As soon as your designs get more complex, are you having a problem with conventional insert molding? Simple fixes are not necessarily optimal, which can lead to manufacturing problems or parts that won’t perform the way you’d like them to. I’m here to introduce you to some innovative techniques that will allow you to overcome these challenging manufacturing problems and create some groundbreaking products.

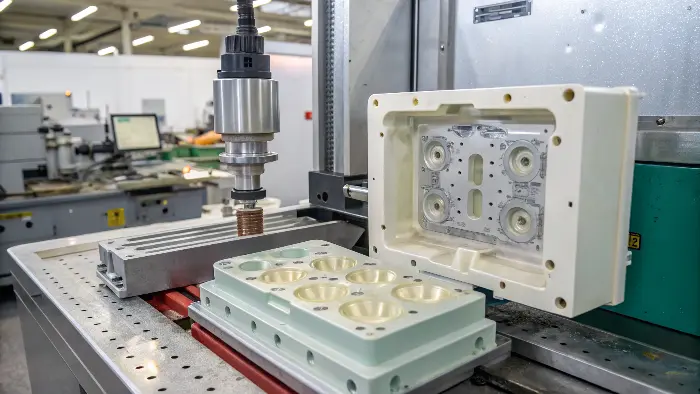

Advanced insert molding processes involve more than the insertion of a simple metal pin into a mold. They involve the use of automation to precisely position inserts, molding to protect delicate inserts, joining different materials or inserts in a single component, and closely monitoring the process to develop strong joints without damage. These processes allow highly integrated and functional components to be produced.

Understanding the fundamentals of insert molding is a great start, but the real magic happens when we explore more advanced approaches. These techniques may allow your designs to take on new dimensions and can help you make parts that are more assertive, more reliable, and even more cost-effective in the long run. Let’s dive into some of these advanced strategies.

How Can Automation Elevate Your Insert Molding Process?

Does it slow your output or give you uneven results when you do it manually? This can be a major problem, especially when you’re running large quantities of manufacturing or making very small or intricate inserts. Automation is a very strong solution.

Insert molding automation utilizes robots or automation to load and position inserts into the mold. This enhances speed, accuracy, and reproducibility compared to manual placement. It reduces the likelihood of defect and can lead to overall increased production efficiency and part quality, especially for complex or high-volume parts.

Let’s look deeper into how automation can transform your insert molding operations.

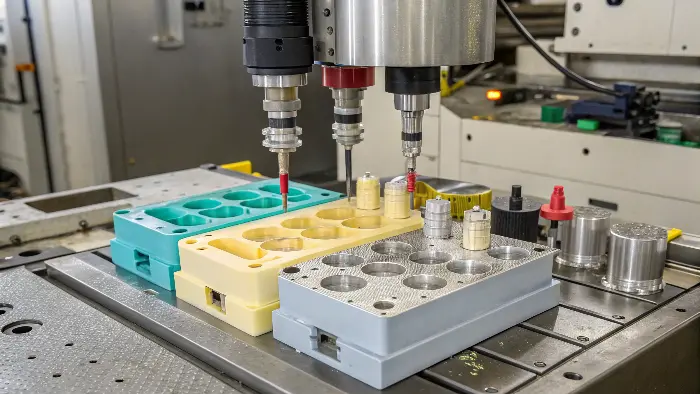

When we talk about automation here, we’re often referring to:

- Robotic Arms: These are probably the most common. Robots can pick inserts from a tray or feeder system and place them accurately into the mold cavity. They can work 24/7 without getting tired.

- Vision Systems: Often paired with robots, vision systems can inspect inserts for defects before placement. They also ensure the robot places the insert in the correct orientation.

- Custom Feeder Systems: These systems automatically supply inserts to the robot or placement mechanism. This keeps the process running smoothly.

