Struggling with cloudy acrylic parts? Defects ruining your optical components? We get it. CKMOLD delivers crystal-clear, high-precision acrylic parts consistently, solving your clarity challenges.

Achieving perfect clarity in optical-grade acrylic injection molded components involves meticulous control over material selection (high-purity PMMA), mold design (highly polished surfaces, optimized gating), and precise processing parameters (temperature, pressure, injection speed). CKMOLD specializes in these, ensuring flawless results.

Getting that perfect, glass-like finish on acrylic parts isn’t just a wish; it’s a science we’ve refined here at CKMOLD. You might be wondering how we tackle the common pitfalls that lead to imperfections. Well, I’m here to share some of the insights we’ve gathered over the years. Stick around, because understanding these details can really make a difference in your projects, especially if you’re like Michael, aiming for top-notch quality and reliability from your suppliers. It’s all about mastering the process, and I believe in sharing that knowledge.

Can Acrylic Actually Be Used in Injection Molding?

Ever wondered if that beautifully clear acrylic can even handle the pressures of injection molding? It’s a common question, especially when optical clarity is non-negotiable. Many worry about degradation or defects appearing.

Yes, acrylic (PMMA) is absolutely suitable for injection molding and is widely used for applications requiring high optical clarity, weather resistance, and good mechanical properties. Proper drying and precise machine settings are key to success.

So, when we talk about using acrylic, or Polymethyl Methacrylate (PMMA) as it’s technically known, in injection molding, it’s a fantastic choice for so many optical applications. I’ve seen it transform products, from simple light pipes to complex lens systems. The material itself is inherently clear, which is a huge plus. But, and this is a big "but," it’s not as simple as just throwing pellets into a machine. Acrylic is a bit like a sensitive artist – it needs the right conditions to perform its best. One of the first things we always drill down on at CKMOLD is material preparation. Acrylic loves to absorb moisture, and if you don’t dry it thoroughly before molding, you’re asking for trouble – think silver streaks or bubbles, which are a disaster for optical parts. We’re talking about drying for several hours at a specific temperature, usually around 80-90°C. It’s a step some might rush, but for us, it’s foundational. It’s like trying to bake a perfect cake with wet flour; it just won’t work. We’ve helped clients like Michael who were getting subpar results elsewhere, and often, improper material handling was a big part of the problem. Getting this right is a cornerstone of our "Master Molding Right" philosophy.

How Can You Improve the Quality of Injection Molding for Optical Parts?

Are you battling with imperfections like flow lines, sink marks, or haze in your molded parts? These issues can be incredibly frustrating and costly, especially for optical components. You need consistent, flawless results.

Improving injection molding quality involves optimizing mold design (e.g., gate location, venting), precise control of processing parameters (melt/mold temperature, injection speed/pressure, cooling time), and using high-quality, properly dried material. Regular machine maintenance is also crucial.

Dive deeper Paragraph:

Improving injection molding quality, especially for something as demanding as optical-grade acrylic, is a multi-faceted beast. It’s not just one thing; it’s a symphony of many things working in harmony. I always tell people, think of it like tuning a high-performance engine. Every component, every setting, has to be just right.

First off, let’s talk about the mold itself. This is where a lot of battles are won or lost.

- Mold Surface Finish: For optical parts, the mold cavities need to be polished to a mirror finish. I mean, really polished. We often go down to an SPI A-1 or A-2 finish. Any tiny imperfection on the mold surface will transfer directly to the acrylic part. We once had a project where the client was getting a slight haze. After a deep dive, we found the previous molder wasn’t achieving the necessary polish. A simple re-polishing, done right, made all the difference.

- Gate Design and Location: Where and how the molten plastic enters the cavity is critical. You want to avoid jetting or turbulent flow, which can trap air or cause flow marks. We often use tab gates or fan gates for acrylic to promote smooth, even filling.

- Venting: Trapped air is the enemy of clarity. Proper venting in the mold allows air to escape as the plastic fills the cavity. If it can’t escape, you get bubbles or burn marks.

Then there are the processing parameters. This is where the operator’s skill and the machine’s capability really shine. - Melt Temperature: Too low, and the acrylic won’t flow properly, leading to short shots or weld lines. Too high, and you risk degrading the material, causing discoloration or reduced strength. For PMMA, we’re typically in the 200-250°C range, but it varies with the grade.

- Mold Temperature: This is super important for acrylic. A warmer mold (say, 60-80°C) helps the plastic flow better, reduces internal stresses, and improves surface finish. Cold molds are a recipe for trouble with acrylic.

- Injection Speed and Pressure: These need to be carefully balanced. Too fast can cause shear heating and degradation. Too slow can lead to premature cooling and flow marks. We often use a profiled injection speed – starting slower, then speeding up, then slowing again for packing.

- Holding Pressure and Time: After the cavity is filled, holding pressure is applied to pack out the part and compensate for shrinkage. Getting this right minimizes sink marks and voids.

I always emphasize to my team, and to clients like Michael who are looking for that edge, that consistency is key. Document everything. Small deviations can have big impacts on optical quality. It’s this attention to detail that helps us "Master Molding Right."What Other Factors Can Be Expected to Contribute to the Part Quality During Injection Molding?

Beyond the obvious like material and machine settings, what else could be messing with your part quality? Sometimes, the hidden culprits cause the biggest headaches, leading to unexpected defects and delays.

Other critical factors include the quality of the injection molding machine itself (consistency, control), environmental conditions (dust, humidity in the molding area), post-molding handling, and even part design complexity influencing flow and stress.

