Difficulties in choosing the appropriate steel and using the wrong material may result in expensive re-repair of molds, low quality parts and wastage of time. As single a choice as this it has effects on the surface finish of your parts and on the life span of your tool in general. You must have a sure means of adjusting the steel to the needs of you without wasting too much in the process or failing in the attempt.

To choose the mold steel, the ideal solution is to weigh four important aspects that are: the kind of plastic resin that you are operating, the volume of production that you need, the preference of how you want your part to come out, and your budget. In the case of corrosive plastics such as PVC, stainless steel (e.g. 420SS) should be used. In the case of abrasive and glass-filled resins, use a hard and wearable steel such as H-13. A steel that is very polishable, such as P-20 or NAK80, is required in case a high-gloss finish is required. Lastly, low-volume runs can possibly be satisfied with a less costly and softer steel.

Choosing the right mold steel feels like a high-stakes decision because it is. It sets the foundation for the entire manufacturing process. Get it right, and you’ll enjoy smooth production runs and high-quality parts for years. Get it wrong, and you’re in for a long series of headaches and unexpected costs. I’ve seen both happen. That’s why I want to walk you through the process, breaking it down into simple, manageable steps. Let’s make sure you have the knowledge to make the right call every time.

Why is choosing the right mold steel so important?

Have you ever watched a project derailed on a continual basis maintained by constant mold? The genesis of this is usually a bad original selection of steel. This choice appears to be minor, yet the consequences of this choice on the success of your project are enormous. It determines your life span of mold, appearance of parts and time and money that you are going to spend in maintenance.

The type of mold steel that is picked is very important as it directly influences the survival of the mold, the quality of the final plastic parts and the overall price of the manufacturing. A balanced steel will not wear off easily, will not be corroded by some plastics, and will have fine cutting to ensure enhanced looks. A wrong decision makes your tools wrong, your production is halted and your investment is not paid back. It forms the basis of a molding exercise.

One client that I can recall at the beginning of my career had requested producing a simple casing. They also insisted on lower-grade steel to save the first quote despite the fact that their target was more than a million units. The mold served well in the first 50,000 shots. But then, problems started. The wearing part started to move and produced more flash on the parts. The surface on the cavity began to develop small scratches, which were passed to their product. They would have spent less on the appropriate steel initially than spending more time on repairing and wasting time. That was a good lesson to me because the initial price of steel is not the only component of the overall equation. We will examine the main properties that you should know to prevent such an error.

A Closer Look at Steel’s Impact

The choice of mold steel is not just a technical detail for engineers; it’s a fundamental business decision. It influences three core areas of your project: cost, quality, and speed.

1. Total Cost of Ownership

The initial price of a block of steel is easy to see. What’s harder to see are the long-term costs.

- Maintenance and Repair: A softer, less durable steel will wear out faster, especially with abrasive plastics or high-pressure injection. This means more time in the toolroom for polishing, welding, and re-machining. Each hour of maintenance is an hour the mold is not making parts and money.

- Mold Lifespan: A mold made from H-13 steel might last for over a million cycles. A mold from a lower-grade aluminum might only last for a few thousand. Choosing a steel that matches your required production volume ensures you don’t have to build a second mold midway through your product’s life.

2. Final Part Quality

The steel is the mirror that shapes your plastic part. Any imperfection in the steel will be transferred to every part you produce.

- Surface Finish: If you need a product with a glossy, mirror-like finish, you need a steel that can be polished to that level, like S-136 or NAK80. A standard P-20 steel will give you a good finish, but it won’t achieve that premium "Class A" polish.

- Dimensional Stability: High-quality steel holds its shape and dimensions under the intense pressure and heat of injection molding. This is crucial for parts with tight tolerances. A less stable steel can warp or flex, leading to parts that don’t fit together correctly.

3. Production Speed and Efficiency

The steel also affects how fast you can run your production cycle.

- Thermal Conductivity: Some steels transfer heat better than others. A steel with high thermal conductivity allows the mold to cool down faster. A faster cooling time means a shorter cycle time, which allows you to produce more parts per hour. For high-volume parts like bottle caps, this can make a huge difference in profitability. Steels like Beryllium Copper (though not technically a steel, it’s used for inserts) are famous for their excellent cooling properties.

Popular Tool Steel Materials for Injection Mold Making

When choosing the appropriate tool steel material in injection mold manufacturing, the choice of material is one of the most important decisions to make concerning the performance, life and quality of the mold. Tool steels are special steels that are designed to withstand temperatures pressure and wear that takes place during the molding process. The various tool steel types have distinct mechanical characteristics and hence can be used in various molding conditions, volumes of production, and types of plastic.

