Do inconsistent quality of plastic parts, frustratingly long cycle times, and material waste eating into your profitability sound all too familiar? These common injection molding problems can stall your production and damage your hard-won reputation. It seems like you’re always fighting the machine to get the results that you need. The key to all this lies in the mastery of one of the most critical variables in the whole process: mold temperature.

Advanced temperature controller system technologies are systems that dynamically heat and cool the mold during the injection molding cycle. Such systems include Variotherm control, conformal cooling, and induction heating, all moving beyond simple steady-state temperatures to provide for very precise thermal management, tailored to a specific plastic material and part geometry. It is this kind of control which is important in optimizing plastic flow, eliminating certain defects such as weld lines and sink marks, reducing cycle times, and achieving superior surface finishes and dimensional accuracy in the finished product.

Understanding precisely how these technologies work is the first step toward unlocking their full potential. For business owners like Michael, who rely on efficiency and quality, getting a grip on these systems isn’t just about technical knowledge—it’s about gaining a serious competitive advantage. Let’s break down the most impactful technologies one by one, so you can see how they can transform your manufacturing operations.

The Effect of Mold Temperature in Injection Molding

One of the most important factors influencing the final strength, quality, and appearance of injection-molded parts is mold temperature. The way molten plastic flows, cools, and hardens can be drastically altered by even little variations in mold temperature. A low mold temperature causes the material to cool and solidify too quickly, which frequently results in weld lines, visible flow marks, poor surface polish, and inadequate filling—particularly in parts with intricate geometry or thin walls. Internal pressures brought on by low temperatures can also make a part more brittle and more likely to warpage or break over time.

Conversely, a higher mold temperature enhances flow behavior and lowers the possibility of flaws like short shots or surface blemishes by allowing the plastic to remain molten for a longer period of time. Additionally, higher temperatures aid in the appropriate orientation of the polymer chains, improving dimensional stability and strengthening the link between layers. For technical polymers like ABS, PC, and nylon, which need higher mold temperatures to attain ideal mechanical characteristics, this is particularly important. Setting the mold temperature too high, however, can lengthen the cycle time, result in excessive shrinkage, or cause problems like flash if the mold isn’t clamped tightly enough.

In the end, the material being used and the particular requirements of the part determine the optimal mold temperature. Manufacturers may reduce faults and manufacturing costs while producing parts with better strength, stability, and surface quality by maintaining the proper temperature range and guaranteeing uniformity across all molds.

What is Variotherm Mold Temperature Control and How Does It Work?

Is it all but impossible to make parts with a perfect, high-luster surface along with precision structural integrity? All too often, the temperature required for an ideal finish is far too high for rapid, efficient cycling, forcing you to make a painful compromise. This can result in defects and a trade-off between aesthetics and performance. Variotherm technology offers a powerful solution to this challenge.

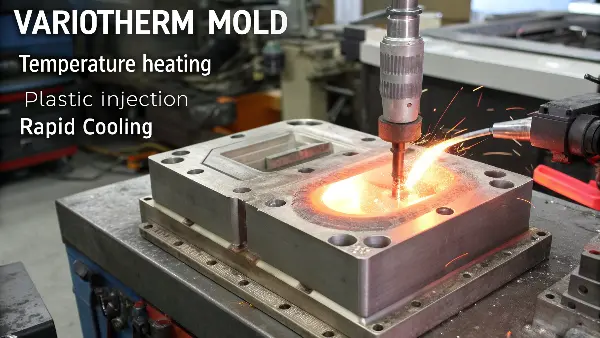

Variothermal mold temperature control, also referred to as dynamic mold temperature control, involves a process in which the mold surface temperature is changed rapidly during a single molding cycle. Just before the plastic is injected, the mold is heated to a high temperature at which the melt can easily flow and perfectly replicate the cavity surface. Immediately after filling the mold, it undergoes rapid cooling to solidify the part quickly for its ejection. This technique eliminates the compromise between surface quality and cycle time.

To truly grasp Variotherm control, you need to understand its phases. I’ve seen this technology completely change the game for clients manufacturing consumer electronics, where a flawless look and feel are non-negotiable. Instead of maintaining a single, compromised temperature, we strategically manipulate it.

