Have you ever designed a fantastic plastic part only to discover that it would be impossible to manufacture? This disconnect between design and reality can result in costly mold modifications, annoying hold-ups, and a subpar finished product. You invest a lot of time and money in a project, only to have it go out of control due to unnoticed production problems. This is where your entire project can be saved by implementing Design for Manufacturing (DFM) from the beginning.

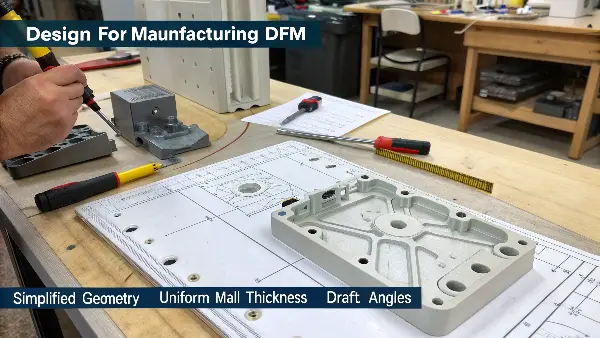

Designing a product to be readily and affordably built is known as Design for Manufacturing (DFM) in plastic part design. This entails actively taking the injection molding technique into account in the early stages of design. Simplifying the part’s geometry, choosing the right material, employing consistent wall thicknesses, and accurately designing elements like draft angles and ribs are all examples of core DFM techniques. Following DFM guidelines significantly lowers tooling costs, expedites manufacturing, improves part quality, and increases the marketability of your product as a whole.

I’ve seen it countless times in my career: a great idea can either fly or flop based purely on how well DFM principles were applied. It’s more than just a technical checklist; it’s a crucial mindset that prevents major headaches and protects your budget. So, let’s unpack what DFM really means for you and your projects. We’ll explore its primary goals and the practical guidelines that can transform your designs from mere concepts into manufacturable, high-quality products.

What is the main objective of design for manufacturing DFM in product design?

You have a creative product concept, but are you sure it can be produced effectively? Many designers ignore the practical realities of manufacturing in favor of a strong emphasis on aesthetics and functionality. This frequent mistake can eventually result in unforeseen expensive expenses and major production obstacles. Your brilliant concept feels like it’s slipping away as deadlines slip and your budget soars. DFM’s primary goal is to avoid this precise situation by incorporating manufacturing expertise into the early stages of design.

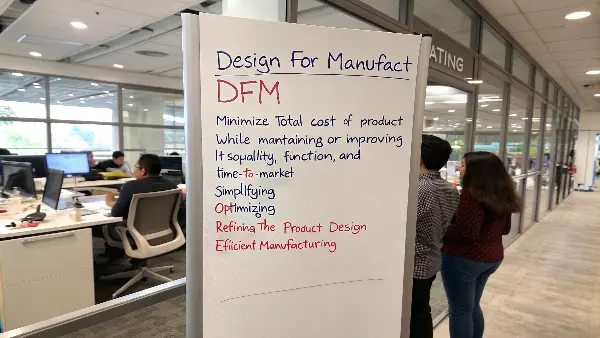

The primary goal of Design for Manufacturing (DFM) is to reduce a product’s overall cost while preserving or enhancing its functionality, quality, and time-to-market. It accomplishes this by streamlining, improving, and honing the product design to enable more effective manufacturing. This entails cutting down on the amount of components, standardizing parts, and creating features that are simple to produce using conventional manufacturing techniques like injection molding. In order to ensure a more seamless production process, DFM ultimately seeks to close the gap between design intent and manufacturing capacity.

DFM’s true strength is found in its comprehensive methodology. Being intelligent from the start is more important than taking shortcuts. A client once presented me with a design for an electronics enclosure that required the screwing together of five distinct plastic components. On paper, everything looked fantastic, but the tooling costs for five distinct molds were exorbitant, and manual assembly added time and expense. We reworked it into a single, sophisticated part with built-in snap-fit features by using DFM. They saved about 40% on the project’s overall cost and were able to launch their product a month ahead of schedule because to this straightforward modification, which also removed four molds and all assembly work.

