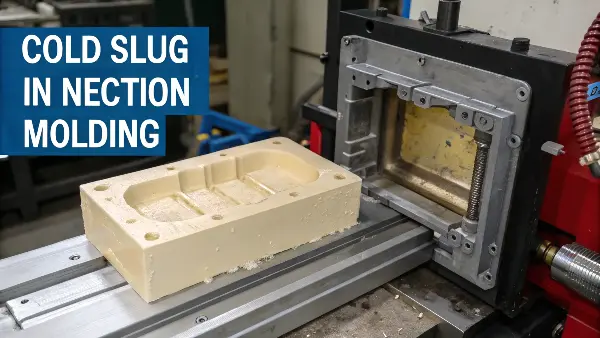

Getting defects on your molded components, it’s a headache, at least if you’re not sure why they’re happening. Cold slug is a typical suspect—a piece of hardened plastic that gets stuck in your mold cavity and ruins your finish. Cold slugs, if they’re not stopped, will cost you time, material, as well as money, in rework or scrap.

Cold slug in injection moldings occurs when plastic melt cools and freezes too soon in the nozzle or runner system prior to reaching the mold cavity. This hardened material, if not addressed, will trickle its way into the part, generating discernible flaws or areas of weakness.

If you’ve ever wondered why your parts have unexpected blemishes or why some cycles seem to produce more rejects than others, understanding cold slugs is key. Let’s break down what cold slugs are, why they matter, and how you can prevent them from affecting your production.

What is the purpose of the cold slug in injection molding?

I was initially puzzled by the term "cold slug" during my initial days at work in mold designing. It seemed like a term for a fault, but as it happened, it was actually a purpose it fulfills during the process. It’s not a mere flaw, but it’s a design feature that helps enhance the quality of a part.

The function of a cold slug during injection moulding is to encapsulate and isolate that initial piece of plastic that hardens and freezes at that nozzle tip, which otherwise would go ahead into that mould cavity and form defects in the final product.

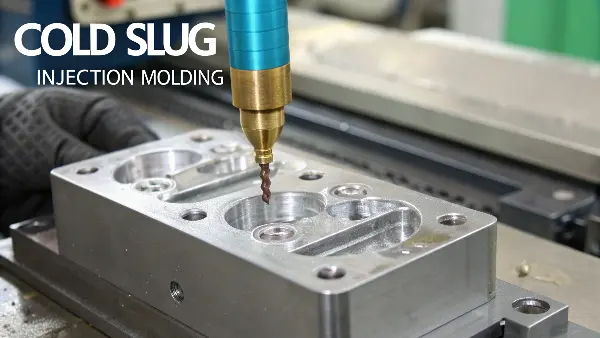

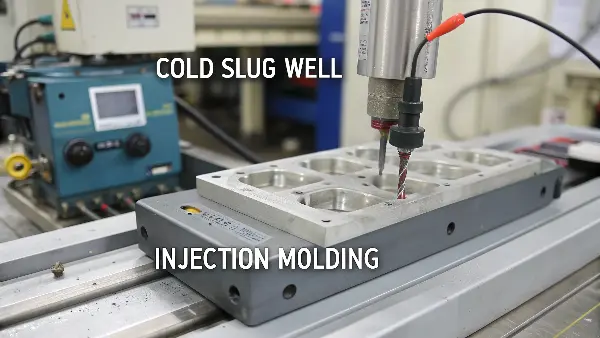

Why do we need a cold slug well?

Cold slug well is a small chamber on the runner end, opposite the gate. It holds back the cold slug—the hardened plastic that gathers at the nose of the nozzle between cycles. Should this cold material enter the cavity, it could create flow marks, thin spots, or incomplete fill. With a cold slug well, I guarantee that the cavity gets only hot, fully molten plastic. This simple feature can make a significant difference in surfacing finish as well as structural integrity.

| Feature | Purpose | Result if Missing |

|---|---|---|

| Cold Slug Well | Traps cold plastic from nozzle | Defects, flow marks |

| Proper Runner Size | Ensures smooth flow, reduces cooling | Incomplete fill, cold slugs |

| Gate Design | Controls entry of plastic into cavity | Poor surface, short shots |

I always pay close attention to the design of the runner and cold slug well. Even a small oversight can lead to recurring quality issues. If you’re seeing random defects, check if your mold has an effective cold slug well.

How to get rid of cold slugs in injection molding?

Cold slug well is a small chamber on the runner end, opposite the gate. It holds back the cold slug—the hardened plastic that gathers at the nose of the nozzle between cycles. Should this cold material enter the cavity, it could create flow marks, thin spots, or incomplete fill. With a cold slug well, I guarantee that the cavity gets only hot, fully molten plastic. This simple feature can make a significant difference in surfacing finish as well as structural integrity.

