Would you like to get rid of long cycle times and distorted parts that are sucking out your profits? Most entrepreneurs accuse the molding machine or the plastic material itself, however, a lot of times the blame is behind the curtain of the mold as well. A poor cooling system can clandestinely cripple your production causing aggravating delays and quality problems that increase the cost.

The best thing to increase the efficiency of injection molding is to optimize your mold cooling. This entails the development of cooling channels which withdraw heat out of the plastic component promptly and evenly. A good system employs parallel cooling circuits, special parts where it gets hard, and even in some cases further techniques, such as conformal cooling. The outcome is a long cycle time will be reduced drastically, less defective parts such as warping and sink marks as well as an increase in overall profitability.

The truth is, cooling accounts for up to 80% of the entire injection molding cycle. It’s the longest and most critical phase. I’ve worked with countless clients like Michael, who were focused on shaving a second off the injection time, not realizing they could cut 10 seconds from the cooling time with a better-designed mold. By focusing on how heat is removed, you can gain a massive competitive advantage. Let’s explore how to design a cooling system that works for you, not against you.

Why Is Cooling the Most Critical Factor in Your Injection Molding Cycle?

Bemoaned by bottlenecks in production that appear to have no apparent explanation? You can be adjusting injection speeds and pressures, but your cycle times hardly change and defects such as warping remain. This inefficiency is not only time based but money based in terms of rejected parts. The issue is that you could be searching in the wrong direction in search of the solution.

The most important stage is cooling since it determines how quickly and how well production will take place. It normally takes up 70-80 percent of the entire cycle time. Efficient cooling leads to solidification of the part with low internal stress and eliminates warping and dimensional instability. You do this by reducing the cooling period to its bare minimum with efficient design which directly results in higher output and profitability and at the same time enhance the consistency and quality of each part that you make.

Many people new to molding think the action happens during injection. But the real money is made while you wait for the part to cool. I had a client making simple plastic trays. Their cycle was 45 seconds. They thought that was as good as it gets. We designed a new mold for them, focusing entirely on a high-flow, parallel cooling circuit. We got their cycle time down to 30 seconds. That 15-second difference meant they could produce 50% more parts in the same amount of time. Their profits soared, all because we paid attention to cooling.

The Two Goals of Mold Cooling

An effective cooling system has two primary objectives that are equally important. Failing at either one will lead to problems.

- Speed: The system must remove heat from the molten plastic as quickly as possible. The faster you can get the part to a stable ejection temperature, the shorter your cycle time will be. This directly translates to higher output and lower cost per part.

- Uniformity: The system must remove heat evenly from all areas of the part. If one area of the part cools significantly faster than another, the differential shrinkage will create internal stresses. These stresses are what cause a part to warp or twist after it’s ejected from the mold.

How Cooling Impacts the Bottom Line

A poorly designed system has direct financial consequences. Let’s look at the breakdown.

| Impact Area | Consequence of Poor Cooling | Benefit of Optimized Cooling |

|---|---|---|

| Cycle Time | Long cooling phase leads to low production output. | Shorter cycles increase machine capacity and output. |

| Part Quality | Warping, sink marks, and inconsistent dimensions. | High-quality, dimensionally stable parts with low scrap rates. |

| Energy Consumption | Machine runs longer per part, consuming more energy. | Lower energy cost per part due to faster cycles. |

| Profitability | Lower output and high scrap rates erode profit margins. | Higher margins from increased efficiency and quality. |

What Are the Main Types of Conventional Cooling Channel Designs?

Everybody understands that it is important to cool the system, but what does a good conventional cooling system look like? It is not sufficient to drill a few holes in order to have the water run through them. A hysterical or poorly designed circuit may form hot spots or inadequate cooling, which is the exact opposite of the intention and you are back to the same ills as you were attempting to resolve.

