Are you unsure whether to choose injection molding or CNC machining as the designer for your new part? It’s a crossroads that happens more often than not, and because of it, costly tool re-work and frustrating production downtime can arise due to initial design choices that turn out wrong. You’ve devoted weeks to getting a design flawless, only to discover that it’s a production nightmare, sending you back to square one and over budget. Know what design fundamentals are paramount in both processes, and this can be prevented.

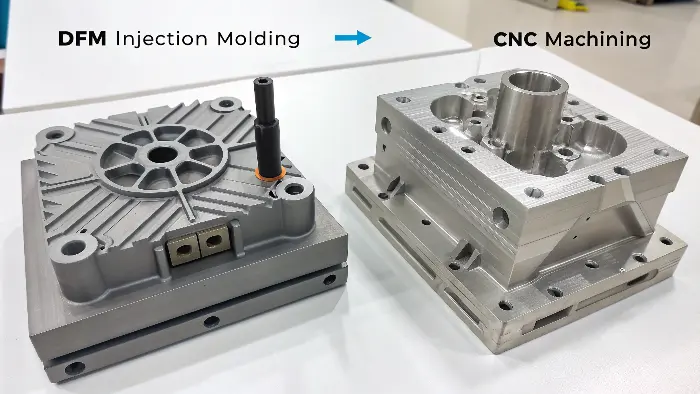

The biggest design variation between DFM of injection molding and DFM of CNC machining stems from what the part will be made of. CNC machining is a subtractive process that involves taking away material, so it has great freedom to develop complex geometries like undercuts. Injection molding is a forming process that puts material into a cavity, so design rules are more about getting the part out of the mold without trouble. Here, you will need to embed draft angles, make wall thickness consistent so it won’t appear as a defect, and be very careful with planning parting lines.

That’s the high-level view, but the devil is in the details. To truly make the right call for your project, you need to understand how these differences impact your design, your costs, and your production schedule. This is where you can save a lot of money and prevent major headaches down the road. Let’s break down the specifics to give you a clear path forward.

What is the Difference between CNC machining and injection molding?

Have you ever stared at two allegedly identical plastic parts and wondered why they were made so differently? They may appear almost identical, yet the path that it followed from a computer file to a tangible object is night and day. Not understanding this key distinction can cause you to design a part that’s ideal for one process and a absolute disaster in the other. This misapprehension often results in surprise costs, redesign, and downtime. Let us establish the key principles of both of these manufacturing giants.

The big thing that’s different is that CNC machining is a subtractive operation, and injection molding is a constructive one. In CNC machining, you begin with a block of raw material and whittle away everything except what you want, as a sculptor chips away at rock. In injection molding, you begin with lumps of melted plastic and force them into a pre-existing cavity, or mold, to define what the part will be. This one fact—carving versus filling—is why all of their other rules of design are so divergent.

To make the best decision for your project, you need to go a bit deeper than just "subtractive versus formative." How you think about designing for each process is completely different.

CNC Machining: The Art of Removal

Using a Computer Numerical Control (CNC) machine, my overarching question is always, "Can this cutting tool reach this face physically?" The work starts as a raw block of material, usually aluminum or plastic, in a billet. The computer program manipulates a rotary cutting tool to take away layer after layer of material till what remains is your final part.

Consider 3-axis versus 5-axis machines. A typical 3-axis machine will move your tool up-and-down, left-and-right, and back-and-forward. That works great for parts that are uncomplicated. A 5-axis machine will tilt your tool and rotate your part so that it can reach very extreme features and angles without having to stop and re-fixture your part. That gives it more ability, but more expense as well. Your design will have to take into consideration tool access, tool size (you can’t make internal corners more extreme than your cutting tool’s radius), and how your part will get held in place (work-holding).

Injection Molding: The Science of Flow and Cooling

In injection molding, therefore, the question becomes again, "How will plastic get into the mold, and how will the finished part come out?" The process involves melting plastic resin, driving it under high pressure into a rigid mold, then cooling and hardening, and finally producing the finished part.