The Variotherm Cycle Breakdown

This normally consists of two main stages within a single molding cycle: the heating phase and the rapid cooling. The mold surface is heated to above the material’s glass transition temperature just before the plastic melt reaches the cavity. This ensures that the plastic is in the flow state just like water, filling all the minute details without flow marks or visible weld lines. The stage is followed by quick cooling: once the cavity is filled, a cooling medium is flushed through the channels to bring the temperature down swiftly. This "freezes" the part in its perfect state and solidifies it for quick ejection, keeping the overall cycle time low.

Heating and Cooling Methods

Different systems achieve this rapid temperature change. Some of the most common methods are:

| Method | Description | Best For |

|---|---|---|

| High-Pressure Water | Pressurized hot water is used to heat the mold, followed by chilled water for cooling. It’s a very common and effective method. | General-purpose applications, complex geometries. |

| Steam Heating | Uses steam for rapid heating, followed by water for cooling. It provides very fast heating rates. | High-gloss finishes, thin-walled parts. |

| Induction Heating | An electromagnetic field heats the mold surface directly. It offers extremely fast and localized heating. | Premium surface finishes, micro-features. |

From my experience, the choice of method depends heavily on the part requirements and budget. For a client producing glossy casings for home appliances, we implemented a steam heating system and the difference was night and day. We eliminated surface defects and cut the cycle time by almost 20%.

Determining the Correct Mold Temperature

Understanding the material you’re molding, the part’s design, and the performance you anticipate from the finished product are all important factors in determining the ideal mold temperature. Every polymer, including PET, PC, ABS, PP, and nylon, has a processing window that includes a suggested mold-temperature range. Since the mold temperature directly influences how the material flows, fills the cavity, and cools, manufacturers typically begin with these parameters. After establishing this baseline, molders adjust the temperature according to the particular geometry of the part. For instance, a slightly higher mold temperature is sometimes needed for thin-wall or highly complex items in order to enhance flow and prevent problems like weld lines or short shots. In contrast, thicker parts might perform better at moderate temperatures to avoid needless increases in cycle time.

The desired surface quality is another consideration when choosing the ideal temperature. A warmer mold aids in the polymer surface’s more exact replication of the mold’s texture if the part requires a glossy, smooth finish—common in consumer goods and car trims. A lower mold temperature could be appropriate for items that merely need to be functional and not aesthetically pleasing. Lastly, molders do brief production tests, gradually changing the temperature and tracking variations in warpage, shrinkage, strength, and visible flaws. Without sacrificing cycle time or production efficiency, this useful, real-world tuning is frequently the most dependable method of determining the optimal temperature, guaranteeing that the process remains stable and the items satisfy quality criteria.

How Does Conformal Cooling Optimize the Molding Process?

Are you constantly fighting part warpage, sink marks, and far-too-long cycle times? The causes of these problems usually relate to one major culprit: inefficient and uneven cooling. Traditional cooling channels, drilled in straight lines, just cannot cool complex part geometries uniformly. This costs you time, money, and quality-a frustration I know many business owners share.

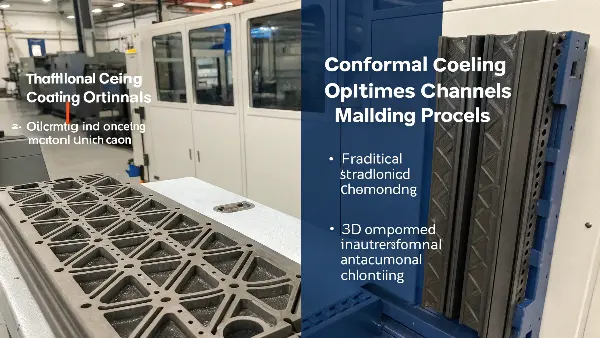

Conformal cooling is an optimization in the molding process wherein cooling channels are created to take the exact shape or "conform" to the geometry of a part. Unlike standard straight-drilled channels, these complex channels are typically made with 3D metal printing (DMLS). This allows the cooling fluid to circulate much closer to the mold surface and provides a highly uniform and significantly faster cooling. The outcome is reduced cycle times, minimized part warpage and stress, and superior overall part quality.

