Choosing the wrong locating ring? Misalignment, leaks, and setup headaches follow. Selecting the right one ensures smooth production and prevents costly errors. It’s a critical first step.

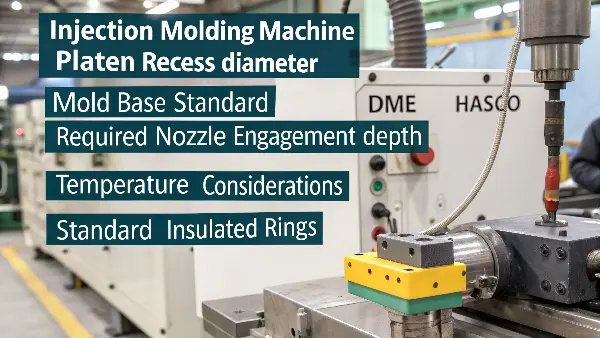

Selecting the optimal locating ring involves matching its outer diameter to the machine platen, choosing the correct height for nozzle engagement, considering material for durability, and adhering to relevant standards (like DME or HASCO) based on the specific mold base and application requirements.

It might seem straightforward – just pick a ring that fits the hole in the machine platen, right? But as someone who’s spent years in mold making and trading, I’ve seen subtle differences in selection lead to big downstream problems. The optimal choice depends on more than just basic dimensions, especially when dealing with different molding scenarios. Let’s explore the factors that guide the best decision for your specific needs.

What are the Main Types and Standards for Locating Rings?

Confused by terms like DME1, HASCO2, standard vs. insulated? Understanding the basic categories and standards is the first step to making an intelligent choice for your mold setup.

Locating rings primarily differ by standard (e.g., DME, HASCO, Misumi), outer diameter (matching the machine platen), height (affecting nozzle reach), and special features like insulation for heated molds. Knowing these distinctions helps narrow down options compatible with your mold base and machine.

Think of these standards like different systems for building blocks. While they achieve the same goal – centering the mold – their specific dimensions and design philosophies can differ slightly. For designers like Jacky, knowing which system the mold base uses is essential.

- ### Standards (e.g., DME, HASCO, Misumi): These are major mold component suppliers, and their standards are widely adopted, sometimes varying by region. A DME locating ring is designed to fit perfectly with a DME mold base and its screw patterns. The same applies to HASCO and others. Mixing standards usually isn’t possible without modification because screw hole locations or counterbores might differ. Always match the ring standard to the mold base standard.

- ### Outer Diameter (OD): This is the most critical dimension. It must precisely match the recess diameter in the injection molding machine’s stationary platen. Common ODs are often around 4 inches (or 100mm), but machines vary, so always verify the machine specification. A sloppy fit here compromises the primary function of centering.

- ### Height (or Length): This dimension determines how far the sprue bushing face sits relative to the machine platen face. It needs to be correct to ensure the machine nozzle can properly reach and seal against the sprue bushing. Different heights accommodate various nozzle lengths and sprue bushing protrusions.

-

### Special Features (e.g., Insulated): For high-temperature molding, insulated locating rings are available. These incorporate an air gap or insulating material layer to reduce heat transfer from a hot mold to the machine platen, saving energy and stabilizing nozzle temperature.

Understanding these basic types is the foundation for selection.Feature Description Importance Standard System compatibility (DME, HASCO, etc.) Ensures fit with mold base screw patterns Outer Diameter Fits machine platen recess Critical for accurate mold centering Height Determines nozzle engagement distance Ensures proper nozzle sealing against sprue bush Special Features E.g., Insulation for high-temp applications Optimizes performance in specific conditions Choosing the right type and standard prevents compatibility issues from the start.

What Key Factors Influence Locating Ring Selection?

Beyond just the basic type and standard, what specific details guide your choice? Overlooking these factors can lead to suboptimal performance, wear, or even damage during the molding process.

Key factors include: the injection molding machine’s platen recess diameter (dictates ring OD), the mold base standard (DME, HASCO, etc.), the required nozzle engagement depth (determines ring height), and potential temperature considerations (requiring standard vs. insulated rings).

