Stuck deciding on the perfect flexible material to suit your product? Deciding between TPE, TPU, and silicone is challenging, and selecting an inappropriate material leads to costly failures and frustrated customers. Imagine your product cracking when it is placed under tension, melting when it is heated, or feeling thin to the touch. These are all potential realities when you do not understand the important differences between these mighty polymers. Let us clear away uncertainty and find a good fit to suit your project.

The best choice depends entirely on your product’s needs. For cost-effective flexibility and simple processing, TPE is often ideal. For superior durability, abrasion resistance, and rebound, you should choose TPU. When your product faces extreme temperatures and requires biocompatibility for things like medical or food-grade applications, silicone is the unmatched champion. Understanding these core strengths is the first step to making a smart, profitable decision for your manufacturing process and ensuring your product succeeds in the market.

I have observed a lot of business owners like Michael get stuck at this point. They are sure that they require something that is flexible yet the technical jargon may be overwhelming. Being a long-time veteran of the mold and manufacturing industry, I have come to discover that these complicated materials are in fact very simple when dissectioned down. The thing is that, as soon as you know their primary qualities, the decision is much more evident. Get down to details and find the best.

What is the difference between TPE and elastomer?

Do you have terms such as "elastomer" and "TPE" used interchangeably so that you’re never quite sure what you’re actually purchasing? This leads to confusion when talking to suppliers and getting materials that are not what you ordered. You may order a particular type of thermoplastic and yet receive a generic rubber that will compromise your production cycle as well as resulting product quality. Let’s once and for all put an end to this basic misconception so that you can communicate eloquently.

Assume that "elastomer" is a general term and "TPE" is a particular type of it. An elastomer is any polymer that is stretchy like a rubber. TPE is short for Thermoplastic Elastomer and is a particular type of elastomer that can be reprocessed when it is melted just like plastic. This is TPEs’ greatest distinction from standard thermoset rubbers that are unable to re-melt. This is a large consideration when it comes to manufacturability.

The Big Picture: What is an Elastomer?

Let’s start with the basics. An elastomer is a big family of materials. The defining feature is elasticity—the ability to be stretched and then return to its original shape. Natural rubber is the classic example we all know. In the industrial world, this family is huge and includes everything from silicone to synthetic rubbers and, of course, TPEs. For a long time, most elastomers were "thermosets." This means once they are heated and cured into a shape (a process called vulcanization), the change is permanent. You can’t melt them down and reuse them. Think of it like baking a cake; you can’t turn the cake back into batter.

The Game Changer: Introducing Thermoplastics

TPEs, which stand for Thermoplastic Elastomers, changed the game. They combine the flexible, rubbery properties of elastomers with the processing advantages of thermoplastics. This means you can melt TPE pellets, inject them into a mold to create a part, and then grind up any scrap material and reuse it. This is a huge advantage. It’s more like melting chocolate to mold it into different shapes; you can always melt it again. This is where TPE and its cousin TPU fit in. They are part of the elastomer family but belong to the modern, efficient thermoplastic branch.

Why This Matters for Your Bottom Line

For a business owner like Michael, this distinction is critical. Using a thermoplastic elastomer like TPE instead of a traditional thermoset rubber can dramatically lower costs and speed up production. Here’s how:

| Feature | Thermoset Elastomers (e.g., Silicone, Natural Rubber) | Thermoplastic Elastomers (TPEs) |

|---|---|---|

| Recyclability | No, scrap is waste | Yes, scrap can be reused |

| Processing | Slower (Compression/Transfer Molding) | Faster (Injection Molding, Extrusion) |

| Curing Required? | Yes, a chemical curing step is needed | No, solidifies on cooling |

| Cycle Times | Long (minutes) | Short (seconds) |

| Cost | Generally higher processing cost | Lower processing cost |

This efficiency means you can produce more parts in less time, with less waste. That translates directly to a healthier bottom line and a more competitive product.

Is TPE more flexible than TPU?

