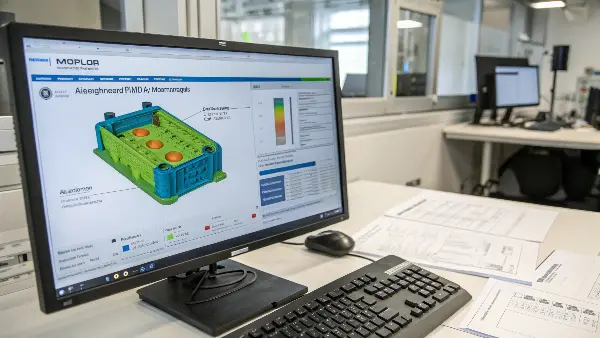

An effective tool in the injection molding industry is mold flow analysis. It forecasts the flow of plastic throughout the molding process. This knowledge is essential for venting design optimization. Good venting guarantees high-quality products and avoids flaws like air traps.

Mold flow analysis identifies the most effective venting solutions by simulating various conditions. This increases efficiency and improves design for manufacturing. Manufacturers can increase product quality and cut waste by using mold flow analysis. Anyone trying to improve their production processes must take this crucial step.

Mold flow analysis is the best method to optimize your design of the venting because it is based on the simulation of the plastic filling process. This is an effective software that is able to determine the precise positions where the air will be stagnated as the mold fills. It is in such gas trap areas, which the designers can locate, that vents can be effectively properly placed and sized during the design of the mold. This is a major step forward to ensure that air is not pressurized and results in defects such as burns and incomplete fills. It conserves large sums of money and time by bypassing expensive trial and error and modifications of the molds in the future.

The slightest scald on a component may result in an entire overhaul of the project. It is frustrating, particularly when you are faced with a very strict deadline. The positive side is that such problems can be nearly always avoided. All that remains to know is the basics of the plastic flow and the air escape. We would like to decompose the most important ones, beginning with the most vital one, venting. With the knowledge of these principles, you can have the key to your manufacturing process and set these flaws into the past.

What is venting in injection molding?

Even though you created the ideal mold, the finished products have burn marks and bubbles. You are unable to determine why. Trapped air with nowhere to go is frequently the cause of this annoying issue. Over time, this trapped air can harm your mold and degrade the quality of your part. However, a small but essential component guarantees that air can escape appropriately, enabling the plastic to fully fill the cavity and produce an ideal part.

Venting is the process of making tiny holes or channels in the mold to let air out of the cavity while the molten plastic is injected. To make room for the plastic, the air that initially filled the empty cavity must be forced out. Vents are designed to be shallow enough for air to escape but too small for the plastic material to flow through. Proper venting is critical for preventing defects like short shots, burn marks, and voids, ensuring complete part filling and high-quality results.

Understanding venting is key to good mold design. I learned that lesson the hard way when I first started. We spent weeks trying to fix a part that had consistent burn marks at the end of the fill path. We tweaked every machine parameter we could think of. The problem wasn’t the machine; it was the mold itself. The air had nowhere to escape. We finally had to take that mold offline, add a few tiny vents, and voilà: the problem went away. That experience taught me that you can have the best machine and the best material, but without a path for the air to leave, you’re just compressing it until it scorches your part.

Common Venting Locations in mold flow analysis

Vents are not placed randomly. They are strategically located where air is most likely to be trapped.

- Parting Line: The most common location for vents is along the parting line where the two halves of the mold meet.

- End of Fill: Vents are always needed at the last point in the cavity to be filled. Mold flow analysis is perfect for predicting this exact spot.

- Ejector Pins: Sometimes, the small clearance around ejector pins can act as a natural vent. In some designs, special vented ejector pins are used.

Proper venting is a sign of a well-engineered mold. It’s a small detail that makes a massive difference in quality and consistency.

The major advantages of Optimized Venting in Injection Molding.

Ventilation processes can also be optimized to improve injection molding processes drastically. It minimizes defects leading to quality parts.

