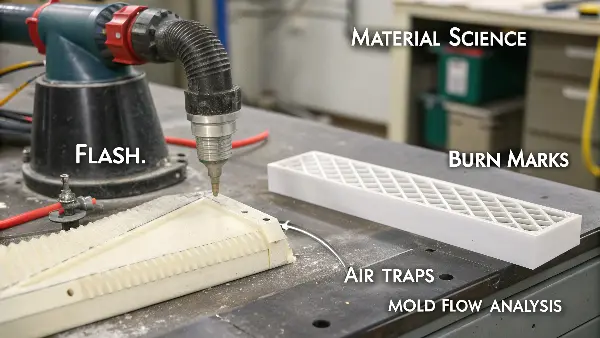

Are you sick and weary of your plastic parts having annoying flaws like burn marks and short shots? These may result in corporate stress, missed deadlines, downtime, and soaring expenses. However, what if something within the mold itself is the primary culprit rather than your material or machine? A well-designed venting system is typically the key to flawless parts—a feature that far too many people ignore.

Using cutting-edge mold flow analysis as a guide, we carefully design a venting system to eliminate air-related flaws. In this manner, we can determine exactly where the air will become trapped as the plastic fills the mold chamber. The air can then escape by using vents that are precisely the correct size and shape in these strategic places. This makes it possible for the molten plastic to completely fill the space and eliminate any flaws that can jeopardize a production run.

It’s simple to concentrate on the major components of mold production, such as the steel, polishing, and mechanics. However, I’ve discovered in my years in this field that the littlest things frequently have the greatest effects. In injection molding, air is the unseen enemy. It will fight back if you don’t provide it a path out, and your completed parts will show the results. I want to explain our methodology and demonstrate how we’ve made venting a science, guaranteeing flawless parts each and every time.

What Are The Common Defects Caused By Poor Venting System Design?

Air-related defects most often originate from ineffective venting systems. These include problems that not only affect comfort but also pose health risks. Recognition of such defects assists in addressing the basic underlying issues.

One common defect is the buildup of indoor pollutants. Without proper ventilation, contaminants like dust and odors accumulate. This can lead to respiratory problems and allergic reactions.

Other concerns include moisture issues: poor venting allows humidity to rise, which in turn encourages mold growth. Besides the property damage this causes, it affects air quality. Mold spores can spread, affecting those who have allergies or asthma.

Following are some of the common defects due to poor venting:

- Growth of mold because of additional moisture

- Bad smells

- Higher energy expenses

The most common defects from poor venting are burn marks, short shots, gas traps (or voids), and flow lines. Burn marks are dark streaks caused by compressed, superheated air. Short shots happen when trapped air prevents the plastic from filling the mold completely. Voids are internal bubbles where gas couldn’t escape, weakening the part. Flow lines are visible patterns where plastic fronts meet but don’t merge properly due to trapped air. All these issues stem directly from a failure to evacuate air from the mold cavity effectively.

Addressing these defects requires systematic venting design. This involves regular inspections and system updates that tackle these challenges to ensure healthier indoor environments.

Understanding these defects is the first step toward preventing them. Early in my career, I remember a project for a client who needed a precise electronic housing. We kept getting burn marks right at the last corner to fill. We tried adjusting injection speed and temperature, but nothing worked. It was only after we painstakingly analyzed the mold that we realized a vent was missing in that exact spot. It was a powerful lesson: you can have the best machine and material, but if the air has nowhere to go, you will always have problems. This experience taught me to treat venting not as an afterthought, but as a critical design feature.

Breaking Down the Defects due to poor Venting System Design

Each defect tells a story about what’s happening inside the mold. By learning to read these signs, we can diagnose and solve venting issues with precision. It’s like being a detective for plastic parts.

- Burn Marks (Dieseling): These look like black or brown scorch marks. They occur when a pocket of air gets trapped and compressed so rapidly by the incoming plastic that it heats up and ignites, burning the plastic front. They most often appear at the very end of the flow path or in deep ribs where air can’t escape.