All-Around Cost Reduction

For good reason, cost reduction is frequently regarded as DFM’s main objective. You can directly lower the injection mold’s complexity by making a part’s design simpler. Lower tooling costs result from fewer design and machining hours spent on a simpler mold. The choice of materials is also very important; DFM advises selecting reasonably priced materials that nonetheless satisfy all practical needs. Through features like uniform wall thickness, which avoids needlessly thick parts that waste plastic and lengthen cycle times, it also promotes the use of as little material as possible.

Enhancing Consistency and Quality

Higher-quality designs are frequently simpler. Making components that are naturally stable and less prone to manufacturing flaws is the main goal of DFM. For instance, using a consistent wall thickness during design helps avoid typical problems like warping and sink marks. The part will eject smoothly from the mold without stress marks or damage if the right draft angles are used. You can lower scrap rates and increase overall product reliability by addressing these possible issues throughout the design phase, which guarantees that every item produced is consistent and satisfies quality standards.

Quickening the Time to Market

In the current competitive environment, speed is crucial. The product development cycle is considerably shortened with DFM. After the initial mold trial, a design that has already been optimized for production needs fewer, if any, adjustments. The designer and the mold maker no longer have to exchange expensive and time-consuming correspondence. Your product reaches your consumers considerably more quickly with fewer tooling delays and a more seamless production ramp-up, providing you a significant competitive edge.

What are the main points of the design for manufacturing DFM guidelines?

You are aware of the significance of DFM, but where do you even start? It might be challenging to determine which technical regulations should be given priority for your particular plastic item because the requirements can appear to be a lengthy and complex list. If you pay too much attention to minutiae or, worse, disregard the principles completely, you are probably creating issues that will be costly and time-consuming to resolve in the future. You may make wise judgments that result in a productive and effective manufacturing process by being aware of the main areas that DFM standards focus on.

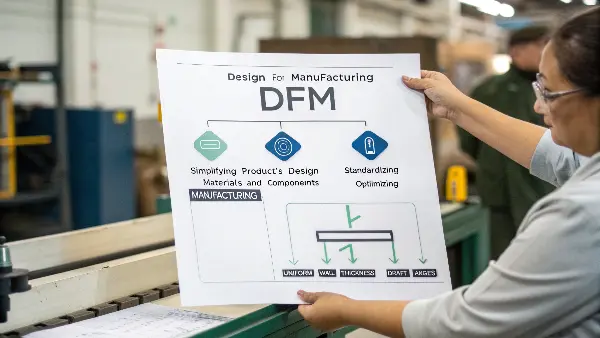

Three crucial areas are the main focus of Design for Manufacturing (DFM) guidelines: streamlining the product’s design, standardizing components and materials, and streamlining the manufacturing process. This translates into certain part geometry guidelines for plastic injection molding, like applying draft angles, keeping walls constant in thickness, and creating efficient ribs and bosses. The standards also stress the need of choosing materials that will guarantee flow and function, as well as designing the part to make mold assembly simple and enable a quick, repeatable molding cycle. They serve as an efficient template.

Practicality is always the main focus of DFM. "What is the simplest, most reliable way to make this part?" is the question that needs to be addressed. This entails examining each feature and determining whether it is actually required or whether it can be accomplished in a more manufacturing-friendly manner. As a mold maker, I frequently see designs that are overly complicated, such as deep ribs that are too thin and lead to filling problems, or sharp interior corners where a radius would be stronger and easier to machine. DFM rules are specifically made to identify and rectify these kinds of details.

Making the Design Simpler

DFM is fundamentally about simplifying. The fundamental idea is "less is more." This area of focus encourages designers to minimize the overall number of components in an assembly, frequently by integrating several purposes into a single molded part. For instance, a DFM approach would incorporate mounting posts and snap-fits straight into the housing rather of utilizing a separate bracket, screws, and housing. There are repercussions from this simplification:

- Fewer Parts: Reduces inventory and supply chain complexity.

- No Assembly: Eliminates labor costs and potential for assembly errors.

- Less Tooling: Lowers the initial investment in molds.

Standardizing Components and Materials

Standardization is another key focus. Why reinvent the wheel when a standard, off-the-shelf solution exists? DFM guidelines encourage using standard sizes for features like holes, bosses, and screw threads. This allows for the use of standard mold components, which are cheaper and more readily available than custom ones. The same logic applies to material selection. Choosing a common, well-understood polymer rather than an exotic, hard-to-process one simplifies the molding process, reduces material cost, and ensures a more reliable supply chain. This focus on standardization brings predictability and cost-effectiveness to the manufacturing process.