You’re going to need a particular softness and formability from your design, but TPE and TPU datasheets seem so similar. This is a source of confusion that is common. Selecting an incorrect one might make your product too brittle to be gripped comfortably or so thin that it won’t give you required structure. This is not just a matter of product feel but of performance. A part that is too firm might break when it is pressed upon, and a part that is too soft might fail when it is put into action, causing product returns and compromise of your product’s reputation.

Generally, TPE offers a wider and softer range of flexibility than TPU. TPEs can be formulated to be extremely soft, almost gel-like, with a Shore hardness as low as 20A. While TPU is also flexible, it’s known more for its toughness and structural integrity at higher hardness levels, typically starting around 60A. So, if your primary goal is maximum softness and a gentle feel, TPE is almost always the more flexible and suitable option for your design.

Understanding Flexibility: A Look at Hardness

When we talk about flexibility in plastics, we’re often talking about "hardness." This is measured on a scale called Shore Hardness. For soft, flexible materials like TPE and TPU, we use the Shore A scale. To give you an idea, a rubber band is around 25A, a pencil eraser is about 40A, and the sole of a sneaker is around 60A. TPE is amazing because it can be formulated to be incredibly soft—down to 20A or even softer, getting into the gel-like Shore OO scale. TPU, on the other hand, typically starts its useful range around 60A and goes up much higher, even crossing over into the Shore D scale, which is used for hard plastics like a hard hat. So, while both are flexible, TPE owns the "softer" end of the spectrum.

TPE vs. TPU: A Head-to-Head Comparison

Flexibility is just one piece of the puzzle. The choice between TPE and TPU often comes down to other performance factors that are just as important. I’ve put together a simple table to show where each one shines.

| Feature | Thermoplastic Elastomer (TPE) | Thermoplastic Polyurethane (TPU) |

|---|---|---|

| Hardness Range | Very Wide (20A – 95A) | Narrower (60A – 70D) |

| Flexibility | Excellent, especially at low hardness | Good, but more rigid and structural |

| Abrasion Resistance | Good | Excellent, very tough and durable |

| Elastic Rebound | Lower, more dampening | High, very "bouncy" and resilient |

| Feel/Texture | Can be soft, velvety, or even sticky | Smooth, dense, and slightly rubbery |

| Cost | Generally lower | Generally higher |

Matching the Material to the Mission

Then how do you decide? Consider the job of your product. If you’re creating the soft-touch grip of a toothbrush or a nonslip grip on a power tool, TPE is your go-to material. Softness and lower cost make it an ideal candidate in these types of jobs. But if you’re creating a protection phone case that must withstand drops, or a caster wheel on an industrial cart that will navigate rough surfaces all day long, you require the higher grade of toughness and abrasion resistance found in TPU. TPU is more expensive, but it provides a grade of durability that TPE cannot come close to achieving.

Which is better, silicone or a thermoplastic like TPE/TPU?

You’re considering silicone and flexible thermoplastics such as TPE or TPU, and they appear to be good flexible materials. But their chemistry is entirely different in a way that will have a huge effect on how they behave and how you make them. This is a make-or-break decision point. Getting it wrong will result in your product breaking down under high temperatures, or it will cost an arm and a leg to make because of slow and difficult-to-control processes that dilute your profit margins. Let’s look at the essentials of how these two families of materials are different.

Neither is "better" overall; they excel in different areas. Thermoplastics (TPE/TPU) are better for high-volume, cost-sensitive applications due to their fast cycle times and recyclability. They offer excellent physical toughness. Silicone, a thermoset, is superior for applications requiring extreme temperature resistance (both high and low), chemical inertness, and biocompatibility. The right choice depends entirely on your product’s operating environment and your manufacturing goals, not just on a simple "better or worse" judgment.

![]()

The Fundamental Divide: Thermoset vs. Thermoplastic

This is the most significant difference, as we mentioned above. TPE and TPU are thermoplastics. You heat them and mould them and they solidify into shape. It is quick and effective and the unused material can be ground down and used again. Silicone is a thermoset. It is usually a two-part liquid (Liquid Silicone Rubber or LSR), which is combined and forced into a hot mold. Silicone is permanently cured into a solid permanent shape by the heat. It is done once like baking a cake. This results in increased cycle time and any scrap that is produced cannot be reused and this may impact the end cost of the part.

