Are you concerned that hidden weaknesses in your plastic parts could lead to unexpected failures? Weld lines are a common issue in injection molding, creating structural weak points that can compromise product integrity, leading to costly recalls and damage to your brand’s reputation. Ignoring them is a gamble that most businesses can’t afford to take. The key is to proactively identify and quantify this weakness through rigorous testing.

To evaluate the structural integrity of plastic parts, you must test the weld line strength using methods like tensile testing, impact testing (Izod or Charpy), and burst testing. Tensile testing measures the force required to pull the part apart at the weld line, providing a clear strength value. Impact testing assesses how the weld line behaves under sudden force, crucial for parts that might be dropped. These quantitative tests, combined with visual inspection, help determine if a part meets its required performance and safety standards.

Understanding these failure points is critical for any manufacturer. In my early days, a client faced critical failures in a casing for a handheld medical device. The parts were cracking right along a subtle line, a classic weld line failure. This experience taught me that simply making a part isn’t enough; you have to guarantee its strength. But before we explore the specific testing methods that can save you from such disasters, it’s essential to understand exactly what a weld line is and how it differs from other molding defects. Let’s build a solid foundation of knowledge first.

What Exactly Is a Weld Line in Injection Molding?

Ever seen a product fail along a perfectly straight line, almost as if it was designed to break there? That’s often a weld line at play, a hidden trap in an otherwise solid-looking part. This seemingly minor defect can be a major liability, creating a point of failure that undermines the entire product’s structural integrity. For a business owner, this means potential product recalls, unhappy customers, and a damaged reputation. The first step to conquering this problem is to truly understand what you’re up against.

A weld line, also known as a knit line or a meld line, is a line or seam formed where two or more separate molten plastic flows meet and fuse inside the mold cavity. This occurs when the mold design requires the plastic to flow around an obstacle, like a core pin for a hole, or when multiple gates are used to fill the part. As these melt fronts meet, they have already begun to cool, resulting in poor molecular chain entanglement and creating a structurally weak area in the final part.

To truly grasp this, let’s go a bit deeper. Imagine two streams of slightly cooled honey flowing around a rock and meeting on the other side. Where they meet, they don’t mix perfectly; they just press against each other, creating a visible seam. The same thing happens with molten plastic. The polymer molecules at the forefront of the flow have started to align themselves in the direction of flow and have lost some of their heat. When two such fronts meet, the molecules don’t have enough time or energy to intermingle and entangle properly before the plastic solidifies. It’s this lack of molecular integration that makes the weld line the weakest part of the component.

There are technically two types of these lines:

- Meld Line: This forms when two flows meet and continue to flow together in the same direction. The angle of their meeting is relatively shallow, making meld lines generally stronger.

- Weld Line (or Knit Line): This is formed when two flows meet head-on. The collision is more direct, which traps more air and leads to even poorer fusion, resulting in a significantly weaker joint.

Understanding this fundamental process is the first step toward controlling it through strategic design and processing.

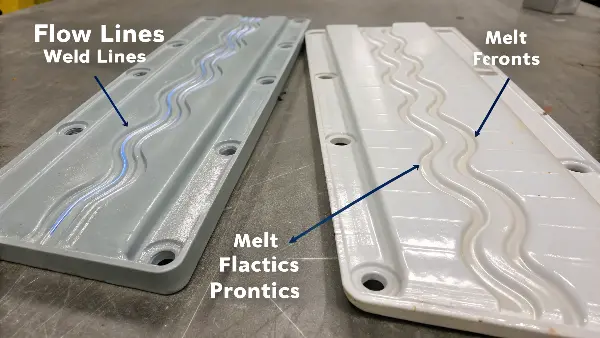

What Is the Difference Between Flow Lines and Weld Lines?

Are you seeing faint lines on your plastic parts and immediately fearing a structural weakness? It’s a common panic, but not all lines are created equal. Misdiagnosing a cosmetic flow line as a critical weld line can lead you down a rabbit hole of unnecessary and expensive "fixes". Conversely, dismissing a weak weld line as a simple cosmetic issue can lead to catastrophic product failures in the field. Knowing the difference is crucial for effective quality control and problem-solving. It saves time, money, and protects your brand.