Your whole design needs to be tuned to this cycle. You need to consider how the molten plastic will move in the mold channels (runners) and spread out in the cavity uniformly. You also need to design that part so that it won’t jam in the mold upon eject. That introduces key DFM guidelines such as draft angles, constant wall thickness, and parting lines, which we will cover in more detail later.

| Feature | CNC Machining | Injection Molding |

|---|---|---|

| Process Type | Subtractive (Material Removal) | Formative (Material Shaping) |

| Starting Material | Solid block (metal, plastic) | Plastic pellets/resin |

| Tooling | Cutting tools (end mills, drills) | Custom-made steel/aluminum mold |

| Key Question | "Can the tool reach it?" | "Can the part be ejected cleanly?" |

| Best For | Prototypes, low-volume, complex geometries | High-volume production, repeatable parts |

What is DFM in injection molding?

Have you ever sent out a part design to get a quote and been stunned at how expensive the injection mold is going to be? Worse, you’ve made a shot of parts and discovered that they warp, crack, or possess ugly surface defects. The final cause, more often than not, is not a poor molder, but a design that was not optimized to work with. The "unmoldable" design results in costly and time-consuming mold redesigns, production line halts, and in the end, a compromised final product. The answer is to get it right in the first place.

Design for Manufacturability (DFM) for injection molding is a collection of design best practices aimed at getting a part easy to manufacture reliably and inexpensively. It’s simply about designing your part optimally based upon how molten plastic moves. That involves taking extra care with certain critical aspects such as incorporating draft angles so your part will eject readily, maintaining wall thickness consistency so that it won’t develop defects such as sink marks, employing radii on corners to minimize stress, and establishing a clear parting line so that the two halves of the mold will join.

Let’s break down the most critical DFM rules that I discuss with my clients every single day. Getting these right is the difference between a successful project and a costly failure.

The Angle of Draft Rule

A draft angle is a slight taper of the faces of your part that run in the direction of opening of the mold. Consider a set of plastic cups; they don’t have vertical walls, they’re tilted so that they won’t stick to each other. The same applies here. Once the plastic sets as it cools, it will shrink and cling to the core of the mold. If there is no draft, then friction and vacuum at ejection will create drag markings, scratch, or even break your part. I typically suggest at least 1-2 degrees of draft in most cases. If your part has a textured finish, then more draft will be necessary to clean up after it.

Necessity of Similar Wall Thickness

This is perhaps the single most critical rule in injection molding. The molten plastic must flow through the mold and solidify at a steady rate. If your part contains both thin and heavy sections, the thin sections will solidify first. The heavy sections, still in a molten condition, will keep cooling and shrinking, pulling away at the already solidified thin sections. This differential shrinkage produces internal stress, in turn leading to warping (the part will twist out of shape), sink marks (mini-depressions at the surface across from a heavy feature), and voids (internal air bubbles). The objective is to design walls as constant in thickness as possible.

Undercuts and Parting Lines

The parting line is that line where the two halves of the mold, known as core and cavity, join. Each of your molded parts will possess one. In design, you will want to plan ahead of time as to where this line will show up, as it will make a permanent impression upon that final part. Above all, you must avoid undercuts. An undercut is anything that will prevent this part from being ejected directly out of the mold. Some examples include side holes or snap-fit pieces. Undercuts necessitate that the mold contain complex, moving parts known as lifters or side-actions, which will Raise costs dramatically and make this tool more complicated. My advice is always: "Can I redesign such that I eliminate this undercut?"

What‘s the Difference Between Design for Manufacturing(DFM) and Design for Assembly (DFA)?

Design for Manufacturing

(DFM) refers to the act of designing a product in such a way that one can easily, cheaply, and reliably manufacture its separate components. It is concerned with the manufacturing steps in itself, taking into account the choice of materials, the production means and tolerances, and the finish.

The use of DFM principles allows designers to decrease the geometry of the parts, select simpler materials to work with, and decrease the number of unnecessary complexities, all of which helps to decrease production costs and enhance efficiency. An example is when a designer makes a component simple in order to be molded in just one step rather than having to undergo a series of machining processes.