Good ventilating will result in high cycle time. Individual components cool at a quicker rate which reduces the production of one in the cycle and efficiency.

Besides, the optimized designs will minimize material waste and manufacturing expenses. This plays an important role in ensuring competitive advantage in manufacturing sectors.

Optimized venting has the following major advantages:

- Minimized air traps and enhanced quality of parts.

- Reduced cycle time because of improved cooling.

- Less material waste and reduction of costs.

- Proper optimization of venting may realize tremendous performance and reliability gains by manufacturers.

These do not only help to improve the quality of the product, but also affect the efficiency of the operations.

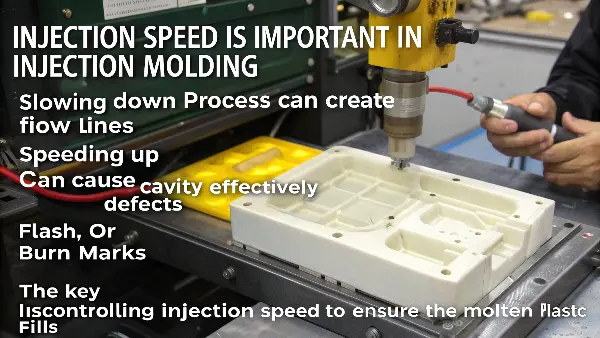

Why is injection speed important in injection molding?

Have you ever tried to fill a complex mold, only to find the plastic freezes before it reaches the end? This results in an incomplete part, called a short shot. Slowing down the process seems logical, but it can create other problems like ugly flow lines. You’re stuck between two bad options, wasting time and material. The key to solving this isn’t just about pushing plastic harder; it’s about controlling how fast you push it, a parameter known as injection speed.

Injection speed is crucial because it directly influences how the molten plastic flows into and fills the mold cavity. A faster speed generates more shear heat, keeping the plastic hotter and less viscous, which helps fill thin walls and complex geometries before it freezes. However, too fast a speed can cause defects like jetting, flash, or burn marks from trapped air. Therefore, controlling the injection speed is essential for managing the filling pattern, part appearance, and overall cycle time, directly impacting the final part quality and production efficiency.

In my experience, injection speed is one of the most powerful tools a molding technician has. It’s also one of the most misunderstood. Many people just set it to a default value and focus only on pressure. But speed is what dictates the "how" and "when" of the filling process. I remember working on a medical device part with a very thin wall section. We kept getting short shots. The team wanted to increase the pressure, but I suggested we profile the injection speed instead. We started slow to allow a smooth flow gate entry and then ramped up the speed dramatically to fill the thin wall before the plastic could cool. It worked perfectly. That day, everyone on the floor learned that speed isn’t just a number; it’s a strategy.

The Balancing Act of Injection Speed

Controlling injection speed is about finding the right balance for your specific part, material, and mold. You have to consider several factors.

- Filling Thin Sections: Fast speeds are necessary for parts with thin walls. The plastic needs to get into the thin area and fill it out before it has a chance to solidify.

- Preventing Defects: Controlling the speed can prevent several common issues.

- Jetting: If the speed is too high at the beginning, the plastic can "jet" across the cavity instead of flowing smoothly, creating a worm-like defect on the part surface.

- Flash: Excessive speed can force plastic into the tiny gaps in the parting line, creating unwanted "flash" that needs to be trimmed off later.

- Gas Traps: A very high speed gives air less time to escape through vents, leading to burn marks.

Using Speed Profiles

Modern molding machines don’t just have one speed setting. You can program a "speed profile," changing the injection speed at different points during the fill.

| Fill Stage | Typical Speed | Purpose |

|---|---|---|

| Initial Fill | Slow | To prevent jetting as plastic enters through the gate. |

| Main Fill | Fast | To fill the main body of the part quickly, especially thin walls. |

| Final Fill | Slow | To allow air to escape from the last point to fill, preventing burns. |

Mastering injection speed is key to mastering the molding process. It allows you to fill the part efficiently while maintaining high cosmetic and dimensional quality.