The primary difference is that a weld line is a structural weakness where two melt fronts meet and fuse improperly, while a flow line is a cosmetic surface defect showing the path of the molten plastic. Weld lines are actual physical seams that reduce the part’s strength. Flow lines are typically wavy patterns or variations in surface gloss caused by inconsistent cooling or injection speed, and they generally do not impact the part’s structural integrity. One is a potential point of failure; the other is an aesthetic issue.

Let’s break this down further to make the distinction crystal clear. I once had a client, Michael, who was ready to scrap an entire production run of enclosures because he saw faint lines around the gate area. He was convinced they were weld lines that would cause the enclosures to crack. After a quick inspection, I was able to show him they were just flow lines—harmless ripples caused by a slight fluctuation in injection speed. We adjusted the process parameters slightly, and the lines vanished. He saved a lot of money and learned a valuable lesson that day.

To help you avoid similar confusion, here’s a simple table comparing the two:

| Feature | Weld Line (Knit Line) | Flow Line |

|---|---|---|

| Cause | Two or more melt fronts meeting and fusing improperly. | Varying injection speeds and inconsistent cooling rates. |

| Appearance | A distinct, sharp line, notch, or groove on the surface. | Wavy patterns, halos, or rings of differing gloss/color. |

| Location | Opposite the gate, or where plastic flows around a core. | Often appears in a circular pattern around the gate area. |

| Impact on Part | Structural. Creates a weak point, significantly reducing strength. | Cosmetic. Affects surface appearance but not part strength. |

| Solution | Adjust part/mold design, change gate locations, optimize process temps. | Stabilize injection speed, adjust melt/mold temperature. |

In short, if you can snap the part and it breaks cleanly along that line, you’re dealing with a weld line. If the line is just on the surface and the part’s strength feels uniform, it’s likely a flow line. Identifying which one you’re facing is the first and most important step in quality control.

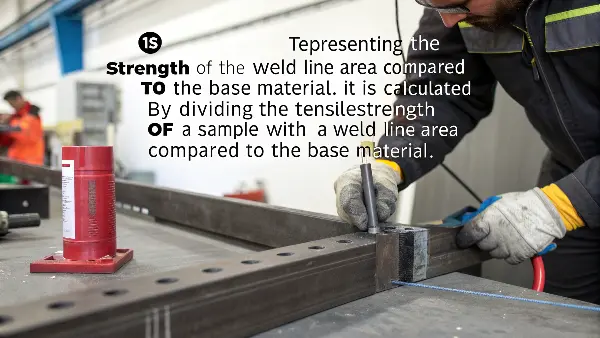

What Is the Weld Line Strength Factor?

You know weld lines are weak, but just how weak are they? Saying a part "might break" isn’t enough for an engineer or a business owner who needs to guarantee performance. You need solid data. Without a way to quantify this weakness, you’re just guessing about your product’s reliability. This uncertainty can lead to over-engineering parts to be safe (increasing costs) or, worse, shipping under-engineered parts that fail (destroying customer trust). The weld line strength factor provides the concrete number you need.

The weld line strength factor is a percentage that represents the strength of the weld line area compared to the strength of the base, unaffected material. It is calculated by dividing the tensile strength of a sample with a weld line by the tensile strength of a sample without one, then multiplying by 100. For example, if the base material has a tensile strength of 50 MPa and the weld line breaks at 30 MPa, the strength factor is 60%. This metric is crucial for predicting part performance and ensuring it meets design specifications.

This factor isn’t a single, fixed number; it’s heavily influenced by several variables, which is why it’s so important to understand what drives it. I remember working on a project for a consumer electronics company. The part was made from a glass-filled nylon. In our initial runs, the weld line strength factor was a dismal 40%. The part was far too brittle. Instead of just changing the material, we systematically analyzed the key influencing factors.

Here are the primary elements that determine the weld line strength factor:

Material Properties

The type of plastic you use is the biggest determinant.

- Amorphous vs. Semi-crystalline: Amorphous polymers (like ABS, PC) generally have better weld line strength than semi-crystalline polymers (like PP, Nylon). This is because their disordered molecular structure allows for better entanglement at the flow front.

