Do ugly weld lines adversely affect the finish and strength of your plastic parts? This is the typical type of injection molding defect that may result in loss of money in terms of rejections and customer complaints and it is like you are facing a losing battle over quality. It is frustrating to have a single defect spoil a whole batch of production and destroy your reputation and bottom line. However, what would you say to being able to be in complete control of the temperature of the mold and the lines would just disappear?

The most important secret to removing the weld lines is to have high and constant temperature of the mold surface during injection. More sophisticated processes such as Rapid Heating and Cooling (RHCM) or conformal cooling are used to assure that the plastic melt ends up meeting at a higher temperature. This enables the entanglement and fusion of polymer chains in a good way before the material solidifies. The outcome is a smooth, robust joint that actually fills the surface and structural flaws of an ordinary weld line resulting in the achievement of high quality parts.

Achieving a flawless surface finish is often the final hurdle in producing a high-quality part. Many manufacturers think weld lines are just an unavoidable part of the process, but that’s simply not true anymore. The technology exists to solve this problem for good. Understanding how these advanced temperature control methods work is the first step toward leaving this frustrating issue behind. Let’s explore the techniques that can elevate your parts from acceptable to exceptional.

What Exactly Causes Weld Lines in Injection Molding?

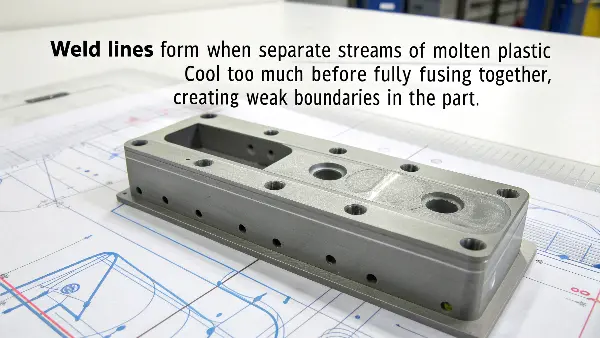

Do you get sick and tired of having thin lines on your molded parts, particularly around holes or intricate structures? This flaw is called a weld line and it appears when two or more fronts of molten plastic come into direct contact with each other within mold cavity. It is an ordinary headache which does not only appear bad but also makes a weak spot in the final product. You may be having a hard time trying to understand why they continue coming at your expense in terms of time and material.

Weld lines are created as individual streams of molten plastic solidify to an extent that they are not able to merge completely. When the plastic passes around an obstacle (such as a core pin) or across several gates, the fronts of the flow converge. At this meeting point, polymer chains are unable to entangle properly in case the temperature and pressure are too low. This forms a feeble, frequently noticeable boundary in the part. Basically this is a very small point of a crack where the plastic did not melt into a single piece.

Understanding the root cause is crucial to finding the right solution. It’s not just about the plastic; it’s about the conditions inside the mold when those melt fronts meet. From my own experience, I remember a project for an automotive client. We were making dashboard components with multiple vents. The weld lines were causing the parts to fail during vibration testing. We realized the melt was cooling too quickly as it traveled the long distance around the vent holes. By addressing the temperature at that exact moment, we solved the problem. The core issue is always the same: the melt fronts are too cold when they meet. Several factors contribute to this problem, each requiring careful attention during the design and processing stages.

Key Factors Influencing Weld Line Formation

To truly tackle weld lines, we need to look at the process variables that directly impact melt flow and temperature. It’s a combination of material properties, mold design, and machine settings.

- Melt and Mold Temperature: This is the most direct factor. A lower melt or mold temperature gives the plastic less time to fuse before it solidifies. The colder the fronts, the more pronounced the weld line.

- Injection Speed and Pressure: Faster injection speeds can help because the plastic spends less time cooling as it travels through the mold. However, too much speed can cause other issues like jetting. Holding pressure also plays a role in packing out the weld line area to improve its strength.

- Part and Gate Design: The geometry of the part is fundamental. Features like holes, ribs, and bosses force the melt to split and rejoin. The location of the gates determines where these flow fronts will meet, and thus, where the weld lines will appear.

Here is a simple table to break down how these factors affect weld line severity:

| Factor | Effect on Weld Lines | How to Adjust for Improvement |

|---|---|---|

| Mold Temperature | Too low = Prominent, weak lines | Increase temperature, use advanced control |

| Melt Temperature | Too low = Poor fusion, visible lines | Increase within material specs |

| Injection Speed | Too slow = Premature cooling | Increase speed cautiously |

| Gate Location | Poor placement = Lines in critical areas | Optimize gate position in mold design stage |

By analyzing these variables, you can begin to systematically eliminate the root causes of weld lines in your products.

Role of Mold Temperature in Controlling Weld Lines

One of the most important elements in the creation and durability of weld lines is mold temperature. A low mold temperature allows the molten plastic to cool rapidly during filling of the cavity, and the flow fronts will meet in a semi-solid condition. As a result, there are visible lines, poor bonding, and decreased mechanical strength at the weld site. The substance remains molten for longer at higher temperatures. This allows the flow fronts to merge in a much smoother fashion.

