Size: A simple, small part needs a less complex and smaller mold than a large part with intricate features, undercuts, side actions, or threads. More complexity means more design time, more sophisticated machining operations, and more skilled labor for assembly and polishing.

- Mold Steel: The type of steel used for the mold is a big cost factor. Pre-hardened steel like P20 is generally cheaper and easier to machine but has a shorter operational lifespan. Hardened steels like H13 or S136 are more expensive and harder to machine but last for millions of shots and are better for abrasive materials or parts requiring a high-gloss finish. I always discuss this with my clients like Jacky, carefully considering their expected production volume and part material.

- Number of Cavities: A single-cavity mold produces one part per injection cycle. A multi-cavity mold produces multiple parts simultaneously, increasing productivity significantly but also increasing the mold’s initial cost and complexity. The decision depends on production volume forecasts.

- Runner System: Cold runners are simpler and cheaper to build into the mold. Hot runner systems are more expensive upfront but reduce plastic material waste and can shorten cycle times, often saving money in the long run for high-volume production. This is a common consideration for consumer electronics parts.

- Required Tolerances and Surface Finish: Tighter dimensional tolerances and high-quality surface finishes (like SPI-A1 for a mirror polish) require more precise machining, more skilled hand polishing, and more rigorous quality control, all of which add to the cost.

- Mold Lifespan (Production Volume): A mold designed for 100,000 shots will be built differently (and usually cheaper) than one designed for 1,000,000+ shots, which requires more durable materials and construction.

Here’s a table to illustrate some common cost drivers and considerations for a designer:

| Cost Driver | Impact on Price | Example | Consideration for Jacky |

|---|---|---|---|

| Part Geometry | High | Complex shapes, undercuts, thin walls increase machining and design time. | Work with molder on DFM to simplify design if possible without compromising function or aesthetics. |

| Mold Material (Steel) | High | H13 tool steel is more expensive than P20 but offers longer life and better wear resistance. | Balance upfront mold cost with required production volume, part material properties, and mold maintenance. |

| Number of Cavities | Medium to High | More cavities = higher initial mold cost but lower per-part molding cost. | Evaluate based on total production quantity, project timeline, and desired cycle time. |

| Hot Runner System | Medium | Adds to mold cost but saves material, reduces cycle time, and improves part consistency. | Often justified for high-volume production of consumer electronics parts where material cost and cycle efficiency are critical. |

| Surface Finish/Tol. | Medium | High polish (e.g., SPI-A1) or very tight tolerances require more labor and precision. | Specify only what’s functionally and aesthetically necessary; over-specifying significantly increases cost. |

Remember, the cheapest quote isn’t always the best value. A poorly made, cheap mold can cost you much more in the long run due to frequent repairs, low-quality parts, production delays, and even damage to your brand reputation. I learned this the hard way early in my career when a "bargain" mold failed prematurely.

How much does injection molding cost in China, then?

Once you have the mold, what about the actual part production cost? Is injection molding in China still a cost-saver for your components? Understanding per-part costs is vital for your product’s profitability, but these can vary significantly based on several factors. Let’s explore the elements that determine injection molding prices in China, helping you budget effectively.

Injection molding costs in China depend on the chosen plastic material, the part’s weight and complexity, the molding cycle time, the size of the injection molding machine (tonnage), and associated labor. While generally lower than in many Western countries, these factors, plus the order quantity, significantly influence the final per-part price. Good, clear communication with your molder is key here.

After the mold is ready and approved, the next step is producing your plastic parts. The cost of injection molding per part is influenced by several key things:

- Plastic Resin Material: The price of raw plastic materials (e.g., ABS, PC, PP, Nylon, TPE) varies greatly. Engineering-grade resins or those with special additives (like UV stabilizers, flame retardants, or glass fibers) will be more expensive than commodity plastics.

- Part Weight (Shot Size): Heavier parts naturally use more material per cycle, directly impacting the material cost component of the per-part price.

- Cycle Time: This is the total time it takes to inject the plastic, cool the part sufficiently within the mold, open the mold, eject the part, and close the mold to prepare for the next shot. Shorter cycle times mean more parts can be produced per hour, reducing the machine time cost allocated to each part. This is where a well-designed mold and an efficient process really pay off.

- Machine Tonnage and Hourly Rate: Larger parts or multi-cavity molds often require larger injection molding machines, which are rated by their clamping force (tonnage). Bigger machines generally have higher hourly operating rates than smaller ones.

- Labor Costs: While labor is generally more affordable in China compared to some other regions, it’s still a factor. This includes machine operators, quality control personnel, and any manual labor for part handling or secondary operations.