Some of the most popular tool steel materials in the present day injection mold making are listed below with their main characteristics and use.

S136 / 420 Stainless Steel – Mold Steel Corrosion Resistant.

S136 (synonymous with AISI 420 stainless steel) is a high-chromium stainless tool steel that resists corrosion and rusting, in even the highly humid or corrosive conditions of molding. It is highly hard and polishable.

Key Properties:

- Maximum hardness during heat treatment 50-54 HRC.

- Ideal corrosion resistance and wear resistance.

- Finishes; High cleanliness mirror polish.

- Good post-EDM or heat dimensional stability.

Applications: - Usually applied to medical, food packaging, and optical molds.

- Capable of molding PVC, acetates and other corrosive resins.

- S136 steel prolongs the life of the mold and provides good finish on its surface even in the extreme conditions.

4140 Alloy Steel

Alloy steel 4140 is a medium carbon steel, which is both chromium-molybdenum and exhibits high strength, toughness, and wear resistance. Its properties are well-balanced, and this is why it is a mold steel that can be used in a variety of applications. You however; must remember that this one is a heat treatment sensitive tool steel i.e. it must be heat treated to give the required properties.

The following characteristics are shown by 4140 Alloy Tool Steel:

- Excellent toughness and tensile strength even in case of heat-treatment.

- Bears the properties of improved machinability compared to most high-carbon or high-alloy steels.

- It is not easy to weld and hence, repairs are slow.

- Poor corrosion resistance as compared to stainless steel tools.

- Typically cost-effective.

D2 Alloy Steel

D2 alloy steel is a high-carbon and high-chromium mold steel and a cold-work steel. It is a very nice selection in the use of dies and cutting tools.

It is also appropriate in high wear purposes like metal injection molding or highly filled polymers injection molding. D2 alloy steel is very resistant to abrasion and high temperature resistance to deformation.

D2 Alloy tool steel exhibits the following characteristics:

- Exquisite wear and abrasion properties.

- Capacity to sustain high temperature of hardness.

- Extremely resistant to heat treatment.

- Toughness less than other mold steels, therefore, it is likely to crack when subjected to high stress.

- Machinability is challenging because it is highly wear resistant and hard.

- It has a low corrosion resistance than stainless steel.

To select the necessary tool steel used in the injection mold making process, one will have to consider the following aspects: the volume of production, the type of the resin, the complexity of the mold design and the type of the surface finish.

Knowing the properties and performance of every material, mold makers are able to make the molds more durable, of high quality, and have reduced maintenance expenses throughout the production cycle.

What are the key properties to consider in mold steel?

Thinking about steel properties can feel overwhelming with terms like hardness and toughness. You might worry you need an engineering degree to understand it all. But what if you could focus on just a few key characteristics that make the biggest difference? It’s about knowing what to look for and why it matters for your specific parts.

When selecting mold steel, you must primarily consider four properties. First, Hardness, which determines wear resistance against abrasive plastics and high cycle counts. Second, Toughness, the steel’s ability to resist chipping and cracking under pressure. Third, Corrosion Resistance, which is vital when molding plastics like PVC that release corrosive byproducts. Finally, Polishability, the steel’s capacity to achieve a smooth, mirror-like surface for high-quality cosmetic parts. These four factors provide a solid framework for your decision.

These main properties are to be focused on, and make the choice easier. You do not have to be familiar with all the different grades of steel produced. Rather, one can pose specific questions. What is the number of parts required to make? This is what drives you to some kind of hardness. Does that matter to the look of my part? This informs you to give more emphasis to polishability. These questions will help you very quickly reduce your number of possible hires when it comes to hundreds of people down to just a few who could be the right fit. This will make your complicated technical issue a rational decision depending on your project objectives. Now, we shall plunge into the meaning of all of these properties to your mold.

Breaking Down the Core Steel Properties

To make a smart choice, you need to understand what these terms mean in a practical sense. It’s less about the numbers on a spec sheet and more about how the steel will behave in your machine.

Hardness

Hardness is the steel’s ability to resist being scratched, dented, or worn down. It’s usually measured on the Rockwell C scale (HRC).

- Why it Matters: A harder steel (higher HRC) provides better wear resistance. This is essential for two reasons:

- High Production Volumes: Every time the mold opens and closes, there is slight wear on the parting lines and shut-off surfaces. Over a million cycles, this adds up. A hard steel resists this wear, keeping the mold precise for longer.

- Abrasive Materials: If your plastic is filled with glass fibers or other abrasive minerals, it acts like sandpaper on the inside of your mold. A hard steel like H-13 or S-7 is needed to stand up to this constant abrasion.

