Choosing the right colors for plastic products often means using masterbatches. But many traditional options aren’t great for our planet. This creates a big problem for companies wanting to be more sustainable. Eco-friendly color masterbatches offer a fantastic solution, helping us color plastics responsibly.

Eco-friendly color masterbatches provide a sustainable way to add color and other properties to plastics during injection molding. They are made with sustainable ingredients, like bio-based materials, recycled content, or biodegradable components. This reduces their environmental impact compared to traditional masterbatches. These special masterbatches can color various plastics, including bio-based and recycled types, making your products greener.

We all want to make choices that are better for the environment. In the world of plastic injection molding, this means looking closely at every part of the process, including how we add color. I’ve spent years in this industry, and I’ve seen a real shift towards sustainability. It’s exciting, and I want to share what I’ve learned about making greener choices with color masterbatches. Let’s explore how these innovative materials can help us.

What plastics can be used for injection molding?

You have a great product idea, and it needs to be made from plastic. But then you wonder, which plastics actually work well with injection molding? It can seem like a huge list, and picking the right one is key. Let’s clear up some of that confusion.

Many thermoplastics are suitable for injection molding. Common examples include Polypropylene (PP), Polyethylene (PE), Polystyrene (PS), Acrylonitrile Butadiene Styrene (ABS), Nylon (PA), and Polycarbonate (PC). These materials are chosen for their good flow properties when melted and their ability to solidify into durable parts. Eco-friendly masterbatches can be used with many of these, especially their recycled or bio-based versions.

When I first started in a mold factory, I was amazed by the variety of plastic resins. Each one had its own personality, its own way of behaving in the mold. We use a lot of different plastics in injection molding. Think about everyday items. The bottle caps on your drinks? Often Polypropylene (PP) or Polyethylene (PE). The casing for your computer mouse? Probably Acrylonitrile Butadiene Styrene (ABS). These are all thermoplastics, which means they can be melted and cooled multiple times without much degradation, making them perfect for injection molding.

Here’s a quick look at some common ones:

| Plastic Type | Common Uses | Key Properties for Molding |

|---|---|---|

| Polypropylene (PP) | Containers, packaging, automotive parts | Good flow, chemical resistance |

| Polyethylene (PE) | Bottles, bags, toys | Flexible, low cost |

| Polystyrene (PS) | Disposable cutlery, CD cases, food containers | Rigid, clear (GPPS), impact (HIPS) |

| ABS | Electronic housings, Lego bricks, car parts | Tough, impact resistant |

| Nylon (PA) | Gears, bearings, automotive components | Strong, wear-resistant |

| Polycarbonate (PC) | Eyeglasses, CDs/DVDs, safety helmets | Transparent, high impact strength |

The great thing is, as we move towards more sustainable practices, eco-friendly color masterbatches are designed to work with many of these standard plastics. And they work especially well if you’re using recycled versions of these plastics or exploring bio-based alternatives. This means you don’t have to compromise on color to be more green.

What are the sustainable plastics for injection molding?

We all want to reduce our environmental footprint. But when it comes to injection molding, finding plastics that are truly sustainable can feel like a big hurdle. It’s a challenge many of my clients face. The good news is, there are options.

Sustainable plastics for injection molding include recycled plastics like rPET (recycled Polyethylene Terephthalate) and rPP (recycled Polypropylene). Bio-based plastics, made from renewable resources like corn starch or sugarcane (such as PLA or PHA), are also great choices. Biodegradable plastics, designed to break down under specific conditions, round out the main options for greener molding.

The term "sustainable plastic" covers a few different types of materials. It’s not just one thing. The goal is to move away from relying solely on virgin, fossil-fuel-based plastics. I remember working with a client who wanted to make their packaging more eco-friendly. We explored several options together.

Here are the main categories:

-

Recycled Plastics: These are made from plastic waste that has been collected, cleaned, and reprocessed. Common examples are:

- rPET (recycled Polyethylene Terephthalate): Often made from old drink bottles. It’s great for new bottles, containers, and even fibers for clothing.

- rPP (recycled Polypropylene): Used for containers, automotive parts, and more.

Using recycled plastics reduces waste, saves energy, and lessens the demand for new fossil fuels. Eco-friendly masterbatches are perfect here because they can help achieve vibrant colors even with the slight variations that can come with recycled materials. Some recycled masterbatches even use recycled plastic as their carrier resin, making the whole colorant system more sustainable.

-

Bio-based Plastics: These plastics are made wholly or partly from renewable resources like corn, sugarcane, or cellulose.

- PLA (Polylactic Acid): Often made from corn starch or sugarcane. It’s popular for food packaging, disposable cutlery, and 3D printing.

- PHA (Polyhydroxyalkanoates): Made by microorganisms. It has interesting biodegradable properties.

Bio-based plastics help reduce our dependence on fossil fuels. When you use bio-based masterbatches with these plastics, you’re creating a product that’s even more aligned with sustainability goals. These masterbatches often use pigments and carrier resins derived from renewable resources too.

-

Biodegradable Plastics: These are designed to break down into natural substances under specific environmental conditions, usually in industrial composting facilities. PLA can be biodegradable under the right conditions.

Choosing a sustainable plastic is a big step. And pairing it with an eco-friendly masterbatch ensures your commitment to sustainability runs through the entire product, color and all.

What are the most eco-friendly plastics?

The term "eco-friendly" gets used a lot. But when we talk about plastics, which ones truly make the biggest positive difference for our planet? It’s an important question, because not all "green" plastics are created equal. We need to look at the whole picture.