How Mold Flow Analysis Finds Problems with Venting

Mold flow analysis is a very useful tool for finding venting problems early. It shows possible problems by simulating how the plastic flows through the mold. This proactive approach stops expensive mistakes from happening later.

Engineers can find air traps and places where there isn’t enough venting by using simulation. The analysis shows how pressure and flow move through space. These insights enable precise design modifications.

Mold flow analysis has found some important venting problems, such as:

- Air traps

- Lines of weld

- Not enough ways for air to flow

By fixing these problems, manufacturers can keep their production running smoothly. The analysis helps find the best places for vents, which makes sure that air flows properly.

This, in turn, leads to better parts and fewer defects.

Manufacturers can use mold flow analysis to find and fix problems before they start making things. This proactive step saves time and money, making the manufacturing process more efficient.

How to Improve the Design of Venting Using Mold Flow Analysis

There are several strategic steps to take when using mold flow analysis to improve venting design. Every step is very important for making a mold that works well.

First, do a full analysis of the first design model. This gives us a starting point for finding possible problems. Use the baseline to see how different situations stack up against each other.

After that, run simulations with different settings, like types of materials and how they are processed. These things affect how plastic flows and can have a big effect on how well the vent works.

When you look at the simulation results, pay close attention to the following:

- Where to find air traps

- Patterns of flow

- Points of pressure

You can change the placement of vents based on this detailed information. Change the locations of the vents to fix air traps and make it easier for air to escape. If you need to, think about other designs.

Finally, use more simulations to check that the optimized design is correct. This makes sure that changes bring about the improvements that are wanted. By following these steps, manufacturers can make venting designs much better, which will lead to higher quality products and more efficient production.

What is the effect of injection pressure on part quality?

You’ve finally fixed your filling issues, but now your parts have ugly sink marks, or they are not the right size. You check the mold, and it seems perfect. You’re producing parts, but they aren’t meeting the quality standards your client demands. This frustrating situation often points not to the mold itself, but to the forces at play after the mold is filled. The secret to solid, dimensionally stable parts lies in the correct application of injection pressure.

Injection pressure has a major effect on part quality, primarily during the packing and holding phases. After the mold is filled, holding pressure is applied to pack more material into the cavity, compensating for shrinkage as the plastic cools. Insufficient pressure leads to defects like sink marks, voids, and poor part dimensions (under-sized). However, excessive pressure can cause flash, part over-packing (stress), and issues with ejecting the part from the mold. Therefore, optimizing injection pressure is critical for achieving the correct part weight, dimensional accuracy, and cosmetic appearance.

I can tell a lot about a molding operation just by looking at their pressure settings. It’s a delicate dance. I once took on a project for an automotive client. Their parts, a set of interior clips, were failing stress tests. The previous molder had tried everything. When we looked at their process, we saw they were using extremely high packing pressure, thinking "more is better" to avoid sink marks. But this was actually creating massive internal stress in the parts, making them brittle. We ran a mold flow analysis, dropped the packing pressure by 30%, and extended the holding time slightly. The parts came out strong, dimensionally perfect, and passed every test. It showed that pressure isn’t about brute force; it’s about precise control.

Two Key Phases of Pressure

Injection pressure is not a single number. It is typically divided into two main stages, each serving a different purpose.

- First Stage (Filling) Pressure: This is the pressure limit set during the injection speed phase. The machine uses whatever pressure is necessary (up to this limit) to achieve the programmed injection speed. Its main job is to push the material into the mold. It overcomes the resistance of the plastic flowing through the nozzle, runners, and cavity.

- Second Stage (Packing/Holding) Pressure: This is the critical phase for part quality. After the cavity is about 95-98% full, the machine switches from speed control to pressure control. This holding pressure is typically lower than the first stage pressure limit. Its purpose is to push a little extra material into the cavity to compensate for the material shrinking as it cools.