- Short Shots/Non-Fills: This is when the part is incomplete because the plastic material couldn’t fill the entire mold cavity. The trapped air acts like a cushion, creating back pressure that stops the flow of molten plastic dead in its tracks. You’ll see this as missing features or an unfinished part outline.

- Voids and Sink Marks: Though sometimes related to cooling, trapped air can also cause these. If gas gets trapped within the part, it forms a bubble, or void, which weakens the part’s structural integrity. On the surface, this can also contribute to sink marks, as the trapped gas interferes with proper packing and cooling.

Here’s a simple table to summarize these common issues:

| Defect Type | Visual Appearance | Primary Cause Related to Venting |

|---|---|---|

| Burn Marks | Black or brown streaks/spots | Trapped air igniting under high compression. |

| Short Shots | Incomplete or missing sections | Air pressure preventing the cavity from filling. |

| Voids | Internal bubbles or sinking | Gas unable to escape from the molten plastic. |

| Flow Lines | Visible lines on the part surface | Air trapped between merging plastic flow fronts. |

Solving these problems starts and ends with giving the air a clear path out.

Important Guidelines for Designing an Effective Venting System

Understanding a few fundamental concepts is necessary to design an efficient venting system. These direct the system’s functionality and efficiency. First, think about the building’s dimensions and design. This influences the dispersion and movement of air. All sections will have balanced ventilation thanks to proper design.

Next, consider the building’s unique requirements. Different buildings need different venting techniques. Ventilation requirements are different for residential, commercial, and industrial structures. Adapting systems to meet these requirements improves occupant comfort and air quality.

Choosing the right materials is also important. Selecting robust, effective materials affects how long a system lasts. Better materials perform better and require less upkeep. As a result, venting systems are dependable and efficient.

Important guidelines to adhere to are:

- Knowing the mechanics of air flow

- Adapting systems to building requirements

- Choosing long-lasting and effective materials

- Providing for energy-efficient functioning

Finally, adherence to building codes is crucial. To guarantee operation and safety, these codes offer guidelines. By following them, systems can be made to run efficiently and securely. This dedication to superior design creates the best possible indoor surroundings.

How Does Mold Flow Analysis Guide Our Venting Strategy?

Have you ever thought that creating molds requires too much guesswork? You purchase a tool, run the initial trial, and then spend days fine-tuning it to address unforeseen issues. In addition to being delayed, this method is very costly. When dealing with intricate pieces where plastic flow is unpredictable, relying solely on experience may result in mistakes. Before a single piece of steel is ever cut, what if you could see precisely how the mold will fill? This is the advantage of a data-driven strategy.

Our complete venting technique is guided by a computer simulation called mold flow analysis. It forecasts the flow, filling, and cooling of the molten plastic within the cavity. As the plastic moves forward, the software indicates the precise places where air will be forced and trapped. We can ensure effective air evacuation by designing and positioning vents with surgical precision after we have a firm understanding of these "air trap" zones. This removes all uncertainty and stops flaws from ever developing in the first place.

To be honest, we operated in this industry the old-fashioned way when I first started. To locate vents, we used common sense, experience, and a little bit of intuition. It was a battle for the tough bits, but it worked most of the time. If we find a burn mark on a mold that is on the press, we would remove the mold, machine a new vent, replace it, and then hope for the best. For us, everything changed when mold flow analysis was implemented. It was similar to flicking on lights in a pitch-black chamber. All of a sudden, we could confidently organize our attack and see the "invisible" enemy—the air.

From Simulation to Reality

The mold flow report is our blueprint for a defect-free part. It gives us several critical pieces of information that directly influence our venting design.

- Fill Time Animation: We watch a virtual animation of the mold filling. This shows us the path the plastic takes and, more importantly, where the last fill points are. These are natural locations for air to be trapped, and are prime candidates for vents.

- Air Trap Analysis: The software has a specific function to highlight potential air traps. It shows us pockets and corners where air will be cornered with no escape route. This is the most crucial piece of data for us. We place vents directly at these predicted locations.

