It’s tempting to inexpensively source molds made in China, but it makes one anxious. You’ve heard of bad quality, late delivery, and skyrocketing costs. You fear that one wrong move might blow your whole project, ending up with a useless piece of steel and a huge migraine. The fact that it is in China makes it that much more intimidating, as it is more difficult to feel confident that you are getting a good price.

To receive a precise China mold price quote, you will need to send a comprehensive Request for Quotation (RFQ). That involves a 3D CAD design, 2D drawings with tolerancing, plastic material specifications, needed mold steel, estimated life of mold, and desired production amount. Giving them this whole package helps good suppliers accurately cost it out and prevents unpleasant cost surprises. It also indicates that you are a professional and legitimate partner, so you will be treated to superior service and favorably priced quotes.

Obtaining a quote is not only requesting a price, but a start to a great partnership. I have witnessed a number of business owners, such as Michael, who are obsessed with the big picture, yet it is the details that matter. An effective request will not only provide you with the right price but it will also enable you to identify a very competent manufacturing partner that comprehends what your project requires. We are going to take a step by step approach to ensure that you get it correctly at the onset.

Why is a Detailed RFQ Your Most Important First Step?

You need a quote, but you don’t know what to send. Insufficient information creates clumsy, unreliable quotes that will vary later. You fear back-and-forth, as it makes time feel wasted, and important details could get left behind, leading to big problems at print time. The initial confusion can make the entire procedure intimidating before it has even started.

A clear Request for Quotation (RFQ) is also critical because it eliminates guesswork. When you lay out in explicit detail your project’s technical specifications—part material, mold steel, finish, and desired life expectancy—you require your vendors to quote under identical terms. That produces a legitimate "apples-to-apples" ratio and eliminates much potential for costs or quality issues further down the line. That is how you get a successful, predictable manufacturing project.

This was a lesson that I learned at a young age. I even had to send a simple 3D file to some suppliers requesting a fast price. The received quotations were all disorganized. One was $5,000, another was $12,000. Why the huge difference? It was due to the different assumptions made by each supplier. A single quoted a small production run using cheap soft steel, and another quoted using the high quality hardened steel constructed to survive a million or more shots. They were formulating quotes of totally different tools without clear instructions. An elaborate RFQ is the means of letting you take charge of the discussion. It establishes a benchmark and makes sure that all of the suppliers are basing their price on your foundation.

The Essential Components of Your RFQ

To build that strong foundation, your RFQ needs to be comprehensive. Think of it as the blueprint for your quote. Here are the absolute must-haves:

- 3D and 2D Files: The 3D model (in .STEP or .X_T format) shows the part’s geometry. The 2D drawing (.PDF or .DWG) provides the critical details the 3D model can’t, like specific dimensions, tolerances, surface finishes, and critical-to-function areas.

- Material Specification: Don’t just say "ABS." Specify the exact grade, like "Sabic Cycolac MG38." Different grades have different shrinkage rates and processing requirements, which directly impacts mold design and cost.

- Mold Specifications: This is where you detail the tool itself.

| Mold Specification | Why It’s Important | Example |

|---|---|---|

| Mold Steel | Determines the mold’s lifespan and cost. Hardened steel is more expensive but lasts longer. | Core: H13, Cavity: H13 |

| Mold Base | The foundation of the mold. LKM is a common standard. | LKM Standard, S50C |

| Number of Cavities | How many parts the mold produces in one cycle. More cavities mean a higher mold cost but lower part price. | 1, 2, 4, or 8 cavities |

| Required Lifespan | How many shots you need the mold to produce. | 500,000 shots minimum |

| Surface Finish | The texture of the final part. SPI standards are common. | SPI-B2 |

By providing this level of detail, you’re not just asking for a price. You are defining the quality and performance you expect. This clarity protects you and ensures the supplier knows exactly what to build.

How Do You Find and Properly Vet Chinese Mold Suppliers?

There are thousands of possible Chinese suppliers out there who claim that they are the best. The question remains, though, how do you weed out who is a legitimate factory versus a middleman? You are afraid of submitting your design to a stranger of a supplier that does not even have the technical expertise to match up to your desired quality. Exploring this initial hunt of Chinese suppliers is like seeking a needle in a haystack.

