To design automotive plastic parts that are tough, affordable, and look great? It feels like you have to sacrifice one to get the other two. This constant trade-off could eventually lead to budget overruns, performance failures, or designs that just don’t meet market expectations. You need a clear strategy to hit all three targets without compromise.

A holistic design approach is what balances performance, cost, and aesthetics. That is selecting materials appropriate for the specific performance required-be it impact resistance or heat tolerance. Also, optimization of part geometry for efficient injection molding reduces costs. Finally, you have to integrate aesthetic requirements from the very beginning of the design process, considering texture and color rather than adding them as an afterthought, allowing all three goals to be met harmoniously.

Finding that perfect balance is a challenge that every automotive designer and engineer faces. I’ve seen countless projects get stuck in this loop of compromising on one critical aspect for another. It’s frustrating when a part that performs perfectly ends up being too expensive to produce, or when a cost-effective part fails basic durability tests. The truth is, these three elements are not independent; they are deeply interconnected. A smart design choice in one area can positively impact the others. Let’s break down how you can navigate this complex process and start making better decisions from the get-go.

What Role Does Plastic Actually Play in Modern Automotive Design?

Feeling the pressure to lighten and make cars more fuel-efficient? Traditional materials like steel are heavy and limit design possibilities. This weight directly affects performance and running costs, while restrictive manufacturing processes can stifle the creativity needed for modern, appealing vehicle designs. Innovation is thus carried out under an unremitting struggle with these physical limitations.

Plastics in modern automotive design are used mainly for weight reduction, which ensures better fuel economy and handling. They provide enormous freedom of design, with complex and aerodynamic shapes that are difficult or expensive to make in metal. Moreover, plastics play a vital role in safety because they can absorb much of the energy of an impact in case of a collision, and they often provide a less expensive manufacturing solution for complicated interior and exterior components, thereby reducing overall vehicle production costs.

When I first started in this industry, the use of plastic in cars was mostly limited to simple interior knobs and trim. Today, it’s a completely different story. Plastics are foundational to automotive innovation. Their role has expanded dramatically because they solve several problems at once. Let’s look closer at the specific advantages that have made plastics so indispensable to car manufacturers. This isn’t just about replacing metal; it’s about unlocking new possibilities in how cars are designed, built, and perform.

Weight Reduction and Fuel Efficiency

The most significant driver for using plastics is weight reduction. A lighter car requires less energy to move, which directly translates to better fuel economy or, in the case of electric vehicles, longer range. In my experience, for every 10% reduction in vehicle weight, fuel efficiency can improve by 5-7%. Materials like polypropylene (PP) and polyamides (Nylon) are used for everything from bumpers and fuel tanks to engine covers, replacing much heavier steel components. This pursuit of "lightweighting" is a top priority for every major automaker.

Design Freedom and Aesthetics

Plastics give designers a level of freedom that metal simply cannot match. Injection molding allows the creation of complex, one-piece components that would otherwise require several parts made from metals to be welded or bolted together. Just think about the grilles, swooping dashboard designs, and integrated spoilers on cars these days. That is plastic at work. This not only improves the aesthetic appeal of the car but also cuts down assembly time and cost significantly.

Safety and Durability

Modern engineered plastics are super tough. They are formulated to absorb and dissipate impact energy in a collision to improve passenger safety. For example, bumpers are molded from impact-resistant polymer blends that can deform without breaking on impact and return to their original shape and appearance following a minor collision. They also need to be durable enough to survive years of sunlight, extreme temperatures, and harsh chemicals without degradation.

| Feature Comparison | Steel | Automotive Plastics |

|---|---|---|

| Density | High | Low |

| Design Complexity | Limited | High |

| Corrosion Resistance | Poor (requires coating) | Excellent |

| Impact Absorption | Deforms permanently | Can be designed to absorb and recover |

| Manufacturing Cost | High for complex shapes | Low for high-volume, complex shapes |

Designing to Class-A Surfaces: Texture, Gloss and Weld Line Control.

In car interiors and exteriors, appearance is of the same importance as mechanical strength. The perceived quality is directly related to surface texture, uniformity of gloss, and the lack of visible lines of welds. These attributes are not determined just by the material choice, but to a large extent by the shape of the moulds, and the location of the gates, the flow, and the level of polish. Sloppy gates may produce light marks or gloss unevenness on open spaces like dashboards, door mouldings and center consoles.

OEM and customers typically are assisted by a company in reviewing Class-A surface requirements during DFM and suggest gate positions, parting line locations and mold steel finishes ( SPI A2, B1, VDI 18-24, etc.) that reduce cosmetic defects. Designing tooling based on aesthetic needs at the very beginning allows the manufacturers not to spend much on texture reworking and surface repair, post-mold trials.

