Choosing the wrong mold steel can lead to costly failures, production delays, and poor part quality. It’s a high-stakes decision that can sink an entire project. Imagine your mold cracking prematurely or your high-volume run getting ruined by wear and tear. You’re left scrambling for a solution, losing time and money. Understanding the key properties of mold steels and matching them to your application is the secret to avoiding these problems.

Selecting the right steel for your injection mold involves balancing several critical factors. You must consider the plastic material being molded, the required production volume, the complexity of the part design, and the desired surface finish. Key steel properties like hardness, toughness, corrosion resistance, and polishability are crucial. For high-volume production with abrasive plastics, a hard, wear-resistant steel like H13 is ideal. For pre-production or low-volume runs, a pre-hardened steel like P20 offers a great balance of cost and performance.

Making the right choice might seem complex, but it’s a systematic process. It’s not just about picking the ‘strongest’ or ‘hardest’ steel. It’s about finding the perfect match for your unique project needs. Let’s break down the criteria we use at CKMOLD to ensure our clients get the performance and longevity they expect from their molds. We’ll explore the common materials and what makes each one suitable for different jobs so you can make informed decisions with confidence.

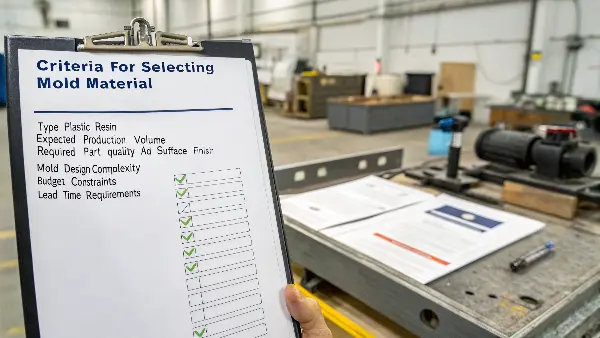

What are the criteria for selecting mold material?

You know material choice is critical, but what specific factors should guide your decision? Without a clear checklist, you might overlook a crucial detail, leading to a mold that underperforms or fails entirely. Don’t let your investment be a gamble based on incomplete information. Let me share the core criteria we evaluate for every single project. This creates a clear roadmap for success and ensures every angle is covered before a single piece of steel is cut.

The primary criteria for selecting mold material include the plastic resin being used (e.g., abrasive, corrosive), the expected production volume, the required part quality and surface finish, and the complexity of the mold design. You also need to balance these with your budget and lead time constraints. Factors like hardness for wear resistance, toughness to prevent cracking, and corrosion resistance for certain plastics are key technical considerations. A systematic evaluation of these points ensures you get the optimal mold life and performance.

When I first started in this industry, I saw firsthand what happens when these criteria are ignored. A company tried to save a little money by using a standard P20 mold for a part made with 30% glass-filled nylon. The abrasive nature of the glass fibers wore down the mold gates and cavity surfaces in less than 50,000 cycles, far short of their 300,000-part goal. The project faced massive delays and cost overruns for repairs. This taught me a valuable lesson: the upfront analysis is the most important step. Let’s go deeper into the specific criteria we use.

Production Volume and Cycle Time

The first question I always ask a client is, "How many parts do you plan to make?" This is the foundation of our decision.

- Low Volume (<10,000 parts): For prototypes or very small runs, you can use softer materials like Aluminum or a mild, pre-hardened steel. The focus is on speed and low cost, not long-term durability.

- Medium Volume (10,000 – 500,000 parts): This is the sweet spot for a versatile workhorse steel like P20. It offers a great balance of machinability, durability, and cost.

- High Volume (500,000+ parts): For long-running projects, you must invest in high-hardness, high-wear-resistance tool steels like H13 or S7. The higher initial cost is easily justified by the extended mold life and reduced maintenance downtime.

Plastic Resin Properties

The plastic you inject has a direct impact on the mold. Some resins are gentle, while others are aggressive.

