Having trouble choosing the correct plastic for a part that has to endure high heat? Getting the wrong material will cause part failure, recalls, and costly delays to your project timeline and bottom line. It’s a daily challenge, but one that can be solved with the correct information. Let’s sort through the top plastics for enduring high heat, so your parts perform optimally under stress.

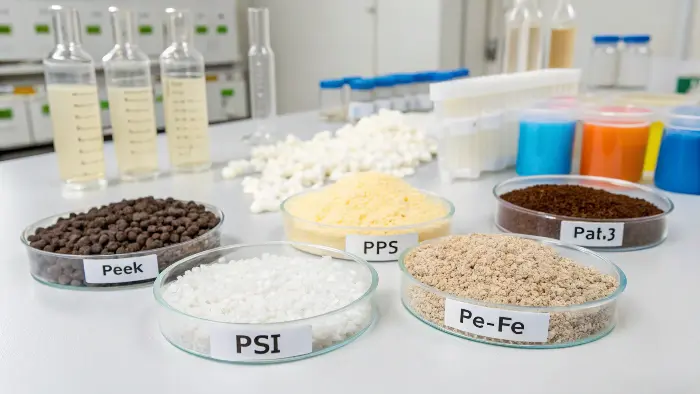

The best plastics for high-heat use are the high-performance polymers, PEEK, PAI, PEI, PPS, and PTFE. These are specifically engineered to maintain their mechanical properties, structural integrity, and chemical resistance at very high temperatures when common plastics would fail. PEEK is generally the best option for the automotive and industrial parts for its thermal stability and high strength, and PPS offers the best balance of heat resistance and chemical inertness and is optimally suited for fuel systems and electrical components.

I have worked my whole life in the mold and manufacturing business, and I have first hand experience of what can happen with the wrong plastic being applied to a challenging environment. A melted component in the hood of a car or a deformed part in a factory floor is not only an inconvenience, but there is a critical failure. However, I also have witnessed the benefit of selective handling of the material which can result in amazing innovation and dependability. It is on this experience that this guide is constructed. Here are the leading candidates to be high-heat applications and we will decompose these to enable well informed decisions to be made when making your next design choice. Enough talk.

What plastic is generally good for high heat?

Finding a "good" plastic for high heat seems to be a moving target, doesn’t it? What it is can be 100°C to one and 300°C and above to another. Using a material that is qualified for moderate heat on an extreme application is a recipe for disaster, making for parts that are distorted, melted, or completely failed. Such ambiguity can be a real source of peril in any design endeavor. Let’s define what "good for high heat" actually consists of in the world of polymers.

Generally speaking, when we use the term high heat plastics, we’re discussing a group of polymers called high-performance polymers. These top-of-the-line types include PEEK (Polyetheretherketone), PAI (Polyamide-imide), PEI (Polyetherimide), PPS (Polyphenylene Sulfide), and PTFE (Polytetrafluoroethylene). They are engineered to run continuously at temperatures above 150°C (302°F), and some, such as PEEK, can tolerate occasional exposure to more than 300°C (572°F). They’re manufactured for the most stringent applications.

When I first started in this business, the world of high-performance polymers seemed incredibly complex. It felt like you needed a chemistry degree just to understand the datasheets. But it really boils down to a few key properties that determine a plastic’s suitability for a hot environment. Let’s break them down.

Understanding Key Thermal Properties

For a designer like you, two numbers are critical: the Heat Deflection Temperature (HDT) and the Continuous Use Temperature (CUT).

- Heat Deflection Temperature (HDT): This tells you the temperature at which a plastic sample will deform under a specific load. It’s a great indicator of short-term heat resistance. Think of it as the "don’t exceed this temperature, even for a minute" warning.

- Continuous Use Temperature (CUT): This is the maximum temperature the material can withstand for its entire service life without significant loss of its properties. This is the number you should focus on for long-term reliability.

A Comparative Look at Top Performers

To make it easier, I’ve put together a table that compares the top five high-heat plastics. This is the kind of chart I wish I had when I was starting out. It helps you see at a glance how these materials stack up against each other.

| Material | Continuous Use Temp. (Approx.) | Heat Deflection Temp. (Unfilled) | Key Strengths | Common Weaknesses |

|---|---|---|---|---|

| PEEK | 250°C (482°F) | 152°C (306°F) | Exceptional strength, chemical resistance | Very high cost, difficult to process |

| PAI | 275°C (527°F) | 280°C (536°F) | Highest strength, wear resistance | High cost, requires post-curing |

| PEI | 170°C (338°F) | 200°C (392°F) | High strength, flame retardant, affordable | Attacked by some chemicals |

| PPS | 220°C (428°F) | 135°C (275°F) | Excellent chemical resistance, dimensional stability | Can be brittle |

| PTFE | 260°C (500°F) | 54°C (129°F) | Unmatched chemical inertness, low friction | Low mechanical strength, high creep |

As you can see, there’s no single "best" plastic. The right choice depends entirely on your specific needs. Do you need the absolute best performance regardless of cost? PEEK or PAI might be your answer. Need great chemical resistance on a tighter budget? PPS is a fantastic contender.