Learning True Cost Drivers: Part Geometry, Tooling Complexity, and Cycle Time.

A material price is just a part of the actual cost of a car plastic part. Long-term production cost is often dominated by tooling complexity, number of cavities, cooling efficiency and cycle time. Deep ribs, thick bosses, undercuts, and complex parting lines are features that might enhance strength or appearance, but add slides, lifters and extra cooling time, raising the price of molds and decreasing productivity.

Mold engineering wise, it is possible to simplify tooling greatly by optimizing the wall thickness, minimizing unnecessary undercuts and creating self-ejecting geometries. On many occasions, CKMold assists clientele to repackage parts, removing side actions, balancing cooling and enhancing cavity layout, at reduced mold cost and shorter cycle times without performance or looks compromised. This is a geometry based cost optimization needed in high volume automotive programs.

Thermal Cycling, Vibration and Long-Term Fatigue Control in Plastic Auto Parts.

In the automotive components, the components are subjected to continuous fluctuation in temperature, engine vibration and long term mechanical loading. Despite passing the preliminary strength tests, variations in thermal expansion, creep action, and fatigue ability could result in noise, distortion or cracking of a plastic part after several years of service. These are some of the effects that need to be taken into account in the selection of the material and structural design.

The stiffness and vibration response are all dependent on Rib orientation, direction of material flow filled with fibers, and local thickness variations. The mold design is also a factor: inadequate cooling architecture may result in residual stress which is subsequently discharged during thermal cycling. Through material simulation, structural analysis, and moldflow validation, the molding companies assist their customers in the development of components that can retain the structure, surface quality, and dimensional stability throughout the life cycle of the vehicle.

What are the most crucial guidelines in the design of plastic parts?

Plastic part design is more than creating the shape you desire to be injection molded, it is also about creating a part that can be produced in high reliability, that it looks attractive, works, and is economical in large quantities. Effective designs blend operational needs and process facts, minimizing flaws, equipment expenses and manufacturing wait times. The following are the basic rules that must be used by all engineers and product designers:

Use Uniform Wall Thickness

One of the rules of thumb when designing a plastic part is to have a uniform thickness on the wall in the entire part. Wall thickness that is too wide can cause internal stresses, sink marks (depressions on the surface), voids and warping with thicker parts cooling slower than thinner ones. Having uniform walls facilitates the even distribution of plastic in the mold cavity thereby preventing uneven shrinkage and also reduces the cooling time thereby enhancing the quality of the part as well as increasing the effectiveness of the production cycle. When change of thickness is inevitable, gradual change, as opposed to sudden change is paramount.

Use Draft Angles to Release Mold.

A draft angle is a minor taper used on the walls which are parallel to the direction of the opening of the mold. The taper permits the part to clean out of the mold without scraping or drag. Practically, the designers usually consider adding 1-2deg of draft on flat surfaces and up to 3deg or even higher on rough surfaces, since textures add friction on the ejection. Unless properly drafted, components will tend to adhere, creep or be damaged cosmetically in production.

Add Radii and Rounded Corners.

Sharp edges focus the stress and prevent the free flow of the material in the mold that may lead to incomplete fills, cracks and high residual stresses in the final piece part. The addition of rounded radii – including minimum internal radii of half the thickness of the adjacent walls – enhances the flow of the material, stress concentration and the structural integrity of the part. Outside rounded edges are also better to the eye and less prone to stress fractures in service.

Functional Ribs and Bosses of Design.

Formal elements such as ribs (thin vertical elements) and bosses (elevated cylindrical elements that allow screw fixing or insert mounting) are essential in supporting plastic components other than merely making the walls thicker. The ribs should usually be 2.5-3 times the height of the wall thickness though not more than 50-60 percent the thickness to prevent sink marks and distortion. The bosses ought to be filled with fillets or gussets and shaped in such a way that there are no super thick areas. These characteristics enhance the stiffness and performance in terms of mechanical performance and independence without compromising manufacturability.

Minimize Complex Undercuts

Anyside that causes a part to be not ejected directly out of the mold is called an undercut. Where needed, undercuts make tooling more complex and expensive and sometimes may necessitate side-actions, lifters or collapsible cores in the mold. Redesign parts where feasible to get rid of or minimize undercuts. In case they are needed, design them in advance, and work hand in hand with your mold maker to combine proper mechanisms.

Maximize the placement of gates and Ejection.