The most eco-friendly plastics are often those with a very high percentage of recycled content, like 100% rPET. Bio-based plastics derived from non-food, renewable sources, or agricultural waste also rank high. Plastics that are genuinely biodegradable in natural environments or home compost systems are also top contenders, though these are less common for durable goods.

When I talk to designers like Jacky, who are always looking to improve product quality and reduce costs while being sustainable, we often discuss what "most eco-friendly" really means. It’s not just about one factor. It’s about the entire life cycle of the plastic.

Here’s how I see it:

-

Plastics with High Recycled Content: Using plastics made from 100% post-consumer recycled (PCR) materials, like rPET from old bottles or rHDPE from milk jugs, is a fantastic choice. This directly reduces landfill waste and the need for virgin plastic production. The challenge here can sometimes be color consistency, but that’s where high-quality eco-friendly masterbatches shine. They are formulated to provide excellent color even in recycled resins. Some eco-masterbatches themselves are made with recycled carrier resins, further boosting the green credentials.

-

Bio-based Plastics from Sustainable Sources: Plastics like PLA (Polylactic Acid) made from corn starch or sugarcane, or bio-PE made from sugarcane ethanol, are good. They come from renewable resources, which can mean a lower carbon footprint compared to fossil-fuel plastics. The "most eco-friendly" bio-plastics would ideally come from non-food crops, agricultural waste, or algae to avoid competing with food production. Eco-friendly masterbatches for these plastics can also be bio-based, using plant-derived carriers and pigments, making the entire colored part more sustainable.

-

Truly Biodegradable Plastics (with caveats): Materials like PHA (Polyhydroxyalkanoates) or some advanced starch-based blends that can biodegrade in home compost or even marine environments are very promising. However, it’s crucial that the "biodegradable" claim is accurate and applies to real-world conditions, not just specific industrial composting facilities that may not be widely accessible. For these, biodegradable masterbatches are essential. They are designed to break down along with the plastic, ensuring the colorant doesn’t hinder the biodegradation process.

It’s also about choosing the right plastic for the right application. A single-use item might benefit most from being easily recyclable or compostable. A durable product might benefit most from being made with high recycled content and designed for longevity. The key is a thoughtful approach, and eco-friendly masterbatches support this by offering sustainable coloring options for all these greener plastics.

What are the biodegradable injection molding resins?

We hear the word "biodegradable" a lot, and it sounds like a perfect solution for plastic waste. But what does it really mean for injection molding resins? It can sometimes be a bit confusing, and it’s important to understand the details.

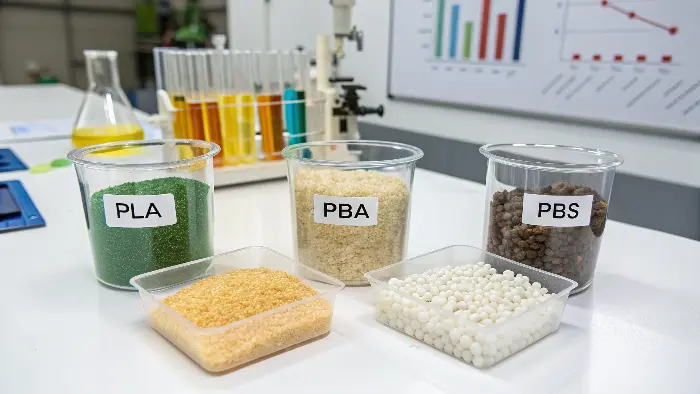

Biodegradable injection molding resins include materials like PLA (Polylactic Acid), PHA (Polyhydroxyalkanoates), and some specially formulated starch-based blends or PBS (Polybutylene Succinate). These plastics are designed to be broken down by microorganisms into natural substances like water, carbon dioxide, and biomass, but usually under specific conditions like industrial composting.

When a client asks me about biodegradable options, the first thing I clarify is what "biodegradable" entails. It’s not magic; these plastics don’t just vanish if you toss them in your backyard (usually). They need specific environments to break down effectively.

Here are some common biodegradable resins used in injection molding:

-

PLA (Polylactic Acid): This is probably the most well-known. It’s derived from renewable resources like corn starch or sugarcane. PLA is "commercially compostable," meaning it will biodegrade in an industrial composting facility where high temperatures (around 55-70°C) and specific microbes are present. It’s used for things like food packaging, disposable cutlery, and agricultural films. I worked on a project for disposable coffee cup lids using PLA, and we paired it with a certified compostable color masterbatch.

-

PHA (Polyhydroxyalkanoates): These are polyesters produced naturally by various microorganisms. PHAs are interesting because some types can biodegrade in a wider range of environments, including soil and marine settings, though the rate depends on the specific PHA type and conditions. They are often more expensive than PLA.

-

Starch-Based Blends: These often combine starch with other biodegradable polymers to improve properties for injection molding. Their biodegradability depends on the overall composition.

-

PBS (Polybutylene Succinate): This is another biodegradable polyester that can be composted. Some forms can also be bio-based.

When using these resins, it’s crucial to use biodegradable masterbatches. If you use a traditional masterbatch, the colorant and its carrier resin might not break down, leaving behind microplastics or hindering the overall product’s biodegradability. Eco-friendly masterbatches designed for biodegradable plastics use carrier resins and additives that are also biodegradable and compostable, ensuring the entire colored part meets the desired end-of-life standards. This is something I always emphasize – the color has to be as green as the plastic itself!

Conclusion

Eco-friendly color masterbatches are a game-changer for sustainable injection molding. They allow us to color recycled, bio-based, and biodegradable plastics effectively and responsibly. By choosing these advanced masterbatches, we can reduce environmental impact and create greener products without compromising on quality or aesthetics.