Parting line is where both halves of the injection mold (core and cavity) separate to allow the molded part to be ejected. It is where you define the split of the mold, direction of mold opening, and location of any witness lines or flash. It does much more than dictate where the mold splits. It defines direction of draft, direction of venting, and formation of many critical features of the molded part. A properly designed parting line results in mold closes properly, geometry holds true, and production stays stable. An improperly designed parting line results in visible seams on the part, flash, mismatched dimensions, and problematic ejection.

The best parting line strategy balances aesthetics, function, and moldability. It puts the line in the least visible location that does not interfere with the function of the part and makes the mold easier to construct. This is usually along a sharp outer edge or at the widest cross-section of the part. A good strategy needs to consider the geometry of the part, draft angles, surface finish, and its interaction with other components to avoid cosmetic flaws, functional failures, and manufacturing problems such as flash or entrapped air.

Draft Angle and Parting Line – How They Work Together in injection molding parting line

Draft angles cannot exist without parting line placement. Draft is tapered added onto walls that are parallel to the direction of mold opening allowing the part to eject without dragging/scuffing/sticking. The location of the parting line determines the direction of mold opening which determines which surfaces need draft and what direction they need to be drafted in.

Ideally, the parting line is located at the natural widest cross section of a part. This allows for most vertical walls to be drafted evenly towards the mold opening. When this occurs there will be smooth ejection, less friction, lower ejector force, and less damage to the surface of the part. The plastic will shrink onto the core as it ejects, and the tapered surfaces allow air to come underneath the part as it is ejecting preventing vacuum lock.

If the parting line is poorly located you can end up with walls that have zero draft left on them or even negative draft when considering the direction of opening. This results in heavy drag marks, excessive ejection force, distorted parts, and damage to the mold surfaces. In some cases the part will stick in the cavity causing damage to the surface of the part (tearing) which may need polishing. Alternatively the part would need to be redesigned or costly side actions may need to be added.

Texture increases draft requirements. The more textured a surface is the more draft is required to allow the part to scrape off. When parting lines intersect textured regions it becomes very hard to control both draft and texture continuity.

How Does the Parting Line Impact Part Aesthetics?

You’ve designed a product with a sleek, smooth finish, meant to look like a premium item. But when the first samples arrive, there’s a noticeable line running right across the main visible surface. This witness mark instantly makes the product look cheap and poorly made. This is something that happens quite often when the parting line is regarded as an afterthought rather than an integral part of a design. A line in a poor place can completely undo any aesthetic you’ve tried to achieve with your design.

Place the parting line on sharp corners or edges, or on noncosmetic surfaces where the parting line can be naturally hidden. Avoid placing the parting line on a flat, curved, or textured A-surface where it will be highly visible. You want the seam between the two mold halves to blend into your part geometry. This maintains the clean, high-quality look you designed while eliminating distracting visual flaws on the final product.

I remember working on a handheld remote control. The original design had a beautiful, curved top surface with a high-gloss finish. The initial parting line proposed by a junior designer went straight across the middle of this surface because it was the widest point. In theory, it was simple for molding. But when we saw the 3D simulation, the witness line was unacceptable. It looked like a cheap toy. We had to rethink the entire approach. The solution was to create a stepped parting line that followed the seam where the top and bottom casings would meet. It made the mold more complex, but the final product looked seamless. The client was happy, and we avoided a product that looked flawed from the start.

Hiding the Line in Plain Sight in injection molding parting line

The best parting line is the one nobody notices. To achieve this, you have to think like a product user, not just a mold maker. Where will their eyes go? What surfaces will they touch? These are your critical cosmetic areas, or "A-surfaces."

- Edges are Your Best Friend: Sharp edges are the easiest place to hide a parting line. The natural change in geometry helps camouflage the slight mismatch or witness mark that is always present.

- Avoid Flat Surfaces: A parting line on a large, flat, or gently curving surface is like a scar. It’s almost impossible to hide, especially on parts with a glossy or smooth texture.

- Texture Considerations: Textured surfaces are tricky. If you place a parting line across a textured area, it will be impossible to match the texture perfectly across the seam. The line creates a clear visual break in the pattern. It’s always better to place the parting line on an edge that borders the textured area.