It is at the gate that the molten plastic flows into the mold cavity. Its position influences material flow, formation of weld lines and finish of surfaces in places that are visible. Gates are to be installed in strong locations not near cosmetic surfaces and more than one gate can be applied to large parts to equalise the flow of the materials. In the same way, the position of ejector pins should also be taken into consideration such that marks are placed in non-observable locations and do not deform thin features. Planning of gates and ejector pins can enhance the aesthetics of parts as well as structural quality.

Take into account the Shrinkage and Material Characteristics.

The rate at which various plastics cool down varies between amorphous and semi-crystalline resins. This will have to be designed to incorporate parts by modeling material flow and shrinkage behavior, either in a digital form or by testing a prototype. This eliminates dimensional error and warpage of finished components. Keep in mind that highly filled or reinforced materials do not shrink equally as well, as well, this affects the design of cavities and tolerancing.

Assemble and Functional Integration Plan.

Design of parts must also be taken into consideration of the way the final part will be joined with other parts. The use of design attributes such as self-locating bosses, snap fits, living hinges and built-in fasteners can help minimize the assembly time and cost. Reflect on whether or not threads will be molded or to be shaped later with the help of inserts, and design correspondingly. This wider perspective serves to make sure that the component does not just mold but fits into larger and bigger assemblies.

Surf Finish/Cosmetic Requirements.

Early surface treatment options such as texturing, polishing or gloss, etc should be specified. Draft and meticulous work on the mold finish are necessary on highly polished surfaces, whereas minor defects in the surface can be obscured in a texture. Early design of cosmetic needs eliminates the expensive changes in moulds that occur in the future and produces a functional and appealing part.

Tooling Before Designing.

To ensure true commitment to costly tooling it is important to simulate plastic flow and cooling (moldflow analysis), create prototypes (3D printing or CNC machining), and do physical validation. Such measures assist in revealing the problems like air traps, weld lines or cooling imbalances in advance of their appearance in production. Early validation lowers the cost of design rework and increases faster production ramp up.

These are critical rules that the engineers can follow to have robust, manufacturable, and cost-effective parts of the plastic, which are uniform walls, proper draft and radii, functional ribs/bosses, considerate gating, shrinkage control, assembly design, and cosmetic planning. These are very common principles in industry and are the foundation of successful injection molding design.

How Do You Select the Right Plastic Material for Automotive Applications?

The wrong choice of plastic in an automotive part can be an expensive mistake to make. You may choose a material that seems suitable on paper, but which may crack under temperature stress, degrade with UV exposure, or fail when impact-tested. The result is costly recalls, warranty claims, and damage to your brand reputation. With thousands of polymers available, the right choice can sometimes become a significant challenge.

First, you must define the functional requirements of the part: mechanical stress, operating temperature range, chemical exposure, and UV resistance. Then you can match those needs with the properties of common automotive polymers like PP, ABS, PC, or PA. Example: PA66 for heat-resistant applications under the hood, while ASA should be used for UV-stable exterior trims. Consider cost and manufacturing process for the best trade-off for the desired application.

I’ve seen projects delayed for months because the initial material choice was based on cost alone, without fully considering the real-world environment the part would live in. A classic example is using standard ABS for an exterior part that will sit in the sun all day. It will look great initially, but it will become brittle and fade over time. You have to think like an investigator, uncovering all the potential stresses the component will face throughout its life. Let’s dive deeper into the key criteria you must evaluate to make an informed and reliable material selection.

Understanding the Environment

Before you can choose a material, you must know where the part will live.

- Under the Hood: Components here face high temperatures, engine vibrations, and exposure to oil, coolant, and grease. Materials like glass-filled Polyamide (PA66-GF30) or Polyphenylene Sulfide (PPS) are excellent choices because they maintain their strength and stability in extreme heat.

- Exterior: These parts, like grilles, mirror housings, and trim, must withstand everything nature throws at them. That means UV radiation from the sun, rain, snow, and road salts. Acrylonitrile Styrene Acrylate (ASA) is often preferred over ABS for its superior UV stability, preventing it from becoming yellow and brittle.

- Interior: Interior components must be durable and aesthetically pleasing. They need to resist scratches, scuffs, and chemical cleaners. Materials like Polycarbonate/ABS (PC/ABS) blends are popular for dashboards and consoles because they offer a great combination of impact strength, heat resistance, and a high-quality surface finish.

Matching Properties to Function

Once you know the environment, you map it to specific material properties.

- Mechanical Properties: Will the part bear a load? You need to look at tensile strength (how much it can be stretched) and flexural modulus (how stiff it is).

- Impact Resistance: For parts like bumpers and interior safety components, you need a material with high impact strength, like Polycarbonate (PC) or Thermoplastic Olefin (TPO).

