Are you weighing 3D printing and injection molding for your next project? It’s a familiar pain. The wrong choice of manufacturing process can destroy your schedule and your dollars. You look at the low part cost of injection molding, but the huge upfront mold investment scares you. When’s the right time to make the jump? Let’s find the exact spot when it becomes the better financial decision.

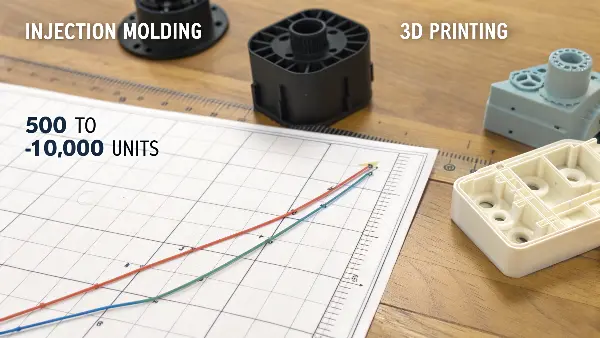

The breakeven point at which injection molding is less expensive than 3D printing is normally somewhere between 500 and 10,000 pieces. This broad range will vary depending on your part’s complexity, material choice, and the 3D printing technology you are pitted against. For inexpensive parts made from standard plasties, the move to molding becomes economical on the low end of the range. For extremely complex geometries, 3D printing may be less expensive for longer. The basic concept is to amortize the high upfront mold cost across many pieces.

So, we have a rough number, but I know that a range as wide as "500 to 10,000 units" isn’t specific enough to bet your budget on. It feels like a huge variable, doesn’t it? To really give you the confidence to make the right call, we need to dig deeper. We have to understand the fundamental differences between these two technologies and exactly how their costs stack up. Let’s break it all down so you can choose the right path for your project, every single time.

How is injection molding different from 3D printing?

You’re familiar with 3D printing and injection molding both being capable of producing plastic components, but do you really have an idea why the two are inherently distinct? It’s a misconception I constantly witness people committing. It can mean choosing a process that’s not suitable for your design, leading to delays, unexpected costs, and a great amount of wasted time. Let’s settle this once and for all. In order to make an accurate decision and make the right choice of process for your project, you first have to be aware of how each process works.

The most dramatic difference is the way it forms the part. 3DP is an additive process, so it lays down an object from the ground up, layer after layer, right from a computer file. Picture it being built with infinitesimally small digital blocks. Injection molding is a formative process. It begins with making a mold, a cavity shaped like your part. It then injects hot material into the cavity to form your part. You build upward, the other fills in.

To really get it, let’s dive a bit deeper into these two approaches. They aren’t just different techniques; they represent two completely different ways of thinking about manufacturing.

The Additive Approach: Building from Nothing

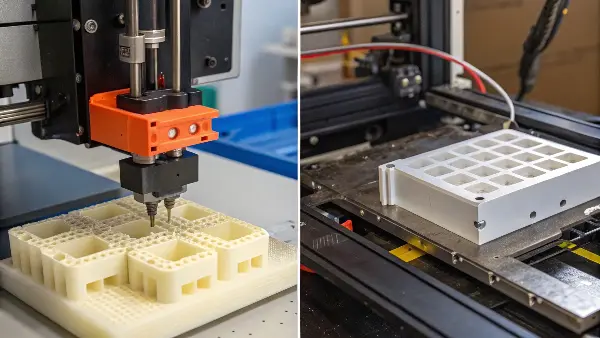

With 3D printing, your part is born from a digital design file (like a CAD file). The printer reads this file and starts building the object from the ground up, one thin layer at a time. Whether it’s melting plastic filament (FDM), curing liquid resin with light (SLA), or fusing powder together with a laser (SLS), the principle is the same: you add material only where you need it.

This gives you incredible design freedom. You can create complex internal channels, hollow structures, and intricate geometric patterns that would be impossible to make with traditional methods. There’s no need to worry about things like draft angles or undercuts because you’re not pulling the part out of a cavity.