Design for Assembly

(DFA) However, focuses on the end product being designed quickly and efficiently to assemble. It focuses on the minimization of parts, easy-to-use components that are easy to orient and to put in place, and uses a minimum number of tools or complicated fastening techniques.

Vise-fit joints or self-locating features are usually implemented in efforts to reduce the time spent on assembling the machine and minimize the chances of making mistakes. The primary aim of DFA is to facilitate the assembly process, reduce labor expenses, and offer reliability to the product.

The main contrast between the two is their emphasis, that is, DFM is concerned with the ease with which every part can be produced whereas DFA is concerned with the ease with which the parts can be assembled. In reality, it is common to find companies integrate the two into what is referred to as DFMA (Design for Manufacture and Assembly) so that its product is not only easy to manufacture, but also easy to assemble. This integrated approach is effective in cost reduction, enhancing product quality and reducing time to market.

What are the advantages of injection molding in cost of production and design flexibility?

You have a product that must be manufactured by the thousand, or even by the million. The idea of installing a CNC machine and hand-cutting each part individually is a logistical and costly nightmare. The price per piece would be too great, and you would never be able to manufacture them quickly enough to supply what is needed. You require a process that is scalable, but perhaps you are afraid of a huge up-front cost and design rules that must be adhered to. That is where injection molding really has its strength.

Injection molding’s big strength is incredibly low cost per part at high quantities. Once you’ve absorbed the up-front expense of the initial mold, you can produce parts in a few seconds for not much more than plastic cost plus machine time. No other process can compete with that scaleability. In design freedom, it accommodates complex geometries, integration of multiple parts into one part to save assembly, and degrees of surface finish, from high-gloss to custom texture, out of the mold.

Let’s look at how these advantages translate into real-world benefits for your business. When I work with clients moving from prototype to full production, these are the points that make the decision clear.

Unbeatable Cost Per Part at Scale

Economics of injection molding are easy: the cost of the mold is high, and then the cost is shared across an extremely large quantity of parts. Having said that, a mold which is priced at 20000 dollars appears costly. However, with a 1,000,000 part order, the tooling is only $0.02/part. Combine low material and production cost and you have a very small cost per part. That is compared to CNC machining where making an individual part costs about the same as making the 10,000th part. The tempo is also a massive consideration. Molding times can be calculated in seconds, and a complicated CNC component might take hours to cut.

Design Consolidation and Complexity

It is a significant money-saving advantage beyond that of simply the part itself. Rather than having to design and build three distinct pieces that must then be assembled with hardware, such as screws, or adhesives, such as epoxy, you typically can design them as one, merged molded part. I’ve witnessed this yield customers huge savings in assembly labor as well as hardware costs. It also produces the finished assembly stronger because it eliminates potential failure points. In addition, injection molding makes it convenient to include features which are exceedingly hard or labor-intensive to machine, such as living hinges (the slender section of plastic that allows a lid to flex) and snap-fit features.

Material Choice and Surface Finish

Under injection molding, a huge library of thermoplastic resins is available. You have the option of selecting a material because of its characteristics, be it that it has to be strong, flexible, resistant to chemicals or resistant to the UV. The color could also be mixed directly into the resin and therefore no paint was required. The other major strength is the surface finish. The complete mold of the steel is finished immediately onto all the parts. And in case you desire a mirror-like high-gloss finish, the mold is polished to the same. In case you require a certain texture, we can apply that texture on the mold. This will save enormous time and money on subsequent finishing tasks.

Injection Molding Use Cases

CKMold is a pioneer Original Equipment Manufacturer, and in this case, they use injection molding to manufacture plastic components to be used in different industries. These sectors include:

Medical and Pharmaceutical

The plastic products in this sector should meet high health and safety requirements. Fortunately, we have more than 23 years of experience in medical injection molding, which means that you will have reliable and durable medical-grade parts. We are specialists in the production of injection-molded medical parts, such as:

- Labware equipment

- Imaging components

- Diagnostic disposables

- Emergency medical devices

- Monitors and appliances used to care for patients.

- Biologic medical devices.

