Are you struggling to integrate metal or plastic inserts seamlessly into your molded parts? It’s a common headache leading to production delays and quality issues. At CKMOLD, we understand these challenges. We offer a comprehensive approach to insert molding, turning complex designs into high-quality, finished products efficiently. Let us show you how we master this intricate process.

CKMOLD handles insert molding projects by meticulously managing every stage, from initial design review and material selection to precise mold engineering for insert placement, and finally, robust process control during production. We focus on ensuring inserts are securely held, properly encapsulated, and that the final part meets all functional and aesthetic requirements, leveraging our deep expertise to overcome common challenges.

Insert molding is a fantastic way to create strong, versatile parts by combining different materials. But it’s not always straightforward. Many designers, like Jacky, face hurdles in getting it just right. I’ve seen many projects come to us after initial attempts elsewhere didn’t quite hit the mark. It’s a process that demands precision at every step. Let’s break down how we approach these projects at CKMOLD to ensure success from the get-go.

What’s the Crucial First Step When We Start an Insert Molding Project?

Ever kicked off an insert molding project only to hit snags because the initial planning wasn’t thorough enough? This can lead to costly redesigns and frustrating delays. We believe a strong start is half the battle. That’s why our first step is always a deep dive into your project’s core needs.

The crucial first step at CKMOLD for an insert molding project is a comprehensive consultation and design review. We meticulously analyze your part design, the insert specifications, material choices, and the intended application. This ensures we understand all requirements and can proactively identify potential challenges, laying a solid foundation for a successful manufacturing process.

When a client like Jacky brings an insert molding project to us, the first thing we do isn’t just look at the CAD files. We talk. We ask a lot of questions. What is this part for? What kind of stresses will it endure? What environment will it operate in? Understanding the end-use is paramount.

Understanding the Core Requirements

We focus on a few key areas during this initial phase:

- Insert Design and Material: Is the insert designed for easy and secure placement in the mold? Are the insert material and the overmolding plastic compatible? Sometimes, a small tweak to an insert’s design, like adding a feature for better grip, can make a huge difference.

- Part Design for Manufacturability (DFM): We look at wall thicknesses around the insert, gate locations, and potential for issues like sink marks or voids. For example, if an insert is quite large, we need to ensure the plastic flow around it is optimal to prevent weld lines in critical areas.

- Tolerances: Tight tolerances are often a feature of insert molded parts. We need to understand what’s critical and what’s not, to balance precision with manufacturing feasibility. I remember a project where an overly tight tolerance on a non-critical feature was causing a high scrap rate. A simple discussion and adjustment saved the client a lot of money.

This detailed upfront work helps us anticipate problems before they even reach the mold-making stage. It’s about setting the project up for success from day one.

How Do We Design Molds Specifically for Flawless Insert Integration?

Worried about inserts shifting during molding, or not being perfectly aligned in the final part? This is a common fear in insert molding, leading to scrap and compromised part integrity. The secret to perfect integration lies in a meticulously designed mold. At CKMOLD, this is where our engineering expertise truly shines.

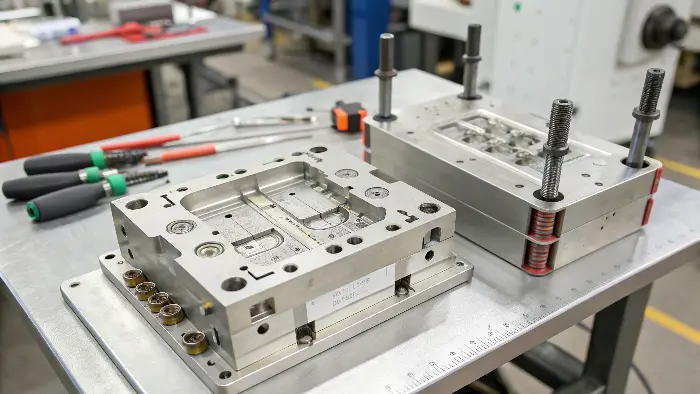

We design molds for flawless insert integration by incorporating precise features to securely hold inserts, such as custom pockets, pins, or magnetic systems. We also carefully consider material compatibility, thermal expansion differences between the insert and plastic, and design gates and runners to ensure gentle, even plastic flow around the insert, preventing damage or displacement.

Designing a mold for insert molding is more complex than for a standard injection mold. The mold doesn’t just shape the plastic; it also has to accurately locate and hold the insert(s) against the forces of molten plastic injection.

Key Mold Design Considerations for Inserts

Here’s how we approach it:

- Insert Location and Retention:

- Manual vs. Automated Loading: Will inserts be hand-loaded or by a robot? This affects the mold design for accessibility and speed. For high-volume projects, we often design for automation.

- Holding Mechanisms: We might use spring-loaded features, custom-shaped cavities, undercuts, or even magnets (for ferrous inserts) to ensure the insert stays put. The choice depends on the insert’s geometry, material, and the molding process.

- Preventing Insert Damage: The pressure and temperature of molten plastic can be substantial. The mold must protect delicate inserts. This involves careful gate design to avoid direct impingement of plastic onto sensitive areas of the insert.

- Material Compatibility and Shrinkage: We account for the different thermal expansion rates of the insert material and the overmolding plastic. The mold design needs to accommodate the plastic’s shrinkage around the insert to ensure a tight fit without cracking the plastic or deforming the insert. I recall a project with a long metal insert; we had to design specific cooling channels around the insert area to manage differential shrinkage effectively.