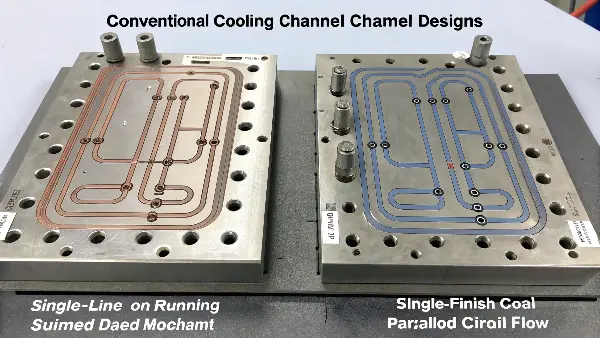

Traditional cooling systems involve straight channels bored in the plates of the molds. Such channels are normally organized either through a series or parallel. A series circuit is a circuit in which one line of coolant flows through the entire circuit which is easy to install and install, but it may cause temperatures to be uneven. A parallel circuit divides the coolant flow into several branches cooling various parts of the machine at the same time thus offering superior temperature control that is much more balanced and can be machine and designed more easily.

The choice between a series and parallel design depends on the part’s geometry and budget. For a simple, small part, a series circuit might be perfectly fine. But for a larger, more complex part, trying to save money with a series design is a huge mistake. I remember a client who insisted on a simple series circuit for a large automotive dashboard component. The coolant temperature increased so much by the end of the circuit that one side of the part was consistently under-cooled, causing it to warp every time. We had to remake the mold with a parallel circuit, a costly lesson in fluid dynamics.

Series Cooling Circuits

This is the simplest form of cooling. A single channel snakes its way through the mold plate.

- How it Works: Coolant enters at one point, flows through the entire circuit, and exits at another.

- Advantages: It’s cheap and easy to machine. It requires fewer connections and less complex plumbing.

- Disadvantages: The coolant heats up as it travels along the path. This means the area at the end of the circuit receives warmer coolant than the area at the beginning, leading to a temperature differential across the part. This is a primary cause of uneven cooling and warping in larger parts.

Parallel Cooling Circuits

This is a more engineered approach that provides far better results for most applications.

- How it Works: The main coolant supply is split into several smaller, parallel branches. Each branch cools a specific section of the mold. The branches then combine again before exiting.

- Advantages: Each section of the mold receives coolant at roughly the same initial temperature and flow rate. This results in much more uniform and efficient cooling across the entire part surface.

- Disadvantages: It is more complex and expensive to design and manufacture. It requires more precise machining and additional plumbing (manifolds, o-rings) to distribute the flow.

Comparing the Designs

| Feature | Series Cooling | Parallel Cooling |

|---|---|---|

| Machining Cost | Low | High |

| Design Complexity | Simple | Complex |

| Cooling Uniformity | Poor, especially on large parts. | Excellent, provides balanced cooling. |

| Pressure Drop | High, due to the long, single path. | Low, as flow is split across shorter paths. |

| Best For | Small, simple parts or low-budget prototypes. | Most production molds, especially for large or complex parts. |

—

What are the Critical Factors in Cooling System Design?

Mold cooling system must be well designed and numerous things should be taken into consideration during the designing of the system. The primary elements of the cooling process are cooling channels, mold material and cooling medium. The following is an overview of the impact of each of these factors on the cooling performance:

Mold Material:

Molding rate is determined by thermal conductivity of the mold material. Copper alloys are highly thermally conductive and therefore they transfer heat and cool faster. They, however, cost more than the cheaper materials such as steel in favor of superior conductivity. The probability of locating an appropriate material consists in striking a balance between the price, wearability, and cooling.

Cooling Medium:

Water is the most commonly used cooling medium, but other cooling mediums exist. Cooling performance can be enhanced by adding additives or alternative fluids, e.g,. glycol-water mixtures. The temperature of cooling medium and cooling medium flow rate also determine cooling efficiency and both should be maximized to achieve optimal results.

Cooling Channel Layout:

The mold has pathways and these are known as cooling channels, and the cooling medium (commonly water) assists in cooling the mold. These channels should be laid out in a uniform manner, which implies uniform cooling. Common channels were employed, though, when the cooling channels conformed to the mold cavity, the cooling became better.