To locate and screen good suppliers, begin by going to sites such as Alibaba, Made-in-China, or industry-specific catalogs. But don’t get that far and then stop. The secret is to dig further. Take a look at their history as a company, examine their website for case studies and equipment lists, and request references in your country by customers. An authentic capable factory will be open and proud to do so, while a trading house will be evasive. A video call to take them on a tour of their factory is also a great vetting tool.

I always tell my clients that finding a supplier is like hiring a key employee. You wouldn’t hire someone based on a resume alone, and you shouldn’t choose a supplier based on a website. You need to verify their claims. I remember helping a client who was about to sign a deal with a supplier that had a fancy website but couldn’t answer basic technical questions about mold cooling. A quick video call revealed they were just a two-person office, not the large factory they pretended to be. We dodged a major bullet. Vetting isn’t about being suspicious; it’s about being diligent. It’s the work you do upfront to ensure a smooth project later.

A Practical Vetting Checklist

When you’ve shortlisted a few potential suppliers, use this checklist to separate the experts from the amateurs.

1. Analyze Their Website and Communication

A professional supplier’s website should be more than a simple brochure. Look for:

- Case Studies: Do they show examples of molds similar to yours? This demonstrates relevant experience.

- Equipment List: Do they list their CNC machines, EDMs, and inspection equipment? This shows their in-house capabilities. A factory that owns its equipment has more control over quality and timing.

- Certifications: Are they ISO 9001 certified? This shows a commitment to a quality management system.

- Responsiveness: How quickly and professionally do they respond to your emails? Clear, knowledgeable English is a very good sign.

2. Conduct a "Soft" Audit

You don’t need to fly to China to inspect them initially. You can learn a lot remotely.

- Ask for a Company Presentation: A serious company will have a presentation ready that details their history, team structure, workflow, and quality control processes.

- Request a Video Call and Factory Tour: Ask the salesperson to walk you through their shop floor with their phone. Let them show you the machines running, the mold assembly area, and their quality inspection room. This is the single best way to verify they are a real factory.

- Check Their Business License: Ask for a copy of their business license. You can use online tools or a local contact to verify its authenticity and see when the company was established. A company with 10+ years of history is generally more stable.

3. Verify Their Expertise

Finally, test their technical knowledge.

- Discuss Your Design: Ask them for their feedback on your part design. A good mold maker will often provide a Design for Manufacturability (DFM) report, suggesting improvements to make the part stronger or easier to mold. This proactive feedback is a sign of a true partner, not just a job shop.

Choosing the right partner is the most critical decision you’ll make. Take your time with this step.

5 Key Factors That Affect Injection Mold Costs When Sourcing from China

The cost of the injection molds imported to China depends on several important factors. Knowing these variables may assist you in judging quotes better and prevent unpleasant surprises:

Mold Complexity

The more complex the part geometry, e.g., thin walls, undercuts, threads, or tight tolerances, the more time and engineering effort are needed to machine the mold. Designs of complex nature can also require side actions, lifters, or the multi-slide feature, which makes the tooling very expensive.

Cavity number and size:

The bigger molds consume more steel, more time for machining and more equipment. In the same way, multi-cavity molds (utilized in making more than one part at a time) may lower the cost of a unit, but will raise the cost of initial tooling.

Tooling Material

Hardened steel (e.g., H13, S136) molds are more expensive than aluminum or P20 steel, and last longer- particularly in high-volume production. The type of material used must suit your anticipated volume of parts, and the life expectancy.

Production Volume

The cost of tooling is constant, and therefore the larger the production the more the cost can be amortized on more parts. By way of illustration, a ten thousand-dollar mold on 100 000 parts only costs the company $0.10 a part, as compared to 1000 parts it would cost the company 10.00 each part.

Surface Finish and Tolerance Requirement.

Mirror finish (SPI A1), textured surfaces (VDI) or fine parting line control can take time to machine and polish parts, raising the cost of molds. These are some of the details that should be considered at an early stage when DFM reviews are being done.