Here’s a simple comparison of good versus bad locations for aesthetics:

| Feature | Good Placement Location | Bad Placement Location |

|---|---|---|

| Cosmetic Surface | On a non-visible bottom or back surface. | Right across the main front or top surface. |

| Edge Detail | Along a sharp, crisp corner or edge. | On a rounded edge where it’s more visible. |

| Textured Area | Along the boundary of the texture. | Directly through the middle of the texture. |

| Logo/Branding | Far away from any embossed or debossed logos. | Crossing through text or graphic elements. |

Thinking about these factors early in the design process will save you from compromising your product’s appearance later on.

What’s the Connection Between Parting Line and Part Functionality?

You have an enclosure that must be waterproof, split into two parts. The parts look great and fit together, but it leaks during testing. You find that there is a small, almost invisible step along the edge where the parts meet. This step-just enough to break the seal-is caused by a slight mold mismatch at the parting line. This demonstrates how a parting line decision can directly affect whether your product actually works. It’s not just aesthetics; it’s performance.

Functionally, the parting line cannot cross critical features such as sealing surfaces, bearing diameters, or alignment pins. Locating a parting line on these surfaces can introduce a small step or mismatch between mold halves, and no matter how slight this imperfection may be, it can inhibit a proper seal or impair mating part alignment or bearing performance, thereby leading to a failure of the product in service. For these reasons, it is important to always locate functional features completely within one mold half.

We once designed a housing for an outdoor sensor. It had a groove for an O-ring to create a watertight seal. The initial design placed the parting line right through the middle of the O-ring groove. It seemed like the simplest way to mold the part. But during our design review, we realized this was a huge risk. Any tiny amount of flash or mismatch in the mold would create a path for water to get in. We spent the extra time redesigning the part and mold. We moved the parting line to the outside edge of the enclosure, keeping the entire O-ring groove on one side—the core side of the mold. It made the mold a little more expensive, but the part was reliable. The first articles passed the water immersion test without any issues. That small change saved us from a potential product recall.

Protecting Critical Features

When you place a parting line, you are essentially deciding where the two halves of a very heavy steel tool will clamp together. It’s impossible for this connection to be absolutely perfect every single time across millions of cycles. There will always be microscopic variations.

- Sealing Surfaces: Any surface that relies on a perfect seal, like one for an O-ring or gasket, must be kept whole. The parting line should never cross it. The entire sealing feature should be on a single, uninterrupted mold surface. This ensures the surface is perfectly flat and smooth, just as you designed it.

- Mating and Alignment Features: Features like pins, holes, or interlocking tabs are used to align your part with another. If a parting line runs through them, any mismatch can throw off the alignment. This could make assembly difficult or cause the final product to feel loose or rattle. Keep these features on one side of the parting line.

- Bearing Surfaces: For parts with holes that will hold a shaft or bearing, the roundness and smoothness of that hole are critical. A parting line running through the center of the hole can create an oval shape or a small step. This will cause friction, wear, and potential failure of the rotating component. It’s often better to use side-actions or lifters to form such holes cleanly.

To check for these issues, always analyze your part in the context of its full assembly. Ask yourself these questions:

- Does this surface touch another part?

- Does this surface create a seal?

- Does this feature align anything?

- Does anything move or rotate against this surface?

If the answer is yes, keep the parting line away from that feature.

Typical Defects Caused by Poor Parting Line Placement

Poor parting line decisions are one of the primary root causes for cosmetic and functional defects in molded parts.

Flash

Flash is excess plastic trapped between the two mold halves along the parting line. Improperly vented or sealed parting lines can lead to flash, caused by inadequate clamping force, worn shut-off surfaces, or uneven pressure if the parting surfaces are complicated or unsupported. Flash appears unsightly and usually requires secondary trimming, resulting in higher labor costs.

Witness Marks

Witness Marks appear where the mold halves meet. Visible A-surface parting lines interrupt gloss continuity and convey lower-quality to the customer. A broad, smooth surface or curved surface that is segmented by the parting line will result in a very conspicuous witness line that can not be polished away.

Mismatch

Mismatch (Offset) occurs when the mold core and cavity are not perfectly aligned. This offset typically results in a step along the parting line. Safety, assembly, and cosmetic concerns can result if there is any mismatch between the mating mold halves, even if it is only a few microns high.

Air Traps and Burn Marks

Air Traps and Burn Marks occur when molten plastic meets trapped air that cannot escape. Areas with inadequate venting will compress and superheat the air trapped in the mold cavity. The compressed air leaves burn marks if severe enough or results in incomplete filling. Most vents are located at the parting line, so complicated or improperly located parting surfaces can limit vent efficiency.