I remember a project where we were making a small connector with several tiny pins. Manually placing these pins was incredibly slow and led to a high scrap rate because they were easily bent or misplaced. We worked with the client to implement a robotic cell with a vision system. The robot could pick and place the delicate pins much faster and more accurately than any human operator. The scrap rate dropped dramatically, and production output soared. It was a clear win for automation.

Benefits and Considerations of Automation in Insert Molding

| Aspect | Description |

|---|---|

| Key Technologies | Robotic arms, machine vision, automated feeder systems, integrated control systems. |

| Main Advantages | Increased speed, higher precision, improved consistency, reduced labor costs, lower scrap rates, enhanced safety. |

| Potential Challenges | High initial investment, requires skilled programming and maintenance, less flexible for very small production runs. |

| Best Suited For | High-volume production, parts with complex or numerous inserts, applications requiring high precision. |

While the upfront cost of automation can seem high, the long-term savings in labor, improved quality, and increased throughput often make it a very smart investment, especially as your production scales up.

Insert Molding Techniques

Manual Insert Molding

Insert molding by manual insert is a method in which the part to be inserted is manually inserted into the mold by the operator prior to injection of molten plastic. This method offers more control of the process and is used in cases of small production lots or production of very intricate molded parts.

But insert molding is labor-intensive, and that increases labor expense and production cost. And further, the manual handling of the parts can create variability and inconsistency in the end product.

Automated Insert Molding

Compared to manual insert molding, insert molding with automation has the benefit of utilizing robots and automation systems to insert the inserted component into the mold. The process has several benefits, including greater precision, consistency, and speed of the manufacturing process.

Automating eliminates the risk of human error and saves labor expense, thus the optimal choice for large-volume production runs is automated insert molding. Automated insert molding is commonly used in the production of electronic components and other applications that need consistency and bulk, such as mass production.

What Are the Secrets to Successfully Molding Around Delicate or Complex Inserts?

Have you ever tried to mold plastic around a very thin metal stamping, a fragile ceramic component, or an intricate electronic assembly? It can feel like walking a tightrope. The high pressures and temperatures of injection molding can easily damage or misplace these delicate inserts.

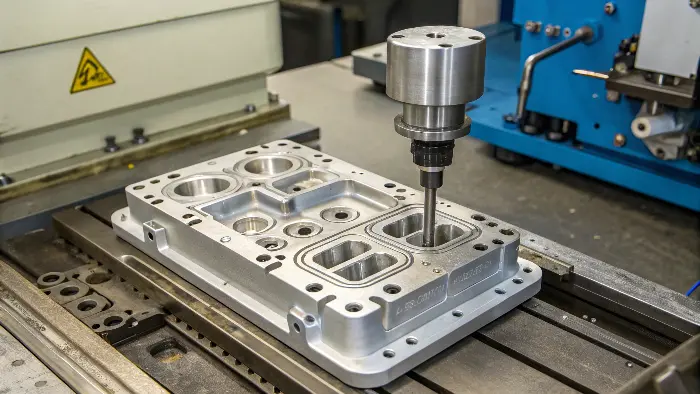

Successfully molding around delicate or complex inserts requires careful mold design, precise control of injection parameters, and sometimes special handling of the inserts themselves. Techniques include using gentle clamping forces, strategically placed gates to control plastic flow, pre-heating inserts, and designing features on the insert to help secure it during molding.

Let’s explore some strategies for protecting these sensitive components.

The challenge is to get the plastic to flow completely around the insert without crushing, bending, or dislodging it.

Here are some key considerations:

- Mold Design:

- Support Features: The mold needs to securely hold the insert in place. This might involve custom-shaped pins or pockets.

- Gate Location and Type: The gate is where the molten plastic enters the cavity. Its location and size are critical. You want the plastic to flow smoothly around the insert, not hit it directly with high force. A submarine gate or a film gate might be better than a direct sprue gate in some cases.

- Venting: Proper venting allows air to escape as the plastic fills the mold, reducing pressure on the insert.