So, there are several variables that affect the injection mold prices in China other than the base price. The consideration of tooling material, mold size, production volume, and other important factors makes the comparison of gearing Chinese suppliers more realistic. And in case you are not sure how these aspects will be relevant to your design, it can be a good idea to consult a knowledgeable mold supplier at the beginning of the process.

What Should You Look for When Comparing Different Quotes?

You’ve sent out your diligent RFQ and now in front of you are a pile of quotes. One is incredibly low, one is incredibly high, and several hover in middle ground. The urge is strong to simply go with cheapest, but there’s that nagging feeling that there must be a catch. How can you be sure that lowest cost means lowest quality?

When comparing quotes, don’t compare price by price. Compare in great detail: what steel of mold is called out, what life of mold (in shots) is being promised, what cavity count, what brand of hot runner (if applicable) is being called out, and what cycle time is being quoted. An inferior price in quotes usually results in softer steel, reduced life, or reduced cycle, ultimately driving up your cost per part. A good quote is descriptive, openly transparent, and substantiates its cost with quality materials.

Here your detailed RFQ will come in handy. You can now make fair comparisons of the quotes as you are the ones who established the standards. In the case of one of my clients, Michael, he was willing to accept a quote that was twenty percent lower than the second place. I advised him to look closer. The lower-cost supplier we have found gave a quote in 718H steel rather than H13 that we ordered. That softer steel would have used half the time on his nylon stuff of glass. The saving that would have been made on the mold would have been lost in the expense of another mold well before it was supposed to be made. Price is only one of the pieces of the puzzle.

Deconstructing the Quote: A Line-by-Line Analysis

A professional quote should be a detailed document, not just a single number. Here’s what to scrutinize.

Price isn’t Everything

The final price is an output, not an input. It’s determined by all the other factors. If a price seems too good to be true, it almost certainly is. It often indicates that corners are being cut somewhere. Ask the supplier to explain how they reached that price.

The Holy Trinity: Steel, Lifespan, and Cycle Time

These three elements are fundamentally linked and have the biggest impact on your total cost of ownership.

- Mold Steel: Your RFQ specified the steel, so your first check is simple: did the supplier quote the steel you asked for? If they proposed an alternative, they should provide a clear, technical reason why. Be wary of generic terms like "high-quality steel." Demand specific grades (e.g., P20, 738H, H13, S136).

- Mold Lifespan: This should be clearly stated in the number of cycles or "shots" the mold is guaranteed for. A mold guaranteed for 1,000,000 shots will be more expensive than one guaranteed for 300,000 shots because it requires hardened steel and more robust construction.

- Cycle Time: This is the time it takes to produce one shot of parts. A faster cycle time means a lower cost per part. It’s a key indicator of a well-designed mold with efficient cooling. A supplier who can’t quote a cycle time may lack experience.

Reviewing the Technical Details

Here’s a quick comparison table to illustrate the point.

| Feature | Supplier A (Higher Price) | Supplier B (Lower Price) | The Impact |

|---|---|---|---|

| Mold Steel | H13 Hardened (52 HRC) | P20 Pre-hardened (32 HRC) | H13 is much more durable, suitable for abrasive materials and long runs. |

| Lifespan | 1,000,000 shots | 300,000 shots | You’d need to buy 3+ molds from Supplier B to match Supplier A’s lifespan. |

| Cooling | Conformal Cooling Channels | Standard Drilled Lines | Conformal cooling is more effective, leading to a shorter cycle time. |

| Cycle Time | 22 seconds | 30 seconds | Supplier A’s mold produces parts ~27% faster, drastically cutting part cost. |

As you can see, Supplier B isn’t really "cheaper." They are quoting a lower-specification tool. The higher initial investment with Supplier A would lead to a much lower total cost over the life of the project.

Are You Making Sense of Payment Terms and Shipping (Incoterms)?