All four of these defects are direct results of improper parting line decisions that neglected sealing, venting, alignment, and wear considerations.

Impact of Parting Line Decisions on Cost

Decisions about where and how to place the parting line have immediate and long-term consequences on tooling cost, manufacturing stability, and maintenance.

Flat parting lines are quickest and cheapest to machine, easiest to seal, and most consistent over tens of thousands of hours of production. Since there is no side action to fit, flat parting lines offer very stable shut-off conditions and have the longest mold life before flashing occurs.

Stepped parting lines require additional machining complexity and time in the fixture. All vertical shut-off surfaces require fitting to guarantee zero offset and additional hardness to prevent wear. Side actions are needed to maintain the seal which increases mold build schedule and quality assurance inspections.

Complex curved parting lines require precision 5-axis machining and significant hand fitting. Larger sealing surface area increases wear and makes it difficult to maintain a tight seal. More frequent maintenance will be required to keep the mold shut-off smooth and free of flash. Any amount of wear or distortion in the mold will be amplified at the parting line causing flash and mismatch, increasing scrap and downtime.

Complex parting lines also limit vent placement, restrict cooling channel routing, and reduce gate location options. These challenges increase engineering hours, raise machining costs, and inflate long-term tooling expense. For these reasons, parting line details should be minimized whenever possible.

How Can You Optimize Parting Line Placement for Better Moldability?

You’ve finished up a design that looks good and works great, but the mold maker comes back and says it’s very hard to build-or it’s going to require expensive, complicated actions. Sometimes it’s because of the parting line, which, although good from an aesthetic standpoint, leads to undercuts or areas with zero draft that create manufacturing headaches. This conflict between design intent and manufacturing reality can drive up costs and lead to production problems.

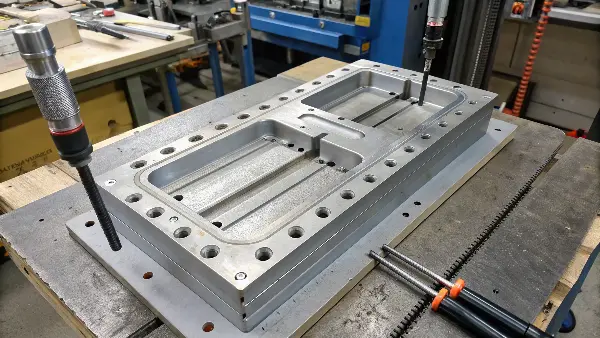

The parting line should be located at the widest cross-section of the part, perpendicular to the mold opening direction for optimum moldability. This simple technique enables the part to be easily ejected from both core and cavity halves without resorting to complicated side-actions. It also provides good drafting on all vertical faces to eliminate scraping, drag marks, and damage to the part during ejection. This reduces mold construction and simplifies the production process, saving time and money.

Having experienced this with many of our colleagues, we have learned the hard way with our early projects. We were designing a deep bucket-like part. Aesthetically, the designer wanted the parting line to be at the bottom edge. That means the whole outside of the bucket was formed in the cavity and the whole inside by the core. But the outer walls were perfectly vertical; that means zero draft. When we tried to eject the first parts, they were sticking in the cavity. We saw long, deep scratch marks along the sides. The force of ejection was such that it was damaging the part and the polished surface of the mold. We had to stop production, take the mold apart, and CNC machine a draft angle onto the cavity walls. That meant the dimensions of the part changed, and re-approval by the client was required. Had we just placed the parting line at the top rim in the very beginning, all the walls would have naturally had draft, and ejection would have been smooth.

Balancing Simplicity and Necessity

The ideal parting line for moldability follows the path of least resistance. It should allow the mold to open and the part to be ejected with a simple, linear motion.

- Draft is Everything: Draft is the small angle applied to the vertical walls of a part. It allows the part to release cleanly from the mold. The parting line’s location determines which surfaces need draft and in which direction. Placing it at the "natural" widest point usually makes applying draft straightforward.

- Avoiding Undercuts: An undercut is a feature that prevents the part from being directly ejected from the mold. Think of a snap-fit hook on the side of a part. If your parting line choice creates an undercut, you will need a side-action or lifter. These are moving components within the mold that add complexity, cost, and potential points of failure. A smart parting line can sometimes eliminate the need for them.