- Insert Preparation:

- Pre-heating: Sometimes, pre-heating the insert can reduce thermal shock and improve the bond with the plastic. It can also help the plastic flow more easily around it.

- Surface Treatment: For some inserts, a special coating or surface treatment can improve adhesion or protect them.

- Process Control:

- Injection Speed and Pressure: Using lower injection speeds and pressures, at least initially, can be gentler on the insert. Multi-stage injection profiles are often used.

- Clamping Force: Use just enough clamping force to keep the mold closed, but not so much that it distorts the mold or damages the insert.

One medical device I worked on had an insert made of extremely fine wire mesh. The first few trials were disastrous—the mesh kept collapsing. We had to redesign the mold with very specific support features for the mesh. We also adjusted the injection profile to fill the cavity much more slowly at the beginning. We eventually had flawless parts after some trial and error. I learned that with delicate inserts, patience and careful adjustments are essential.

Protecting Delicate Inserts During Molding

| Technique | Description |

|---|---|

| Mold Design | Strategic gate placement, insert support features, adequate venting, balanced runner systems. |

| Insert Handling | Pre-heating, careful manual or robotic placement, potential use of carriers or fixtures. |

| Process Parameters | Controlled injection speed and pressure (often multi-stage), optimized melt and mold temperature. |

| Material Selection | Choosing plastics with lower melt viscosity or lower processing temperatures if possible. |

Successfully molding around delicate inserts is a real skill. It often involves a close collaboration between the part designer, the mold maker, and the molding technician.

When Does Multi-Material Insert Molding Become the Smart Choice?

Are you designing parts that need different properties in different areas, perhaps combining a rigid structure with a flexible seal, or integrating multiple conductive paths? Sometimes, a single plastic material around a single insert isn’t enough. This is where multi-material insert molding comes into play.

Multi-material insert molding is an advanced technique where multiple inserts, potentially made of different materials, are placed into a mold, and then one or more plastic materials are injected to encapsulate them. It can also involve combining insert molding with overmolding principles in a single, complex part to achieve diverse functionalities.

Let’s dive deeper into this sophisticated approach.

This technique allows for the creation of highly integrated components that would otherwise require extensive assembly.

Think about these scenarios:

- Multiple Inserts: You might need to embed several different metal contacts, a sensor, and a reinforcing bar all within the same plastic housing. This requires a mold designed to hold all these inserts securely in their correct positions.

- Insert Molding Combined with Overmolding: Imagine an electronic module (the insert) that needs to be sealed and also have a soft-touch button. You could first insert mold a rigid plastic around the module, and then, in a subsequent step (or using a two-shot process), overmold a flexible material to create the seal and button.

- Inserts of Different Materials: You could have a brass threaded insert for strength and a separate ceramic insert for electrical insulation, both embedded in the same plastic part.

I recall a project for an automotive application. The part needed to be a structural component, provide electrical connections, and have a sealed interface. We designed a process that involved placing two different metal stampings (one for structure, one for conductivity) and a pre-formed rubber seal into the mold. Then, a high-strength engineering plastic was injected to tie everything together. This multi-material insert molding approach replaced a complex assembly of five separate parts, saving cost and improving reliability.

Applications and Benefits of Multi-Material Insert Molding

| Aspect | Description |

|---|---|

| Core Concept | Integrating multiple, often dissimilar, inserts and potentially multiple plastic resins in one molding cycle or sequence. |

| Typical Configurations | Multiple metallic inserts, combination of metallic and non-metallic inserts, insert molding followed by overmolding. |

| Key Advantages | Highly integrated functionality, reduced part count, simplified assembly, improved performance and reliability. |

| Design Considerations | Complex mold design, material compatibility (for bonding), precise insert placement, sophisticated process control. |

This technique pushes the boundaries of what’s possible with injection molding. It allows for the creation of very smart, compact, and efficient parts. However, it also demands a high level of expertise in design, tooling, and processing.

