Do you design a product and get stumped over selecting materials? You require a strong, dependable plastic, yet concern yourself with what it will do under the sun. The wrong material selection will cause it to crack, fade, and ultimately, be a flawed product that will harm your reputation. Here, recognizing the significant distinctions among standard materials such as ASA and ABS will become utterly vital to your success.

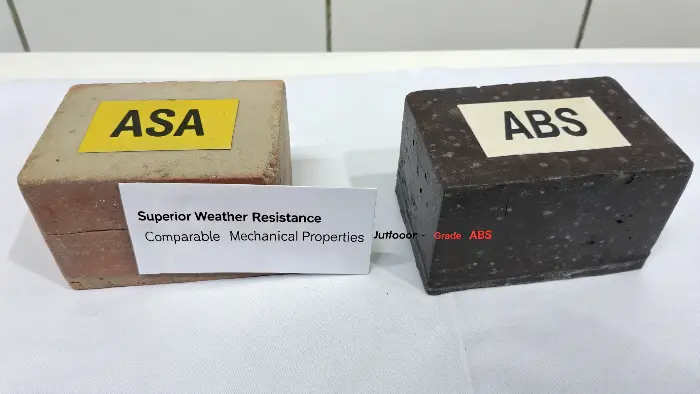

For exterior and automobile parts, ASA is preferred to ABS. ASA possesses identical outstanding mechanical strength and impact capability as ABS, with one significant added trait: outstanding resistance to UV radiation and weathering. ASA parts will not yellow nor become hard with age when placed in direct sunlight. While ABS is a wonderful inexpensive material that is great in interior types of parts, it will degrade and fail quickly in exterior types of conditions, so ASA is by far more sturdy and reliable.

One of the most important decisions as a product designer is the choice of the material. It touches upon performance and life-span as well as cost and production. I have witnessed too many projects that designers reverted to what they were familiar with, and that is usually ABS. It is a great multifunctional plastic, and I carry it everywhere. However its greatest weakness is a deal-breaker to some applications. You just need to know when it is not appropriate and when it should not be compared with its closest companion, ASA, it is time to choose the more reasonable, safer and more adequate on the end. But what otherwise are the real comparisons between these two materials?

Is ASA as good as ABS?

You are already acquainted with ABS. The workhorse of the plastics industry—tough, easy to mold, and inexpensive. So when a new material such as ASA is mentioned, it is in one’s nature to be slightly skeptical. One might be wondering if one is taking away the reliable qualities of ABS in exchange for simply one new advantage. That doubt alone may make one reach for that old familiarity, even though it may not after all be ideal in one’s application. The reality is that ASA was developed as a better-than-ABS.

Yes, in practically every mechanical aspect, ASA is the equal of ABS, and in weatherability, it’s much superior. You can think of ASA as "outdoor-quality ABS." The impact resistance, stiffness, and tensile strength are equivalent. The processing pressures and temperatures are equivalent too, so often identical molds can be employed without alteration. The critical parameter that ASA deviates in that it contains an acrylic elastomer instead of a butadiene elastomer, so it possesses excellent UV radiation resistance, which does not occur in ABS.

Breaking it down to my clients, I usually begin by demonstrating to them that ASA is not an entirely distinct and foreign substance. It is more of a professional edition of a close acquaintance. In my case, mechanical performance is so comparable that in most cases they are interchangeable as far as strength is concerned. I recall a project of a company, which produced housings to agricultural sensors. ABS had been in use by them. We proposed a change to ASA of a new product line that would be more open to the elements. An experiment with the same mold was carried out.

The resultant ASA components worked exactly in all our internal drop and stress tests. The only distinction was the fact that our ASA samples that we had kept on the factory roof under a test were still in their original state exactly 1 year later, and the ABS samples were yellow and brittle.

Naturally, one of the factors is always price. ASA resin normally costs 10-20 percent higher than a general ABS. This is a very important calculation to a designer. You need to question whether the extra time of lastingness is worth the premium. Personally, professionally, the answer is always yes, in my opinion, in case the part will spend any considerable amount of time outdoors. Such a minor upfront cost will stop you paying warranties, replacements and damaged brand image in the future. It is just a sacrifice of peace of mind in the long-run.