- Fillers and Fibers: Adding fillers like glass or carbon fiber can drastically reduce weld line strength. The fibers tend to align with the flow direction. When two fronts meet, the fibers don’t bridge the gap effectively, creating a resin-rich, fiber-poor plane of weakness.

Processing Conditions

How you mold the part is just as critical.

- Melt Temperature: Higher melt temperatures give the polymer chains more energy and time to entangle before solidifying, leading to a stronger weld line.

- Mold Temperature: A warmer mold prevents the melt fronts from cooling too quickly, promoting better fusion.

- Injection Speed & Pressure: Higher injection pressure and speed can increase friction and heat at the flow front, but if too high, it can misalign fibers. It’s a delicate balance.

By increasing the melt and mold temperatures for that nylon part, we were able to boost the strength factor to over 70%, meeting the client’s requirements without changing the design. Understanding and controlling these variables is how you move from hoping a part is strong enough to knowing it is.

How Can You Avoid or Minimize Weld Lines in Injection Molding?

You now understand what weld lines are and how to measure their weakness. The next logical question is the most important one: how do you get rid of them or at least make them harmless? Constantly fighting weld line failures after production has started is an exhausting and expensive cycle. You’re left with a warehouse full of weak parts and frustrated clients. The real solution isn’t just in testing for the problem, but in proactively designing and processing it out of existence from the very beginning.

To avoid or minimize weld lines, you must focus on optimizing three key areas: part design, mold design, and processing parameters. Strategically placing gates in part design can move weld lines to less critical areas. In mold design, using hot runner systems and proper venting helps maintain melt temperature and allows trapped air to escape. Finally, adjusting processing parameters like increasing melt temperature, mold temperature, and injection pressure will promote better fusion between the melt fronts, significantly increasing the weld line’s strength.

This holistic approach is the only way to effectively manage weld lines. You can’t just tweak one setting and expect a perfect result; it requires a coordinated effort across the entire manufacturing process. Let’s dive deeper into each of these three pillars of weld line mitigation.

1. Strategic Part Design

The best time to fix a weld line is before the mold is even machined.

- Gate Location: This is your most powerful tool. By using mold flow simulation software, you can predict exactly where weld lines will form based on different gate locations. The goal is to position the gate so that any resulting weld line forms in an area of the part that experiences low stress or is non-cosmetic. For a long, thin part, gating at one end is better than gating in the middle, which would create a head-on weld line right in the center.

- Part Geometry: If you can’t move the weld line, you can reinforce it. This can be done by increasing the wall thickness in the area where the weld line is predicted to form or by adding a rib structure behind it to provide extra support.

2. Intelligent Mold Design

The mold itself plays a huge role in how the plastic flows and fuses.

- Gate Type and Size: Using a larger gate can reduce the pressure drop and help maintain melt temperature, improving flow. For parts with multiple weld lines, a hot runner system with valve gates allows for sequential filling, where you can control which gates open and when, effectively "painting" the cavity with plastic to control weld line location and quality.

- Venting: When two melt fronts meet, they can trap a pocket of air or gas. Without an escape route, this bubble gets compressed and prevents the fronts from fusing properly, creating an even weaker weld line. Proper vents machined into the mold at the location where weld lines are expected to form are absolutely critical for letting this trapped air out.

3. Optimized Processing Parameters

Once the mold is built, your final lever for control is the injection molding machine itself.

- Increase Temperatures: As discussed before, higher melt and mold temperatures are your best friends for improving weld line strength. They keep the plastic molten for longer, giving the polymer chains more time to entangle at the seam.

- Adjust Pressure and Speed: Increasing the packing pressure after the initial fill helps to squeeze the two melt fronts together, improving fusion. A faster injection speed can also help by delivering the material to the weld line location with more residual heat.

By systematically addressing these three areas, you can transform weld lines from critical failure points into manageable and non-critical features of your plastic parts.

Conclusion

In conclusion, weld lines are a serious consideration in plastic part manufacturing, but they don’t have to be a source of failure. By understanding what they are, how they differ from cosmetic defects, and how to quantify their impact using a strength factor, you gain control. Proactive adjustments in part design, mold construction, and processing parameters are the key to ensuring the structural integrity and reliability of your final product.