What plastic can withstand 100 degrees Celsius?

You have an application where a component must be reliable at 100°C (212°F), water’s boiling point. Your first reaction is to use a high-performance plastic like PEI, but then you see the price. Over-designing the material selection can drive your cost sky-high and render your product non-competitive. It is a easy trap that wastes resources and dollars. So how do you choose a material that does the job but isn’t overkill?

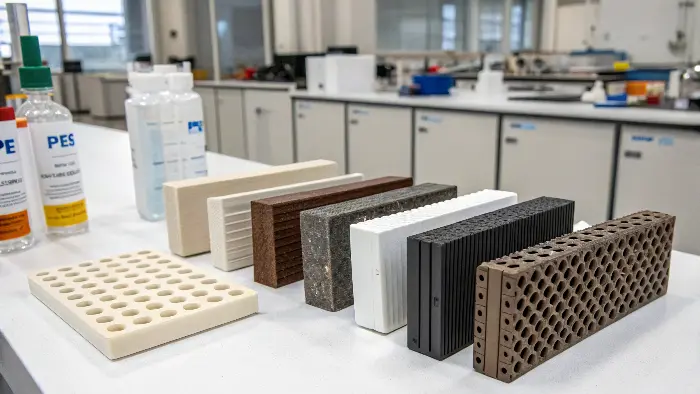

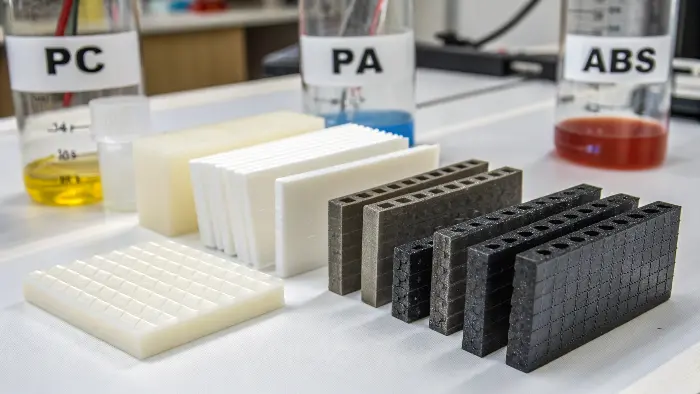

For use close to 100°C, you have plenty of excellent and affordable options in the engineering plastics category. Polycarbonate (PC), certain types of Nylon (Polyamide, or PA), and even certain high-heat ABS types are all more than capable of withstanding this temperature. These plastics are an excellent balance of thermal performance, mechanical strength, and cost and are ideal for much consumer and industrial product where excessive heat is not a consideration.

I remember a project years ago for a client making handheld electronic devices. The original design specified a fancy, high-temperature material for the housing. When I looked at the operating requirements, the internal temperature never exceeded 85°C. We suggested switching to a standard grade of Polycarbonate. The change saved them over 40% on material costs per unit, which made a huge difference to their bottom line. It’s a perfect example of how matching the material to the actual need is a core part of smart design.

Balancing Cost and Performance

The key is to not pay for performance you don’t need. The plastics in this category are often called "engineering plastics" because they bridge the gap between commodity plastics (like Polyethylene) and high-performance polymers (like PEEK).

Common Engineering Plastics for Moderate Heat

Let’s look at a few of the most common choices for the ~100°C range. These are the workhorses of the plastics industry.

| Material | Heat Deflection Temp. (Approx.) | Key Strengths | Common Applications |

|---|---|---|---|

| PC | 130°C (266°F) | Excellent toughness, optical clarity | Electronic housings, safety glasses, headlight lenses |

| PA66 | 80-120°C (176-248°F) | Good mechanical strength, wear resistance | Gears, bushings, automotive clips, power tool housings |

| PBT | 65-150°C (149-302°F) | Good electrical properties, dimensional stability | Electrical connectors, sensors, automotive switches |

| ABS (High-Heat) | 98°C (208°F) | Good impact strength, easy to process, good aesthetics | Automotive interior parts, appliance housings |

When selecting from this group, consider factors beyond just heat. For example, if you need impact resistance and transparency, Polycarbonate is a clear winner. If you need good wear resistance for a moving part like a gear, PA66 (often glass-filled to boost its HDT and stiffness) is a classic choice. For electrical connectors, PBT’s stability and insulating properties are perfect. It’s all about looking at the complete picture of your application’s demands.