Common Problems Related to Pressure

Getting the pressure right is essential for avoiding common defects.

- Low Holding Pressure: If the holding pressure is too low, not enough material is packed in to fight shrinkage. This leads directly to:

- Sink Marks: Depressions on the surface of the part, usually over thick areas like ribs or bosses.

- Voids: Air bubbles trapped inside the part.

- Short Shots: If the switchover from fill to pack happens too early, the part may not be completely filled.

- High Holding Pressure: Too much pressure can be just as bad, causing:

- Flash: The high pressure can force the mold halves apart slightly, allowing plastic to escape.

- Over-packing: This puts too much material in the cavity, leading to high internal stress and making it very difficult to eject the part.

Optimizing pressure is a critical step in producing consistent, high-quality parts that meet your customers’ exact specifications.

What is the difference between injection speed and injection pressure?

You’re trying to set up a new molding process, but the machine’s control panel has a dozen settings for speed and pressure. It’s confusing. You adjust one, and it seems to affect the other. This leaves you guessing, making random changes and hoping for the best, which is a slow and expensive way to solve problems. To truly control the process, you must understand that speed and pressure are two different tools that work together, each controlling a specific part of the injection cycle.

The main difference is that injection speed controls how fast the screw moves forward to fill the mold, while injection pressure is the force behind that movement. During the initial filling stage, the process is typically speed-controlled; the machine uses whatever pressure is needed (up to a set limit) to achieve the target speed. Once the mold is nearly full, the process switches to being pressure-controlled. During this "packing" or "holding" phase, a specific pressure is maintained to compensate for material shrinkage as the part cools.

I often explain this to new engineers using a simple analogy: think of watering your garden with a hose that has a spray nozzle. The speed is like how quickly you turn the handle on the faucet. It controls the volume of water coming out per second. The pressure is what’s building up inside the hose. If you put your thumb over the end, the pressure builds up even if the speed (flow from the faucet) is the same.

In molding, we control the speed to manage how the plastic flows and looks, and we control the pressure to make sure the final part is solid and dimensionally correct. They are linked, but they control different outcomes. Understanding this separation is the first step to becoming a true molding expert, moving from guesswork to scientific, repeatable results.

A Step-by-Step Look at the Process

Let’s break down a typical injection cycle to see how speed and pressure hand off control to each other.

-

Injection Start (Speed Control):

- What it does: The screw starts moving forward at a programmed speed (e.g., 50 mm/second).

- The Goal: To control the flow front of the plastic, preventing defects like jetting and ensuring a consistent cosmetic finish.

- Pressure’s Role: The machine’s hydraulic system provides the necessary pressure to maintain this speed. If the plastic is thick, it needs more pressure. If it’s thin, it needs less. The pressure here is a result of trying to achieve the set speed. We set a maximum pressure limit just for safety.

-

Switchover Point (The Handoff):

- This is the critical moment when the mold is about 95-98% full. The machine changes its primary command from "move at this speed" to "apply this pressure."

-

Packing and Holding (Pressure Control):

- What it does: The machine now applies a constant, pre-set pressure (e.g., 600 bar).

- The Goal: To force a small amount of extra material into the cavity to compensate for shrinkage as the plastic cools and solidifies. This is what prevents sink marks and ensures the part meets its target dimensions.

- Speed’s Role: At this point, the speed is very low, often close to zero. The speed is now a result of applying that constant pressure against the solidifying plastic.

This two-stage approach gives us the best of both worlds: fine control over the aesthetic and flow characteristics during filling, and precise control over the dimensional and structural integrity during cooling.

Conclusion

In the end, creating a perfect molded part comes down to controlling how plastic flows and how air gets out of the way. We’ve seen that proper venting is not an afterthought; it’s a critical design element. We also know that injection speed and pressure are the two key levers we pull to manage this process. Speed governs the fill, and pressure ensures the final part is solid and accurate. Using a tool like mold flow analysis allows us to get it right from the start.