The concept of conformal cooling might sound complex, but its impact is very direct and powerful. Think of it like a custom-tailored suit versus one bought off the rack. A standard cooling layout is a one-size-fits-all approach that rarely fits complex parts perfectly. Conformal cooling, on the other hand, is designed for a perfect fit, targeting heat exactly where it needs to be removed.

The Strategic Advantage of Uniform Cooling

The biggest advantage is consistency. In a mold with conventional cooling, sections like thin walls cool at a rate much faster than thick areas or corners. This temperature variation creates internal stress as the part cools and solidifies, and is a direct contributor to warpage and sink marks. I remember working on a project for an automotive client involving a complex dashboard component; we had warpage issues for weeks with a conventional mold. Once we remade the core and cavity with conformal cooling channels, the warpage issue was practically eliminated.

Key Performance Improvements with Conformal Cooling

The benefits extend far beyond just reducing defects. By placing cooling channels strategically, we can dramatically increase the rate of heat transfer.

| Performance Metric | Traditional Cooling | Conformal Cooling | Impact |

|---|---|---|---|

| Cycle Time | Standard | Reduced by 20-50% | Faster production, higher output. |

| Part Warpage | Common issue | Drastically reduced | Better dimensional stability and quality. |

| Cooling Uniformity | Uneven | Highly uniform | Minimized internal stress, fewer defects. |

| Design Freedom | Limited by cooling access | High | Enables more complex part geometries. |

Implementing conformal cooling is an investment, as it often requires additive manufacturing. However, for high-volume production or mission-critical parts, the ROI from reduced cycle times and lower scrap rates is often undeniable. It gives you the ability to produce parts that were once considered impossible to mold efficiently.

Why is Induction Heating a Game-Changer for Surface Quality?

Do you need a "Class A" surface finish, with no weld lines or gloss variation, directly from the mold? For many electronic, automotive, and medical products, such perfection often requires secondary operations such as painting or polishing that add considerable expense and time. This extra step adds complexity and eats into your margins, which is a constant headache for anyone focused on lean manufacturing.

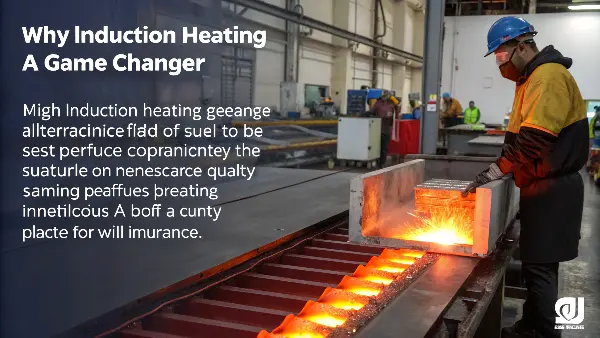

Induction heating changes everything because it allows very fast, localized heating of the mold surface immediately before injection. By passing a high-frequency alternating current through it to form an electromagnetic field, it only heats the steel surface of the cavity, while leaving the bulk of the mold cool. The result is that in mere seconds, the surface temperature goes up, allowing the plastic to flow perfectly, thereby giving a perfect, high-gloss finish. The weld lines disappear because the melt fronts merge at a much higher temperature.

The magic of induction heating lies in its speed and precision. Unlike other methods that heat the entire mold block, induction is like using a surgical laser. It focuses energy exactly where it’s needed—on the cavity surface—and does it almost instantly. This capability opens up new possibilities for part design and quality.

How Induction Delivers Flawless Surfaces and Mold Temperature in Injection Molding

When plastic melt flows into a relatively cool mold, the instant it contacts the steel, it begins to "freeze." Where two flow fronts meet, they are already partially solidified, creating a weak and often visible weld line. With induction heating, we heat the mold surface to well above the plastic’s melt temperature just milliseconds before injection. When the two flow fronts meet, they are still fully molten and can merge perfectly on a molecular level. I have used this process on high-end consumer electronic housings and find it completely eliminates the tell-tale signs of a weld line. It gives the appearance of a part carved from a single piece of polished material.