Dive deeper Paragraph: You’re right, it’s not just about the plastic and the big machine settings. There are a bunch of other things that can make or break the quality of your injection molded parts, especially when we’re aiming for optical perfection with acrylic. I’ve learned over the years – sometimes the hard way! – that you have to look at the whole picture. One big one is the environment. For optical parts, we’re practically talking cleanroom conditions, or at least a very well-controlled environment. Dust is a killer. A tiny speck of dust landing in the mold or on the molten plastic can embed itself in the part, creating an inclusion that’s unacceptable for optical applications. We had this one client who was getting tiny black specks in their lenses. Turns out, their old supplier had a poorly maintained air filtration system near the molding machines. It’s these "small" things! Humidity in the air can also affect how some plastics process, though with proper material drying, this is less of an issue for the material itself, but high humidity can sometimes contribute to condensation issues on cooler molds if not managed. Then there’s the part design. Sometimes, designers, with all good intentions, create features that are really challenging to mold perfectly. |

Design Feature | Potential Issue for Optics | CKMOLD Approach |

|---|---|---|---|

| Sharp internal corners | Stress concentrations, cracks | Recommend generous radii, discuss DFM early | |

| Abrupt wall thickness changes | Sink marks, voids, flow issues | Advise gradual transitions, coring out thick sections | |

| Very thin sections | Fill problems, fragility | Analyze flow, suggest material or gate adjustments | |

| Complex geometries | Trapped air, difficult ejection | Advanced mold design, strategic venting & ejection |

This is why at CKMOLD, we love to get involved early, during the Design for Manufacturability (DFM) stage. We can spot potential issues and suggest tweaks that make a world of difference downstream. It’s all part of helping our clients, like Michael, avoid costly redesigns and production headaches. And let’s not forget post-molding handling. Freshly molded acrylic parts can still be a bit sensitive. How they’re ejected, cooled, and packed matters. Rough handling can cause scratches or stress. We often use robotic part removal and custom packaging solutions for delicate optical components. It’s that last mile of care that ensures what comes out of the mold stays perfect.

What Is the Best Plastic for Injection Molding for Optical Clarity?

You need parts that are as clear as glass, but strong and easy to shape. With so many plastics out there, which one truly offers the best optical clarity for your injection molded components?

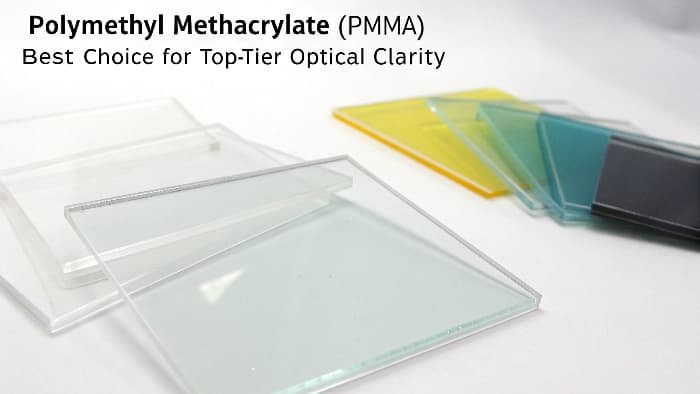

For top-tier optical clarity, Polymethyl Methacrylate (PMMA), commonly known as acrylic, is often the best choice. It offers excellent light transmission (around 92%), UV stability, and good scratch resistance, making it superior to many other clear plastics.

Dive deeper Paragraph:

When someone asks me, "Jerry, what’s the absolute best plastic for optical clarity in injection molding?" my mind almost always jumps to PMMA, or acrylic, first. It really is the king in many respects. Think about it – its light transmission is fantastic, often cited around 92%, which is even better than some types of glass! This inherent clarity is why you see it used in everything from high-end display screens to automotive lighting and precision lenses. I remember working on a project for a company developing a new medical diagnostic device. They needed a viewing window that was incredibly clear and also biocompatible. Acrylic was the star.

However, "best" can sometimes depend on the specific nuances of the application. While PMMA is my go-to for pure clarity and UV resistance, there are other contenders that shine in different areas:

- Polycarbonate (PC): This one is known for its incredible impact strength – it’s super tough. Its clarity is very good, though typically not quite as high as PMMA, and it can be more prone to scratching if not hard-coated. If you need something that can take a beating and still be clear, PC is a strong candidate. We use it for safety glasses, machine guards, and robust electronic housings. The downside? It’s more sensitive to processing conditions and requires very good drying.

- Cyclic Olefin Copolymer (COC) / Cyclic Olefin Polymer (COP): These are more specialty materials, but for certain high-end optical applications, especially in medical and diagnostics, they are amazing. They offer excellent clarity, low birefringence (important for polarized light), and great moisture barrier properties. They can be a bit pricier and require specialized processing knowledge, but the results can be stunning.

- Polystyrene (PS): General-purpose polystyrene can be very clear and is inexpensive, but it’s brittle and not very durable. You might see it in things like disposable petri dishes or light-duty display cases. For demanding optical applications, it usually doesn’t make the cut.

For Michael, running a business focused on plastic components for consumer electronics, the choice often comes down to balancing clarity, cost, and mechanical properties. If the part is a lens or a light guide where pristine clarity is paramount, PMMA is usually the winner. If it’s a protective cover that also needs to be clear but might take some knocks, PC could be considered. My advice is always to thoroughly discuss the end-use requirements. That’s how we, at CKMOLD, help you select the material that truly is "best" for your specific needs. It’s about making mold knowledge accessible, just like our mission states.Conclusion

Achieving perfect clarity in optical acrylic parts is a detailed process. It demands material expertise, precise mold design, and meticulous process control. CKMOLD masters these elements to deliver flawless components every time.