- The Trade-off: Generally, the harder the steel, the more brittle it becomes and the harder it is to machine. This means machining costs might be higher.

Toughness

Toughness is the steel’s ability to absorb energy and resist cracking or chipping when subjected to sudden impact or high pressure.

- Why it Matters: Injection molding involves immense clamping and injection pressures. If a mold has delicate features like thin ribs or sharp internal corners, a brittle steel could crack. A tough steel can flex slightly under stress without breaking. This is why a shock-resistant steel like S-7 is often used for molds that experience high impact.

- The Balance: Hardness and toughness often have an inverse relationship. The challenge is finding a steel that is hard enough to resist wear but also tough enough to prevent catastrophic failure. This is why heat treatment is so critical; it allows us to fine-tune this balance.

Corrosion Resistance

This is the steel’s ability to resist rust and chemical attack.

- Why it Matters: Some plastics, like PVC and acetal, release corrosive gases during the molding process. This can attack the surface of the mold, causing rust and pitting. This damage ruins the part’s surface finish and can even clog tiny vents. Using a stainless steel (e.g., 420SS, S-136) is a must in these cases. It’s also a good choice for molds that will be stored in humid environments.

Polishability

Polishability refers to how smooth and glossy the steel’s surface can become after polishing.

- Why it Matters: For parts like lenses, clear covers, or high-end electronic casings, the surface finish is everything. The quality of the polish on the mold core and cavity directly determines the finish on the plastic part. Steels with a very fine and uniform grain structure, like NAK80 or S-136, can be polished to a mirror-like "Class A1" finish. A standard P-20 steel, while good, can’t achieve this level of clarity because its grain structure is not as refined.

How does the plastic resin you use affect your steel choice?

Is it a standard plastic such as polypropylene that you are shaping, or more combative such as glass-filled nylon? Lots of individuals do not pay attention to the fact that the plastic is attacking the mold. Incorrect choice of steel when working with a challenging resin could ruin a tool in a matter of seconds of its projected life. What you are left is a rusty worn-out mould and a heap of bad parts.

A selection of steel has the plastic resin as one of the main factors. In case of corrosive resin where the resin is corrosive such as PVC or Acetal, a stainless steel such as 420SS or S-136 is required to avoid rusting and pitting. A very hard, wear-resistant steel such as H-13 or D-2 is required when using abrasive resins that contain either glass or mineral fillers (e.g. PA+GF) to ensure that the mold is not worn away. To have a high-gloss optically smooth finish on parts that call out resins such as PC or PMMA, you would need a clean, high polishable steel such as NAK80.

Think of it like choosing the right tires for your car. You wouldn’t use summer tires for driving in a snowstorm. In the same way, you shouldn’t use a standard P-20 steel for molding a corrosive or highly abrasive plastic. I once worked with a company making industrial sprinkler heads from CPVC. Their first mold, made from standard P-20, started to show rust spots after just a few weeks. The parts started sticking, and the surface finish degraded. We rebuilt the core and cavity using S-136 stainless steel, and that new tool ran flawlessly for years. Matching the steel to the resin is not optional; it’s essential for long-term success.

Matching Steel to Resin: A Practical Guide

The interaction between the plastic resin and the mold surface is a critical consideration. Different plastics create different challenges for the steel. We can break this down into three main categories: corrosive, abrasive, and optical.

Challenge 1: Corrosive Resins

Some resins release acidic byproducts when heated to their melting point. This is a chemical attack that happens on a microscopic level.

- Common Culprits: Polyvinyl Chloride (PVC), Chlorinated Polyvinyl Chloride (CPVC), and some flame-retardant additives.

- The Damage: These acids eat away at the steel’s surface, causing rust and pitting. This damage is directly transferred to the plastic part, ruining its appearance and texture. It can also cause parts to stick in the mold, leading to ejection problems and production slowdowns.

- The Solution: The only reliable solution is to use a stainless steel. These steels contain chromium, which forms a passive, non-reactive layer on the surface, protecting it from chemical attack.

- Good: 420 Stainless Steel (420SS) is a common, cost-effective choice. It offers good corrosion resistance for most applications.

- Better: S-136 is a premium, high-purity stainless steel that offers superior corrosion resistance and can also be polished to a mirror finish.

Challenge 2: Abrasive Resins

Many high-strength plastics are reinforced with fillers like glass fibers, minerals, or carbon fiber. These fillers provide strength and stiffness to the part but are highly abrasive.