Comparing Heating Technologies for Surface Quality

Induction isn’t the only way to heat a mold, but it offers unique advantages, especially for high-end applications.

| Feature | Induction Heating | Cartridge/Water Heating | Steam Heating |

|---|---|---|---|

| Heating Speed | Extremely fast (seconds) | Slow (minutes) | Fast (seconds to minutes) |

| Energy Efficiency | Very high | Low to moderate | Moderate |

| Heating Zone | Highly localized (surface only) | Heats entire mold block | Heats entire mold block |

| Best Application | Eliminating weld lines, high-gloss, micro-textures | General-purpose temperature maintenance | High-gloss finishes |

While the initial setup for induction heating can be more complex, the payback in eliminating post-processing steps can be massive. For any business owner like Michael looking to produce premium products efficiently, induction heating is a technology that should be on their radar. It turns the mold itself into the final finishing tool.

Can High-Pressure Water Systems Offer Precise Temperature Control?

Are you in need of a robust and reliable method to execute dynamic temperature control without the extreme complexity or cost of systems like induction heating? Many manufacturers feel they’re stuck between basic, steady-state temperature control and highly advanced, niche technologies. They need a workhorse solution that offers precision, speed, and versatility across a broad range of applications.

High-pressure water systems indeed provide very effective and accurate temperature control in injection molding. These are also commonly known as PWUs, or pressurized water units, and they utilize water heated under pressure to achieve temperatures well beyond normal water boiling points-up to 180°C or 356°F. By rapidly switching between circuits of high-temperature water for heating and chilled water for cooling, they can execute a Variotherm process with very good responsiveness and uniformity, thus becoming versatile and popular.

I’ve relied on high-pressure water systems for countless projects over the years. They represent a fantastic balance of performance, cost, and reliability. Their power comes from a simple principle of physics: water under pressure has a higher boiling point. This allows us to use water—an excellent, safe, and inexpensive thermal transfer fluid—to achieve the high molding temperatures needed for many engineering-grade plastics.

The Mechanism of Pressurized Water Control

It is a rather straightforward setup: a self-contained unit heats water in a pressurized and control circuits. This superheated water is pumped through the mold’s cooling channels to bring the cavity surface up to the target temperature before injection. Immediately upon filling of the part, the system’s valves rapidly switch over, flushing out the hot water and pumping chilled water from a second circuit through the very same channels. This rapid switch allows for rapid cooling to take place that will solidify the part and minimize cycle time. We can achieve control so fine that we can program certain temperature profiles at various stages of the molding process.

Advantages of Using High-Pressure Water

This method has become an industry standard for good reason. It combines the benefits of dynamic heating with practicality.

- High Thermal Efficiency: Water has a high specific heat capacity, meaning it can carry a lot of thermal energy. This makes it very efficient for both heating and cooling the mold steel.

- Uniformity: Because the water flows through the entire network of cooling channels, it provides very even heating and cooling across the mold surface, which is crucial for preventing warpage and internal stress.

- Versatility: This technology works well with a wide variety of molds and materials, from standard commodity plastics to more demanding engineering polymers that require higher processing temperatures.

- Cost-Effectiveness: Compared to more exotic technologies like induction, the initial investment and operating costs for high-pressure water systems are often much lower, offering a faster return on investment.

For a client producing thick-walled polycarbonate lenses, we used a PWU to manage the long hold times and prevent sink marks. The ability to keep the mold hot during injection and then cool it efficiently was key to achieving a crystal-clear, dimensionally stable part.

Conclusion

In other words, advanced temperature controller system is no longer a nice-to-have-it is a must-have for companies willing to remain competitive in injection molding. Technologies like Variotherm control, conformal cooling, induction heating, and high-pressure water systems provide the precision that allows processors to overcome long-standing challenges. On top of part quality improvements, mastering mold temperature will slash cycle times and unlock new levels of efficiency and profitability. It’s an investment in getting the process right from the start.