Computational Fluid Dynamics (CFD) Analysis:

CFD software is applied by engineers to help them simulate the flow of the cooling medium through channels. As part of CFD modeling, the temperature distribution and heat transfer within the mold are computed to identify hotspots or poorly cooled spaces. Such simulations allow engineers to rearrange the channel layout or change flow rates controllably, thereby enhancing cooling.

Conformal Cooling:

Conformal cooling channels do not have the characteristics of the straight-line channels that have a constant distance between the channels and the mold. This is a more homogeneous cooling and minimizes cycle time. In other cases, 3D printing technology can produce conformal cooling channels, which have a higher design freedom.

Cycle Time Optimization:

The end objective of optimization is to decrease the cycle time with minimal or no effect on the quality of parts. Cycle time may be reduced through the increase of uniformity in cooling and high conductor materials. Engineers can test with shorter cycle times and see what difference it makes to the quality of the part to come up with the best balance.

High-Conductivity Mold Inserts:

Mold inserts can be manufactured out of high-conductivity materials such as copper alloys and fitted into the areas that require fast cooling. These materials are very costly, but they are used in strategic areas with minimal use, providing more cooling in the critical areas without a change of the entire mold material.

Advanced Cooling Technologies for the Optimization of the Mold’s Cooling System

The cooling stage is currently one of the longest steps of the production cycle in modern injection molding-its influence on the total molding time is usually 50-70 percent. Consequently, increased productivity, quality of parts, and cost reduction are direct consequences of optimizing the cooling of the mold.

The recent advancement of cooling technologies has turned the conventional cooling systems to extremely efficient and strictly regulated processes. These inventions enable the manufacturers to attain quicker cycle time, even temperature spread, and improved dimensional stability of molded components.

Conformal Cooling Channels

The application of conformal cooling channels can be described as one of the most important innovations in the design of molds. Conformal cooling lines are not designed as a straight-line drilled channel, but rather 3D-printed or machined along the shape of the geometry of the part. The design allows the transfer of heat to the entire surface of the mold uniformly, eliminating hot spots and lowering the cooling period by a huge margin. The outcome is a reduction in cycle times, an increase in part uniformity, and less warpage. Conformal cooling is of particular use in complex parts or molds that have a complicated shape that standard cooling paths are not able to reach.

Large Thermal Conductivity Substances.

The other useful approach to maximize cooling efficiency is the use of high thermal conductivity materials like beryllium copper, aluminum alloys or copper inserts to the mold. These materials conduct heat far quicker than the usual tool steels and allow the heat to be removed rapidly in a thick or hot region. Being applied in strategic manner, they may shorten the cycle time by a third without compromising dimensional accuracy. This method is especially applicable to the moulds that are either very unevenly cooled or are working with thick-walled or transparent plastics.

High-tech Cooling Inserts and Baffles.

In case of molds, which do not fit snugly in conformal channels, sophisticated cooling inserts, baffles, and bubblers are used to enhance heat dissipation. These elements guide the passage of coolant in parts that are most likely to retain heat hence maintaining a uniform temperature all through the mold. The current designs have been noted to apply spiral or helical baffles which increase turbulence and heat exchange and consequently enable cooling efficiency to be achieved without necessarily redesigning the entire mold. This renders them a relatively cheap method of retrofitting old tooling.

Flow Control and Cooling Fluids of High-Efficiency.

Optimized flow control systems and intelligent cooling fluids are another important element of modern mold cooling. Nano-fluid mixtures or glycol based fluids are now replacing or improving traditional water based coolants, which provide a higher thermal conductivity. Moreover, there are automated flow control units that have sensors and temperature measurements to ensure that the coolant has the best velocity and pressure throughout the channels. This ensures not only that no temperature variation is brought but also mold life is prolonged due to the absence of thermal stress.

Minimization of Cooling with Additive Manufacturing.