- Abrasive Resins: Plastics with fillers like glass or mineral fibers (e.g., GF-Nylon, PBT) act like sandpaper on the mold surface. This requires a very hard steel (H13, D2) heat-treated to a high Rockwell hardness (HRC) to resist wear.

- Corrosive Resins: Materials like PVC or some flame-retardant plastics release corrosive gases during molding. This will rust standard tool steels. For these applications, a stainless steel like 420SS or S136 is essential.

Part Complexity and Finish Requirements

The design of your part dictates the properties needed from the steel.

- Complex Geometries: Intricate parts with thin walls or delicate ribs need a steel with good dimensional stability during heat treatment and good machinability.

- Surface Finish: If your part needs a mirror-like, optical-grade polish (SPI A-1), you need an extremely clean and high-quality steel like S136 or NAK80. These steels are manufactured with very few impurities, allowing for a flawless finish. For a standard textured finish, P20 is more than adequate.

| Criteria | Key Consideration | Recommended Steel Property |

|---|---|---|

| Production Volume | Low, Medium, or High number of shots | Hardness & Wear Resistance |

| Plastic Material | Abrasive fillers or corrosive off-gassing | Hardness & Corrosion Resistance |

| Part Finish | Textured, matte, or high-gloss optical | Polishability & Steel Cleanliness |

| Part Design | Thin walls, sharp corners, complex actions | Toughness & Machinability |

| Budget | Upfront tool cost vs. long-term maintenance | Material Cost & Lifespan |

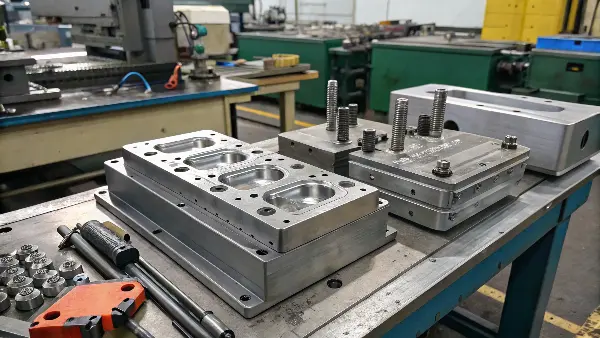

What types of materials are most used with injection molding?

The world of mold steels is vast, with dozens of grades and codes like P20, H13, S7, and 420SS. It’s easy to get lost in the jargon and feel unsure if you’re being recommended the right material. This uncertainty can be stressful when a significant investment is on the line. I’ll demystify the common choices and explain exactly where each one shines, so you can speak the language of your mold maker and have a productive conversation.

The most common materials for injection molds are tool steels, categorized into groups like the ‘P’ series, ‘H’ series, and ‘S’ series. P20 is a versatile, pre-hardened steel widely used for medium-volume runs and prototypes due to its excellent balance of machinability and cost. H13 is a hot-work tool steel, favored for high-volume, high-pressure applications with abrasive materials. For molds requiring high polish or corrosion resistance, stainless steels like 420SS or S136 are the go-to choice.

Think of these steels as different tools in a toolbox. You wouldn’t use a sledgehammer to hang a picture frame. Likewise, you wouldn’t use a basic steel for a million-cycle run with a highly abrasive plastic. Each one has a specific job. Over the years, I’ve built thousands of molds, and a handful of these materials cover over 90% of all applications. Understanding them is the key to mastering mold design. Let’s break down the most popular players.

The Workhorse: P20 Steel

If there is one "standard" mold steel, it’s P20. It’s a pre-hardened steel, which means it arrives from the supplier with a decent hardness (typically around 30-32 HRC). This saves us the time and expense of a separate heat treatment process after machining.

- Properties: Good machinability, fair polishability, and excellent cost-effectiveness.

- Best For: Prototype molds, medium production runs (up to ~400,000 shots, depending on the plastic), and parts that don’t require a mirror finish. It’s perfect for consumer goods, electronic housings, and general-purpose applications.

