Struggling to find reliable shrinkage rates1 for different plastics? This uncertainty leads to design errors, costly mold rework, and project delays for designers like Jacky. You need accurate data.

A comprehensive "database" is best compiled from material supplier datasheets2, industry handbooks, and specialized software, as shrinkage varies greatly with material grade, additives, and processing conditions. This guide helps you navigate these sources.

Transition Paragraph:

Finding the exact shrinkage rate for every plastic imaginable in one single, universally accepted database can be a bit of a holy grail. I’ve spent years in this industry, and what I tell everyone, from budding designers to seasoned engineers like Jacky, is that precision comes from diligence. You need to know where to look and how to interpret the data. The good news is, the information is out there, and understanding how to access and apply it will set you apart. Let’s explore how to build your own understanding and where to find these critical values for your next project.

What Exactly Is the Shrinkage Rate in Injection Molding?

Heard the term "shrinkage rate" but unsure what it truly means for your parts? Misunderstanding this fundamental concept often leads to dimensional inaccuracies and parts that don’t fit, causing major headaches.

The shrinkage rate is the percentage by which a plastic material contracts as it cools from its processing temperature in the mold to room temperature. This value is crucial for sizing mold cavities accurately.

Dive deeper Paragraph:

When we talk about shrinkage rate, we’re talking about a fundamental property of plastics. Imagine you’re filling a mold with hot, molten plastic. As this plastic cools and solidifies, its molecules pack closer together, and the overall volume decreases. This reduction in size is what we call shrinkage. It’s typically expressed as a percentage or a decimal (e.g., 2% or 0.02). For instance, if a material has a 2% shrinkage rate, a 100mm feature on a part will actually be about 98mm after cooling if the mold isn’t compensated. My early days in the factory were filled with lessons about this. I remember one project where we overlooked the difference in shrinkage between two seemingly similar grades of ABS – the parts were just slightly off, but enough to cause assembly issues. That taught me the importance of checking the specific datasheet every single time. It’s not just one number; it’s influenced by many things:

- Material Type: Amorphous plastics (like ABS, PC) generally shrink less and more uniformly than semi-crystalline plastics (like PP, Nylon).

- Additives: Fillers like glass fibers or talc typically reduce shrinkage but can make it directional.

- Processing Conditions: Mold temperature, melt temperature, packing pressure, and cooling time all play significant roles.

Understanding these nuances is key for Jacky and anyone designing for injection molding.What Is Considered a Normal Shrinkage Rate for Molding?

Wondering if there’s a "standard" shrinkage value you can use for most plastics? Applying a generic rate across different materials is a recipe for disaster, leading to parts that are too big or too small.

There’s no single "normal" shrinkage rate; it varies widely from under 0.5% for some filled materials to over 3% for certain unfilled semi-crystalline plastics. Each material family has its own typical range.

Dive deeper Paragraph:

One of the first things I learned, and something I always stress to designers like Jacky, is that "normal" is relative in the world of plastic shrinkage3. There isn’t one magic number. Instead, we look at typical ranges for different families of plastics. For amorphous materials like Polystyrene (PS) or Polycarbonate (PC), you might see shrinkage values from 0.4% to 0.7%. They tend to be fairly predictable. Then you have semi-crystalline materials4 like Polypropylene (PP) or Nylon (PA), which can shrink much more, often in the range of 1.0% to 2.5%, or even higher for some grades without fillers.

| Here’s a simplified table to give you an idea: | Material Family | Typical Shrinkage Range (%) | Notes |

|---|---|---|---|

| ABS | 0.4 – 0.7 | Amorphous, good dimensional stability | |

| Polycarbonate (PC) | 0.5 – 0.7 | Amorphous, strong, low shrinkage | |

| Polypropylene (PP) | 1.0 – 2.5 | Semi-crystalline, common, varies widely | |

| Nylon (PA6, PA66) | 0.8 – 2.5 | Semi-crystalline, moisture sensitive | |

| HIPS | 0.4 – 0.7 | Amorphous, similar to ABS | |

| LDPE/HDPE | 1.5 – 4.0 | Semi-crystalline, high shrinkage | |

| POM (Acetal) | 1.8 – 2.5 | Semi-crystalline, good lubricity | |

| PBT | 1.5 – 2.2 | Semi-crystalline, often filled |

These are just general guidelines. I’ve seen projects where a specific grade of PP, perhaps with a mineral filler, had a shrinkage as low as 0.8%. Conversely, an unfilled HDPE for a large, thick-walled part might push towards the higher end of its range. Always, always refer to the specific material supplier’s datasheet for the grade you intend to use. That’s the golden rule.

How Much Material Shrinkage Value Is Considered for HIPS Material in Percentage Value?

Need to design a part using HIPS and looking for its specific shrinkage? Using an incorrect value, even for a common material like HIPS, can throw off your tolerances and lead to production issues.

High Impact Polystyrene (HIPS) typically has a shrinkage rate in the range of 0.4% to 0.7%. This relatively low and consistent shrinkage is one of its advantages for many applications.