The process of additive manufacturing (3D printing) has also transformed the design of mold cooling by allowing complex internal geometries that are not possible by traditional machining. Molds can be produced with conformal cooling channels customized to the specific requirements of the tool with metal 3D printing technologies such as Selective Laser Melting (SLM) or Direct Metal Laser Sintering (DMLS). These high-technology molds provide not only high cooling and lower cycle time, but also lower energy usage, and additive manufacturing has become a foundation of the modern optimisation of moulds.

Digital Monitoring Tools and Simulation.

The modern optimization of mold cooling is also based on the individual mold flow simulation software like Moldex3D, Autodesk Moldflow, or SolidWorks Plastics. The tools enable engineers to predict the heat conductivity, coolant flow, and temperature gradients prior to the production of the mold. Digital analysis enables designers to anticipate possible hot spots, modify cooling systems and optimize flow rates, which all result in faster and more accurate mold design.

Cooling system optimization is a crucial criterion for achieving shorter production cycles, reduced energy consumption, and improved part quality. The technologies that are changing the designing and functioning of molds include advanced technologies like conformal cooling, variotherm system, high-conductivity material, and computer simulating.

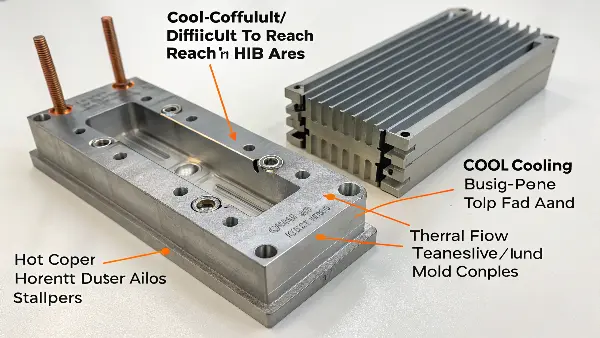

How Do You Cool Difficult-to-Reach Areas in a Mold?

What to do with such a long narrow core piece, with a deep rib, to which the usual drilled cooling line can invent no penetration? There is no way such places would not turn into hot spots. They cool more slowly than the others of the part, leaving local sink marks, bending and forcing you to waste more time increasing the cycle time instead of increasing it.

Mold makers also have special features that are used to give cold to hard to reach areas. The most common are the baffles and bubblers that transfer the coolant further into the pins of cores and pins of thermal pipes that are made up of very conductive copper alloys. These components act as heat sinks and they receive heat energy in the isolated space and conduit the heat energy to the primary cooling system in the mold base.

One of my clients, Michael, was producing a small housing with several tall, thin bosses for screws. The tips of these bosses were always causing sink marks on the cosmetic surface opposite them. Standard cooling lines were too far away to have any effect. We modified the mold to include small-diameter bubblers in each core pin that formed the bosses. The direct cooling completely eliminated the sink marks and allowed him to shorten his cycle time by four seconds. It’s a perfect example of how a small, targeted solution can solve a major quality problem.

Baffles: Splitting the Flow

A baffle is a simple but effective device. It’s a blade of metal placed inside a cooling channel.

- How it Works: A single, straight cooling channel is drilled. The baffle is placed in the middle, dividing the channel into two semi-circular paths. Coolant is forced to flow up one side of the baffle and down the other. This creates turbulence and improves heat transfer compared to a simple open channel.

- Best Use: Good for medium-length cores where you need better heat transfer than a simple drilled line can provide.

Bubblers: Fountain of Coolant

A bubbler is slightly more complex and is essentially a "fountain" of coolant inside the mold.

- How it Works: A small tube is placed inside a larger cooling channel. Coolant is forced up through the central tube to the very tip of the feature (like a core pin). It then "bubbles" over and flows back down the outside channel. This delivers the coldest coolant directly to the hottest spot.

- Best Use: Ideal for cooling long, thin cores or deep features where getting coolant to the tip is critical.

Thermal Pins: The Heat Superhighway

Thermal pins work on a different principle. They don’t carry fluid.