Optimizing the Manufacturing Process

This is where DFM gets specific to the chosen manufacturing method, in our case, injection molding. The guidelines are entirely focused on making the molding process as smooth and efficient as possible. This includes designing parts with adequate draft angles for easy ejection, avoiding undercuts that require complex and expensive side-actions in the mold, and ensuring uniform wall thickness to promote even cooling and prevent defects. It’s about designing the part for the process, not forcing the process to accommodate a difficult part.

| DFM Focus Area | Key Guideline | Benefit |

|---|---|---|

| Simplification | Reduce part count by combining functions | Lower tooling & assembly costs |

| Standardization | Use standard sizes for features and materials | Reduced cost, improved availability |

| Process | Design with draft, uniform walls, no undercuts | Faster cycle times, higher quality, less scrap |

What is an Injection Molding DFM Report?

A Molding Injection To guarantee that a plastic part can be molded effectively, consistently, and at the lowest feasible production cost, a DFM Report is a technical document produced prior to the start of tooling. It detects manufacturing hazards, emphasizes design changes, and provides engineers with a clear road map for optimizing part shape, mold structure, and overall production feasibility.

Simply put, by identifying problems before the mold is created, a DFM report helps you steer clear of costly tooling errors.

The Significance of a DFM Report

Thousands of dollars are spent on injection molds. A minor design error, such as a thin wall, undercut, or poorly placed gate, can result in:

-

The Warpage

-

Marks from sinks

-

A challenging ejection

-

Weak structural elements

-

brief life of mold

-

longer cycle time

By assessing the part from all angles and making early corrective recommendations, a DFM report lowers these hazards.

What’s Usually Included in an Injection Molding DFM Report:

1. Part Geometry Review

-

Consistency of wall thickness

-

Design of the rib and boss

-

Analysis of draft angles

-

Undercut identification

-

Stress points or jagged edges

Making ensuring the part can fill correctly, cool uniformly, and discharge with ease is the aim.

2. Evaluation of Moldability

The report determines if the part can be molded successfully. This comprises:

-

Filling behavior and material flow

-

Possibility of gate location

-

Needs for venting

-

Position of the ejector pin

-

Recommendation for the parting line

3. Identification of Risks

Typical problems noted in DFM:

-

Sink mark-prone areas

-

Bulky or thick areas

-

Possible lines of welding

-

Not enough draft

-

Sections that are thin and could result in brief shots

Typically, each problem is highlighted with pictures and recommended solutions.

4. Suggestions Regarding Mold Structure

The DFM recommends the following construction method for the mold:

-

The quantity of cavities

-

Comparing hot and cold runners

-

Lifters or side motions

-

Cavity/core orientation

-

Layout of cooling channels

Cycle time, part quality, and tooling cost are all impacted by these choices.

5. Optimization of Manufacturing

Additionally, a quality DFM report offers recommendations for:

-

Cut down on cycle time

-

Boost your strength

-

Reduce the amount of materials used

-

Avoid warpage

Make sure that production is constant.

The DFM Report is prepared by whom?

After receiving your 3D part file (STEP, IGES, or STL), the injection mold manufacturer or tooling engineer typically creates the DFM report. Before the mold is machined, the report is sent for evaluation and approval.

The DFM report examines the product from two primary angles: the tooling side and the product side. This thorough report offers a better comprehension of the product and necessitates technical knowledge to guarantee accuracy. It is meant to help with the design process and offer insightful information.

When Is a DFM Report Required?

You ought to ask for it:

-

Prior to mold production

-

When altering an already-existing component

-

When switching out materials

-

When switching to a new source for tooling

It acts as a last "health check" prior to steel investment.

An Injection Molding DFM Report is a crucial pre-tooling document that assesses your part design, pinpoints potential hazards, and suggests enhancements to guarantee seamless, economical mass production. Time and money are saved, and once molding starts, the chance of faults is greatly decreased.

What are the 5 principles of DFM?

You’re attempting to implement DFM, but your efforts may seem dispersed if you lack a defined structure. One issue, such as wall thickness, may be resolved, but another, such as an unmoldable undercut, may result. In addition to wasting time, this trial-and-error method may leave you wondering if your design is really optimized. You need a straightforward, trustworthy set of guidelines to help you make judgments and make sure you’re covering all the bases. You can methodically and successfully prepare your part design for manufacturing by adhering to the five fundamental DFM principles.