The Formative Approach: Filling a Void

Injection molding is just the reverse. The heavy lifting comes before you create your first part. You must design and build a high-precision tool, typically made of steel or aluminum, known as a mold. This mold is a negative of your part. You are then ready to run when your mold is complete. You clamp your mold into an injection molding machine, melt plastic pellets until they are liquid, and inject this molten plastic under high pressure into the mold cavity. The plastic solidifies on cooling, the mold opens, and your completed part drops down. This process can be repeated every few seconds.

Key Differences at a Glance

The best way to see the difference is to compare them side-by-side.

| Feature | 3D Printing (Additive) | Injection Molding (Formative) |

|---|---|---|

| Process | Builds part layer by layer | Injects material into a mold |

| Tooling | No tooling required | High-cost, custom mold required |

| Setup Cost | Very low | Very high ($2,000 – $100,000+) |

| Per-Part Cost | Stays relatively high and constant | Becomes very low at high volumes |

| Speed | Slow per part (hours) | Fast per part (seconds) |

| Best For | Prototypes, custom parts, low volume | Mass production, high volume |

| Design Freedom | Very high, complex geometries | Limited by mold constraints |

| Materials | Wide range, but can be expensive | Huge variety of cheap commodity plastics |

I once worked with a client who had a brilliant design for a medical device. It was perfect for 3D printing, with complex internal cooling channels. But when they wanted to scale up to 50,000 units, they brought the design to me for molding. We had to spend two weeks re-designing the part, simplifying the channels and adding draft angles, just to make it moldable. Understanding these differences from the start would have saved them that time and effort.

Cost Comparison Breakdown: Injection Molding and 3D Printing

One of the most significant aspects when deciding on a preference between injection molding and 3D printing is the cost factor. The two approaches are useful in diverse production purposes as 3D printing is better at prototyping and low volume output, and injection molding rules large-scale production. The following is the break down of the costs in detail so that you can determine what process can give better value according to your production scope and design objectives.

Tooling and Setup Costs

Injection Molding:

High initial investment: Injection molding needs metal molds that are engineered with high precision, which can be made out of steel or aluminum. Tolling expenses may range between 3,000 and 100,000 and above, including the cost of toolling, parts complexity, size and number of cavities.

Economies of scale: When the mold is prepared, the number of units produced costs less, a lot less, to produce. This renders injection molding very cost efficient in mass production.

3D Printing:

No tooling fee: 3D printing does not need molds or set-up. It is a digital process which implies that all of the parts can be printed directly out of a CAD file.

Perfect fit in prototyping and small-scale production: 3D printing is an appropriate technology because it requires low set-up and can be used to manufacture small batches on demand or during short production runs.

Verdict:

The cost of Injection Molding is more expensive initially but less expensive in volume.

The 3D Printing is less expensive to begin with but more costly in larger quantities.

Material Costs

Injection Molding:

Through bulk thermoplastics like ABS, PP or Nylon, which are cheap in form of pellets.

The material cost can range between 2-4 kg per kg, which is the average.

Less wastage because of effective use of materials.

3D Printing:

Counts on filaments, powders or resins which are normally more costly.

The cost of the material goes between 20 and 150per kg and is taken on the basis of the technology (FDM, SLS, SLA, etc.).

Supports and failed prints are some of the waste that is produced.

Verdict:

Injection molding has reduced material prices and efficiency on a large scale run, whereas 3D printing materials are more expensive.

Speed and Cost of Production Labor.

Injection Molding:

The cycle times once the molds are established are extremely quick 10 to 60 seconds/part.

It is best suited to the production of thousands of parts that are of the same kind and require little labor.

But preparing and designing the mold may require 4-8 weeks until the actual production goes on.

3D Printing:

The rate of production is determined by the type of printers and complexity of the parts; a single part can take a number of hours to be finished.

The setup costs of labor are low and post-processing (removal of supports, surface finishing, etc.) cost more.

