Twin-shot moulding has been a real game-changer in how we make plastic parts. Many consumers really desire aesthetically pleasing products with excellent functionality. These usually come at the cost of more operations or higher costs when creating parts using varied colors or materials. Twin shot moulding solves this problem by letting us use two plastics in one process.

Twin-shot moulding, otherwise known as two-shot or multi-shot injection molding, involves the process of injecting two different plastic materials into a single mold in two stages. It makes parts with multiple colors or materials without extra assembly steps.

If you want to know how this works and why it matters, keep reading. I will explain the basics, compare it to other methods, and show you how it can help your projects.

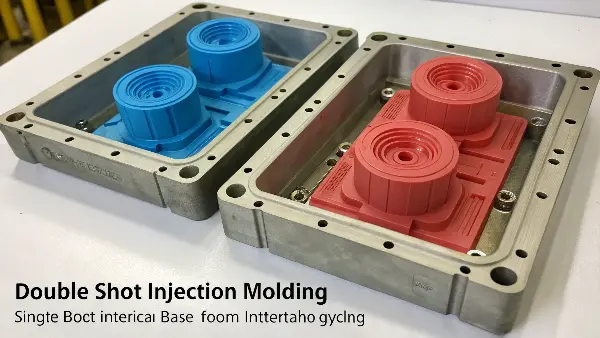

What is double shot injection molding?

Double-shot injection molding is the process that enables us to make parts from two different plastics in one cycle. This helps many designers who find it difficult to combine materials or colors without extra work. Double-shot molding will make this easier and faster.

Double shot injection molding refers to the process of injecting two different plastics into a mold in two steps: The first material forms the base, and the second material is injected onto or around the first, creating a single finished part with two materials or colors.

Let’s look deeper at how double shot injection molding works. First, the mold is designed with two cavities or sections. The first plastic is injected into the mold to form the base shape. Then, the mold rotates or shifts, and the second plastic is injected onto the first. This creates a strong bond between the two materials. The process is fully automated, so there is no need to handle or assemble the parts by hand.

Here’s a simple table to show the steps:

| Step | Action | Result |

|---|---|---|

| 1 | Inject first plastic | Forms base part |

| 2 | Rotate or shift mold | Prepares for second injection |

| 3 | Inject second plastic | Bonds to first, adds features |

| 4 | Eject finished part | Complete, two-material product |

This process is great for making products like toothbrushes (with soft grips), buttons, or any part that needs two colors or materials. It saves time and reduces mistakes because everything happens in one mold.

Advantages and disadvantages of two-shot molding

Improved Product Quality

Two-shot injection molding is used to create components having outstanding bond between two materials. The bond is strong and consistent because both materials are moulded in the same cycle, eliminating such problems as delamination or weak joints.

Cost and Time Efficiency

The early molding structure is complicated, but the two-shots molding process eliminates the secondary assembly work, glues, or manual labor. This results in quicker production cycles and reduced total manufacturing costs when doing high volume production.

Increased Flexibility in Design.

This enables production of sophisticated designs through the combination of hard and soft plastics, various colors, or various material properties into one molded section. It is perfect to use with ergonomic grips, multi-color parts, or other parts with more than one functional zone.

Harder and More Sturdy Components.

The fact that the two materials are molded together and not assembled separately results in the end product, which is stronger and resistant to stress, impact, and wear. It comes in handy especially with high-performance applications.

Better Aesthetics

The 2-shot technique allows smooth multicolor or texture designs and also does not necessitate painting or printing. This enhances aesthetics and at the same time provides a clean and even finish to the surface.

Reduced Assembly Errors

The possibility of both human and mechanical assembly mistakes is significantly reduced by using the combination of two materials in one process, leading to the high quality and accuracy of every aspect.

Two-Shot Molding Disadvantages

High Initial Investment

Two-shot molds are quite expensive to design and produce compared to single-shot ones. The needed machinery is also more costly and advanced, this way is less appropriate when the production volume is low.

Multifaceted Form Design and Installation.

In two-shot molding, accuracy of the alignment of the mold, compatibility of the material, and control of the process is vital. Any fault in these factors may lead to improper bonding, flaws, or contamination of materials.

Lack of Material Compatibility.

Not every plastic can bond successfully with every other. The choice of material to use in both shots is very critical since the final product can either be poorly adhesive or the entire product will fail when it is put into use.

Longer Development Time

The first design stage may be more time-intensive than the traditional molding processes because of the complexity of its design, testing, and validation.