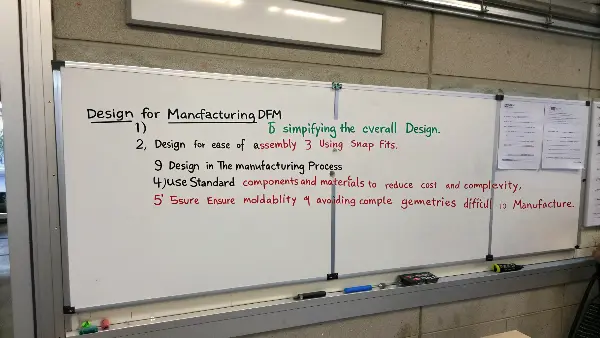

The following are the five core tenets of Design for Manufacturing (DFM): 1) Reduce the number of parts by making the overall design simpler. 2) Use features like snap-fits to design for ease of assembly. 3) Design for the Manufacturing Process by adhering to its guidelines, such as when it comes to molding draft angles. 4) To cut expenses and complexity, use standard components and materials. 5) Make the part simpler and use fewer manufacturing operations to finish it. Together, these ideas result in a high-quality product that is easier, quicker, and less expensive to make.

These five principles are the foundation of every successful DFM analysis I’ve ever conducted. They are not just abstract theories; they are practical rules that I apply daily when reviewing client designs. I often walk my clients through these principles one by one, using their own 3D model as an example. It’s amazing to see the "aha!" moment when they realize that a small change, guided by one of these principles, can solve a major manufacturing problem they didn’t even know they had. Let’s break down each one so you can apply them to your own work.

1. Minimize Part Count

This is DFM’s golden rule. Each component of a product adds a step to the assembly process, needs to be handled, and needs its own tooling. It’s better to have fewer pieces. Combine several components into a single, attractive piece whenever you can. Consider adding brackets, clamps, or springs straight into your primary plastic casing, for instance. By removing possible points of failure between distinct components, this not only reduces tooling and assembly costs but also improves the end product’s reliability.

2. Easy-to-assemble design

Making assembly as easy as feasible is your next objective if you are unable to decrease the number of parts to one. This entails creating self-locating components that can only be assembled correctly. Parts can be seamlessly guided into position by utilizing characteristics like leading edges and chamfers. The best strategy is to use integrated attachment features to completely do away with fasteners like glue and screws.

- Snap-fits: These are a fantastic way to create strong, fast, and tool-free connections.

- Press-fits: Excellent for creating permanent, tight seals between parts.

3. Manufacturing Process Design

The capabilities and constraints of the manufacturing process must be taken into consideration while designing your part. This is crucial for injection molding. You must adopt the mindset of molten plastic. The design must make it easy for the plastic to enter and fill the mold chamber. It must also discharge cleanly and cool uniformly. This involves following the major design criteria we’ll examine next, such as maintaining consistent wall thickness, adding draft angles to all vertical surfaces, and avoiding sharp corners. Defects, delays, and cost overruns are inevitable if these guidelines are broken.

4. Make Use of Standard Parts

Whenever possible, use conventional parts rather than ones that are created to order. This holds true for the raw materials themselves as well as for fasteners and inserts. It is far more economical and dependable to use a common grade of polycarbonate (PC) rather than requesting a custom-blended polymer with lengthy lead times. You can save time and money by using standard M3 screws to design bosses and holes with standard dimensions. This enables your mold maker to employ pre-made, off-the-shelf mold components.

5. Make Manufacturing Operations Simpler and Less Complex

Consider your part’s complete journey, from the molding machine to the finished product. Cost and time are increased with each additional step or procedure. Is it possible to design the part in a way that eliminates the need for secondary procedures like drilling, cutting, or painting? For instance, a post-molding painting or blasting procedure may not be necessary if the mold has a textured surface. Designing writing or logos right into the mold reduces the need for printing or attaching labels afterward. Having a completed part emerge straight from the injection mold is the aim.

What are the design rules for plastic parts made by injection molding?

You’ve embraced the ideas of DFM, but now you need to transform them into precise, practical design rules for your plastic part. Knowing that you must "design for the process" is one thing, but understanding precisely what that entails in terms of wall thickness, radii, and draft angles is quite another. Your design is merely a guess in the absence of these specific rules. These specifics have the power to make or break your part, resulting in either aesthetic flaws or even total failure. You can make sure your product is durable, high-quality, and simple to manufacture by adhering to established injection molding design principles.