- Order Quantity: Larger production runs usually result in a lower per-part price. This is because the initial setup costs for the machine and mold are spread over a greater number of units.

- Secondary Operations: Any post-molding processes will add to the cost. This can include things like painting, pad printing, silk screening, ultrasonic welding, heat staking, assembly, or special packaging.

Here’s a breakdown of typical cost components in injection molding:

| Component | Description | Impact on Per-Part Cost | Tip for Jacky |

|---|---|---|---|

| Material Cost | Cost of the plastic resin per kilogram, including any colorants or additives. | High | Choose the most cost-effective material that meets all performance and aesthetic requirements. Consider regrind usage if appropriate. |

| Machine Time | Cost per hour for operating the injection molding machine, based on its size and capabilities. | Medium | Optimize mold design for the fastest possible, stable cycle time. Ensure efficient cooling. |

| Labor Cost | Cost for machine operators, quality control inspectors, and any manual secondary operations. | Medium | Discuss automation possibilities for part removal or inspection for high-volume parts to reduce labor dependency. |

| Setup Cost | One-time cost to set up the mold on the injection molding machine for a production run. | Low (when amortized over large runs) | Consolidate orders where possible to minimize setup frequency and its impact on per-part cost. |

| Overhead & Profit | The molder’s operational costs (rent, utilities, administration) and their profit margin. | Medium | Build a good, transparent relationship with your molder for fair and sustainable pricing. |

When I work with clients like Jacky, who designs parts for consumer electronics, we often run detailed cost simulations or get transparent quotes to understand these costs thoroughly. It’s important to get a clear breakdown from your Chinese supplier. Don’t just look at the final per-part number; understand how they arrived at it so you can identify potential areas for cost optimization.

5 Best Mold Manufacturers In China

Let’s see some mold manufacturers of China which you can count for your project.

1. Yahong Moulding Co., Ltd.

Yahong was established in 1997 and covers an area of 22,000 square meters. They are dedicated to precision injection mold design and production, injection molding, spraying, assembly, and SMT of electronic products. Yahong uses ISO9001, ISO14001. TS16949 international standard management systems. Yahong offers automotive electronics, civilian intelligent household appliances, tri-proof microcontrol systems, microelectronics, and other intelligent control fields. Yahong has become the strategic partner of well-known brands such as Panasonic, Yanfeng Visteon, Yanfeng Seats, Eastone, Continental Automotive, Omron, etc.

2. CKmold

Founded in 2002, CKmold is a leading injection molding tool and CNC machining company. With more than two decades of experience in the business, they are providing the best quality products in our field.

The staff of 60 highly qualified professionals is committed to doing the best for their customers. From the smallest of mold details down to the precision of CNC machining, CKmold is a shining example of the harmony of the latest technology and human expertise.

The primary goal at CKmold is to bring concepts and implementation together, delivering incomparable services specifically crafted to meet clients’ unique needs. Here’s what you receive:

Injection Molding Tools: With modern technology and strong experience, we create and produce high-quality injection molds that ensure precision and reliability. Our molds are designed to perform at their best, giving you a competitive advantage in today’s competitive marketplace.

CNC Machining Services: Our advanced CNC machining facility is equipped to undertake intricate operations with high precision. Right from the process of prototyping to mass production, our professionals ensure that every single detail is properly engineered.

3. Hi-tech moulds Co., Ltd.

The company is established in January 2004, with a total land area of 80 acres, of which the factory area is 36,000 square meters. Hi-tech Moulds was certified with the ISO 9001 quality management system in 2006, ISO14001 environmental management system, and ISO45001 occupational health and safety management system in 2017. Compliant with technology and management innovation and using advanced technical equipment and effective management measures, Hi-tech continues to offer excellent automotive injection mold design and professional project management services

4. SINO MOULD

Sino Mould founded in 2000, and has a 70,000-square-meter mold-manufacturing base. It’s specialized in the production of all types of products and die-casting molds, widely used in electrical appliances, lighting, automobile accessories, and other aluminum mold production, aluminum alloy die-casting. SINO MOULD has a strong and experienced designing team of over 80 members, providing high-quality die-casting molds, with advanced CAD / CAE / CAM systems, mature die-casting forming process simulation and analysis. Since its founding over 25 years ago, SINO MOULD has obtained over 100 patents in mold design, mold structure manufacture, plastic part inventions, plastic part function optimization, and new inventions in the plastic industry.

5. Kelon mould Co., Ltd.

Kelon was established and put into production in June 1995, covering a floor area of 14,000 square meters. Kelon has over 80 technical R&D personnel and over 300 highly qualified technical workers.

