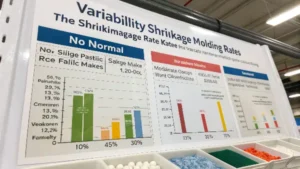

How Do Processing Parameters Affect Injection Mold Shrinkage Rates?

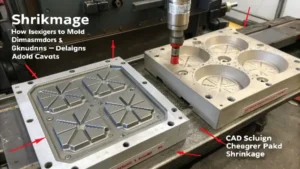

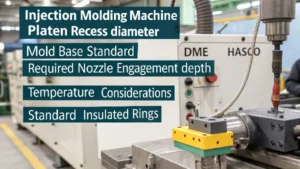

Are your injection molded parts consistently out of spec due to shrinkage? This common issue leads to wasted material, production delays, and frustrated clients. I’m here to help you understand how to control it. Processing parameters like melt temperature, mold temperature, injection pressure, holding pressure, and holding time critically influence