- Weld Line Prediction: The analysis also shows where different fronts of molten plastic will meet. If air is trapped at these meeting points, it creates a weak, visible line called a weld line. By placing a vent there, we allow the air to escape, ensuring the plastic fronts merge together cleanly and strongly.

The process has become a standard part of our workflow:

| Stage | Action Taken | Benefit |

|---|---|---|

| 1. Simulation | Run mold flow analysis on the 3D part model. | Predicts fill pattern, pressure, and air traps. |

| 2. Analysis | Identify all potential air trap and weld line locations. | Creates a "map" for where vents are needed. |

| 3. Design | Integrate vents of the proper type and size into the mold design. | Ensures a clear path for air to escape. |

| 4. Manufacturing | Machine the vents into the mold steel with high precision. | Turns the data-driven design into a physical reality. |

This strategy transforms venting from a reactive fix into a proactive, engineered solution.

What Are The Different Types Of Vents We Use In Our Molds?

Do you think a vent is just a straightforward mold groove? That is the general concept, but a one-size-fits-all method of venting can result in new issues, such as plastic flashing into the vent channel. varied solutions are needed for varied part shapes, materials, and mold locations. It can be as inefficient to use the incorrect kind of vent as it is to have none at all. It’s like trying to use a screwdriver when you need a wrench; it won’t work properly.

We employ a variety of vent kinds, each selected for a particular function. The perimeter vent, a shallow tube machined on the parting line, is the most widely used. We use vent pins or vented core pins, which have tiny flats ground on their sides, for ejector pins or isolated locations. We might employ porous mold inserts, which are composed of a unique steel that lets air pass through while blocking the plastic, for broad, flat sections or materials that outgas a lot. The secret is to fit the type of vent to the particular requirements of the mold area.

Choosing the right tool for the job is a core principle in any craft, and mold making is no different. I think of our selection of vent types as a specialized toolkit. Years ago, we might have just used a standard parting line vent for everything. But as parts became more complex, we had to get smarter. For instance, we were making a deep, bucket-shaped part where air was getting trapped at the bottom. A parting line vent was useless. That’s when we started using vented ejector pins at the base, and the problem vanished. This taught us that a flexible and knowledgeable approach to venting is essential for modern injection molding.

Choosing the Right Vent for the Job

The selection of a vent isn’t random; it’s a calculated decision based on the mold’s design and the insights from our mold flow analysis. Each type has its advantages and is suited for different situations.

- Parting Line (Perimeter) Vents: This is the most common and fundamental type. It’s a shallow channel (the "vent land") cut from the edge of the cavity to the outside of the mold on the parting line. The depth is critical—deep enough for air, but too shallow for plastic to flow through. It’s great for venting the general perimeter of a part.

- Vent Pins: When an air trap is predicted in an area far from the parting line, we use an ejector pin or a dedicated pin and grind a small flat on its side. This flat creates a tiny channel for air to escape along the pin and out the back of the mold. It’s an ingenious way to vent isolated hot spots.

- Porous Mold Inserts: Sometimes, you need to vent a large surface area where traditional vents would be impractical or would leave marks on the part. For these cases, we use inserts made from sintered, porous steel. The material is full of microscopic pores that are large enough for gas molecules to pass through but too small for the long-chain polymer molecules of the plastic.

Here is how we decide which to use:

| Vent Type | Best Use Case | Key Advantage |

|---|---|---|

| Perimeter Vent | Around the main outline of the part. | Simple to machine, effective for general venting. |

| Vent Pins | Deep ribs, bosses, or isolated air traps. | Vents areas that are unreachable by the parting line. |

| Porous Inserts | Large, flat cosmetic surfaces or fast-filling parts. | Provides continuous venting without leaving tool marks. |

By mastering these different techniques, we ensure that no matter how complex your part is, we can create a venting strategy that guarantees a flawless result.

How Do We Determine The Right Size and Location For Vents?

Have you ever seen a perfect-looking part, only to find a thin, razor-sharp edge of plastic sticking out where it shouldn’t be? This is called "flash," and it’s often caused by a vent that’s too big. On the other hand, if a vent is too small, it won’t let the air out fast enough, and you’re back to dealing with burn marks. The success of venting hinges on getting the size and location just right. It’s a game of micrometers where precision is everything. How do you find that perfect balance?