The company is involved in R&D, design, and production of all kinds of large and medium-sized stamping, injection molding, and thermoforming foam molds, committed to providing high-quality products and services to manufacturing enterprises in home appliances, automobiles, kitchen, and bathroom products. Kelon produces over 1,000 sets of stamping molds, 600 sets of injection molds, and 80 sets of thermoforming foam annually. This ranks it among the largest and most advanced mold production bases in the Pearl River Delta.

So, Who is the Best Mold Maker in China?

There’s no single "best" mold maker in China that fits everyone’s needs perfectly. The "best" mold maker for you depends entirely on your project’s specific requirements: the complexity of your part, expected production volume, type of plastic material, available budget, and crucial quality standards. Focus on finding a reliable and suitable partner who communicates effectively and truly understands your needs.

Everyone wants the "best," but in manufacturing, and especially in a vast market like China, "best" is relative. The mold maker that’s perfect for a simple, high-volume promotional toy part might not be the best choice for a complex, tight-tolerance medical device component or a highly aesthetic consumer electronics housing like Jacky might design. Instead of searching for a mythical single "best" entity, I always advise focusing on finding the right fit for your specific project and your company’s operational style.

Here’s what I’ve learned to look for over my years in the industry, which aligns with my core insights about what makes a good mold maker:

- Experience and Specialization: Do they have demonstrable experience with parts similar to yours in terms of size, complexity, and material? Some mold makers specialize in automotive components, others in consumer electronics, medical devices, or packaging. A specialist often understands the specific nuances, common challenges, and typical quality standards of that particular industry.

- Technical Capability:

- Engineering Team: Is their engineering team experienced and proactive? Can they provide insightful Design for Manufacturability (DFM) feedback? This is crucial for designers like Jacky to optimize designs before steel is cut.

- Quality Control Systems: What processes do they have in place to ensure quality? Look for things like ISO certification (e.g., ISO 9001), documented material inspection, in-process quality checks, and thorough final inspection protocols.

- Communication and Service: This is hugely important, especially when working remotely. Can you communicate effectively with their team? Do they have project managers who speak good English and understand technical details? Do they respond promptly and transparently? Good communication, as I mentioned in my insights, is absolutely key to a smooth project.

- Understanding of Your Standards: They need to not only understand but also demonstrate their ability to meet your company’s quality expectations, material specifications, testing protocols, and documentation requirements. Sharing your standards clearly upfront is vital.

- References and Track Record: Don’t hesitate to ask for case studies of similar projects or references from other customers, preferably from your industry or country. A proven track record of successful projects builds confidence.

- Willingness to Partner: Do they view your project as a one-off transaction, or are they interested in building a long-term partnership? A good mold maker will work collaboratively with you to solve problems, offer suggestions, and achieve the best possible outcome for your product.

Instead of a single "best," think in terms of suitability and alignment with your needs:

| Factor | What to look for | Why it matters for Jacky (Product/Mold Designer) |

|---|---|---|

| Relevant Experience | Proven projects in consumer electronics, similar plastic materials, and part complexity. | Reduces their learning curve, leads to better understanding of specific challenges (e.g., aesthetics, tight fits, EMI shielding). |

| Engineering Strength | Strong DFM capabilities, mold flow analysis expertise, experienced mold designers. | Helps optimize Jacky’s designs for manufacturability, durability, and cost-effectiveness. Provides valuable technical feedback. |

| Robust Quality Systems | ISO 9001 certification, comprehensive QC procedures, good metrology equipment (CMM, projector). | Ensures parts consistently meet specifications, reduces defects, minimizes rework, and upholds product integrity. |

| Effective Communication | Fluent English-speaking project manager, responsive team, proactive updates, clear documentation. | Critical for managing projects remotely, resolving technical queries quickly, and ensuring alignment throughout the project. |

| Cultural Understanding | Experience working with Western companies, understanding of international quality expectations and business practices. | Leads to smoother collaboration, fewer misunderstandings about standards, and a more predictable project flow. |

I always tell people, including experienced designers like Jacky, to vet at least three to five potential suppliers thoroughly based on these criteria. The "best" mold maker for you is the one that best matches your specific project needs, your quality standards, and your preferred way of working, ultimately becoming a reliable and valuable extension of your own team.

Conclusion

Finding a reliable mold maker in China involves looking beyond just the initial price. Focus on their proven experience, solid technical skills, capacity for clear and consistent communication, and a genuine understanding of your specific standards and project goals. This comprehensive approach will lead you to a true partner who helps ensure your project’s success and the quality of your final product.