Do you have a problem with quality and speed in your injection moulding process? The wrong settings of temperature, pressure or cooling may result in expensive defects, lengthy cycles and wastage of material. It is as though it is a battle all the time. The initial step towards becoming a master of your production and having consistent and high-quality results is to understand the relationship between these three important variables.

Injection molding is very much interrelated with temperature, pressure, and cooling time. Increased melt and mold temperature has a longer cooling period but may enhance flow. The injection and holding pressures are used to fill and pack the mold properly, which also determines the amount of heat required to be removed. These three factors should be optimized jointly to reduce the cycle time and avoid defects such as sink marks or warping to have an efficient and stable process.

This balance is crucial. I’ve seen many projects get delayed simply because the team didn’t fully grasp how one small adjustment could throw everything else off. It’s not just about tweaking one setting; it’s about understanding the entire system. Let’s break down how each element plays its part and how they work together to create the perfect part. Ready to dive deeper into how you can take control of your process?

How to Understand the Injection Molding Process?

Injection molding plays a central role in modern manufacturing. The process consists of a number of distinct phases, each vital in its own right for the production of precise parts.

First, the material is melted into a viscous state. It is then injected into a mold designed with high precision. That mold defines the shape and structure of the final product.

Material injection molding process involves several steps:

- Melting the raw material

- Injecting it into the mold cavity

- Holding it under pressure

- Cooling and solidification

- Ejection of finished part

Master these steps, and one can ensure efficiency and precision. Every step affects the cycle time of the whole process. The objective is to make quality parts faster, quicker, and at an efficient rate, which requires correct comprehension of the process.

What Really Determines the Cycle Time for Injection Molding?

Is your production falling behind schedule because of unexpectedly long cycle times? Every extra second on a cycle adds up, eating into your profits and delaying deliveries. It’s frustrating when you can’t pinpoint exactly what’s causing the slowdown. The key is to understand that cycle time is a sum of many stages, with cooling time very often being the most substantial part of it. Let’s break it down.

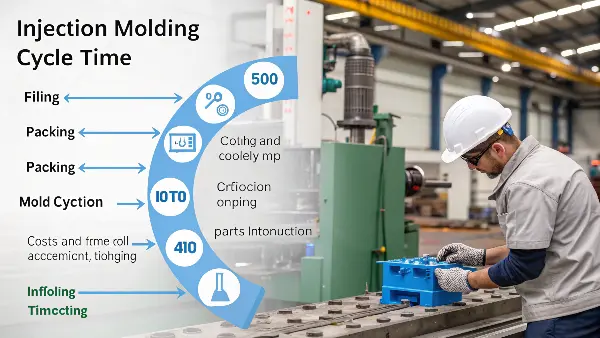

The total injection molding cycle time is the sum of its unique phases-filling, packing (or holding), cooling, and mold opening/part ejection. Whereas all phases have their importance, the time required for cooling usually is the longest and most dominant part of the cycle, often more than 50% of the total time. Hence, the factors that affect cooling, like part thickness and mold temperature, are the most influential parameters on the total cycle time.

When my clients, like Michael, look to optimize production, cycle time is the first thing we analyze. It’s the heartbeat of the manufacturing process. A shorter, consistent cycle time means higher output and lower costs per part. But speeding it up recklessly can lead to disaster. It’s a system composed of several distinct steps, each contributing to the total time. Let’s look at what’s happening inside that machine.

The Four Stages of an Injection Molding Cycle

- Filling Time: This is how long it takes for the molten plastic to fill the mold cavity. It’s usually very fast, just a few seconds. The speed here depends on injection pressure and the viscosity of the plastic, which is tied to its temperature. Faster isn’t always better; too fast can cause defects.

- Packing/Holding Time: After the cavity is filled, we apply pressure to pack more material in. This compensates for material shrinkage as it cools. This stage is critical for part accuracy and avoiding sink marks. It’s directly tied to pressure and how the material solidifies.

- Cooling Time: This is the big one, the marathon stage of the cycle. The part has to cool down enough to become solid so it can be ejected without deforming. As I mentioned, this often makes up the bulk of the cycle time.

- Mold Open/Ejection/Mold Close Time: This is the mechanical part of the cycle. The mold opens, the ejector pins push the part out, and the mold closes again for the next shot. This is usually a fixed time based on the machine’s speed.