We determine the right vent size and location through a combination of material science and mold flow analysis. The location is dictated by the simulation, which shows us exactly where air traps will form—typically at the end of the flow path. The size, specifically the vent depth, is determined by the viscosity of the plastic being used. Low-viscosity materials like nylon require very shallow vents (e.g., 0.01 mm), while high-viscosity materials like PVC can tolerate deeper vents (e.g., 0.05 mm), ensuring air escapes without plastic flash.

This is where experience merges with data. The mold flow software tells us where to put the vent, but the material datasheet and our own experience tell us how big to make it. I remember a job where we were molding a polycarbonate lens. We followed the simulation for location, but the team machined the vent depth based on a general-purpose plastic. The result? Every single part had fine flash around the edge. We had to take the mold apart, weld the vent shut, and re-machine it a tiny bit shallower. That tiny difference—just a hundredth of a millimeter—was the difference between a reject and a perfect part. It’s a lesson you don’t forget.

The Science of Sizing and Placement

Getting venting right involves two key principles: go where the air goes, and make the door just big enough for the air to slip through.

1. Strategic Location

The fundamental rule of placement is to put vents at the last point of fill. As the plastic fills the cavity, it acts like a piston, pushing all the air in front of it. This air gets cornered at the very end of the flow path.

- Mold Flow is Key: As discussed, our mold flow analysis is the primary tool for identifying these locations.

- Natural Air Traps: We also look for natural trap areas based on geometry. Any deep rib, tall boss, or corner where flow fronts meet is a potential trouble spot that needs a dedicated vent. We aim to place vents generously—it’s better to have too many than too few.

2. Precision Sizing

The dimensions of the vent are critical, especially the depth.

- Vent Depth: This is the most important dimension. It must be shallow enough that the solidified "skin" of the plastic freezes off instantly upon contact, preventing the rest of the material from flowing into it. This depth varies by material.

- Vent Land: This is the length of the shallowest part of the vent channel. It’s usually between 5-10 mm long to ensure the plastic freezes off before reaching the deeper relief channel.

- Relief Channel: After the land, the vent opens into a deeper channel that allows the air to escape quickly to the outside atmosphere.

Here’s a quick reference for typical vent depths for common materials:

| Plastic Material | Viscosity | Recommended Vent Depth (mm) |

|---|---|---|

| Polystyrene (PS) | Low | 0.01 – 0.02 |

| Nylon (PA) | Very Low | 0.01 – 0.02 |

| Polypropylene (PP) | Medium | 0.02 – 0.04 |

| ABS | Medium | 0.02 – 0.04 |

| Polycarbonate (PC) | High | 0.03 – 0.05 |

Mastering this delicate balance of location and size is what separates an average mold from a high-performance, trouble-free tool.

Why Is Vent Maintenance Just As Important As The Initial Design?

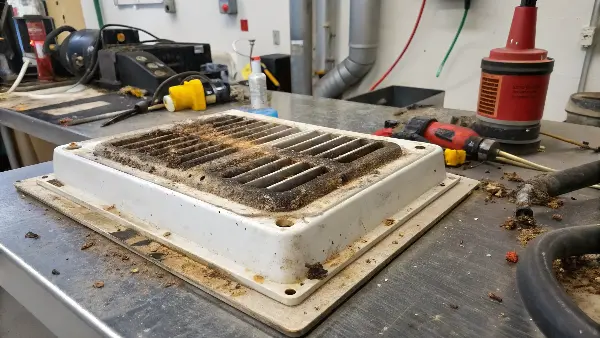

You have a perfect mold with a brilliant venting system, and production is running smoothly. But after a few thousand cycles, you start to notice old problems creeping back in—a hint of a burn mark here, a slight short shot there. What’s going on? It’s easy to assume the mold is wearing out, but often the issue is simpler and far easier to fix. Your vents, the very channels designed to prevent these problems, can get clogged, rendering them useless. Neglecting vent maintenance is like ignoring the oil change on a high-performance car; eventually, it will fail.