Verdict:

High-speed mass production relies on injection molding, whereas the low-volume, design-flexible project is most appropriate with the 3D printing.

Design Flexibility and Costs of iteration.

Injection Molding:

It would be costly and time consuming to change a mold design.

Best where final designs are produced to be mass produced.

3D Printing:

Flexible and adaptable to high degrees–they can be altered instantly at no additional tooling expense.

Breakthrough in the fastest prototyping and testing a number of iterations.

Verdict:

3D printing is good in terms of flexibility in design whereas injection molding is good when the final design is determined.

When deciding on injection one or 3D printing, it depends on production volume, costs, and stage of the project. To use 3D printing is the most advantageous and versatile option to use when prototyping quickly, in batches, or to experiment with designs. Injection molding offers unparalleled cost efficiency of the part per unit after the initial capital expenditure in mass production and uniform quality of manufactured products.

Is injection molding really cheaper than 3D printing?

You’re told injection molding is the "cheap" way to mass produce, but then you are quoted a mold and it costs thousands, if not tens of thousands, of dollars. That’s a sticker-shocking amount and gets you to question everything. Can you truly justify such a large upfront expenditure when you can simply begin to print parts for a few dollars apiece? It seems a huge gamble. Let’s lay out the true cost structure of both means so you can clearly see where the money goes.

No, injection molding isn’t always cheaper. For low runs, 3D printing is almost always the cheaper option because there’s no tooling involved. Injection molding’s cost-effectiveness comes in when you’re running a big bunch of parts. Your upfront cost of your mold gets amortized over the size of units you run. When your run becomes large enough, your cost-per-part becomes well below what you’ll pay for a 3D-printed part and becomes your choice.

The decision to use injection molding is purely a numbers game. It’s all about that breakeven point. Let’s look at the numbers more closely.

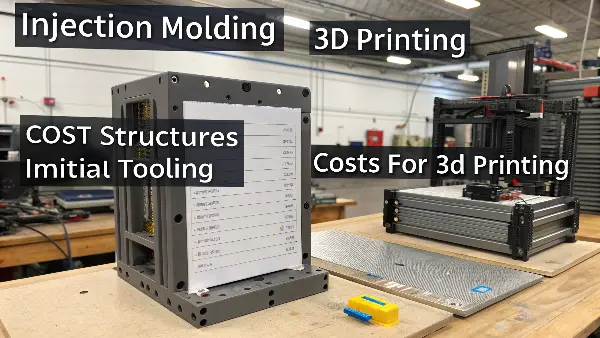

The Cost of a Mold: The Big Hurdle

The mold is the largest single cost factor in the injection molding. This is a very high engineered item of steel or aluminum and it must be machined to unbelievable tolerances. A mold can cost as little as a few thousand dollars as a simple, one-cavity aluminum mold, or as high as in the millions of dollars as a complex multi-cavity hardened steel mold. It is your first investment and this is a massive one. This cost is zero in 3D printing. You put in your file and press print.

Per-Part Cost: Where Molding Shines

This is where the tables turn. The price of each part of the mold once that is paid would be incredibly low. You are often working with commodity plastic pellets which cost very little and your machine cycle time is a matter of seconds. Your per part cost could be pennies, then.

In the case of 3D printing, part costs are significantly more expensive and do not change much. The individual components are very time-consuming to print (minutes or hours), and the specialized materials are costlier than unprocessed plastic pellets. Print a single or a thousand part and it will cost you approximately the same.

Calculating Your Breakeven Point

Let’s use a simple, practical example. Imagine you’re making a small plastic housing for an electronic device.

| Cost Factor | 3D Printing (FDM) | Injection Molding |

|---|---|---|

| Tooling / Mold Cost | $0 | $6,000 |

| Material & Labor Per Part | $7 | $1 |

Now let’s see how the total cost changes with volume:

-

At 100 Parts:

- 3D Printing: 100 parts * $7/part = $700

- Injection Molding: $6,000 + (100 parts * $1/part) = $6,100

- Winner: 3D Printing

-

At 1,000 Parts:

- 3D Printing: 1,000 parts * $7/part = $7,000

- Injection Molding: $6,000 + (1,000 parts * $1/part) = $7,000

- This is your Breakeven Point!