Here is a table to put it in perspective for a typical part:

| Stage | Description | Typical % of Cycle Time | Key Influences |

|---|---|---|---|

| Filling | Injecting molten plastic into the mold. | 5-10% | Injection Pressure, Melt Temp |

| Packing | Holding pressure to compensate for shrinkage. | 10-20% | Holding Pressure, Melt Temp |

| Cooling | Solidifying the part inside the mold. | 50-70% | Part Thickness, Mold Temp |

| Ejection | Robot/mechanical time to open and close. | 10-15% | Machine Speed, Mold Design |

As you can see, cooling is where you win or lose the time game. Small improvements in filling or ejection are great, but a 10% reduction in cooling time can have a massive impact on your overall efficiency. That’s why we focus so much on the factors that control it.

The effect of injection molding temperature and pressure

The temperature plays a critical role in injection molding. It mostly influences the flow of the material. The right temperature settings make the material to melt evenly. This enables it to be used in filling the mold.

The temperature of injection molding is dependent on the type of material. The various plastics melt at varying temperatures. An example would be that polypropylene melts when it is hot as compared to polycarbonate. Hence, it is important to know the properties of the material.

Excessively high temperature may lead to degradation of the material. This causes such defects as discoloration and weakening. On the other hand, a low temperature will not allow the entire filling of the mold. This may lead to incomplete components and scrap.

Here are some important facts concerning temperature:

- The optimum temperature is determined by the material properties.

- Even melting results in easy flow and quality.

- In case the temperature is excessive, degradation will take place.

- Unfilled filling is caused by low temperatures.

- Adjustment of temperature is sensitive. They have a substantial effect on the molding process and the final product quality.

The Importance and effect of Pressure in Injection Molding

In injection molding, pressure is important for accurate part shaping; it forces the molten material into the mold cavity. There, under holding pressure, the material solidifies.

Excess pressure leads to defects such as part deformation. It can create flash problems, where the excess material leaks out. However, too little pressure creates voids or incomplete parts. It is crucial to control the pressure level to achieve quality.

Consider these pressure points:

- Provides force for material injection.

- Prevents part deformation and defects.

- Holds material in mold until it has solidified.

Optimum pressure is achieved, enabling uniformity while reducing defects. Attaining the proper pressure requires insight into how materials behave. Informed pressure management is critical to any successful injection molding.

What Factors Affect the Cooling Time in Injection Molding?

Are you finding it difficult to reduce cycle times without compromising part quality? You might lower the cooling time in the machine’s settings, only to pull out a warped or distorted part. This happens because cooling isn’t just a timer; it’s a thermal process influenced by many variables. Focusing only on the machine’s setting without understanding the root causes is a common mistake. Let’s look at what truly dictates the cooling phase.

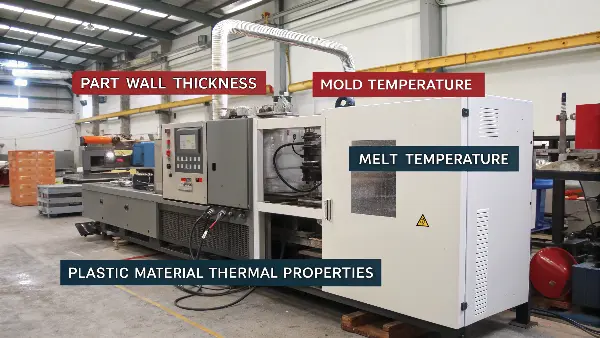

The most significant factors affecting cooling time are part wall thickness, mold temperature, melt temperature, and the plastic material’s thermal properties. Thicker walls take exponentially longer to cool. A warmer mold can improve part finish but extends cooling. A hotter melt flows better but adds more heat that must be removed. Finally, each plastic type has its own rate of heat transfer, which directly impacts how quickly it can solidify.

To truly master cooling time, you have to think like a thermal engineer. Heat must be removed from the molten plastic, through the steel of the mold, and carried away by the cooling fluid. Anything that slows this transfer of heat will extend your cycle time. When I work with a new mold design, these are the critical elements I review to predict and optimize the cooling performance.

The Core Four of Cooling

It all boils down to four main areas. If you can control these, you can control your cooling time.

- Part Design (Wall Thickness): This is the number one factor, without a doubt. The time it takes for heat to escape is related to the square of the wall thickness. This means doubling the wall thickness can quadruple the cooling time. This is why we always push for uniform wall thickness in part design. A thick boss on a thin wall will create a hot spot that dictates the cooling time for the entire part.