Equipment Limitations

Two-shot operations can only be done with particular injection molding machines. Those manufacturers who do not have compatible machines have to invest in new equipment, which makes it more expensive in the initial cost and less flexible.

What is dual molding?

Dual molding is also known as using two materials in one part. The term gets confusing for many, but dual molding, twin shot, and double shot mean about the same thing.

Dual molding refers to the molding of two different materials together in one operation, with the result of combining properties into one part like color, texture, or hardness.

Now, let’s break down what makes dual molding special: the main idea behind it is to merge the best features of two materials. For example, you might want a hard plastic for strength, a soft rubber for grip. Dual molding lets you do this in one step. A special mold and a machine with two injection units is used in this process. The first material is injected, then the second is added while the first is still in place, creating a strong bond between the two.

Here’s a table showing some common uses:

| Product Example | Material 1 (Base) | Material 2 (Overlay) | Benefit |

|---|---|---|---|

| Toothbrush handle | Hard plastic | Soft rubber | Comfort grip, strong core |

| Power tool housing | Rigid plastic | TPE (rubber) | Shock absorption, durability |

| Buttons | Colored plastic | Clear plastic | Visual effect, tactile feel |

Dual molding is popular in consumer electronics, automotive parts, and medical devices. It helps designers create parts that look better and work better, all in one process.

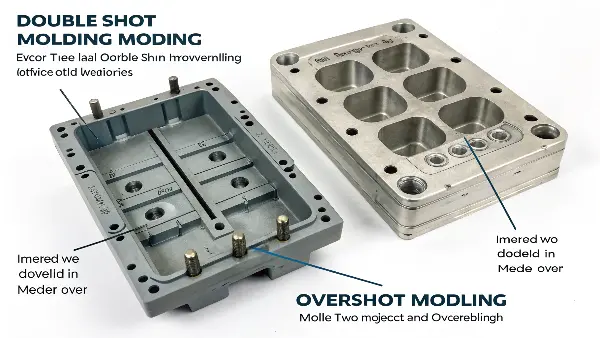

What is the difference between double shot and overmold?

Most people confuse double-shot molding with overmolding, but even though both methods deploy two materials, the process and results differ. Knowing the difference will help you in choosing the right method for your project.

Doubleshot molding: Two materials are injected into a single mold in two steps, creating a single part in one cycle. Overmolding: One material is molded over another pre-made part, often in different steps or molds.

Let’s compare the two methods:

| Feature | Double Shot Molding | Overmolding |

|---|---|---|

| Number of steps | One cycle, two shots | Two or more cycles |

| Mold type | Special two-shot mold | Standard mold, may need two molds |

| Part handling | No manual handling | May require manual placement |

| Bond strength | Strong chemical bond | Good, but sometimes weaker |

| Speed | Faster, more automated | Slower, more manual |

| Example | Toothbrush, buttons | Tool grips, phone cases |

Double shot molding is best when you want high precision and strong bonds between materials. Overmolding is useful when you need to add a soft layer to an existing part or when the base part is made elsewhere.

Advantages and disadvantages of overmolding

Increased Product Capability.

You can use overmolding to mix two or more materials of varying properties to enhance the performance of a product. An example would be a very strong plastic base that has a soft rubber coating to enhance grip, comfort or to absorb impact.

Strong Material Bonding

Since the second material is molded right around the first one, a chemical or mechanical bond is created between the two. This will remove the use of adhesives or fixing agents and will also provide durability.

Better Ergonomics

Soft-touch surfaces made through overmolding enhance the ease for users and decrease the fatigue on the hands of the users such as tools, handles, or consumer items. It also improves safety in form of non-slip and cushions surfaces.

Improved Aesthetic Appeal

Overmolding has an appealing smooth finish. It enables designers to combine various color, texture or surface designs in a single process, providing the products with high quality, professional appearance without any extra painting or coating.

Less Assembly Time and Cost.

Owing to the fact that overmolding combines two or more materials into a single finished component, it removes the secondary production processes such as gluing or assembling. This accelerates the process of production and lowers the usage of labor and materials in large-volume production.

Shock Absorption and Vibration.

Vibration and impact can also be absorbed by the use of soft elastomer layers that are added using overmolding which protect sensitive components in electronic devices, medical tools and automotive parts.

Overmolding Disadvantages

Expensive Starting Tooling and Equipment.

The cost of designing and production of molds to be overmolded is higher than normal molding. It is usually costly in terms of specialized molds and machines, and is therefore not economical in quantities of production.