- Limitations: It’s not hard enough to withstand highly abrasive plastics for long runs, and it will rust if used with corrosive materials or stored improperly.

The High-Endurance Champion: H13 Steel

When a project demands high volume and durability, we turn to H13. This is a hot-work tool steel that is delivered soft (annealed) and must be heat-treated after machining. This extra step is what gives it its incredible properties.

- Properties: Excellent wear resistance, high toughness, and great strength at elevated temperatures. It can be hardened to 48-52 HRC.

- Best For: High-volume production runs (1 million+ shots), molding abrasive materials like glass-filled nylon, and for die-casting applications.

- Limitations: It is more expensive than P20 and requires a precise heat treatment process, adding to the lead time and cost of the mold build.

The Polished Professional: Stainless Steels (420SS, S136)

When clarity or corrosion is a concern, stainless steel is the only answer. S136 is a very common grade of 420 stainless that is produced with extremely low impurities.

- Properties: Excellent corrosion resistance and the ability to be polished to a flawless, mirror-like finish (SPI A-1).

- Best For: Molds for optical parts like lenses and light pipes, medical devices that require sterilization, and for running corrosive plastics like PVC.

- Limitations: Stainless steels are significantly more expensive and can be more challenging to machine than P20 or H13.

How do you choose the right material for specific injection molding needs?

You understand the criteria and know the common materials. But how do you connect the dots for your specific project? Choosing a material that’s "good enough" can leave performance on the table, while over-specifying wastes your budget. This decision paralysis can easily delay a project’s timeline. I’ll walk you through a practical thought process, using real-world examples to show you how we match the steel to the job perfectly at CKMOLD.

To choose the right material for your needs, start with your plastic resin and production volume. For a 500,000-shot run of glass-filled nylon, you need a wear-resistant steel like H13. For a 50,000-shot run of ABS for a non-cosmetic part, P20 is a cost-effective choice. If you’re molding clear polycarbonate for lenses, a high-polish stainless steel like S136 is non-negotiable. Always consider the application first—the part’s function dictates the necessary steel properties, from hardness to corrosion resistance.

The right choice becomes clear when you let the application lead the conversation. It’s a process of elimination based on non-negotiable requirements. Let’s run through a few common scenarios that I encounter regularly with clients like Michael. This will show you exactly how the theory applies in practice.

Scenario 1: High-Volume Automotive Component

- The Part: An under-the-hood bracket for an engine.

- Plastic Resin: PA66 with 30% glass fiber (highly abrasive).

- Required Volume: 1,000,000+ parts over the product’s life.

- The Analysis: The two key drivers here are extreme volume and a very abrasive plastic. This is a classic case where durability is paramount. P20 steel would wear out far too quickly, leading to parts falling out of spec and constant, costly mold maintenance. The only logical choice here is H13 tool steel. We would machine the mold and then have it professionally heat-treated to achieve a hardness of around 50 HRC. The higher upfront investment in H13 is easily justified by the guarantee of mold longevity and consistency across the million-part run.

Scenario 2: Consumer Electronics Housing

- The Part: The casing for a new smart home remote control.

- Plastic Resin: ABS (a general-purpose, non-abrasive plastic).

- Required Volume: 250,000 parts.

- Required Finish: A light, sandblasted texture (MT-11010).

- The Analysis: Here, the situation is different. The volume is medium, the plastic is not abrasive, and the finish is a simple texture, not a high polish. Using H13 here would be over-engineering and a waste of money. The perfect fit for this project is P20 steel. It’s cost-effective, machines beautifully to create the textured surface, and can easily handle a 250,000-part run with ABS without significant wear. This choice delivers the required performance at the best possible price point.

Scenario 3: Medical Diagnostic Device

- The Part: A handheld diagnostic tool with a clear window for viewing results.

- Plastic Resin: Polycarbonate (for the clear window) and a flame-retardant ABS for the housing.