- Common Culprits: Glass-Filled Nylon (PA+GF), Glass-Filled Polycarbonate (PC+GF), and mineral-filled Polypropylene (PP+Talc).

- The Damage: As the molten plastic injects into the mold under high pressure, these hard filler particles act like sandpaper, literally scraping away the steel. This wear is most severe in high-flow areas like the gate and on sharp corners. The result is a loss of dimensional accuracy and flash.

- The Solution: You need a steel with very high hardness and wear resistance.

- Good: H-13 Tool Steel is a workhorse for these applications. It’s heat-treated to a high hardness (typically 48-52 HRC) and offers a great balance of wear resistance and toughness.

- Better: For extremely abrasive materials or very long production runs, you might consider even harder tool steels like D-2 or using special surface coatings (like PVD Titanium Nitride) on a base steel like H-13 to further increase surface hardness.

Challenge 3: Optical and High-Cosmetic Resins

For products like lenses, light pipes, or premium electronic enclosures, the visual quality is paramount.

- Common Culprits: Polycarbonate (PC), Acrylic (PMMA), and Polystyrene (PS).

- The Damage: This isn’t damage, but a requirement. These parts need a perfectly smooth, clear, or high-gloss surface. Any tiny imperfection, scratch, or graininess in the steel will be visible on the final part.

- The Solution: You need exceptionally clean and uniform steel that can be polished to a mirror finish.

- Good: P-20 is a pre-hardened steel that can be polished to a good B-1 or A-3 finish, suitable for many consumer products.

- Better: NAK80 is a pre-hardened, high-polish steel that can achieve a Class A-1 mirror finish without needing secondary heat treatment. It’s known for its excellent consistency.

- Best: S-136 (a stainless steel) can also be hardened and polished to the highest optical standards, with the added benefit of corrosion resistance.

| Resin Challenge | Example Resins | Key Steel Property | Recommended Steel |

|---|---|---|---|

| Corrosion | PVC, Acetal | Corrosion Resistance | 420SS, S-136 |

| Abrasion | PA+GF, PC+GF | Hardness / Wear Resistance | H-13, D-2 (or coated) |

| High Polish | PC, PMMA, PS | Polishability / Cleanliness | NAK80, S-136 |

| General Purpose | PP, PE, ABS | Balanced Properties | P-20, 718H |

What are the most common mold steels and what are they used for?

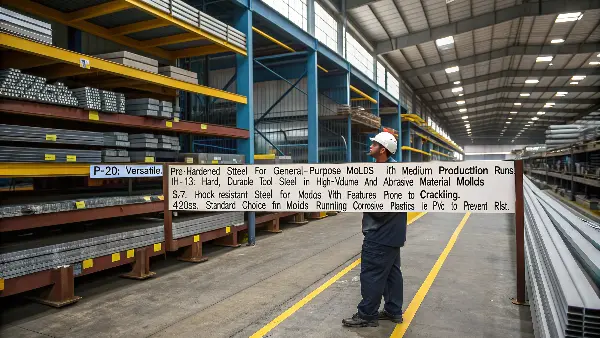

The first step into a warehouse of a steel supplier is nauseating. You see codes like P-20, H-13, S-7, and 420SS. You can just get lost and question whether you are doing the right decision. You are afraid to select a costly steel when a less costly will perform and worse enough, you do not pick a cheaper steel that does not work.

All of the most popular intelligence steels of mold are specific. P-20 is a general-purpose, medium-run production, and pre-hardened steel in molds of all sizes. The high-volume and abrasive material molds are high volume molds that are hard and durable and made of H-13. S-7 is resistant to shocks and steel is applied on molds which develop cracks easily. Lastly, the standard option of the molds operating corrosive plastics such as PVC is the 420 Stainless Steel (420SS) to avoid corrosion.

Imagine that these steels are tools of a tool box. A hammer would never be used to turn a screw. P-20 is such a tool that resembles your adjustable wrench well used–suits most jobs. This diagnostic socket wrench is H-13, a high torque socket wrench. You have the S-7, the beat up impact driver. And 420 SS is your plumbing, rust proof, tool. Recognition of the main use of each of these widespread steels comprises, approximately, 80 percent of all injection molding projects you will ever come across. We will consider each one of them in greater detail.

A Practical Lineup of Industry Workhorses

While there are hundreds of specialty steel grades, most molds are built using a handful of trusted, well-understood materials. As a business owner, knowing these four will give you the confidence to discuss tooling with any mold maker.

1. P-20: The All-Rounder

- What it is: A pre-hardened steel, usually delivered at around 30-32 HRC. "Pre-hardened" means it doesn’t require major heat treatment after machining, which saves time and money.