Practical steps to eliminate cold slugs

I first look at the cold slug well. It needs to be deep enough and wide enough to accommodate hardened plastic. If it is narrow, there is a chance that cold slugs will escape to the cavity. Secondly, I look at nozzle temperature. If it gets too cold, plastic will freeze before it reaches the runner. Be sure that this temperature stays as outlined for material.

At other times, the issue lies with the runner system itself. Abrupt corners or abrupt changes in direction will slow up the melt or freeze it prematurely. I re-engineer runners with gradual transition areas and steady cross-sections. Maintenance during regular intervals is also crucial. Build-up at nozzles or runners will narrow down flows and form cold areas.

| Solution | Action Taken | Expected Result |

|---|---|---|

| Cold Slug Well Design | Increase size, optimize location | Traps cold slugs effectively |

| Nozzle Temperature | Adjust to material specs | Prevents premature cooling |

| Runner System | Smooth, consistent design | Reduces cold spots |

| Maintenance | Clean nozzle and runners regularly | Prevents build-up, blockages |

By following these steps, I’ve seen a significant reduction in cold slug-related defects. It’s a combination of good design, proper settings, and regular upkeep.

How do Nozzle Temperature Settings Prevent Cold Slugs in Injection Molding?

The nozzle temperature conditions in injection molding are very important in avoiding cold slugs, which are hardened portions of plastic that may create flaws in the molded components. This can be prevented by proper nozzle temperature regulation in the following way:

1. Secures Uninterrupted Melt.

The molten plastic is maintained at a constant and fully-molten temperature when the nozzle temperature is controlled appropriately, and the molten plastic is flowing through the barrel to infiltrate the mold cavity.

When the nozzle is too cold, the melt may start to solidify at the tip of the nozzle and form a cold slug that flows into the mold and leaves blemishes on the surface or weak points on the part.

2. Staves off Premature Cooling at the Gate.

The nozzle is the last contact point where plastic gets inside the mold. The dropped molten plastic (or drooling) can be avoided by keeping the temperature slightly lower than that of the barrel, though (without being too low), enough to achieve a smooth transition between melting and not melting.

The balance should be good to make sure that the melt does not solidify too soon and seal up the gate or the runner.

3. Minimizes Temp. Gradients.

An evenly heated nozzle leads to the elimination of variations in temperature between the barrel and the nozzle. Changes in temperature may result in the failure to fill or a cold slug when the temperature drops suddenly, and may cause degradation of materials or stringiness when the temperature is too high.

4. Helps in the Consistency of Cycles.

A constant nozzle temperature is conducive to maintaining a constant flow behavior. Cold slugs normally appear when the machine starts or after a machine has been stopped and the nozzle becomes cold. PID temperature control Nozzle heaters can greatly reduce this risk, and can also be used to make sure every shot starts with the melt at the correct flow temperature.

5. Collaborates with Cold Slug Well Design.

A cold slug well to the runner system is usually incorporated with the best nozzle temperature to collect any small cold material that may occur during the injection start-up. Proper nozzle temperature controls minimise the amount of such material, which improves the efficiency of the mould and the quality of the part.

The proper temperature of the nozzle, neither too high nor too low, will help ensure the establishment of a completely molten and stable flow of polymer to the mold, thereby avoiding the development of cold slugs and enhancing the quality and consistency of the part’s surface.

What are the marks of a cold slug?

When you examine molded pieces, there are a few surefire clues that will indicate cold slug issues. They are generally simple to find once you know where to look.

The characteristic of a cold slug in injection molding are minute, hard spots or striations on a part’s surface, usually near or at a gate or along a flow. They will often manifest as dull, stained, or rough areas that are different from the remainder of the piece.

How to identify cold slug defects

Cold slug marks usually show up as tiny, round blemishes or streaks. They can be harder than the surrounding material and may even cause weak points if they’re large enough. I often find them near the gate, where the first material enters the cavity. Sometimes, they look like flow lines or weld lines, but they feel different to the touch—harder and sometimes raised.

Here’s a quick guide to identifying cold slug marks:

| Mark Type | Location | Appearance | Texture |

|---|---|---|---|

| Spot | Near gate/flow path | Dull, discolored, raised | Hard, rough |

| Streak | Along flow lines | Thin, uneven, shiny/dull | Hard, sometimes brittle |

| Patch | Random areas | Irregular, rough | Harder than part |

If I see these marks, I check the cold slug well and runner design first. Sometimes, adjusting the process parameters can help, but often it’s a design issue that needs fixing.

Why is Nozzle Design Crucial in Preventing Cold Slugs?

The design of the nozzles plays a vital role in avoiding the occurrence of cold slugs since its design will be of direct impact on the way the molten plastic will flow out of the barrel into the mold. A properly designed nozzle makes the melt flow smooth and consistent without premature cooling or material hang-up either can cause cold slug formation.

