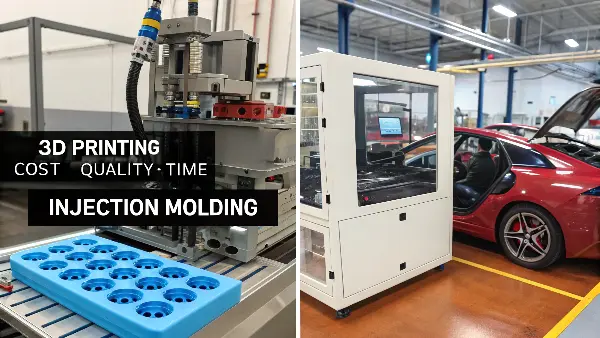

When it comes to making car components, deciding between 3D printing and injection moulding may cause a headache. Both are effective, but both carry strengths as well as weaknesses, and opting for the wrong one may result in time being wasted, increased expenses, or a loss of quality.

Spur-prototyping and low-volume production are ideally done with 3D printing, while injection moulding is appropriate for high-volume production with repeated quality at a lower cost-per-part. It’s your project’s scale, time, and quality requirements that will dictate which of both to utilize.

If you’re like me, you want to make the best decision for your project. I’ve spent years working with both methods, and I know how important it is to weigh cost, quality, and time. Let’s break down these factors to help you choose the right process for your automotive parts.

Which automotive parts are best suited for 3D Printing Vs. Injection Molding?

Automobile production nowadays also has much to do with 3D printing and injection molding. Their choice is based on volume of production, parts complexity, mechanical performance as well as costs. The particular benefits of each of the processes to particular automotive parts are different and in most instances, they are complementary to each other as opposed to being competitive.

Car Component Ideas Most Ideal to 3D Print.

The use of 3D printing is mostly applicable in processes whereby flexibility, speed, and customization are considered more than mass production. It enables designers and engineers to create prototypes, low volume components and lightweight structures within a short time frame and in an efficient manner.

Concept Models and prototypes.

Prototyping and concept models are also done through 3D printing to include dashboards, mirror housings, and headlight frames. It facilitates rapid design validation and testing without the cost of having to fabricate molds. It is used to make quick design changes in product development by automotive engineers and to make the concept-to-production transition more efficient.

Custom or Low-Volume Parts

In the case of small-batch or custom production, 3D printing offers unrivalled flexibility. These are parts to make old cars look new, a specialty accessory, or mods to a racing car. Because it does not involve any tooling, manufacturers can economically produce a single part or small quantities, and is suitable in one-off or custom automotive applications.

Low-weight Structural Components.

The lightweight in 3D printing has been identified to be a high success in brackets, clips, ducts, and housings. The lattice structure can be incorporated into these parts, which can be lighter but stronger and resilient. The reduction of weight is particularly beneficial to electric cars and performance cars, in which vehicle weight is a strong determinant of energy efficiency and speed.

Tooling, Jigs, and Fixtures

The automotive industry has extensively employed 3D printing in the creation of personalized tooling, assembling jigs, and assembling fixtures to amass products and carry out inspections. They can be printed quickly and these elements can reduce the time spent on production, and 3D-printed tools are simpler to modify and save the money on the design, and increase the efficiency of operations at the production line.

Components of Customization of the interiors.

The 3D printing has a high degree of customization, which enables the manufacturer to design distinct interior components including air vents, control knobs, and dashboard inserts. This method works best in the individual or luxury car interiors that have a small production and a unique design as the main selling factors.

Automotive Parts that are most suitable in terms of injection molding.

High volume automotive production of parts is still done by injection molding. It also offers high levels of consistency, stability, and accuracy, and hence suits the structural, aesthetic and safety-related parts.

Plastic Components produced in large quantities.

Large quantities of parts like bumpers, dashboards, interior panels and door trims, among others, are produced with injection molding. After a mold is made, it is possible to make millions of the same parts in haste at a low unit cost. The process is used to achieve repeatability, high-dimensional accuracy, and good surface finish.

Exterior Structural Parts

Mirror housing, grilles, fenders, and light covers are also parts that are injected in the molding process because these parts require the strength, durability and smooth surface finish. Production of molded parts is possible at a constant quality and with weather-resistant properties that are critical in exterior vehicle applications.