Performance Under Pressure: Key Differences

The different chemistry of these materials gives them unique strengths and weaknesses. For a business owner, understanding this table is key to avoiding costly mistakes.

| Feature | Silicone (Thermoset) | Thermoplastics (TPE/TPU) |

|---|---|---|

| Temperature Resistance | Excellent (-60°C to 200°C+) | Moderate (-30°C to 100°C) |

| Biocompatibility | Excellent, often medical/food grade | Possible with special grades, but less common |

| UV Resistance | Excellent, great for outdoor use | Good, but can degrade over time without additives |

| Abrasion/Tear Resistance | Fair to Good | Good to Excellent (especially TPU) |

| Processing Speed | Slower (minutes per cycle) | Very Fast (seconds per cycle) |

| Recyclability | No | Yes |

A Real-World Example: Choosing for the Kitchen

I remember a client who wanted to make a new line of kitchen spatulas. He initially chose TPE because the material and processing costs were lower. During testing, however, we found that the TPE spatula started to get soft and deform when left resting on the edge of a hot frying pan. It just couldn’t handle the heat. We switched the design to use food-grade silicone. While the cycle time for each part was longer, the final product was a huge success because it performed exactly as customers expected. It’s a perfect example of how the product’s environment dictates the material choice, sometimes overriding initial cost concerns.

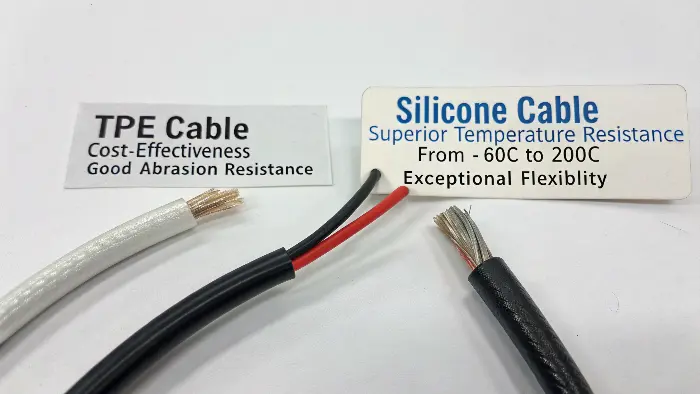

What is the difference between a TPE cable and a silicone cable?

You must buy cables to your electronic gadget, and TPE and silicone are both available as supplies. They might seem very similar to the mere eye but they might be very different in performance and price. It is one of the decisions that have a direct influence on the quality and the life of your product. Choosing the incorrect cable jacket may result in broken insulation during cold weather or a melted nightmare during hot weather or just a product that feels cheap and lets down your customers right after they take it out of the box.

The primary distinction is in temperature resistant and feel. The cables are silicone and they can withstand a much broader range of temperatures, -60degC to 200degC, which is why these cables are suitable in extreme environments. They are also very soft and pliable. TPE cables are cheaper and possess greater abrasion, and lifespan in daily usage. TPE provides excellent performance to cost ratio of most consumer electronics, whereas silicone is the most expensive but is used in industrial or automotive applications or high performance.

The Heat Test: Temperature Performance

This is the most critical difference for cables. A TPE cable is perfectly fine for a phone charger that sits on your desk. It can handle the minor heat from charging and typical room temperatures. But imagine that cable is inside a car engine bay or used with industrial machinery. The high heat would quickly cause the TPE to soften, melt, and fail. This is where silicone shines. Its ability to remain stable and flexible at 200°C (400°F) is something TPE can’t touch. Similarly, in freezing conditions, TPE can become stiff and brittle, while silicone remains flexible, preventing the insulation from cracking when bent.