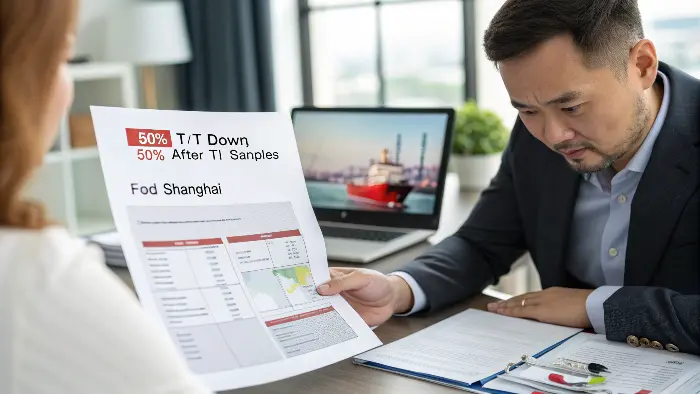

You’ve matched technical specifications and are virtually at the point of choosing a supplier. Now, you’re checking payment terms: "50% T/T down, 50% after T1 samples." And shipping terms "FOB Shanghai." You’re not entirely clear what that means, and you worry about sending that kind of money overseas without being clear about risks and obligations.

Normal Chinese mold payment terms are a percentage down payment (30-50%) in advance, a percentage after initial sample trial (T1), and balance due before shipping. Shipping terms like Incoterms (FOB, Free On Board, and EXW, Ex Works) govern who bears costs and risks at each. Recognizing what they imply is critical. For example, FOB means that you pay in getting the mold to the shipyard, shipping thereon being yours. Getting precise about such issues prevents confusion over unexpected costs.

I always spend time explaining this to my clients because it’s a common point of confusion. A client once assumed their "EXW" quote included shipping to the port. They were hit with an unexpected bill for local transport, customs clearance, and port handling fees, which soured their relationship with the supplier. It wasn’t the supplier’s fault; the terms were stated clearly. But the client didn’t understand what they meant. Agreeing on a price is only half the battle; agreeing on the terms of the deal is just as important for a smooth and predictable transaction.

Breaking Down the Financials and Logistics

Let’s demystify these common terms so you can negotiate confidently.

Typical Payment Structures

The phased payment structure is designed to protect both you and the supplier.

- First Payment (Down Payment): 30-50%. This is typically paid via Telegraphic Transfer (T/T) when you place the order. This allows the supplier to purchase the mold steel and begin work. It’s a sign of your commitment.

- Second Payment: 30-40%. This payment is due after you have approved the first samples from the mold, known as "T1" samples. This is a crucial milestone. It confirms the mold is built and functional. Never make this payment until you have the physical samples in your hands and have approved them.

- Final Payment: 10-30%. This is the final balance due after you give final approval and just before the mold is shipped. The supplier will typically hold the mold until this final payment is received.

This structure mitigates your risk. You don’t pay the full amount until you have proof that a functional mold exists.

Understanding Common Incoterms

Incoterms are a set of globally recognized rules that define the responsibilities of sellers and buyers for the delivery of goods. Here are the most common ones for molds:

| Incoterm | What the Supplier Pays For | What You (the Buyer) Pay For | Key Takeaway |

|---|---|---|---|

| EXW (Ex Works) | Nothing. Their only job is to make the mold available at their factory. | Everything: picking it up from their factory, inland transport, export customs, ocean freight, insurance, import customs, and final delivery. | Maximum responsibility for you. This often seems cheapest but has many hidden costs. |

| FOB (Free On Board) | Inland transport to the specified port (e.g., Shanghai) and clearing the goods for export. | Ocean freight, insurance, import customs at your end, and delivery from your local port to your facility. | A very common and balanced option. The supplier handles their side of the logistics, and you handle yours. |

| CIF (Cost, Insurance, and Freight) | Everything included in FOB, plus the cost of ocean freight and insurance to your destination port. | Unloading at your port, import customs clearance, and final delivery. | More convenient, but you may pay more as the supplier chooses the freight forwarder. |

For most buyers in the US or Europe, FOB is the best balance of cost and control. It makes the supplier responsible for the complexities of Chinese export procedures, while leaving you in control of the main international shipping leg. Always ensure the Incoterm is clearly stated in your quote and on the Proforma Invoice (PI).