Functional Components on the Interiors.

Other internal parts that demand high precision and uniform performance, like seatbelt housings, switch assemblies and console frames, can also be manufactured through injection molding. The process offers a great texture control and tight fit which is a perfect fit and maintains long operation.

Components of Safety and Performance.

Safety-critical parts such as airbag housings, pedal systems, and gear knobs will be best done by injection molding. These components should be able to work effectively with stress, and the repeatability of molding guarantees uniform quality and strength in large volumes of production.

Decision Making between 3D Printing and Injection Molding.

Overall, 3D printing is best applied to low-volume, customized, or complex components with flexibility and design freedom as the main criterion. Injection molding, conversely, is favored in mass production, when there is need to have consistency, high strength and durability. The simplest rule to follow is 3D printing when a print run is less than 1,000 units or injection molding when the production is large quantities of thousands of identical parts.

Both injection molding and 3D printing are necessary in the automotive industry to create a rapid prototype, custom order, and lightweight construction, and to offer scalability, reliability, and cost-efficiency to the large production volumes. The two approaches when used in a strategic manner enable manufacturers to reduce development time cycles, enhance product performance, as well as, satisfy a wide range of market needs.

Which Method Offers Better Cost Efficiency for Automotive Parts?

Choosing the most cost-effective manufacturing method can make or break a project. The automotive industry is especially sensitive to cost, as margins are tight and competition is fierce.

Injection molding is more cost-efficient for large production runs due to lower per-part costs, while 3D printing is more affordable for prototypes and small batches because it avoids expensive tooling.

When I first began with the mold business, I was taken aback at the initial costs of injection molding. The just tooling itself costs tens of thousands of dollars. But once you create the mold, individual pieces get extremely inexpensive to make. This puts injection molding as the outright champion for high-volume production. But with 3D printing, there’s practically no initial cost for set up. You can print a single piece or a small order with no tooling. This is ideal for prototype or for custom pieces.

Here’s a simple table to compare the costs:

| Factor | 3D Printing | Injection Molding |

|---|---|---|

| Tooling Cost | None | High (mold required) |

| Per-Part Cost (Low) | High | High |

| Per-Part Cost (High) | Moderate | Low |

| Best For | Prototypes, small batches | Large-scale production |

If you’re making hundreds of thousands of parts, injection molding is the way to go. But if you’re testing a new design or only need a few parts, 3D printing will save you money and time.

How Do Quality and Material Choices Compare Between 3D Printing and Injection Molding?

Material and quality choice are extremely important in auto production. Auto body parts need to withstand high standards of strength, durability, and aesthetics.

High surface finish, strength, and material homogeneity are produced by injection molding, while 3D printing outputs with design flexibility but with potential limitation in finish as well as in material properties.

I’ve seen firsthand how injection-molded parts come out with a high-quality, smooth, even finish. They’re durable and can be made out of a range of automotive-quality plastics. This is important for parts that need to work under conditions of heat, stress, or impact. 3D printing, while improving every year, but still falls short of injection-molded parts in strength and finish. Line markings will be visible, and some of the printed materials may not hold up under harsh conditions.

Let’s look at the differences in more detail:

Material and Quality Comparison

| Aspect | 3D Printing | Injection Molding |

|---|---|---|

| Surface Finish | Rougher, visible layers | Smooth, consistent |

| Strength | Lower (depends on method) | High, reliable |

| Material Range | Growing, but limited | Very wide |

| Tolerance | Moderate | Tight, precise |

| Best For | Complex, custom shapes | Functional, durable parts |

If your part needs to look perfect and last for years, injection molding is usually the better choice. But if you’re experimenting with new shapes or need a quick prototype, 3D printing gives you the freedom to iterate fast.

How do material properties compare for automotive-grade parts by method?

Automobile-grade material characteristics between 3D printing and injection molding are significantly different.

The Properties of Injection Molding Material.

- Injection molded components have a higher capability of withstanding mechanical strength, durability, and thermal resistance, and are therefore suitable in harsh automobile conditions.

- The process accommodates the wide variety of high-performance thermoplastics including ABS, polycarbonate, nylon and glass-filled polymers.