Which type of plastic is commonly used in automotive parts requiring high heat resistance?

The conditions inside the hood of the contemporary vehicle are quite hostile. You have high heat from the exhaust and combustion systems, constant vibration, and exposure to aggressive fluids like fuel, oil, and coolant. To choose a plastic that would break down under such conditions is not merely a design flaw; it’s a safety risk that can lead to vehicle failure and humongous recalls. So, what do car engineers use in such applications?

For high-temperature engine parts, engineers generally turn to plastics like PPS (Polyphenylene Sulfide), PEEK (Polyetheretherketone), and high-temperature Nylons (PPA, PA46). These resins are chosen based on their field-proven ability to withstand continuous operating temperatures of high intensity as well as chemical exposure degradation. They provide the reliability and long product life necessary for engine compartment, fuel system, and transmission components, where failure is not acceptable.

In my business, my company supplies a lot of molds to auto customers. I’ve seen the move from metal to plastic in so many under-the-hood components. The demand for lighter, more fuel-efficient cars has stretched polymer science to its limits. The plastics we’re discussing aren’t just replacing metal; in many applications, they’re enabling new designs that can’t be achieved with traditional materials. They enable the creation of complex geometries, parts consolidation, and weight reduction, and all of these are critical goals in the auto business.

Under-the-Hood Champions

The choice of plastic is directly tied to the part’s location and function. A part bolted directly to the engine block sees a very different world than a sensor housing a foot away.

- Polyphenylene Sulfide (PPS): This is a star player in automotive. Its incredible chemical resistance makes it perfect for fuel system components, pump housings, and electrical connectors that are exposed to corrosive fluids. Glass-filled grades are extremely rigid and stable at high temperatures.

- Polyetheretherketone (PEEK): When the heat and stress are at their absolute most extreme, PEEK is the answer. It’s used for parts like thrust washers in transmissions, turbocharger components, and piston rings. It maintains its strength at temperatures where other plastics would have already failed.

- High-Temperature Polyamides (PPA, PA46): These are a step up from standard nylons. They offer better heat and chemical resistance, bridging the gap between engineering plastics and true high-performance polymers. They are often used for engine covers, air intake manifolds, and thermostat housings.

Why Chemical Resistance is Just as Important as Heat Resistance

A common mistake I see designers make is focusing only on the Heat Deflection Temperature. In an automotive application, chemical resistance is equally vital. A plastic might have a great HDT, but if it becomes brittle and cracks after a few months of exposure to motor oil, it’s the wrong choice.

Here’s a quick look at where these materials shine:

| Automotive Application | Typical Plastic Choice | Reason |

|---|---|---|

| Fuel Pump Housing | PPS | Excellent resistance to gasoline and ethanol blends. |

| Transmission Thrust Washers | PEEK | Extreme wear resistance and strength at very high temperatures. |

| Air Intake Manifold | PPA or PA66 (GF) | Good balance of heat resistance, stiffness, and cost-effectiveness. |

| Turbocharger Impellers | PEEK or PAI | Withstands extreme rotational stress and temperatures over 200°C. |

| Sensor Housings | PBT or PPS | Excellent dimensional stability and resistance to automotive fluids. |

When you’re designing an automotive part, always get a clear picture of the chemical environment. This will help you narrow down your material choices just as much as the temperature requirements will.

Comparison of Heat Resistance: Metals vs. Plastics

Due to their reduced density, heat-resistant plastics are also one step ahead of the more traditional metals like stainless steel. These plastics like PEEK, PTFE, and PPS are better at heat resistance but much lighter compared to metals. The attribute is particularly desirable in aerospace and automobile applications.

Weight reduction enhances fuel efficiency, emissions, and maneuverability in such applications. Heat-resistant plastics are fundamentally corrosion-proof. They provide a critical advantage in applications where metals may oxidize or corrode. Plastics like PTFE are better than metals in chemically adverse environments due to their chemical and heat resistance.

But their drawback is that they will have a lesser maximum working temperature compared to metals. While materials like PAI are already at a high thermoplastic level themselves, with the ability to maintain and provide good resistance up to approximately 400°C, metals or stainless steel, as an example, can tolerate much hotter temperatures and, in the same instance, can preserve their strength. What this means is that metals are best suited for high-uptake applications such as jet propulsion or industrial furnaces.

Another place that metal is superior to the use of plastics is in thermal conductivity. Stainless steel, as an example of metals, is better in thermal conductivities than plastics. Thus, they are beneficial in applications where dissipation or absorption of heat is required. Heat-resistant plastics only have relatively low thermal conductivity values that are applicable in heat insulation materials. They are only sometimes desired in the application of heating material that needs fast conduction of heat.