A Deeper Look at the Materials

To really understand the comparison, it helps to look at a few key properties side-by-side.

| Feature | Acrylonitrile Butadiene Styrene (ABS) | Acrylate Styrene Acrylonitrile (ASA) |

|---|---|---|

| UV Resistance | Poor (Yellows and becomes brittle) | Excellent (Maintains color and properties) |

| Impact Strength | Excellent | Very Good to Excellent |

| Tensile Strength | Good | Good |

| Heat Resistance | Good (HDT around 80-100°C) | Good (HDT around 85-105°C) |

| Processing | Easy to mold | Easy to mold (similar to ABS) |

| Cost | Lower | Higher (10-20% more than ABS) |

| Appearance | High gloss finish possible | High gloss finish possible |

This table clearly shows that you are not losing any significant mechanical or processing advantages when you choose ASA. You are simply paying a small premium for superior weatherability.

ASA vs ABS: Analysis Of Application Areas

Outdoor and weather resistance.

It is also no secret that ASA is highly resistant to outdoor conditions. It can be exposed to the sun and rain at all times and changing weather without losing its color and gloss. This is especially useful when it comes to products that have to be long-lasting in appearance like outdoor furniture, automotive exterior trims, and signage. ABS, however, lacks the UV resistance, and would be found degrading, yellowering, or brittle when exposed to the outside, without protective coats or additives. That is why ABS would be more appropriate where the weathering is not a variable (indoor environment).

Mechanical Strength and Impact Resistance.

ABS has a better edge over toughness in interior applications. It is very impact and mechanical stress-resistant due to its butadiene content, and is therefore a widely used material in power tool housings, luggage shells, and sporting goods. ASA also has good impact resistance but in this area, it is a bit weaker than ABS. Nevertheless, the ASA is more resistant to wear over time when subjected to outdoors conditions thus making it more stable in playground equipment, outdoor casings, and agricultural machinery parts.

Chemical Resistance and Thermal Stability.

ASA is better than ABS in terms of long-term heat exposure. Its chemical composition enables it to resist aging with heat, i.e., it is not easy to lose mechanical properties when subjected to higher temperatures or direct sunlight. This feature renders it applicable in application like under-the-hood car parts, outdoor appliance enclosures, and electrical enclosures. ABS is good in moderate temperatures but less durable when exposed to prolonged heating or when in presence of some chemicals. It is still popular in consumer electronics and household goods, where the conditions of operation tend to be more controlled.

Cost and Economic factors.

Cost-wise, ABS is normally cheaper and simpler to handle and is a viable option when dealing with high-volume consumer products. It is cheap, thus making it popular in its application in household appliances, electronics, and toys where cost is a key factor. ASA, on the contrary, is costlier based on its improved weatherability and longevity. Nonetheless, when it comes to applications in which outdoor durability and performance are important, the extra cost of ASA is clearly worth it, which is why it is used in the automotive, construction, and outdoor equipment sectors.

Industrial Applications Overview

The decision in favour of ASA or ABS is usually determined by the environment in which it is to be used. ASA is the market leader in areas where exterior performance is required like in automotive finishes, roofing, signage and marine parts. As an indispensable part of consumer electronics, toys, power tools and automotive interiors, ABS is tough, versatile, and easily finished. Both materials have established their niche and therefore, manufacturers can choose the appropriate one according to the durability requirements, environmental risks, cost goals and flexibility in design.

Is ABS suitable for outdoor use?

You’ve created a component that must be strong and inexpensive, and ABS appears to meet all of the criteria. The part is lovely, but by now, you’re aware that there will be a section that will be subjected to direct sunlight. You may think about simply going ahead with ABS and taking your chances, reasoning that it will undoubtedly be okay. But this is a huge risk. A couple of months of direct sunlight will cause that shiny, gorgeous part to appear old, inexpensive, and delicate, which could jeopardize customer acceptance and failure.