- Chemical Resistance: Will the part be exposed to gasoline, wiper fluid, or car wash detergents? Make sure your chosen polymer won’t degrade. Polypropylene (PP) is known for its excellent chemical resistance.

Here’s a quick-reference table for common automotive plastics:

| Polymer | Common Applications | Key Strengths |

|---|---|---|

| PP (Polypropylene) | Bumpers, battery cases, interior trim | Cost-effective, chemical resistance, flexible |

| PA (Polyamide/Nylon) | Engine covers, intake manifolds | High heat resistance, mechanical strength |

| PC/ABS (Polycarbonate/ABS) | Dashboards, instrument panels | High impact strength, good heat resistance |

| ASA (Acrylonitrile Styrene) | Mirror housings, grilles, cowls | Excellent UV resistance, good aesthetics |

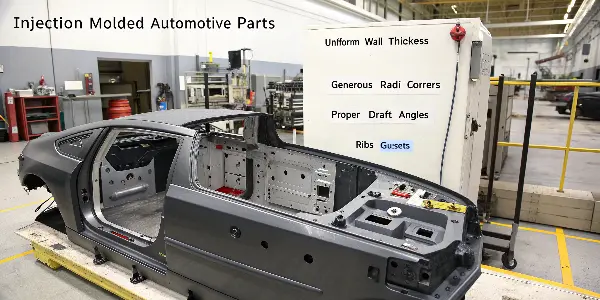

What are the Most Critical Guidelines for Injection Molded Automotive Parts?

Even with the ideal material, a poorly designed part will fail. Common mistakes such as varying wall thickness, sharp corners, or improper gate locations result in weak, warped, or aesthetically imperfect parts. Delays in production, added tooling expenses, and a high percentage of scrap result from these issues. You waste a lot of time and money curing problems that really should have been avoided when you designed it.

The most crucial rules of thumb for injection molded parts are to keep the wall thickness uniform to avoid sink marks and warping, and to add generous radii to all corners in order to decrease stress concentration and enhance material flow. You should also include proper draft angles for ease of ejection from mold. Finally, use strategically placed ribs and gussets to add strength without increasing wall thickness, which creates cosmetic defects.

In my years of running a mold factory, I can tell you that the best designs are the ones that consider the manufacturing process from day one. An engineer might design a part that is theoretically strong, but if it can’t be molded efficiently, it’s a failed design. These guidelines aren’t just suggestions; they are fundamental rules that govern the physics of molten plastic flowing into a steel mold. Ignoring them is a recipe for disaster. Let’s break down the most important ones.

Uniform Wall Thickness

This is the golden rule of plastic part design. When molten plastic cools, it shrinks. If one section of your part is much thicker than another, the thick section will cool slower and shrink more, pulling on the adjacent thinner section. This causes problems like sink marks – small depressions on the surface, voids – internal bubbles, and warp. Always strive for a consistent thickness throughout the part. If you need to vary the thickness, make the transition gradual, not abrupt.

Radii on All Corners

Sharp internal corners are a big no-no. They produce intense stress concentrations, which will leave the part weak and susceptible to cracking under load, while disrupting the natural flow of molten plastic as it fills the mold and causing incomplete parts. As a general rule, the inside radius should be a minimum of 0.5 times the wall thickness. The outside radius should then be the inside radius plus the wall thickness. Smooth, rounded corners make for a stronger, more manufacturable part.

The Power of Ribs and the "Box Effect"

What if you need a part to be really stiff, but you can’t make the walls thicker? The answer is ribs. Adding thin ribs to a surface dramatically increases its strength and rigidity without adding much material or creating thick sections. This leads to what’s known as the box effect. By designing a network of intersecting ribs, you create closed-cell, box-like structures. This geometry is incredibly efficient at resisting bending and twisting forces, giving you maximum strength with minimal material usage and weight. However, be careful: ribs should be designed to be about 50-60% of the main wall thickness to avoid causing sink marks on the opposite surface.

Draft Angle

A draft angle is a small taper given to the vertical walls of a part. Consider trying to pull a perfectly straight-sided cup out of a tight mold; the friction would cause it to stick. By tapering the sides even as little as 1 to 2 degrees, the part releases from the mold much more easily. This prevents drag marks, scratches, and damage to the part during ejection. Every surface parallel to the mold opening direction requires a draft angle.

Conclusion

Designing plastic automotive components is a delicate balance among performance, cost, and aesthetic considerations. The key is not which one to choose but how to make them complement one another through intelligent design considerations. With the right materials for the job and adherence to basic injection molding principles like uniform walls and the use of ribs for strength, parts can be designed to be strong, affordable, and attractive, meeting the high standards of the automotive industry.