The following describes how nozzle design is an important consideration:

1. Controls Heat Retention and Melt Flow Path.

A well-developed nozzle has equalized temperatures and smooth flow paths thus limiting the possibility of an acute corner or dead area where plastic may be held back to cool.

This can occur if the flow path is not uniform or the nozzle tip design is unsatisfactory, molten resin can partially cure before flowing into the mold – creating a cold slug which would be trapped in the part or the runner.

2. Stops Radiation of heat at Nozzle Tip.

Contact between the sprue bushing and the nozzle tip is what defines the amount of heat that is retained or lost during injection.

The nozzle tip is stream lined and perfectly sealed to avoid loss of heat at the interface.

A bad seal or air holes will result in fast cooling of the melt in the area around the nozzle exit and a cold plug of material can be formed in between shots.

A heated nozzle tip that is precisely regulated as to temperature also helps in avoiding such cooling.

3. Allows correct Shut-Off and Flow Control.

Some types of nozzle, like a shut-off or a valve, will have some form of mechanism that will not allow drooling or back flow of molten plastic between cycles.

These designs maintain the melt in the heated area lessening exposure to the ambient temperature and eliminating the possibility of cold slugs being introduced into the next shot.

4. Reduces Dead Spots and Flow Restrictions.

Smooth internal endowment and smooth tapers of nozzles enhance laminar flow and material hang-up is minimized.

The sudden appearance or disappearance of dead spots or changes in the diameter leads to resin remaining and cured in patches, which may be transferred into the mold cavity as semi-solid lumps as they cool.

5. Involvement in Cold Slug Well and Sprue Design.

The design of the nozzle should complement the cold slug and sprue entry well in the mold. An incorrect nozzle to sprue alignment or a difference in diameter may establish a turbulence or heat loss.

Molten plastic flows freely with little cooling when both the nozzle and the sprue is well matched, therefore, no slugs of cold material are formed.

The nozzle design is well engineered so that temperature is smooth, there are no dead zones and the resin is always molten thus not cooling too fast. It is a very effective eliminator of cold slugs when used with advanced temperature control and the correct design of the mold, and it is also used to increase the quality of molded parts.

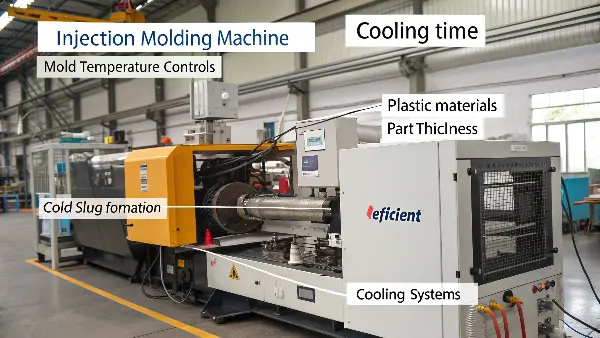

What factors affect the cooling time in injection molding?

While addressing cold slug problems, castings’ cooling time also comes into consideration. Cooling time impacts how fast metal will solidify, which may contribute to cold slug development.

Factors affecting injection mould cooling time are mould temperature, plastic, part thickness, as well as a cooling system’s efficiency. Cooling time will be accelerated at a risk of a greater danger of a cold slug if not appropriately controlled.

Breaking down the cooling time factors

One of the key variables in injection molding is cooling time. It gets too fast if the mold gets too chilly, which will boost the risk of cold slugs. It gets too slow if it gets too warm, which causes cycle times to extend as a result of a decrease in productivity. I always compensate for both factors to obtain optimal results.

Material type matters a lot. Some plastics cool faster than others. For example, polypropylene cools slower than ABS. Part thickness is another big factor. Thicker parts take longer to cool, so I adjust the cooling system accordingly.

The cooling system itself must be efficient. I check for proper water flow, clean channels, and even temperature distribution. If any part of the mold is cooler than the rest, it can create cold spots where slugs form.

| Factor | Effect on Cooling Time | Impact on Cold Slug Formation |

|---|---|---|

| Mold Temperature | Higher temp = longer cooling | Too low = more cold slugs |

| Material Type | Some cool faster/slower | Fast-cooling = higher risk |

| Part Thickness | Thicker = longer cooling | Thin parts = faster, more slugs |

| Cooling System | Efficient = even cooling | Poor system = cold spots |

By understanding and controlling these factors, I can minimize cold slug problems and improve part quality.

Conclusion

Cold slugs during injection moulding occur as a result of early solidification of plastic in the nozzle or runner. By knowing its role, its markings, as well as mould design optimisation and operating parameter optimisation, I may minimise defects and enhance product quality. Proper attention to cooling time coupled with regular maintenance helps maintain cold slug control.