- Components have high dimensional precision and close tolerances with a good surface finish (smooth, glossy or matte depending on the design of the mold).

- Molded parts have a higher heat tolerance that is typically required when automotive parts are involved and work under high-temperature conditions.

- Injection molding materials also tend to comply with industry requirements of bio-compatibility and food safety, which may be a concern to some automotive interior components.

Material Properties of 3D printing.

- The materials of the 3D printing are growing fast yet are still limited as compared to injection molding.

- With them there is much design freedom and capability to create complex shapes, however, the printed parts can be weaker, less durable and less able to resist thermal effects as compared to molded parts.

- The surface finish can contain noticeable layer lines and can necessitate post-processing of a smoother look.

- The heat resistance is less unless high temperature special filaments or resins are involved.

- In 3D printing, there are less options of materials that can be used based on their biocompatibility and regulatory certifications.

- The mechanical properties depend extremely upon the printing technology (SLA, SLS, FDM, etc.) and material employed, however, generally, injection molded components will perform better than printed components in structural applications.

Injection molding is still the choice to go with parts of automotive grade when the strength and durability is paramount whereas 3D printing is used in prototyping, small volumes and highly complex shapes when material constraints are not critical.

Which Process Is Faster for Automotive Prototyping and Production?

Time is money in the automotive world. Getting parts quickly can mean the difference between hitting a deadline or missing it.

3D printing is much faster for prototyping and small runs, while injection molding is faster for mass production once the mold is ready.

When designing a new product, we needed prototypes fast. 3D printing enabled us to go from CAD file to physical part in a day. No more delayed molds, no more long set-ups. But as soon as they had to produce thousands of parts, injection moulding entered. Once the mould had been designed, we could produce hundreds of parts an hour.

Here’s a breakdown of the time factors:

Time Comparison Table

| Stage | 3D Printing | Injection Molding |

|---|---|---|

| Setup Time | Minutes to hours | Weeks (for mold making) |

| Production Speed | Slow (one at a time) | Very fast (many per hour) |

| Iteration Speed | Very fast | Slow (new mold needed) |

| Best For | Prototyping, custom parts | High-volume production |

If you need a part tomorrow, 3D printing is your friend. If you need 10,000 parts next month, injection molding will get you there.

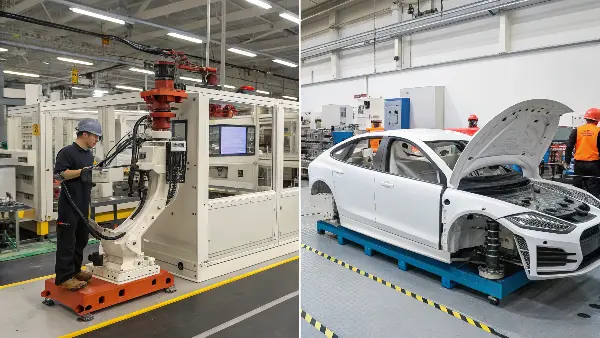

What Are the Main Applications of Each Method in the Automotive Industry?

Both 3D printing and injection molding have found their place in automotive manufacturing, but they serve different needs.

3D printing is mainly used for prototyping, custom tools, and low-volume specialty parts, while injection molding is used for mass production of functional components and exterior parts.

In my experience, 3D printing excels when you want to prototype a new design, create a custom jig, or produce a body part that’s exclusive to a given vehicle. It’s also excellent for producing aftermarkets for older vehicles where molds are no longer available. Injection molding, meanwhile, anchors mass production. It’s employed for anything from dashboards to door handles to under-the-hood items.

Here’s a summary of typical applications:

Automotive Applications Table

| Method | Typical Uses |

|---|---|

| 3D Printing | Prototypes, custom tools, low-volume parts, legacy parts |

| Injection Molding | High-volume parts, structural components, interior and exterior trim |

If you’re working on a new model or need to test fit and function, 3D printing is invaluable. But when it’s time to ramp up production, injection molding is the industry standard.

Conclusion

The decision between 3D printing and injection molding for the automotive business will rest with your needs for speed, quality, and cost. 3D printing excels at prototypes, as well as for low-volume production, whereas injection molding has no equal for high-volume production with high quality. It will benefit you to know this so that you select correctly with your next project.