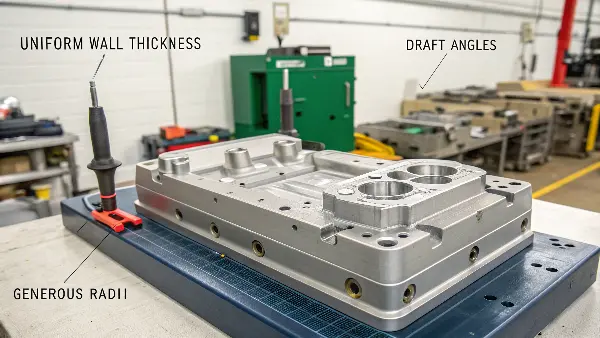

Key design guidelines for injection molding include maintaining a uniform wall thickness to prevent sink and warp, adding a draft angle (typically 1-2 degrees) to all vertical faces for easy ejection, and using generous radii on all corners to improve plastic flow and reduce stress. Additionally, you should design ribs and bosses correctly—ribs should be 50-60% of the wall thickness—and avoid creating undercuts that would complicate the mold. Following these rules is essential for creating a successful and cost-effective molded part.

These aren’t just suggestions; they are the laws of plastic part design. I’ve spent my career fixing designs that violate these fundamental rules. A client once came to me with a part that kept cracking during testing. The problem? Every single internal corner was perfectly sharp. Sharp corners are massive stress concentrators. By simply adding a small radius to those corners, we distributed the stress and completely solved the cracking issue. Let’s go through the most important guidelines you need to implement in every design.

Uniform Wall Thickness

This is arguably the most important guideline. Molten plastic needs to flow and cool evenly. If one section of your part is very thick and another is very thin, the thick section will take longer to cool and will shrink more. This differential shrinkage causes internal stresses that can lead to warping, sink marks (depressions on the surface opposite the thick section), and even voids inside the part. Aim for a consistent thickness throughout your part. If you absolutely need to change thickness, make the transition gradual and smooth.

Draft Angle

Imagine trying to pull a perfectly straight block out of a tight-fitting box; it creates suction and friction. The same thing happens in an injection mold. A draft angle is a slight taper, typically 1 to 2 degrees, applied to all faces parallel to the direction of mold opening. This tiny angle prevents the part from scraping against the mold wall during ejection, ensuring a clean release and a good surface finish. Textured surfaces require even more draft, often 3 to 5 degrees or more.

Radii on Corners

Sharp internal and external corners are problematic for several reasons. For the part itself, they create high stress concentrations that can lead to cracking under load. For the manufacturing process, sharp internal corners are difficult for plastic to flow into, potentially causing incomplete filling. Sharp external corners on the part correspond to sharp internal corners in the mold, which are difficult to machine and can be weak points in the tool itself. Always add a generous radius to all corners. A good rule of thumb is to make the inside radius at least 50% of the wall thickness.

Ribs and Bosses

Ribs are used to add strength and stiffness to a part without adding significant thickness. Bosses are raised cylindrical features used for mounting or alignment. To avoid defects, these features must be designed correctly.

- Ribs: To prevent sink marks on the opposite surface, a rib’s thickness should be no more than 50-60% of the primary wall thickness. Their height should ideally be less than three times the wall thickness.

- Bosses: The walls of a boss should also follow the 50-60% rule. It’s also good practice to add gussets or connecting ribs to the base of the boss to strengthen it and improve material flow.

Following these core guidelines will solve 90% of the problems typically seen in plastic part design and set you on the path to a successful product.

Conclusion

Learning a complicated set of rules is not the goal of Mastering Design for Manufacturing. It’s about changing your perspective so that you start thinking about the whole production process. You can close the gap between concept and reality by streamlining your design, adhering to important rules like consistent wall thickness and draft, and concentrating on efficiency. A higher-quality product that reaches the market sooner is the outcome of this proactive strategy, which also saves you money and time.

Having in-depth conversations with the client is an essential next step after completing the DFM report. To guarantee alignment, every item in the report is examined and verified with the client. The mold designer cannot begin creating the mold in accordance with the established parameters until this exhaustive review procedure is finished.