- Orthopedic instruments

Military and Defense

The military environment is dependent on the technology and products that can survive under the most severe conditions on earth. We provide products to the industries with military parts, which will ensure that there is uniformity, functionality, and durability. The molded parts include:

- Handheld comms

- Guidance systems

- Decoys

- Weaponry

- Munitions

The new developments in manufacturing

The manufacturing industry is dynamic, so it can always keep up with the competition and tackle the current challenges. Such inventions assist in improving customer satisfaction and reducing recurrent supply chain, labor, and demand fluctuations. The new manufacturing trends include:

Industry 4.0 and Automation

These industries enhance efficiency in production activity since they allow monitoring equipment remotely, operating, and servicing it. This brings about flexibility, safety, and access through augmented real-time operation.

Sustainability practices

The growing level of environmental and social concern among manufacturers is driving the growing popularity of sustainability practices. The CKMold has put in place a number of programs that strive to reduce its environmental footprint, energy usage, and waste. They include:

- Recycling scrap plastic

- Use of sustainable suppliers of materials.

- The use of light-efficient bulbs

What are the Disadvantages of injection molding?

Injection molding is the ideal solution to mass production, yet there are rumors of huge initial expenses and projects stalling because a minor design modification was desired too late in the process. The dread of spending countless thousands of dollars in a steel tool only to discover it is faulty or that the market dictates a different feature, is a valid fear among many entrepreneurs. Such inflexibility can be seen as a huge risk that will stall a project even before it begins.

The primary disadvantages of injection molding are the high initial tooling cost and the long lead time required to build the mold. A high-quality production mold is a complex piece of engineering that can cost thousands of dollars and take weeks or even months to manufacture. The other significant drawback is the lack of design flexibility once the mold is complete. Any changes, no matter how small, often require expensive and time-consuming modifications to the steel mold, making the process unsuitable for early-stage prototyping or low-volume runs.

It’s crucial to be honest about these trade-offs. Understanding the disadvantages is just as important as knowing the benefits. Let’s look at the challenges you need to be prepared for.

The High Cost and Long Lead Time of Tooling

It is a fact that a good injection mold is an expensive investment. They are generally made of hardened steel which can endure the molding process at great pressure and high temperatures that take hundreds of thousands of cycles. They take hours of hand-polishing and final assembly, and need precision tools such as CNC mills and EDM machines to make. This is quite contrary to the CNC machining. In the case of a CNC project, the tooling is simply the conventional cutting bits, which cost relatively little. It is sometimes possible to begin machining parts immediately after the design is finished. Under molding, a tool-building stage of 4 to 12 weeks, or more, must be considered.

The Challenge of Design Modifications

This is something I always impress upon my customers. CNC machining is incredibly agile. If you want to modify a feature, you revise the CAD drawing and run a new program. You might have a new part in hand tomorrow. Injection molding puts your design firmly in steel. When that mold gets made, your flexibility is close to zero. If you find out that you need to make a design modification, you’re confronted with reshaping that mold.

This is a challenging process. One might jokingly say that it’s "easy to take steel away, but not so easy to put it back." If you must increase a feature of yours in size, it may be possible to machine more steel away out of the mold cavity. However, if you must make a feature smaller, this involves adding steel back, typically by precision-welding it back in initially, followed by a re-machining of this location. This is costly, risky, and greatly increases time in your project. This is exactly why it’s imperative to get that DFM spot-on before it’s time to cut steel.

Restrictions on Part Geometry

These DFM restrictions that we’ve been going over so far—angles of draft, planar walls, no undercuts—are not guidelines; they are restrictions of your freedom of design. While it is feasible that you can do complicated geometries, there will always be that ultimate restriction that the part must be ejectable out of a two-piece mold. This is a whole different universe than 5-axis CNC milling, where basically any geometry that strikes your imagination is possible, with only machine time and cost per part as the trade-off.

Conclusion

It’s a straightforward trade-off between DFM for injection molding and DFM for CNC machining. CNC machining has unprecedented design flexibility and speed to market for prototypes and low-run quantities, and there are very few constraining design rules. Injection molding gives unparalleled low cost per part in high quantities, but it requires a huge upfront tool cost and rigid adherence to DFM guidelines. The correct answer is completely dependent upon your project’s quantity, cost, and long-term objectives.