- Venting and Gating: The parting line is also the primary location for vents, which let air escape the cavity as plastic flows in. A simple, flat parting line is easy to vent. A complex, stepped line can trap air, leading to incomplete parts or burn marks. It also influences where you can place the gate, which is where plastic enters the part.

Here’s how different parting line choices affect moldability:

| Parting Line Type | Mold Construction Complexity | Risk of Defects | Production Speed |

|---|---|---|---|

| Flat & Simple | Low (cheapest) | Low (easy to vent & control) | High (simple cycle) |

| Stepped | Medium | Medium (potential for flash) | High |

| Curved/Complex | High | High (trapped air, wear) | Potentially Slower (more complex) |

You always have to weigh the cost of a more complex mold against the aesthetic or functional benefits. Sometimes, a side-action is unavoidable. But you should always start by seeing if a simpler parting line can achieve the same result.

Are There Different Types of Parting Lines to Consider?

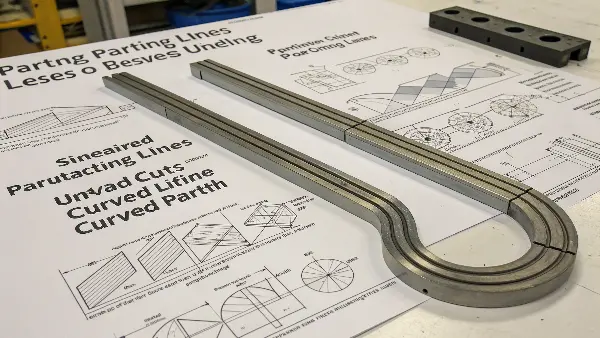

You may think a parting line is simply one flat plane, but for many complex parts, this just does not work. It would create undercuts or inaccurately capture the geometry of the part. It’s here that designers can get stuck-trying to solve a 3D problem with a 2D solution. In reality, the parting lines could be as complicated as the parts themselves, and knowing about your options often is key to unlocking better designs.

There are indeed several types of parting lines beyond the simple flat plane. The common ones include stepped and curved parting lines. A stepped parting line shifts between different levels, following the geometry of the part, which is usually done when there are features at different heights to avoid undercuts. A curved or complex parting line follows an irregular, non-linear path. Normally, such a parting line is used when the shape is highly organic or spherical in nature. The right type depends purely on the geometry of the part and design requirements.

I was working on the project for a medical device that had a very smooth ergonomic shape, almost like a stone. A flat parting line was impossible; it would have created massive undercuts on all sides. We couldn’t use a stepped line either, as there were no flat edges to follow. The solution was a complex, curving "S-shaped" parting surface that followed the curvature of the part perfectly. Creating this in the mold was tricky; it required precise 5-axis CNC machining to ensure the core and cavity surfaces matched perfectly. Any deviation would result in terrible flash. It was a very expensive mold, but it was the only way to produce the part as the industrial designer had envisioned it-without any witness marks on the curved cosmetic surfaces.

Choosing the Right Tool for the Job

Each type of parting line has its own purpose, and understanding them allows you to handle more complex designs.

Flat Parting Line

This is the simplest and most common type. The parting surface is a single, flat plane.

- Best for: Simple, boxy, or cylindrical parts with clear draft from one point. Think of a plastic cup or a project box.

- Pros: Easiest and cheapest to machine in the mold. Provides a good seal, reducing the risk of flash.

- Cons: Not suitable for complex shapes. Can force you to compromise on aesthetics by placing the line in a visible area.

Stepped Parting Line

Here, the parting line follows a path that steps up or down to accommodate features at different heights.

- Best for: Parts with ribs, bosses, or tabs on an outside wall that would otherwise be an undercut.

- Pros: Allows you to avoid using side-actions for simple features. Can be used to hide the line along existing geometric edges.

- Cons: More complex to machine than a flat line. The vertical sections of the step (called shut-offs) can be prone to wear and flash if not perfectly aligned.

Curved or Complex Parting Line

This type follows a complex, non-linear contour on the surface of the part.

- Best for: Highly organic shapes, spheres, or parts with complex surface geometry where a flat or stepped line is not possible.

- Pros: Provides the most flexibility for aesthetic placement on complex parts. It is often the only way to mold a very curvy design.