Vent maintenance is crucial because over time, vents become clogged with residue from the plastic, called outgassing. These deposits build up and obstruct the narrow vent channels, effectively sealing off the escape route for air. Regular cleaning of the vents is essential to remove this build-up and restore their function. Without routine maintenance, a perfectly designed mold will slowly begin to produce defective parts, erasing all the benefits of the initial high-quality design and leading to production losses.

I always tell my clients that a mold is a living tool. It requires care and attention to keep performing at its peak. I’ve seen customers spend a lot of money on a top-tier mold, only to let it degrade on the production floor due to a lack of basic cleaning. They’ll call us frustrated about part quality, and the first question I always ask is, "When was the last time you cleaned the vents?" More often than not, a simple cleaning procedure solves the problem instantly. That’s why we not only design effective vents but also educate our clients on how to maintain them. A partnership for success goes beyond just delivering the tool.

A Simple but Critical Process

Keeping vents clear isn’t complicated, but it requires discipline and a regular schedule. The frequency of cleaning depends heavily on the type of plastic material being used, as some materials release more volatile gases than others.

Causes of Vent Clogging:

- Outgassing: Many plastics, especially materials like PVC and flame-retardant grades, release corrosive gases and waxy residues when heated. These deposits solidify on the cooler mold surfaces, right inside the vents.

- Mold Release Agents: Over-spraying mold release can also lead to build-up that clogs the vents.

- Material Dust and Debris: Small fines or dust from the plastic pellets can be carried into the mold and deposited in the vent channels.

A Proactive Maintenance Schedule:

We advise our clients to establish a cleaning schedule based on their production volume and material type. A good approach includes:

| Frequency | Task | Tools & Method |

|---|---|---|

| End of Shift | Quick visual inspection of parting line vents. | Check for any visible residue or build-up. |

| Daily/Weekly | In-press cleaning of accessible vents. | Use brass tools or approved solvents to gently scrape or wipe vents clean. Never use steel tools that can damage the mold surface. |

| During Tool Pulls | Thorough cleaning of all vents. | Disassemble components if necessary to access vent pins and internal vents. Use ultrasonic cleaners for deep cleaning of porous inserts. |

By treating vent maintenance as a critical part of the production process, you protect your investment, ensure consistent part quality, and maximize the operational life of your mold. It’s a small effort that pays huge dividends.

Best Practices for Maintenance and Inspections

Effective running of the venting systems requires regular maintenance. Through maintenance, the systems operate efficiently without hitches. Lack of maintenance often causes problems with air quality.

Frequent inspections assist in the early detection of areas of concern, avoiding expensive repairs or complete failures of systems. Proper maintenance further extends the life of venting equipment.

The following are best practices for maintaining venting systems:

- Schedule regular inspections and cleanings

- Change filters as needed

- Check vents and ducts for blockages

- Make sure all elements are working properly.

This will not only ensure good indoor air quality but also increase energy efficiency. A properly designed maintenance program is integral to a system being reliable and long-lasting.

Collaboration and Compliance: Ensuring Safe and Efficient Systems

The design of a good venting system does require cross-discipline collaboration. Architects, engineers, and HVAC specialists need to work in close tandem. The result is thoroughly integrated and functional systems.

Also, compliance with local building codes is important. Standards mean safety and effectiveness; it is not about following the rules but about ensuring quality and reliability.

Key aspects that encompass collaboration and compliance include:

- Communication among design team members

- Keeping updated with all codes and regulations.

- Ensuring designs meet all safety standards

These practices help in achieving systems that are both safe and efficient, thereby improving indoor environments.

Conclusion

Effective design of the venting system makes for superior indoor air quality. Incorporation of modern innovations into the design process, focusing on key principles, may significantly reduce air-related defects.

Smart designs not only improve indoor air quality but also comfort and health for the occupants, along with ensuring energy efficiency. Integrating smart technology together with continuous maintenance will keep the systems effective and updated. By giving importance to these aspects in the venting design, buildings can offer healthier environments and sustainably operate for years to come.