Cost Advantages of Chinese Injection Mold Manufacturing

China has a long-standing reputation of providing plastic injection molds at very competitive rates, and it is a favorite source of many manufacturers around the globe. However, what is it that makes sourcing molds in China cost-effective?

Reduced Labor Costs

The skilled manufacturing labor in China is still cheaper than in most Western nations. This will directly cut down the tooling production cost, manual finishing and maintenance (there are no guarantees that quality is compromised), particularly when the supplier is experienced.

Efficiency of equipment and processes

The high-end factories in China have the newest CNC machining centers and EDM equipment, as well as automated quality control lines. Such investments allow high efficiency, quick turnaround time, and consistent quality of the mold at a low unit cost of production.

Integrated Supply Chains:

The industry of the mould of China enjoys very well-developed regional ecosystems. There are numerous suppliers who are close to steel suppliers, heat treatment companies, surface finishes, and injection molding partners. This kind of vertical integration simplifies the working process, slows down logistics, and minimizes management expenses.

Adaptable Production Capabilities

Do you require a quick prototype mold, a low-volume aluminum tool, or a high-volume hardened steel mold, Chinese manufacturers can adapt to the requirements of the project size. This ease allows you to not commit too much to tooling at the beginning and allows later production to be scaled with ease.

Economies of Scale

A good number of Chinese mold makers cater to international clients in large numbers. This gives them the opportunity to standardize their production processes, purchase materials in large quantities, and optimize machine use- reducing the total cost of production of molds.

Naturally, pricing does not give the full story. The actual worth is in striking a balance between the price and quality, lead time and dependability of suppliers. The sourcing of plastic injection molds in China can provide such a balance to many companies, particularly in cases where there is large-scale or repeat production.

How Can Effective Communication Prevent Costly Misunderstandings?

You’ve selected your supplier and are ready to get started in getting the project going. But you’re dealing with a team that happens to be thousands of miles away, in a time zone that’s not yours, whose first language is not necessarily English. You worry that a small misunderstanding could become a gigantic error in the final mold. How do you keep them in step with yourself in getting this whole thing completed?

Successful communication is concise, clear, and consistent, with the use of visual aids at every turn. Agree in writing by email of all key decisions, changes, and approvals to create a paper trail. Establish daily, short weekly calls to review status. Use marked-up screenshots and photographs to explain issues instead of explaining by narrative alone. This anticipatory, documented approach eliminates the culture and language gap, decreasing error possibility.

Of this I cannot overestimate the importance. I once arbitrated a conflict in which a client claimed he or she wanted a matte finish. That was to them a certain kind of bead-blasted feeling. To the supplier it was a normal EDM finish. The resulting sections did not satisfy the client and was a huge delay and argument. This issue would have been avoided in case the client would have merely provided a standard finish code (such as an SPI or VDI number) or a physical sample plaque. Don’t assume anything. Communicate too much, and overly with images.

Best Practices for Clear Cross-Cultural Communication

Building a mold is a collaborative process. Your ability to communicate effectively with your supplier is just as important as their ability to cut steel.

1. Establish a Single Point of Contact

On both sides, there should be one main person responsible for communication—usually you or your engineer, and a dedicated project manager or sales engineer on their side. This prevents conflicting information from being sent by different team members.

2. Put Everything in Writing

A phone call or WeChat conversation is great for quick questions, but any decision, change request, or approval must be followed up with an email. This creates a clear paper trail that can be referred back to. For example, if you approve a DFM report, send an email stating, "I confirm that we approve the DFM report dated [Date], and you can proceed with the mold design based on this."

3. Use Visuals Extensively

A picture is truly worth a thousand words, especially when there’s a language barrier.

- Mark Up Your Drawings: Use arrows, circles, and notes on screenshots of your 3D model or 2D drawings to highlight specific areas of concern or to explain a change.

- Reference Photos: If you’re trying to describe a defect on a sample part, take a clear photo and circle the issue. This is much more effective than trying to describe a "small sink mark next to the rib."