Complex Process Control

In overmolding, there is a need to have a strict control of temperature, pressure and to have time so that there can be a good bonding. Any variation of these parameters would result in defects including bad adhesion, warping or incomplete encapsulation.

Poor Material Compatibility.

All materials do not bond well in overmolding. In order to achieve compatibility between the chemicals and thermal conditions of the base and overmold materials, careful choice is necessary. As an example, thermoplastic elastomers cannot bond well with some hard plastics.

Longer Production Cycle

This is a multistage process; it would require molding, cooling and after that, overmolding, and this may take more time than single-shot molding.

Potential for Defects

Unless the mold design or material flow is optimized, it may cause such problems as delamination, voids, or flash. These flaws impact on the appearance and functionality of the product.

Challenging Repair or Recycling.

When two materials have been bonded, it becomes hard to separate and use them again or recycle. This may add wastes or make it difficult to end-of-life recycle products.

Choosing between two-shot molding and overmolding

Deciding between two-shot molding and overmolding depends on factors such as your product design, production volume, material requirements, and cost considerations. Both these techniques combine multiple materials in one part; however, the processes used and the outcomes can be quite different from each other.

1. Difference in Process

In two-shot molding, one machine injects two materials in separate stages in a single, continuous molding cycle. The first material forms the base, and the second is injected directly onto it while still in the mold.

Overmolding, on the other hand, usually entails two separate molding processes: creating a base part, cooling it, and placing it into another mold for the second material to be applied.

In other words, two-shot molding is integrated and automated, whereas overmolding is semi-sequential, possibly involving manual handling between steps.

2. Production Volume and Cost

Two-shot molding is best suited for high-volume production where the initial tooling investment can be justified. In exchange, once the mold is ready, parts are produced faster with fewer assembly steps and also with consistent quality.

Overmolding is more cost-effective in low to medium production runs, where flexibility is needed or when only minor design variations are required without investment in complex dual-shot molds.

For long-term cost savings on large batches, two-shot molding is usually the better option.

3. Material Compatibility

Two-shot molding requires that materials bond chemically or thermally within the same cycle, so material choices are more limited.

Overmolding provides more latitude because it allows for a broader range of materials, including those combinations that would not fuse in a single shot, since the second shot can depend on mechanical adhesion instead of chemical bonding.

Choose two-shot molding for the stronger integrated bond, overmolding for greater material versatility.

4. Design Complexity

Two-shot molding is really best for high-precision parts featuring complex geometries, tight tolerances, and smooth transitions between materials.

Overmolding is effective in less complicated designs, such as the addition of a soft-touch grip or protective coating over an existing plastic, metal, or electronic substrate.

Overmolding provides more freedom and lower risk if design aesthetics, texture, or comfort is key.

5. Product Application

Use two-shot molding when integrated multi-material functionality is needed for various products, such as automotive switches, electronic housings, and medical components.

Use overmolding for consumer goods, hand tools, or any application where ergonomics and surface finish are more important than production speed.

If your project requires precision, speed, and high output, the process of two-shot molding yields much better efficiency and product integrity. However, for design flexibility, lower tooling cost, and softer material integration, overmolding is more practical.

For many manufacturers, the final choice is more often based on a balance between cost, complexity, and production scale, and is dependent on long-term volume manufacturing using two-shot molding, while overmolding is preferred for versatile, small production runs.

What is double shot injection?

Another term for twin shot or double shot molding is double shot injection. Many people refer to these terms as the same thing, but it’s important to know how the process works and why it’s useful.

Double-shot injection refers to the process of injecting two different plastics in a mold in two stages, resulting in one part with two materials or colors in just one cycle.

Let’s look at why double shot injection is so popular. The main reason is efficiency. By combining two materials in one mold, you save time and reduce costs. There is no need for extra assembly or gluing. The parts come out of the mold ready to use. This process also allows for more creative designs. You can use different colors, textures, or even transparent and opaque plastics together.

Here’s a table showing the main benefits:

| Benefit | Description |

|---|---|

| Cost savings | Fewer steps, less labor |

| Better quality | Stronger bonds, fewer defects |

| Design flexibility | More colors, materials, and shapes possible |

| Faster production | Parts finished in one cycle |

| Improved appearance | Clean lines, no visible seams |

Double shot injection is used in many industries, from electronics to automotive to medical devices. It helps companies make better products, faster.

Conclusion

Twin-shot moulding, otherwise called double shot or dual moulding, is a very powerful process that enables us to combine two plastics in one step. It saves time, cuts costs, and opens up new design options. By understanding the differences between twin shot, overmolding, and other methods, you can choose the best process for your next project.