Dive deeper Paragraph:

HIPS, or High Impact Polystyrene, is a material I’ve worked with extensively for consumer product housings and a variety of general-purpose parts. For designers like Jacky, it’s often a good choice due to its ease of processing and decent impact strength. When it comes to shrinkage, HIPS is an amorphous thermoplastic, which means it generally exhibits lower and more uniform shrinkage compared to semi-crystalline materials. Typically, you’ll find its shrinkage rate falls within the 0.4% to 0.7% range. For example, if you’re designing a 200mm long feature in HIPS, and assuming an average shrinkage of 0.55% (or 0.0055), you’d calculate your mold dimension accordingly.

However, even within this relatively narrow range, factors can influence the exact value:

- Wall Thickness: Thicker sections might exhibit slightly higher shrinkage as they take longer to cool and pack out.

- Processing Parameters: Melt temperature, mold temperature, and packing pressure can subtly affect the final shrinkage. Higher mold temperatures, for instance, might allow for more complete relaxation and thus slightly more shrinkage, though still within the typical HIPS range.

- Grade Variations: While HIPS is fairly consistent, different manufacturers or specific grades (e.g., high gloss vs. matte finish grades) might have slight variations. I recall a project involving very precise snap-fits with HIPS; we had to ensure our mold temperature was controlled very tightly to maintain consistent shrinkage part-to-part. Compared to something like Polypropylene, which can have a much broader shrinkage range, HIPS is generally more forgiving, but precision still demands attention to detail from the material datasheet.

So, How Do You Actually Calculate Shrinkage for an Injection Mold?

You have the shrinkage rate, but how do you use it to design the mold cavity? Simply guessing or making the mold "a bit bigger" is not a professional approach and will likely fail for precise parts.

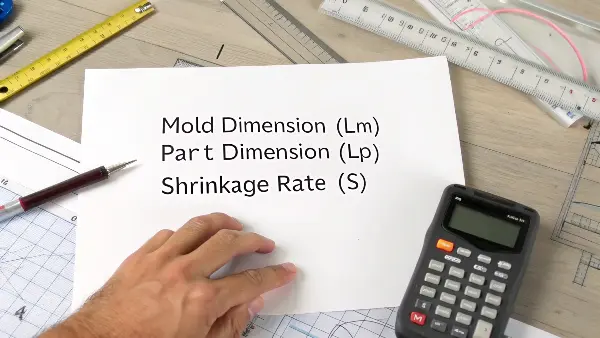

To calculate the mold dimension, use the formula: Mold Dimension (Lm) = Part Dimension (Lp) / (1 – Shrinkage Rate (S)). ‘S’ must be the decimal form of the material’s specific shrinkage percentage.

Dive deeper Paragraph:

Okay, so we’ve talked about finding shrinkage rates. Now, let’s get practical with how Jacky or any designer actually uses this information to size a mold cavity. The fundamental formula I use daily, and the one you should burn into your memory, is:

Lm = Lp / (1 - S)

Let’s break this down:

Lmis the Mold Dimension. This is the actual size you need to make the corresponding feature in the mold cavity.Lpis the desired Part Dimension. This is the final size you want that feature to be on the cooled plastic part, as per your design specification.Sis the Shrinkage Rate of the specific plastic material you’re using, expressed as a decimal. So, if a material datasheet says the shrinkage is 1.5%, you useS = 0.015.

For example, if Jacky is designing a part that needs a critical dimensionLpof 150mm, and the chosen material (say, ABS) has a shrinkage rateSof 0.5% (or 0.005), the mold cavity dimensionLmwould be:

Lm = 150mm / (1 - 0.005) = 150mm / 0.995 = 150.7537... mm

So, the mold cavity would need to be machined to approximately 150.75mm for that feature.

It’s crucial to getSfrom the material supplier’s datasheet for the exact grade of plastic. General values are starting points, but specific grades, especially those with fillers (like glass fibers), can behave differently. For glass-filled materials, you’ll often see two shrinkage values: one for "flow direction" and one for "cross-flow direction." This is because the fibers align with the flow, restricting shrinkage in that direction more than across it. In such cases, you have to apply these different rates to your mold dimensions accordingly, which is critical for preventing warpage. I’ve seen many parts turn into potato chips because this anisotropic shrinkage wasn’t accounted for!Conclusion

Finding precise shrinkage rates requires consulting supplier datasheets and understanding material families. Applying these correctly in calculations is key for accurate mold design and successful part production, benefiting designers like Jacky immensely.

-

Understanding shrinkage rates is crucial for accurate design and avoiding costly errors. Explore this link for detailed insights. ↩

-

Material supplier datasheets provide essential data for accurate shrinkage rates. Discover how to access these valuable resources. ↩

-

Understanding plastic shrinkage is crucial for designers to ensure product quality and performance. Explore this link for in-depth insights. ↩

-

Exploring semi-crystalline materials is essential for understanding their behavior in manufacturing processes. Gain valuable knowledge on this topic. ↩