- How it Works: A thermal pin is a sealed copper tube containing a wick structure and a small amount of working fluid. The hot end is placed in the isolated area of the mold. The heat causes the fluid to vaporize. The vapor travels to the cold end (which is touching a main cooling line), condenses back into a liquid, and releases its heat. The liquid then flows back along the wick, and the cycle repeats. It’s a passive, super-efficient heat pipe.

- Best Use: Excellent for very isolated hot spots where running a water line is physically impossible.

| Component | Mechanism | Complexity | Effectiveness |

|---|---|---|---|

| Baffle | Divides a channel to force turbulent flow. | Low | Good |

| Bubbler | A tube directs coolant to the channel’s end. | Medium | Very Good |

| Thermal Pin | A passive heat pipe transfers heat via phase change. | Medium | Excellent |

What Is Conformal Cooling and Is It Worth the Investment?

You have maximized the traditional cooling but you continue to struggle with every minute of the cycle time on a complicated part. The conventional drilled lines of traditional cooling simply cannot reach out to all the curves and characteristics of your part, and they are inevitable hot spots. You have heard of conformal cooling but the cost is too high.

Conformal cooling is a highly developed process of making molds in which the cooling channels are shaped to trace exactly the geometry of the part, or conform with its geometry. This is normally done through use of metal 3D printing (DMLS). It has an incredibly rapid and uniform heat transfer by locating the cooling channels at an optimum and constant distance between all sides of the part which cannot be achieved by traditional straight-line drilling. This radically shortens cycle times as well as removing warping.

The first time I proposed a conformally cooled mold to a client, they were shocked by the quote. It was nearly double the cost of a conventional tool. But this was for a high-volume consumer product where they planned to run millions of cycles. We ran a simulation showing a potential 40% reduction in cycle time. We built the tool, and the simulation was right. The extra cost of the mold was paid back in production savings in less than six months. After that, the tool was pure profit. It’s not for every project, but when it fits, the return on investment is massive.

How is Conformal Cooling Made?

You can’t create these complex, curved channels with a drill bit. The technology that makes it possible is Direct Metal Laser Sintering (DMLS), a form of 3D printing for metal.

- Design: The cooling channels are designed in CAD software to perfectly trace the part’s surfaces.

- Printing: A machine lays down a thin layer of metal powder (like tool steel). A high-powered laser fuses the powder in the shape of a cross-section of the mold insert, leaving the channels hollow.

- Layer by Layer: The process repeats, building the insert layer by layer with the complex cooling channels trapped inside.

- Finishing: The printed insert is then heat-treated and finished just like a conventional mold insert.

The Real-World Benefits

The advantages go beyond just speed. The uniform cooling provides unparalleled part quality.

| Feature | Conventional Cooling (Drilled) | Conformal Cooling (3D Printed) |

|---|---|---|

| Channel Geometry | Straight lines only. | Freeform curves that follow the part surface. |

| Heat Removal | Uneven. Hot spots are common in complex areas. | Extremely uniform. Eliminates hot spots. |

| Cycle Time | Baseline. Limited by the least efficient cooling area. | Can be 20-50% shorter. |

| Part Quality | Good, but prone to warping and sink marks in complex parts. | Excellent. Minimal internal stress, superior dimensional stability. |

| Initial Mold Cost | Lower. | Significantly higher. |

| ROI | Standard. | Very high for high-volume production or very complex parts. |

Conformal cooling isn’t a magic bullet for every project. But for business owners like Michael, who are running high volumes of complex parts, it’s a strategic investment that can provide a decisive competitive edge.

Conclusion

Finally, the motor of your injection molding process is the cooling system. Design that is designed intelligently, carefully, and well-engineered an intelligent parallel circuit such as smart circuit, the purpose of using bubblers, or advanced conformal system; this is a direct investment in your bottom line. It provides less time in cycles, quality parts and profitability. We think at CKMOLD we have mastered cooling, we have mastered molding and we are here to make sure you are good at it too.