I remember a client struggling with inconsistent short shots. We eventually traced it back to using a locating ring that was slightly too short for their machine/nozzle setup. The nozzle wasn’t sealing consistently under pressure. It highlights how interconnected these factors are. Let’s break them down:

- ### Machine Platen Recess Diameter: This is non-negotiable. The locating ring OD must match the machine’s platen bore diameter accurately. You need the technical specifications of the specific injection molding machine the mold will run in. Measure if unsure, don’t guess. A common size is ~3.99 inches (~101.35mm) for a nominal 4-inch ring, designed for a slight clearance fit.

- ### Mold Base Standard: As mentioned, stick to the standard used for the rest of the mold base (e.g., DME, HASCO). This ensures the mounting screws align correctly and the ring integrates properly with other components like the sprue bushing.

- ### Nozzle Engagement (Ring Height): This requires considering the machine nozzle’s length and profile, and the sprue bushing’s design (how far it protrudes or sits recessed relative to the top clamp plate). The locating ring height must position the sprue bushing inlet so the nozzle can make firm, leak-proof contact. Too short, and the nozzle won’t reach or seal well. Too tall, and the nozzle might crash or not fit. Calculating the stack-up is crucial.

-

### Operating Temperature: Will the mold run hot (e.g., for engineering resins like PEEK or PSU)? If so, heat loss through the locating ring can be significant, affecting nozzle temperature stability and wasting energy. An insulated locating ring, with its thermal break design, is often the optimal choice here. For standard temperature molds (like polyolefins), a standard hardened steel ring is usually sufficient and more cost-effective. Factor Consideration Impact on Selection Machine Platen ID Exact diameter of the recess in the machine Determines the required Outer Diameter (OD) Mold Base System Brand/standard of the mold base (DME, HASCO…) Determines the required Ring Standard/Screw Pattern Nozzle/Sprue Setup Machine nozzle length, sprue bushing position Determines the required Ring Height Mold Temperature Expected operating temperature of the mold Determines need for Standard vs. Insulated Ring Carefully evaluating these factors ensures you select a ring that functions correctly within the entire system.

How Do Specific Applications Impact Ring Choice?

Does a high-volume production mold need the same ring as a short-run prototype tool? The demands of the application itself should definitely influence your selection for long-term reliability and performance.

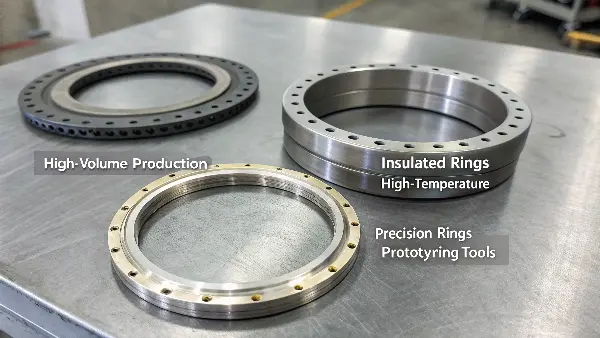

High-volume production often benefits from durable, hardened steel rings. High-temperature applications may necessitate insulated rings. Precision applications demand rings with tight tolerances and consistency. Prototyping might allow for more standard options if temperature isn’t extreme.

Think about the life expectancy and running conditions. A mold designed to run millions of cycles needs components built for endurance, while a prototype mold might prioritize speed of manufacture or lower initial cost. Matching the ring to the application makes sense. Here’s how different scenarios might guide selection:

- ### High-Volume Production: Durability is key. These molds run constantly and are mounted/dismounted frequently. A standard, high-quality hardened steel locating ring is typically the best choice. Its wear resistance ensures the critical OD tolerance holds up over time, maintaining consistent centering. Cost is a factor, but reliability usually outweighs small savings on a cheaper, less durable ring.

- ### High-Temperature Applications: As discussed, if the mold requires high heat (e.g., > 150°C / 300°F), an insulated locating ring is strongly recommended. It minimizes heat sinking into the machine platen, improving process stability near the nozzle and saving significant energy over the mold’s life. Materials like PEEK, PEI, PSU often warrant this.