What plastic has a high heat capacity?

You’re building a casing for delicate electronics. You’ve already chosen a material that has a high heat deflection temperature so it won’t warp. But you’re still concerned about thermal management. A sudden heat spike can destroy components within before the casing even gets warm. That’s where something known as heat capacity comes in, and if you don’t consider it, you can have thermal problems you didn’t expect.

**High specific heat, or heat capacity, plastics take extra energy to increase in temperature. PTFE (Teflon) and PEEK have a relatively high specific heat. This implies that they store and take in greater amounts of thermal energy before increasing appreciably in temperature. This characteristic makes them very good thermal insulators and avoids them from varying in temperature in case of extreme heat changes, safeguarding the elements that they hold.

This is a more technical aspect of material selection, but it’s one that can make a huge difference. Think of it this way: heat resistance (like HDT) is about strength at high temperatures, while heat capacity is about thermal inertia. It’s about how quickly or slowly the material reacts to changes in heat. For some applications, you want a material that heats up and cools down fast. For others, you want one that resists temperature change, acting like a thermal buffer.

Heat Resistance vs. Heat Capacity: What’s the Difference?

It’s easy to confuse these concepts, but they describe two very different things. Let me try a simple analogy.

- Heat Resistance (HDT/CUT): Imagine two frying pans, one made of thin aluminum and one of thick cast iron. You can heat both to 400°F without them melting or warping. They both have high heat resistance.

- Heat Capacity (Specific Heat): Now, which one heats up faster? The thin aluminum pan gets hot almost instantly. The heavy cast iron pan takes a long time to heat up, but it also stays hot for a long time after you turn off the stove. The cast iron has a much higher heat capacity.

In plastic design, this "cast iron" effect can be very useful.

Practical Implications for Design

A high heat capacity can be a benefit or a drawback, depending on your goal.

- Benefit (Insulation): For a housing protecting electronics, a high heat capacity is great. A sudden external heat spike will be absorbed by the material, and the temperature inside will rise much more slowly, giving the electronics a better chance to survive.

- Shortcoming (Molding Cycle Time): In injection molding, a material with a high heat capacity is slower to cool in the mold. It can cause longer cycle times and increased cost of production. It’s always a compromise I negotiate with my customers. We must weigh the part’s end-use performance and the constraints of manufacturing.

Here is a table showing the specific heat capacity for a few common plastics to give you a frame of reference.

| Material | Specific Heat Capacity (J/g·°C) | Thermal Behavior |

|---|---|---|

| PTFE | ~1.04 | High; excellent thermal insulator. |

| PEEK | ~0.92 | High; good thermal stability and insulation. |

| Nylon (PA66) | ~1.7 | Very High; absorbs a lot of heat energy. |

| Polycarbonate (PC) | ~1.2 | Moderate; good all-around thermal properties. |

| PPS | ~0.8 | Low; heats up and cools down relatively quickly. |

So, next time you’re selecting a material, ask yourself: Do I just need it to be strong when it’s hot, or do I also need it to resist changes in temperature? The answer will lead you to a much more refined and effective material choice.

Which manufacturing methodologies would be best suited with heat-resistant plastics?

In the selection of the manufacturing process for one of the heat-resistant plastics, you will be required to consider the type of plastic that you will utilize, the part geometry, the run size, and the cost ceiling. Below, we will review the applicability of our top manufacturing processes with regard to the heat-resistant plastics.

Injection molding and high-temperature-resistant plastics

Injection molding produces parts with high precision and surface finish, regardless of whether they have complicated geometries. Though high tooling costs render it no longer economical when small quantities of parts are required, it’s typically the initial selection when large production runs (large-volume production) are in order.

Heat-stable polymers like PEEK, PPS, and polyamides are preferable in injection molding because they can withstand high processing temps.

CNC machined parts and high-temperature plastics

CNC parts offer high precision and close tolerancing with essentially all grades of heat-resistant plastic. Both basic and complex parts can be manufactured utilizing the capabilities of CNC machines, especially in medium- and low-volume work.

3D printing and heat-resistant plastic

3D printing is often utilized in the context of prototyping and small-scale production with heat-resistant polymers like PEEK and PEI – specifically parts with complex, custom geometries. The flexibility in design is prime and material consumption is optimized.

Conclusion

Selecting an appropriate plastic that can withstand high-heat applications is a very important choice that must achieve a balance between performance, environmental issues, and cost. Whether moderate heat with PC-and PA to the extreme market automotive and industrial with PPS and PEEK, the solutions are numerous. So the trick is to move beyond one data point and take the full measure of the needs of your project thermal, mechanical and chemical to make sure that your not really just mastering your molding right.