No, regular ABS is not ideal for long-term exposure outdoors. This is because it has very low resistance to ultraviolet (UV) radiation, such as sunlight. The butadiene rubber component of ABS degrades upon exposure to UV radiation, also known as photo-oxidation. This is a chemical reaction that makes the plastic lose its color, becoming yellow or brown, and more notably, makes it very brittle. Whatever application that requires hardness in sunlight will find ABS parts failing early, usually by cracking up or completely breaking apart.

The science behind this failure is quite straightforward. The “B” in ABS stands for butadiene, a type of rubber that gives ABS its fantastic toughness and impact strength. Unfortunately, the chemical structure of butadiene contains double bonds that are easily broken apart by the high-energy photons in UV radiation. As these bonds break, the long polymer chains that give the plastic its strength are degraded. The material loses its ability to flex and absorb impact, which is why it becomes so brittle. This isn’t a slow process; the damage can become noticeable in just a few months of direct sun exposure.

I learned this lesson the hard way in my early career. We had a customer that needed to build a large order of enclosures in an outdoor lighting system. In order to keep costs low, they wanted to use a commodity white ABS. They looked great as they came out of the mold. About eight months later, we began to get calls. The mounting tabs on the enclosures were breaking loose when electricians went to service the lights. We got some of the broken parts back in, and I was appalled. The plastic had developed a sickly yellow color and was so brittle, you could break it in half with your fingers like a cracker. It was a very expensive lesson in materials science. We had to replace the whole batch with ASA parts at our own expense in order to preserve the relationship.

So, can you make ABS work outdoors? Absolutely, but it involves more steps. You can use specialized grades of ABS that include UV stabilizers, but that’s a cost-adding measure. You can paint or coat a protective layer over your ABS part. That, too, is another manufacturing step and yet another potential failure point—if the paint flakes off or delamination occurs, then your underlying ABS is exposed and will begin to degrade. When you tally up the cost of a UV-stabilized grade of ABS or a secondary paint operation, though, it often comes out to about as much money, or more, than if it had simply cost of entry to use ASA in the first place.

Key Comparisons of ABS and ASA

In comparison of ABS and ASA, the differences are mostly regarding the durability, cost, appearance, and performance in various settings. ABS is a tough, impact resistant plastic that is used in an indoor setting, and ASA is used in prolonged outdoor use. ABS is cheaper and has great surface finish selections, making it the perfect choice for consumer goods and electronics. Conversely, ASA is much more resistant to UV rays, weathering, and heat, thus more suitable in outdoor furniture, automobile exterior applications, and in the construction industry.

ABS is a little stronger in impact resistance, especially in indoor environment, but it loses its characteristics more rapidly when exposed outside. ASA balances have a balance between strength and the outstanding weatherability assurance of performance over time in demanding environments. Processing-wise, the two are both simple to mold and finish, but ABS is more popularly used when it has to be painted or plated, or 3D printed. Another determining factor is cost. ABS is cheaper, whereas ASA is also expensive, but the price is worth it in terms of use in the outdoors.

On the whole, the decision between the ABS and the ASA is based on the environment of application. ABS is preferred for indoor products that are cost-sensitive and those whose use is aesthetically driven. In the case of outdoor and weather-exposed and durability-oriented use, ASA is the superior material.

Is ABS or ASA better for outdoor use?

When you’re designing a product meant to live outdoors, such as a piece of garden equipment, a housing for electronics, or an accessory for a boat, your reputation is on the line. The product needs to look good and perform flawlessly for years, not just one season. Choosing a material that degrades under the sun will inevitably lead to unhappy customers, expensive warranty claims, and a perception that your brand produces low-quality goods. Your product’s success depends entirely on choosing a material built to withstand the elements.

ASA is unequivocally better than ABS for any outdoor application. While ABS degrades quickly when exposed to sunlight, becoming brittle and discolored, ASA is specifically engineered to resist UV radiation and harsh weather. ASA maintains its original color, surface gloss, and mechanical properties like impact strength even after years of outdoor exposure. This makes it the clear and ideal choice for any product that requires long-term durability and aesthetic stability in an outdoor environment. You trade a small increase in material cost for a massive improvement in product lifespan.