- ### Precision Molding: For applications demanding very tight tolerances on the final part, every element of consistency matters. While standard locating rings are usually made to good precision, ensuring the ring has tight OD tolerances and is installed perfectly flat becomes even more critical. Consistency in centering cycle after cycle helps maintain stable filling patterns. Material choice remains standard hardened steel unless high temps are also involved.

- ### Prototyping / Short Runs: Here, a standard hardened steel ring often suffices, assuming no extreme temperatures. Speed of availability and compatibility with readily available mold bases might be the primary drivers. Unless there’s a specific technical reason (like testing a high-temp material), the added cost of an insulated ring might not be justified.

-

### Multi-Mold / Multi-Machine Environments: If you have multiple molds running in multiple machines, standardizing locating ring ODs where possible (e.g., using adapter plates on smaller machines to accept a larger standard ring size) can simplify logistics and mold setup procedures. Application Primary Concern Likely Ring Choice/Feature High Volume Durability, Wear Standard Hardened Steel (High Quality) High Temperature Heat Loss, Stability Insulated Locating Ring Precision Parts Alignment Consistency Standard (Tight Tolerance), Perfect Install Prototyping Speed, Cost Standard Hardened Steel Standardization Logistics, Simplicity Consistent OD across molds (where feasible) Considering the application helps optimize the selection for performance and longevity.

Why Do Material and Precision Tolerances Matter?

It’s just a steel ring, right? Does the exact material or tiny variations in size really make that much difference? Yes, especially when you’re aiming for reliable, high-quality production over the long haul.

Locating ring material (typically hardened steel) ensures durability against wear from mounting and clamping forces. Precision tolerances on the OD guarantee a snug, repeatable fit in the platen, which is crucial for consistent mold alignment and part quality over many cycles.

I once visited a shop that was having intermittent flash issues they couldn’t pin down. After checking everything else, we inspected the locating rings on their high-volume molds. Some were visibly worn on the OD from countless setups, creating just enough slop to cause slight misalignment under clamp pressure. Switching to new, high-quality rings solved the problem. It proved that material and precision aren’t trivial details.

- ### Material: The standard material is a hardened tool steel, similar to what’s used in other mold components (like H-13 or similar grades). Why hardened steel?

- Wear Resistance: The OD constantly rubs against the machine platen during mold mounting and removal. Hardness prevents this surface from wearing down quickly, which would lead to a loose fit.

- Compressive Strength: The ring is part of the mold stack under full clamp tonnage. It needs to resist deformation or crushing.

- Durability: Resists dings and damage during handling.

While exotic materials aren’t usually needed, ensuring the ring is made from properly hardened, quality steel is important for longevity. Cheap, unhardened steel rings will wear out quickly.

- ### Precision Tolerances:

- Outer Diameter (OD) Tolerance: This is critical. The ring needs a close fit in the platen – not so tight it binds, but with minimal clearance. Typical tolerances might be in the range of +0 / -0.05mm (+0 / -0.002 inches) relative to the nominal size intended for the platen bore. This ensures repeatable, accurate centering every time the mold is set. Loose tolerances lead to inconsistent alignment.

- Height Tolerance: Less critical than OD, but still important for consistent nozzle sealing. Ensures the sprue bushing face is always presented at the same height relative to the platen.

-

Flatness and Parallelism: The mounting face must be flat and parallel to the top face to ensure it sits squarely on the mold plate and presents itself correctly to the platen. Feature Aspect Importance Reason Material Hardened Steel Wear resistance, compressive strength, durability OD Tolerance Tight, consistent clearance fit Ensures accurate, repeatable mold centering Height Tolerance Consistency Ensures consistent nozzle engagement/sealing distance Flatness Mounting face needs to be very flat Prevents tilting, ensures square installation Investing in a ring made from good material with tight tolerances pays off in reliable performance and extended service life.

Conclusion

Selecting the right locating ring isn’t just about basic fit; it involves matching standards, height, material, and features to the specific machine and application. This careful choice is fundamental for efficient, repeatable, and high-quality injection molding operations. Don’t overlook this critical component.