-

At 10,000 Parts:

- 3D Printing: 10,000 parts * $7/part = $70,000

- Injection Molding: $6,000 + (10,000 parts * $1/part) = $16,000

- Winner: Injection Molding (by a huge margin)

As you can see, the initial pain of the mold cost pays off dramatically as your volume increases.

How part complexity affects the breakeven between injection molding and 3D printing processes?

Breakeven point between injection molding and 3D printing is the point at which the overall cost per part of the two processes are equal. Part complexity is one of the factors that play a crucial role in this. The increased complexity of designs will also have a direct impact on the cost of toolsing, cycle times, and the general production efficiency, all of which will swing the pendulum in favor of these two manufacturing processes.

Part complexity is a huge factor in injection molding as the cost and time used to prepare a mold are affected. Parts with complicated geometries, deep undercuts, thin walls or textured surfaces need sophisticated mold designs. These molds may require extra inserts, side actions, or additional cooling channels which may push tooling costs well up.

An example is a simple molded part where a $5,000 mold will be sufficient and breakeven at 500 to 1,000 units and a very complex part may have a required 50,000 mold and may not be cost-effective until 5,000 to 10,000 parts are made. When the mold is created though, the price per part is extremely low and this makes injection molding the best choice when dealing with mass production of a finalized design.

Conversely, 3D printing is much less part sensitive. As it uses a digital file to create parts one layer at a time, it doesn’t create a lot of additional cost when creating complex shapes, internal structures, or unique details. The cost variables in 3D printing are mainly the time spent on printing, the material used and post processing, but not geometric complexity. This puts 3D printing in a good position in terms of low volume production or in cases where high-level prototyping is required and would otherwise costly to achieve in injection molding.

It is seen that as part complexity moves to the right, the breakeven point moves away further towards 3D printing. High costs of formation of molds make injection molding more expensive whereas 3D printing costs are relatively consistent, independent of geometry.

In injection molding, once production levels are high, simple and repetitive components are best produced by injection molding since the process becomes much more cost-effective. Nevertheless, in more complex or personalized components, 3D printing may still be the most cost-efficient option – even at larger production quantities.

Overall, complexity defines the point at which the cost crossover is executed. Simple designs with high volumes of production are better suited to injection molding, whereas complex low-volume parts are better made through 3D printing because they do not require the expensive tooling. The more complex the design the further the cost benefit of injection molding is pushed away instead of 3D printing which makes it the smarter choice to apply when flexibility of design, customization and efficiency in prototyping is required.

What’s the most cost-effective 3D printing method for early prototypes?

You’ve decided to 3D print a few of your initial prototypes to validate the design. Well done. You look at what’s available and are faced with a blur of acronyms: FDM, SLA, SLS, MJF. Each has varying price tags and abilities. You pick the wrong one and you’ll end up overpaying for a crude fit-check model or receiving a prototype that’s not good enough for your purposes of testing. Let’s cut through the confusion and establish the best place to get started.

For most early-stage prototypes, Fused Deposition Modeling (FDM) will be almost invariably the cheapest and easiest method of 3D printing. You’ll find FDM printers anywhere, and the plastic filament for them, such as PLA or ABS, is extremely cheap. This process is best for 3D printing physical models-cheap and quick-to evaluate the form, fit, andsimple function of your design. It has the lowest resolution, but its low cost makes it best for evaluating an iterative series of design changes without going over budget.

Choosing the cheapest option is great for early stages, but as a designer, you know that "cheapest" isn’t always "best" for every situation. You need to match the technology to your specific goal for that prototype.