- Provide Examples: When specifying a color or texture, provide a Pantone color code or a standard texture plaque number (e.g., VDI 3400 Ref 27).

4. Structure Your Updates

Request a simple, weekly progress report from your supplier. It should include:

- What was completed this week (with photos).

- What is planned for next week.

- Any questions or issues that have come up.

This simple structure keeps the project on track and ensures that potential problems are identified early, not right before the shipping date. Clear, consistent, and documented communication is the oil that keeps the global manufacturing machine running smoothly.

What Are the Hidden Costs You Should Watch Out For in a Mold Quote?

You’ve gotten a price that appears final and the cost fits in your budget. So far, so good. But there is this uneasy suspicion about "hidden fees." What if there are surprise fees for changes, shipping, or taxes that aren’t included in the quotation? Those unexpected costs could totally blow up your project’s finances and render the whole deal much less appealing.

Mold quoting costs often show up later after it is too late. Be wary of vague language. Important places to seek clarity include modification fees (what if T1 samples require adjustments?), cost of texturing, shipping and insurance (included or extra?), import tax and duties in your nation, and spare parts cost. An honest supplier will itemize them or tell you upfront. You always want to say, "Are there any other expenses I should take notice of that are not included in this price?"

This is a critical checkpoint before you sign anything. I remember a client who chose a supplier based on a low initial quote, only to be charged $500 for every minor geometry tweak after the T1 samples. Another supplier’s quote didn’t include any spare parts, so when a fragile ejector pin broke after a few thousand cycles, my client had to pay extra and wait for the replacement to be shipped from China, causing production downtime. A comprehensive quote isn’t just about the mold itself; it’s about the entire project lifecycle.

Uncovering Potential Extra Charges

To protect your budget, you need to think like a detective and look for what isn’t there. Here are the most common areas where hidden costs can pop up.

1. Mold Modifications and Adjustments

No mold is perfect on the first try. The T1 samples will likely reveal the need for small adjustments ("tweaks") to the steel to get the part dimensions just right.

- The Trap: A supplier quotes a very low price but then charges high fees for every adjustment.

- The Solution: Get the modification policy in writing. A good supplier’s quote will typically include one or two rounds of minor modifications free of charge. Ask them: "How many revisions are included in the price after the T1 trial?"

2. Surface Finishes and Texturing

Special finishes cost money.

- The Trap: The quote covers a basic polished finish (e.g., SPI-B1), but you later decide you need a textured finish (e.g., MT-11010). The supplier then presents a large, separate bill for the chemical etching process.

- The Solution: If you know you will need a specific texture, specify it in your RFQ. If you are unsure, ask the supplier to list texturing as an optional, separate line item in the quote so you know the cost upfront.

3. Shipping, Insurance, and Duties

This is the biggest source of surprise costs.

- The Trap: A quote lists the price as "EXW" (Ex Works), and the buyer doesn’t realize this means they are responsible for all shipping costs, including transport within China, export fees, ocean freight, and insurance.

- The Solution: As we discussed, clarify the Incoterm. For a clearer budget, you can ask your supplier for a "CIF" or "DAP" quote, which includes shipping costs to your port or even your door. Also, remember that you are responsible for paying import duties and taxes to your own government. This is never included in a Chinese supplier’s quote. Use an online calculator or a customs broker to estimate this cost.

4. Spare Parts

Molds have wearing components that will eventually need to be replaced.

- The Trap: The mold is delivered with no spare parts. When a component fails, you have to halt production and place an emergency order.

- The Solution: A professional quote should include a list of recommended spare parts, such as ejector pins, springs, and seals. This should be a standard part of the package. Confirm that it’s included.

By asking these pointed questions before you commit, you can turn a quote from a simple price tag into a reliable, comprehensive project budget.

Conclusion

Obtaining a mold quote in China does not need to be something that is risky to gamble. The process can be controlled by creating an elaborate RFQ, vetting your suppliers properly, scrutinizing quotes other than the price and ensuring that there is a clear communication. This attention will turn you into no longer a mere buyer but an informed partner, so you will set up your project with the long-term success, as you will be equipped with a high-quality mold that fits your budget and technical needs.