- Material Selection (Thermal Properties): Different plastics cool at different rates. A material’s thermal diffusivity describes how quickly it can transfer heat. For example, semi-crystalline materials like Polypropylene (PP) and Nylon (PA) have a sharp melting point and release a lot of latent heat during solidification, often requiring more cooling than amorphous materials like ABS or Polystyrene (PS). You can’t change the material’s nature, but you must account for it.

- Mold Design (Temperature Control): The mold is the heat exchanger. The efficiency of your cooling channels—their size, placement, and proximity to the part cavity—is critical. I’ve seen poorly designed molds where one side of the part cools much slower than the other, causing warpage. The mold temperature itself is a balancing act. A colder mold cools faster but can cause flow issues or poor surface finish.

- Processing Parameters (Melt Temperature): The hotter the plastic you inject, the more heat you have to remove. Running the melt temperature at the lower end of the recommended range for the material can help reduce cooling time. However, if you go too low, the plastic becomes too viscous, leading to incomplete filling or high injection pressures. It’s about finding that sweet spot.

Understanding these factors moves you from simply setting a timer to intelligently managing the thermal dynamics of your process. This is how you gain precise control over both cycle time and part quality.

What Is the Formula for Cooling Time of a Mold?

Are you looking for a more scientific way to predict your cycle times instead of just relying on trial and error? Guessing your cooling time can be inefficient and lead to inconsistent results on the production floor. You need a reliable starting point. While a perfect, universal formula is complex, there are excellent models that give you a strong, data-driven estimate. This helps you plan production and quote jobs more accurately.

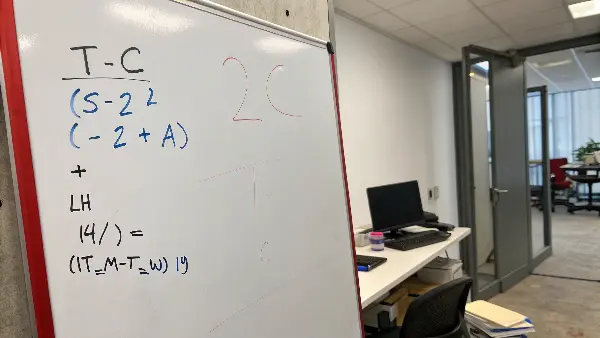

*A common formula to estimate cooling time (t_c) is the Ballman and Shusman formula, which simplifies the complex physics into: t_c = (s^2 / (π^2 α)) ln[(4/π) ((T_m – T_w) / (T_e – T_w))]. In this equation, ‘s’ is the thickest wall section, ‘α’ is the thermal diffusivity of the plastic, T_m is the melt temperature, T_w is the mold wall temperature, and T_e is the part’s ejection temperature.**

Formulas can seem intimidating, but they are incredibly powerful tools. This one, in particular, breaks down the abstract concept of "cooling" into concrete variables you can measure and control. It’s the engineering backbone behind the intuitive adjustments a seasoned technician makes. I use calculations like this in the early stages of a project to set realistic expectations for cycle times and to identify which parameters will have the biggest impact. Let’s make sense of what each part of this formula is telling us.

Breaking Down the Cooling Time Formula

The formula might look complicated, but the story it tells is simple. It quantifies the "Core Four" factors we just discussed.

s²(Wall Thickness Squared): This term mathematically confirms that wall thickness is the most powerful influence. Thesstands for the thickest section of your part. Because it’s squared, its impact grows exponentially. This is why a 2mm thick wall doesn’t take twice as long as a 1mm wall to cool—it takes closer to four times as long. This highlights why designing for consistent, minimal wall thickness is paramount.α(Thermal Diffusivity): This Greek letter, alpha, represents the thermal properties of your chosen plastic. It’s a measure of how quickly a material can have its temperature changed. Materials with a high alpha value, like some filled nylons, will cool faster. Amorphous plastics like PC often have lower alpha values than semi-crystalline ones like PP. This value is a constant for your material, which you can find on its technical data sheet.ln[...(The Temperature Logarithm): This entire section deals with the temperatures involved.T_m(Melt Temperature): The starting temperature of the plastic.T_w(Mold Wall Temperature): The temperature of the mold surface the plastic touches.T_e(Ejection Temperature): The target temperature where the part is solid enough to be ejected.