- Cons: The most difficult and expensive to machine. Requires high-precision CNC machining and fitting. The complex shut-off surface has a higher risk of flash and requires more maintenance over time.

Thinking beyond a simple flat line opens up a world of possibilities for your designs.

Design Considerations for Strategic Parting Line Placement

The strategic placement of a parting line affects more than just where you want the visible seam to be located on a finished part. By defining it early and correctly in your design process, you can increase production stability, part consistency, tool longevity, and lower total part cost through reduced scrap rates (no secondary trimming or rework), easier mold construction (less lead time, better cycle repeatability), higher dimensional accuracy, perfect surface continuity across the parting line and reduced machining hours, fitting time, and maintenance costs.

Material Properties and Their Impact on Parting Line Location

Plastics have different mold separation behavior, shrinkage rates, and abilities to replicate surface details. Glossy and amorphous materials like ABS, PC, and PMMA have near-zero resistance to separating along the parting line and will reproduce parting line witness marks with high fidelity.

Semi-crystalline materials like PP, PE, and POM shrink more during cooling and can have one mold half pull harder on the part during ejection which can cause the part to want to stick to one side of the parting line versus the other. Glass fiber reinforced materials place anisotropic properties right at the parting line which can affect fiber orientation, surface lay down (roughness), mismatch sensitivity, and accelerated wear on shut-off surfaces. Elastomers and soft-touch materials are often used to mask parting lines visually but have very little resistance to flash, making seal quality across the parting surface even more critical to part functionality.

Knowledge of how your chosen polymer will flow into the mold, shrink away from the mold walls, and release on ejection allows you to work with material behavior when placing your parting line rather than fighting against it.

Parting Line Considerations for Balanced Flow, Proper Venting, and Optimal Gating Location

Since the parting surface is the primary location for mold vent placement, you should always analyze your parting line location in relation to how the melt flows and packs into the mold. Trapped air has nowhere to escape but through small vents machined into the parting surface. Complex, interrupted, or multileveled parting lines with incomplete vent paths through every level can cause air traps that result in burn marks, short shots, or unstable flow fronts.

The location of your parting line also directly limits where gates can be placed as well as how the melt front advances across the mold cavity. Weld lines formed because gate location was too close to the parting surface may appear on visible cosmetic surfaces or right next to structural ribs features if the parting surface was not considered when placing gates. Strategic use of a simple parting line allows vents to be placed at the terminus of filling/packing zones and gates to be located so that melt fronts converge within hidden low-stress areas.

As you can see, parting line strategy plays a critical role in not only where the mold opens but where air evacuates, how melt flow fronts balance out, and overall surface quality.

Analyzing Parting Line Strategy with Simulation and Digital Moldflow Analysis

The process of designing molds has changed dramatically over the past couple decades. Moldflow and similar CAE analysis tools allow designers to see predicted filling, packing, cooling, and warpage behavior before the mold ever cuts steel. Software can also show designers where air is likely to get trapped, where weld lines will occur, and how much your part will shrink relative to the core and cavity.

With simulated digital prototypes, designers can iterate through different parting line locations to see how draft direction and ejection forces change or how well placed vents allow air to escape early in the mold design process. Instead of costly design changes after tooling is finished, risk is reduced by using the tool to verify parting line decisions early on. Test runs become more productive by minimizing trial and error during mold commissioning, and parting line placement can be optimized based on product geometry and actual process behavior.

DFM Analysis and Communication Between Product Designers and Mold Engineers

Oftentimes the problem with parting lines starts at the very beginning of the product development process. Industrial designers are focused on the aesthetics and functionality from an end user perspective. Mold engineers are focused on how to create that design with draft angles, where to place shut-offs, and how the part will eject. When designers and engineers collaborate as a team early in the DFM review process, parting lines can be used to enhance the product’s geometry rather than forced into place late as a design compromise.

Early involvement allows the placement of ribs, bosses, seals, textures, and other features to be balanced with ideal parting line placement. It also opens the door for realistic conversations about when stepped or curved parting surfaces are necessary due to function and when a simpler parting line would create a more robust, economical tool.

Conclusion

Placing a parting line is an act of balance. You need to consider the part’s ultimate appearance, how it has to function, and the real-world realities of manufacturing. You can get around some very common problems by placing the line on a non-obvious edge, keeping it away from critical functional features, and knowing when to use more than just a flat plane. This care at the beginning is what separates a good part from a great one.