FDM: The Go-To for Low-Cost Prototypes

Fused Deposition Modeling (FDM) is the technology most people picture when they think of 3D printing. It’s like a robotic hot glue gun that draws your part one layer at a time with melted plastic filament. Its biggest advantages are speed and low cost. You can have a physical part in your hands in a matter of hours for just a few dollars in material. This is invaluable when you’re in the early design phase. You can print a part, test its fit, find a flaw, tweak the CAD model, and print a new version the same day. This rapid iteration is what FDM excels at.

When to Consider Other Methods (SLA/SLS)

Sometimes, you need more than just a basic shape.

- Stereolithography (SLA): If your prototype needs a smooth surface finish and fine details, like for a marketing photoshoot or a presentation model, SLA is a better choice. It uses a laser to cure liquid resin, resulting in parts that look much more like a final, injection-molded product. It costs more than FDM, but it’s worth it when appearance matters.

- Selective Laser Sintering (SLS): If you need a prototype for functional testing that requires good mechanical strength and durability, you should look at SLS. This process uses a laser to fuse nylon powder together, creating strong, tough parts that can handle real-world stress. It’s one of the more expensive options, but it’s cheaper than machining a metal prototype.

Matching the Method to Your Goal

Here’s a simple way to think about it. I always ask my clients, "What question does this prototype need to answer?"

| Technology | Best For Answering… | Common Materials | Relative Cost |

|---|---|---|---|

| FDM | "Does it fit? Is the basic shape right?" | PLA, ABS, PETG | $ |

| SLA | "Does it look good? Are the fine details correct?" | Standard & Engineering Resins | $$ |

| SLS | "Is it strong enough? Will it survive testing?" | Nylon (PA11, PA12) | $$$ |

As a designer like Jacky, your job is to use the right tool for the job. Use FDM to fail fast and cheap. Use SLA to impress stakeholders. Use SLS to validate mechanical performance. Knowing when to spend a little more on a prototype can save you from a very expensive failure down the line.

Conclusion

Decision-making between 3D printing and injection molding isn’t a matter of "which one’s best"—but a strategic choice dependent on your part quantity. For prototyping and low runs, the rapidity and zero-tool-cost of 3D printing can’t be beaten. But once your quantity surpasses the breakeven quantity, normally in the range of 500 to 10,000 parts, injection molding’s low-cost-per-part yields huge financial savings. Becoming proficient in this decision is an important element to making your project a financial winner.

FAQs About 3D Printing and Injection Molding Methods

Which is more expensive the cost of injection molding or 3D printing?

Both injection molding and 3D printing are different in costs, depending on the quantity of production and the complexity of a design. Injection molding is costly in terms of initially tooling the mold, since the metal moulds have to be made and machined, but once that has been accomplished, each extra part is massively cheap, hence it is very good in high volume production. Conversely, 3D printing does not need any kind of tooling and therefore the startup expense is minimal, yet, the per unit cost is quite high, particularly when one is dealing with large quantities.

Can 3D printing and injection molding be combined?

Yes, it is common in many manufacturers to combine both techniques at various stages of production, where 3D printing can be used in rapid prototyping, where the design is tested in terms of fit, functionality, and beauty before any costly commitment to the manufacturing of molds. Mass production of final components is done through injection molding after the design is finalized. This mixed methodology is time-saving, less risky, and more design accurate to scale up.

Is additive manufacturing injection molding?

No. Injection molding is not additive manufacturing.

Injection molding is an additive or subtractive process, in which the plastic molten material is introduced into a mold cavity to create parts after it has cooled and hardened. It uses ready made moulds and it is most appropriate in mass production. Additive manufacturing (3D printing), on the other hand is an approach of creating parts in layers directly based on digital files without molds. This makes it to be perfect in customized or complex geometries and quick prototyping.

What is the quickest production process?

In the case of mass production, injection molding becomes much quicker when the mold is prepared. The time per part may be as little as several seconds to a minute and by this means thousands of the same part can be produced in a day.

On the contrary, 3D printing can also take a few hours to print only a few part, especially when the design is large or complex. Nonetheless, it is quicker with either initial prototypes or single samples, as no production of moulds is required.