- Required Volume: 100,000 parts.

- The Analysis: This scenario has a critical requirement that overrides almost everything else: the need for optical clarity on the window. This requires a mold surface that can be polished to a perfect mirror finish (SPI A-1). Furthermore, some flame-retardant additives can be corrosive. P20 cannot be polished to this level, and H13, while better, is not ideal. The clear and correct choice is a high-grade stainless steel like S136. Its purity allows for a flawless polish, and its inherent corrosion resistance handles any outgassing from the plastic. The higher material cost is a necessary part of achieving the product’s functional and aesthetic requirements.

What is the strongest material for injection molding?

Everyone wants the "best," and in manufacturing, "best" often gets confused with "strongest." You might ask your mold maker for the strongest steel available, thinking it will prevent all potential problems. But this common misconception can lead you to choose a material that’s actually wrong for your application—one that might be too brittle, difficult to machine, and unnecessarily expensive. Let’s redefine what "strong" really means in the context of mold making.

There isn’t a single "strongest" material, as mold strength is a balance of different properties. Hardness resists wear from abrasive plastics, while toughness resists chipping and cracking under stress. A very hard steel can be brittle. For example, H13 steel, when properly heat-treated, offers an excellent combination of high hardness and good toughness, making it incredibly robust for high-pressure, long-run molding. However, for applications requiring extreme impact resistance, a tougher but less hard steel like S7 might be considered "stronger" because it’s less likely to fracture.

The most important concept to understand is that in metallurgy, strength is not a single value. It’s a trade-off, primarily between two key properties: hardness and toughness. Getting this balance right is the true mark of an expert mold designer. Asking for the "strongest" is the wrong question. The right question is, "What kind of strength does my specific application require?"

Hardness vs. Toughness: The Core Trade-off

Think of the difference between a glass plate and a rubber mat. The glass is very hard; it’s difficult to scratch. However, if you drop it, it shatters because it has low toughness. The rubber mat is easy to scratch (low hardness), but you can bend it, twist it, and hit it with a hammer, and it won’t break because it has high toughness. Mold steels operate on this same principle.

- Hardness (measured in HRC): This is the steel’s ability to resist surface indentation, scratching, and wear. It is absolutely critical when you are molding abrasive plastics.

- Toughness: This is the steel’s ability to absorb energy and deform without fracturing. It is critical for molds with features that might chip or crack, like sharp internal corners or aggressive side-actions.

When to Prioritize Hardness

You need to prioritize hardness when wear is your primary enemy. I once had a client who insisted on using P20 for a part with 20% glass fiber to save on upfront costs, against our recommendation. The mold gates wore out after just 30,000 shots, leading to flash and inconsistent parts. We had to stop production and remake the core and cavity in H13. The lesson? For long runs with abrasive plastics, high hardness is non-negotiable. Steels like H13 and D2 are heat-treated to high HRC values specifically for this purpose.

When to Prioritize Toughness

You need to prioritize toughness when the risk of fracture is high. Imagine a mold for a part with a snap-fit clip. The steel that forms that little undercut feature is under a lot of stress during every single cycle. If you use a steel that is too hard and brittle, that delicate feature could simply snap off. For these applications, a shock-resistant tool steel like S7 is the champion. It’s not as hard as H13, but its exceptional toughness makes it the "stronger" choice because it’s far less likely to break.

The true strength in mold making comes from the optimal balance. This is why H13 is so revered—it offers a fantastic combination of high hardness to resist wear and good toughness to resist cracking. It’s the balanced athlete, the all-around strongman for the most demanding jobs.

Conclusion

Choosing the right mold steel is about a smart match, not just brute strength. By evaluating your production volume, plastic type, and part requirements, you can balance cost and performance. This approach, matching steel to the specific application, is the foundation of a successful molding project. It’s how we at CKMOLD ensure our partners get the quality and longevity they need to succeed. Master Molding Right.