Daily Use vs. Extreme Conditions

For a product like Michael’s consumer electronics, TPE is often the smarter choice. It’s tough enough to withstand being repeatedly plugged in, wrapped up, and thrown in a bag. Its superior abrasion resistance means it won’t scuff up as easily as silicone. TPE provides the durability needed for the average consumer’s lifestyle at a very competitive price point. Silicone cables are reserved for when performance cannot be compromised. Think of medical equipment where reliability is a matter of life and death, or high-performance charging cables marketed with a "premium, tangle-free" feel.

Cost and Feel: The User Experience

There’s a reason high-end brands are starting to use silicone for their charging cables. Silicone has a unique, soft, silky feel that users associate with quality. It’s also incredibly limp and flexible, which means it doesn’t tangle easily. This creates a superior user experience that can justify a higher price. TPE cables are much cheaper to produce. The material itself is less expensive, and it can be extruded over the wires much faster than silicone, leading to significant manufacturing cost savings. Here’s a quick summary:

| Feature | TPE Cable | Silicone Cable |

|---|---|---|

| Use Case | Consumer Electronics, everyday use | Industrial, Automotive, Medical, Premium Consumer |

| Temperature Range | Good (e.g., -30°C to 100°C) | Excellent (e.g., -60°C to 200°C) |

| Durability | Very Good (high abrasion resistance) | Good (lower tear strength) |

| Flexibility/Feel | Stiffer, standard plastic feel | Extremely flexible, soft, premium feel |

| Cost | Lower | Higher |

Conclusion

Ultimately, it is not a question of finding a single best material between TPE, TPU, and silicone, but rather of which material best suits your product. TPE is your choice of affordability in flexibility. TPU is an unparalleled tough material and durable. Silicone can perform the jobs that others may fail to do, at the highest temperatures and in those applications that require purity. Knowledge of these fundamental variations can enable you to create and produce more efficient, reliable and well-fitted products, which fit well in their intended use.

FAQs:

What is the greatest difference among TPU, TPE and Silicone?

Their performance and chemical structure are the major difference.

TPU (Thermoplastic Polyurethane): is a plastic that is tough and flexible, abrasion-resistant, and highly elastic.

TPE (Thermoplastic Elastomer) is less expensive and is softer in nature and it is a rubber-like elastic compound mixed with ease of processing in thermoplastic.

Silicone is a non-thermoplastic elastomer, however, which is very tough in extreme temperatures, strong in chemical nature, and retains its flexibility in the long run.

What is the material of choice of flexible parts?

TPU is the best solution when flexible and strong components are required but the material should be able to remain elastic even in heavy mechanical systems.TPE provides a compromise between comfort and economy in the case of soft-touch grips, seals or consumer products. Silicone can be used in medical or food grade applications because of its non-toxic and high temperature resistance qualities.

Is TPU stronger than TPE?

Yes, TPU is usually stronger and more durable than the vast majority of the TPE. It has high tensile strength, tear resistance, and abrasion resistance which makes it ideal to be used in high-performance such as phone cases, hoses and industrial seals. TPE is not as tough as it is less resistant to wear and chemicals.

What are the temperature resistances of each?

TPU -40degC -120degC (up to 150degC in the short term).

TPE: -30C to 80C (with formulation)

Silicone: 250degC -60degC (capable of higher peaks)

Silicone is the most suitable one in case you are using it in heat or sterilization.

What is the material that is friendlier to the environment?

TPU is recyclable as well as TPE because they are thermoplastics. Regardless, silicone is not a traditional recyclable material, however, it is chemically stable and long lived, which minimizes waste. A few contemporary programs have been doing silicone, particularly in medical or industrial effluences.

What material is more chemically resistant?

The best chemical and UV resistance is silicone with TPU coming second. TPE is prone to swelling or degradation on solvents, fuels or oils. TPU is also resistant to a lot of abrasion and various industrial chemicals, which is why it can be used in the automotive and mechanical parts.

Are these materials coloured or customizable?

Yes, TPU and TPE are easy to color and tailor-made in the process of molding. Silicone may as well be coloured but typically needs special heat-resistant colours. Surface texture, transparency, or matte/glossy finish is possible on all three materials.