- Best for: General-purpose molds for non-abrasive plastics like ABS, PP, and PS. It’s the default choice for prototypes and medium-volume production runs (typically up to 400,000 cycles). It has good machinability and can be polished to a decent quality finish (B-grade).

- Limitations: It’s not hard enough for abrasive, glass-filled materials and will wear out quickly. It also doesn’t have corrosion resistance.

- Analogy: The reliable family sedan. It’s affordable, versatile, and gets the job done for most everyday tasks.

2. H-13: The Endurance Champion

- What it is: A chromium-molybdenum hot-work tool steel. It’s delivered soft (annealed) and must be machined, then heat-treated to its final working hardness of 48-52 HRC.

- Best for: High-volume production molds (1 million+ cycles) and molds for abrasive materials like glass-filled nylon. Its high hardness provides excellent wear resistance. It’s also the standard for die-casting molds due to its strength at high temperatures.

- Limitations: Requires a separate, carefully controlled heat treatment process, which adds cost and time to the mold build. Machining it after hardening is very difficult.

- Analogy: The heavy-duty pickup truck. It’s built for tough jobs, long hauls, and carrying heavy loads. It costs more and requires more maintenance, but it’s incredibly durable.

3. S-7: The Tough Guy

- What it is: A shock-resistant tool steel. Like H-13, it’s heat-treated after machining. Its main feature is exceptional toughness.

- Best for: Molds with features that might crack or chip under high stress, such as molds with forced ejection or those that require high clamp tonnage. It’s also used for plastic extrusion dies and blanking tools. It combines medium hardness with superior toughness.

- Limitations: It doesn’t have the extreme wear resistance of H-13 or the polishability of a dedicated finishing steel. Its primary strength is impact resistance.

- Analogy: The off-road vehicle. It’s designed to absorb impacts and handle rough conditions without breaking apart.

4. 420 Stainless Steel (420SS): The Protector

- What it is: A martensitic stainless steel. Its key ingredient is chromium, which gives it excellent corrosion resistance. It can be heat-treated to a hardness level similar to P-20.

- Best for: Molds running corrosive resins like PVC. It’s also great for medical or food-grade applications where cleanliness and rust prevention are critical. It’s also a good choice if the mold will be stored for long periods in a humid plant.

- Limitations: It is generally more expensive than P-20 and can be more challenging to machine. A premium version, S-136, offers even better corrosion resistance and the ability to be polished to a mirror finish.

- Analogy: The all-weather vehicle with a rust-proof coating. It’s specially equipped to handle harsh, corrosive environments where other vehicles would quickly degrade.

Why CK Mold Is a Trustworthy Steel Mold Tooling Maker

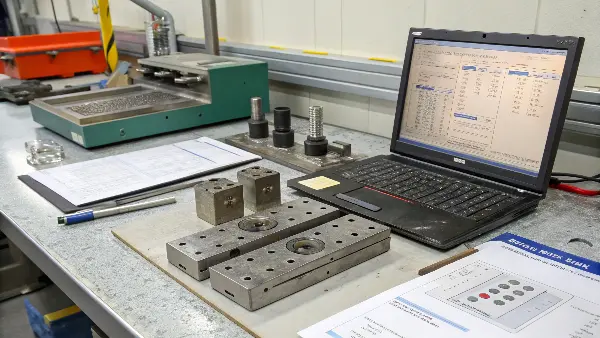

An elite custom mold maker, CK Mold built its reputation upon supplying high-accuracy steel mold tooling to meet today’s industry applications. Equipped with the most advanced CAD/CAM design systems, high-tech CNC machining centers, and years of experience in tool steel processing, CK Mold ensures each mold has unparalleled precision, toughness, and performance.

From a prototype to a mass production mold, the company provides full solutions based on customer requirements in the automotive, medical, packaging, and consumer electronics markets. With technical innovation, high-quality inspection, and international-standard material like P20, H13, and S136 tool steels, CK Mold’s advanced engineering ensures stable and long-lasting results.

Global clients depend on CK Mold to deliver projects on schedule, at attractive prices, and with quick technical support. From precision injection mold to die-casting mold to custom mold part, CK Mold is your go-to provider of high-quality steel tooling mold to optimize efficiency and maximize output.

Conclusion

Ultimately, it is a compromise of selecting the appropriate mold steel. It concerns the trade off between the requirements of your plastic resin, the duration of your production run, your standards of quality and your budget. You will be in a better position to make a wise choice that can save you money and made you not regret in the future by learning more about the essence of hardness, toughness, resistance to corrosion and polishability. Such decision is the actual basis of an effective molding project.