Example: Mold Features for Insert Stability

| Feature Type | Description | Benefit |

|---|---|---|

| Custom Pockets | Precisely machined cavities that match the insert’s shape. | Excellent positional accuracy. |

| Locator Pins | Pins that engage with holes or features on the insert. | Secure alignment, prevents rotation. |

| Shut-off Areas | Areas where the mold closes tightly against the insert to prevent flash. | Clean part lines, no plastic leakage. |

| Pre-heating/Cooling | Channels in the mold to control the temperature of the insert or surrounding area. | Manages thermal stress, improves bonding. |

By focusing on these details, we create molds that are not just tools, but precision instruments for perfect insert integration.

LOOP END

LOOP START

What Common Hurdles Appear in Insert Molding, and How Do We Tackle Them?

Even with careful planning, insert molding can present unique challenges during production. Are you concerned about issues like inserts moving, plastic flashing around them, or poor bonding? These problems can derail timelines and inflate costs. Recognizing and addressing these hurdles proactively is key to smooth manufacturing.

Common hurdles in insert molding include insert shifting or damage, plastic flash, incomplete fill around the insert, and poor adhesion between the insert and plastic. We tackle these by optimizing mold design for secure insert holding, precise process control (injection speed, pressure, temperature), careful material selection, and sometimes pre-treating inserts to enhance bonding.

Insert molding is a bit like a delicate dance between the insert, the mold, and the plastic. When one step is off, problems can arise. Over the years, I’ve seen my share of these, and we’ve developed robust strategies to overcome them.

Addressing Key Insert Molding Challenges

Here are some common issues and how we approach them:

- Insert Shifting or Misalignment: This is perhaps the most frequent concern.

- Cause: Insufficient support in the mold, excessive injection pressure, or insert design not conducive to secure holding.

- Solution: We refine the mold’s holding features (as discussed earlier), adjust injection parameters to be gentler during the initial fill around the insert, and sometimes suggest minor modifications to the insert itself for better stability. For instance, adding a small tab or detent can make a big difference.

- Plastic Flash: Molten plastic seeping into unwanted areas, like seams around the insert.

- Cause: Poor shut-off in the mold, excessive clamping force, or too high injection pressure/speed.

- Solution: We ensure mold mating surfaces are perfectly aligned and that shut-offs around the insert are crisp and precise. Process parameters are also fine-tuned.

- Poor Adhesion/Bonding: The plastic doesn’t stick well to the insert.

- Cause: Material incompatibility, contaminants on the insert surface, or insufficient mechanical interlock.

- Solution: This often goes back to material selection. We ensure the chosen plastic has good chemical affinity with the insert material. Sometimes, pre-treating the insert (e.g., plasma treatment, primer application) or designing mechanical interlocks (e.g., grooves, knurling on the insert) is necessary. I remember a project where we incorporated a subtle undercut on the insert, invisible in the final product, which dramatically improved the mechanical bond.

- Damage to Inserts: Delicate inserts can be bent, crushed, or broken.

- Cause: High injection pressure directly on the insert, improper handling during loading.

- Solution: Strategic gate placement to avoid direct impact, and careful design of insert loading mechanisms, whether manual or automated.

By systematically diagnosing and addressing these potential issues, often during the DFM and mold design stages, we minimize disruptions during production.

How Does CKMOLD Ensure Top Quality and Smooth Production Runs for Insert Molded Parts?

Getting the design and mold right is crucial, but how do you ensure consistent quality across thousands of insert molded parts? Fluctuations in production can lead to defects and wasted resources. At CKMOLD, our commitment to quality extends throughout the entire production run, ensuring every part meets your specifications.

CKMOLD ensures top quality and smooth production by implementing rigorous process controls, including real-time monitoring of molding parameters, regular quality checks (both automated and manual), and meticulous maintenance of molds and machinery. We also focus on efficient insert handling and, where beneficial, employ automation to maintain consistency and reduce cycle times.

Once the mold is proven and the process parameters are dialed in, the focus shifts to maintaining consistency and efficiency during mass production. For a product designer like Jacky, knowing that the 10,000th part will be as good as the first is critical.

Our Approach to Production Excellence

Here’s how we maintain high standards:

- Process Control and Monitoring:

- We use modern injection molding machines with precise controls over temperature, pressure, injection speed, and cooling time. These parameters are carefully documented and monitored.

- For critical projects, we implement statistical process control (SPC) to track variations and make adjustments before parts go out of spec.

- Insert Handling and Loading:

- Consistency in insert placement is key. For high-volume production, we often recommend or implement automated insert loading systems. This not only speeds up the cycle but also reduces the chance of human error or contamination.

- Even with manual loading, we establish clear work instructions and train operators thoroughly. I’ve seen how a well-organized workstation for insert loading can significantly improve output and quality.

- Quality Inspections:

- First Article Inspection (FAI): Before mass production, a detailed inspection of the initial parts is done to verify all dimensions and requirements.

- In-Process Checks: Regular checks are performed during the production run. This can include visual inspections, dimensional measurements, and functional tests (e.g., pull tests for insert retention).

- Final Inspection: A final quality control check before parts are packaged and shipped.

- Mold Maintenance: Insert molding can sometimes be more demanding on molds due to the interaction with the inserts. Regular cleaning, inspection, and preventative maintenance of the mold are crucial to prevent wear and tear that could affect part quality.

We believe that a proactive approach to production, combining technology with disciplined processes, is the best way to deliver consistently high-quality insert molded components. It’s about mastering the details, every step of the way.

Conclusion

In essence, CKMOLD’s comprehensive approach to insert molding projects, from meticulous initial design reviews and specialized mold engineering to robust production controls and quality assurance, ensures your complex components are manufactured right. We turn challenges into successful, high-quality parts, helping you bring your innovative products to market efficiently.