Performance gap is not nuanced. In routine weathering tests, such as the Xenon Arc test that tests months of sun exposure over a shortened period of time, the outcomes are brutal. A significant color change and can be lost over half of original impact strength will be observed in an ABS sample. Contrarily, an ASA sample will experience very little change in color and will retain nearly all its toughness. The fact that the acrylic rubber of ASA is far more stable during UV light than the butadiene rubber of ABS explains this. It just does not decompose in a similar manner.

Moreover, the outdoor resistance is not limited to UV light. A material should also be heat, cold, rain and humidity resistant. ASA has been doing very well in this area as well. This is because of its stable chemical structure that does not absorb moisture that can destroy other plastics with time.

I was once engaged in a project involving the development of housings of the poolside control panels. The client also feared the strong sun of Florida as well as the constant splashing of the chlorinated water. ABS was not even discussed. We selected ASA and it was the ideal option. Years on, said housings continue to serve and almost as well as the day they were put up. It is this type of reliability that makes ASA to be so trustworthy when it comes to all the hard-duty outdoor jobs.

Key Applications for ASA’s Weatherability

- Automotive Exteriors: Mirror housings, grilles, cowls, and trim.

- Construction & Building: Siding, window profiles, gutters, and deck components.

- Recreational Equipment: RV parts, boat hulls, hot tub panels, and outdoor furniture.

- Electronics & Signage: Housings for outdoor security cameras, satellite dishes, and commercial signs.

In all these instances, ASA provides the "fit and forget" durability that designers and consumers expect from a high-quality product.

Is ASA good for car parts?

As an automotive designer, you face some of the most demanding material requirements of any industry. The parts you design must be lightweight, strong, and perfectly finished. They must also endure a brutal environment, from scorching desert heat and direct sun to freezing temperatures, road salt, and impacts from road debris. A material failure isn’t just a cosmetic issue; it can be a safety hazard, and the automotive industry has zero tolerance for that kind of risk.

Yes, ASA is an excellent material for many automotive parts, particularly for exterior components. Its greatest strength is its outstanding UV resistance, which prevents parts like mirror housings, radiator grilles, and trim pieces from fading, yellowing, or cracking in the sun. ASA also provides good heat resistance to withstand the temperatures near the engine bay and the impact strength needed to handle minor knocks and road debris. Car manufacturers frequently specify ASA for these parts because it guarantees long-term durability and maintains the vehicle’s aesthetic appeal over its entire lifespan.

ASA has found its way into the hands of automakers due to a number of reasons. First is aesthetics. Right out of the tool, ASA can be molded with a high-gloss surface finish that is rated as Class A. It implies that it does not need painting in lots of aspects, particularly those that are shaped in black or any other widespread color. This is a massive saving in production cost and time as the painting is done away with. It also avoids the chances of the car having chipped or peeled paint throughout the life of the car. The last finish is the material, and it is also a significant advantage.

I have dealt with a number of projects that involved the creation of aftermarket automotive parts and the dilemma of ABS or ASA is frequently encountered. We had once developed a series of custom spoilers. In order to maintain the low prototyping costs, the early useful models were engineered out of ABS. They used to look so good but we knew they would never make it in the actual world. To demonstrate the point, we left an ABS spoiler on the roof of our place. It was hideously weathered, and full of small cracks on its surface, after one Texas summer. The last production components were of ASA. It increased slightly on the material cost per unit but the reliability was something not to be compromised. Customers who purchase parts to make their cars personalized, want to know them last long and ASA does not fail to keep this.

It is important to note, however, that while ASA rules the exterior, ABS is still a king on the interior of the car. For parts like dashboard panels, center consoles, and door trim, there is no direct, prolonged UV exposure. In that environment, the excellent strength and lower cost of ABS make it the most logical and economical choice. It’s all about using the right material for the specific application.

Conclusion

The decision between ABS and ASA is actually reduced to one simple question, will your part be exposed to the sun? ABS is still a great product that offers excellent strength and easy processing at a very reasonable price and can be used in any indoor application, where UV protection is not a major issue.

But ASA is by far the better product in the case of any portion that will be exposed to the elements or even applied to the outside of a car. Weathering and UV radiation will not harm it and its long-lasting properties are built in its structure, therefore your product will have a long-lasting use, and its functionality will be maintained, as well as its looks and your image as a designer.