The ratio (T_m - T_w) / (T_e - T_w) shows us how much the temperature needs to drop relative to the difference between the mold and the final part. A bigger difference between melt and mold temperature means more heat to remove, extending the time. This calculation transforms abstract concepts into a concrete number, giving you a powerful starting point for setting up your process.

How Do You Calculate Cooling Time in Injection Molding?

So you have the formula, but how do you actually use it in a real-world scenario? Reading an equation is one thing, but applying it to your own parts and materials is what matters. Business owners like Michael need practical tools, not just theory. The process involves gathering specific data about your part, your material, and your machine settings, then plugging them into the formula. This turns guesswork into a calculated estimate.

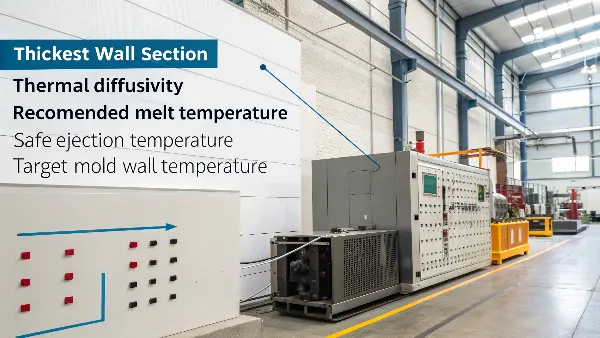

To calculate cooling time, first identify the key variables: find the thickest wall section (s) from your part’s 3D model. Get the thermal diffusivity (α), recommended melt temperature (T_m), and safe ejection temperature (T_e) from the material’s data sheet. Determine your target mold wall temperature (T_w). Then, input these values into the cooling time formula to get an estimated time. This serves as an excellent starting point for process setup.

Let’s walk through a practical example. This is exactly what my team and I do when we’re evaluating a new project. It helps us avoid surprises on the factory floor. Imagine we are making a simple box lid out of ABS plastic. I’ll show you step-by-step how to go from a drawing and a data sheet to a solid cooling time estimate. This is the bridge between design and efficient production.

A Practical Step-by-Step Calculation

Let’s use the ABS box lid as our example.

Step 1: Gather Your Part and Material Data

First, we need our variables. This is the most important step.

- Wall Thickness (s): We analyze the CAD file and find the thickest section of the lid is 3 mm (or 0.003 meters).

- Material Properties (from the ABS data sheet):

- Thermal Diffusivity (α): For a general-purpose ABS, this is typically around 1.1 x 10⁻⁷ m²/s.

- Melt Temperature (T_m): The recommended range is 220-250°C. Let’s start in the middle at 235°C.

- Ejection Temperature (T_e): ABS is rigid enough to eject around 85°C.

- Process Parameter:

- Mold Wall Temperature (T_w): For a good surface finish on ABS, we’ll aim for 60°C.

Step 2: Plug the Values into the Formula

Now we take our cooling time formula:

t_c = (s² / (π² * α)) * ln[(4/π) * ((T_m - T_w) / (T_e - T_w))]

And substitute our values:

t_c = (0.003² / (π² * (1.1 x 10⁻⁷))) * ln[(4/π) * ((235 - 60) / (85 - 60))]

Step 3: Solve the Equation

Let’s do the math piece by piece:

s² = 0.000009π² * α = 9.87 * 1.1 x 10⁻⁷ = 1.0857 x 10⁻⁶s² / (π² * α) = 0.000009 / (1.0857 x 10⁻⁶) = 8.29T_m - T_w = 175T_e - T_w = 25ln[(1.273) * (175 / 25)] = ln[1.273 * 7] = ln[8.911] = 2.187

Finally: t_c = 8.29 * 2.187 ≈ 18.14 seconds

Our calculated cooling time is about 18 seconds. This is a powerful starting point. We can now set the machine’s cooling timer to 18 seconds for the first trial run and adjust from there. This scientific approach is far more efficient than starting at 30 seconds and slowly working your way down.

Conclusion

In injection molding the balance between temperature, pressure and cooling time is critical. The interaction among these parameters is complex, and affects the total cycle time and quality of the product which is being molded. When these factors are properly managed, it will result in efficient production and quality parts.

Optimal performance is made possible through a consistent monitoring and adjustments. Knowing the correlation between temperature, pressure and cooling enables proper manipulations that lead to cost reductions and efficiency. The ability to control these factors is central in dealing with the obstacles of injection molding process and gaining a competitive advantage in production.