How Do You Ensure Strong Bonding and Prevent Insert Damage in Advanced Applications?

You’ve designed a complex part with intricate inserts. You’ve even figured out how to place them. But how do you make sure the plastic actually sticks to the insert properly, and that the insert isn’t damaged or weakened during the molding process? This is crucial for the part’s long-term performance.

Ensuring strong bonding and preventing insert damage involves a combination of good material selection, smart insert design with mechanical interlocks, appropriate surface treatments for inserts, and precise control over the injection molding process parameters like temperature, pressure, and cooling rate.

Let’s look at the key factors for achieving a robust and reliable insert-molded part.

A weak bond or a damaged insert can lead to part failure, so this is a critical area.

- Material Compatibility:

- Some plastics bond better to certain insert materials than others. For example, some engineering plastics can form chemical bonds with treated metals.

- Consider the thermal expansion differences. If the plastic and insert expand and contract at very different rates, it can stress the bond or the insert.

- Mechanical Interlocks:

- Don’t rely solely on chemical adhesion. Design features on the insert like grooves, knurls, holes, or undercuts. The molten plastic flows into these features and creates a strong mechanical lock when it solidifies. This is often the most reliable way to secure an insert.

- Insert Surface Preparation:

- Cleaning the inserts is essential to remove oils or contaminants that could weaken the bond.

- Sometimes, surface treatments like plasma treatment, chemical etching, or applying a primer can significantly improve adhesion.

- Process Control:

- Melt Temperature: The plastic needs to be hot enough to flow well and wet the surface of the insert.

- Packing Pressure and Time: Adequate packing pressure helps to push the plastic into all the features of the insert and minimize voids.

- Cooling Rate: Controlled cooling helps to manage shrinkage and reduce stress in the part.

- Simulation and Testing:

- Mold flow analysis software can help predict how the plastic will flow around the insert and identify potential problem areas.

- Always test the finished parts to ensure the bond strength and insert integrity meet your specifications.

I’ve seen cases where a simple change, like adding a small groove to an insert, made all the difference between an insert that pulled out easily and one that was locked in solidly. It’s often these small details in design and process that lead to success in advanced insert molding.

Strategies for Robust Insert Integration

| Strategy | Details |

|---|---|

| Material Selection | Choose plastics compatible with insert material; consider thermal expansion. |

| Mechanical Design | Incorporate knurls, undercuts, holes, or threads on the insert for mechanical locking. |

| Surface Treatment | Cleaning, etching, or plasma treatment of the insert surface to enhance adhesion. |

| Process Optimization | Precise control of melt temperature, injection pressure, packing phase, and cooling. |

| Quality Assurance | Mold flow simulation, destructive and non-destructive testing of bond strength and insert integrity. |

By paying close attention to these elements, you can create intricate insert-molded parts with assurance that they are robust and dependable. CKMold’s Contribution to the Emergence of Insert Mold Technology

The Role of CKMold in Advancing Insert Mold Technology

1. Collaboration and Personalization

As one of the leading innovators in injection molding technology, CKMold offers its clients an opportunity to collaborate with it on optimizing the insert mold process to their specifications. CKMold’s team of experts collaborates closely with manufacturers in developing tailored solutions that guarantee optimal efficiency, precision, and cost-effectiveness.

2. Sophisticated Equipment and Technology

CKMold’s investment in high-tech equipment and computer programs is the secret to the insert mold technology’s success. The new equipment streamlines and automates the process of inserting, and the leading-edge software simulations ensure that mold designs are optimal for peak performance. By always employing the latest technology, CKMold is leading the pack.

Conclusion

Premium insert molding technology truly unlocks a universe of possibility for creating high-level, highly functional parts. Automation, precise handling of fragile inserts, experimentation with multi-material construction, and attention to robust bonding enable you to shatter hard manufacturing challenges. I hope these comments will inspire you to take your own designs to new heights and experience even more success.