Thus, a cleaner, stronger weld line forms. Proper mold heating also tends to reduce internal stresses and improve part strengths-much-needed benefits for complex geometries or polymers with a tendency to solidify rapidly. Maintaining the optimum mold temperature based on the type of polymer used will drastically minimize defects in weld lines and lead to better quality and more durable molded parts.

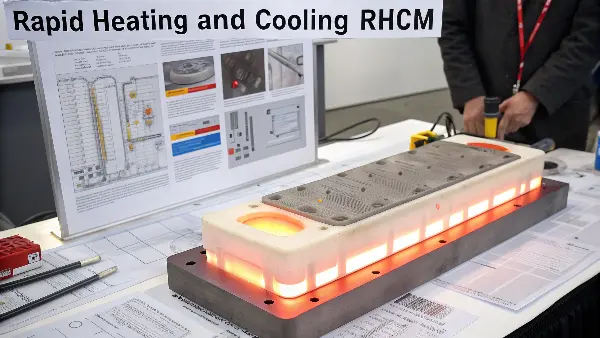

How Does Rapid Heating and Cooling (RHCM) Prevent Weld Lines?

Do you make components where a perfect and high-gloss finish is a matter of non-negotiation? With high-end consumer electronics or luxury car interiors, the smallest weld line would be unacceptable. You have probably experimented with raising the total base temperature of the mould and have discovered that this does not only raise cycle times, but also can ruin the material. You are then at crossroads between compromising on quality or compromising on efficiency of production, which is frustrating to any business owner.

Variotherm or Rapid Heating and Cooling (RHCM) technology is a direct solution to the weld line issue, where the subject of the injection is heated to a very high temperature, usually above the glass transition temperature of the plastic, right before injection. This guarantees that the melt fronts are very fluid when converging hence they fuse flawlessly. The part is then cooled immediately after the cavity as the part would be solid and a quick ejection would be done. This gives the process a hundred percent removal of weld lines and gives a better and shiny surface finish.

The concept of RHCM sounds complex, but the benefit is simple: it gives you the best of both worlds. You get the perfect surface quality associated with a very hot mold, plus the short cycle time of a cold mold. I recall working with a client who made high-end coffee machine housings. The glossy black finish was their signature feature, but weld lines from the handle mounts were a constant issue. We implemented a steam-based RHCM system. The mold heated to 160°C in seconds, we injected the plastic, and then cooled it just as fast. The weld lines vanished completely. The client could finally deliver the premium product their brand promised without any compromises.

Breaking Down the RHCM Process in Mold Temperature

RHCM isn’t a single method but a category of technologies designed to rapidly change the mold’s temperature. The goal is to create an ideal environment for the plastic to flow and then quickly solidify it for ejection. This dynamic process gives us incredible control over the final part quality.

- Heating Phase: Before the plastic is injected, the mold surface is heated very quickly. This is the key step for weld line elimination. Common methods include passing high-pressure hot water, steam, or using electrical induction or cartridge heaters embedded near the cavity surface.

- Injection Phase: With the mold surface hot, the molten plastic is injected. The hot cavity walls prevent the melt from forming a frozen skin layer too early, allowing it to flow easily and the separate fronts to merge seamlessly.

- Cooling Phase: As soon as the part is filled, the heating source is turned off and a cooling medium (usually chilled water) is flushed through the channels to bring the mold temperature down rapidly. This solidifies the part and minimizes the overall cycle time.

Here’s a comparison of common RHCM heating methods:

| Heating Method | Advantages | Disadvantages | Best For |

|---|---|---|---|

| Steam Heating | Very fast heating rates, uniform heat | Requires a steam generator, high pressure | Large parts, fast cycles |

| Hot Water | Safer than steam, good control | Slower heating than steam | Medium-sized parts, high precision |

| Induction Heating | Extremely fast, targets specific areas | High initial cost, complex coil design | Molds with inserts, localized heating |

Choosing the right RHCM method depends on your part size, material, and production goals, but each offers a powerful way to eliminate weld lines for good.

Material Selection’s Role in the Formation of Weld Lines

The type of plastic material used for injection molding will directly influence the formation of the weld lines, as well as their appearance or weakness. Materials with low melt flow, such as reinforcements or highly filled plastics, would thus provide more visible and brittle weld lines, since the fibers or fillers interfere with the bonding of the two melt fronts. Quick-cooling plastics, like crystalline polymers, may also produce weak weld lines because the material solidifies faster and does not fuse well at the meeting point.

Colorants, flame retardants, and other fillers are examples of additives that can further alter flow behavior and make a surface more prone to flaws. On the other hand, materials with higher melt strength and good flow properties result in

- Stronger

- Smoother weld regions

Reducing the visibility of the weld line and improving the overall strength and quality of the molded item can be achieved by carefully choosing the polymer grade, adjusting the filler quantity, or using modified materials with better flow.

Role of Mold Maintenance and Cleanliness in Preventing Weld Lines

Mold maintenance and cleanliness have a direct impact on how smoothly molten plastic flows inside the cavity, making them crucial variables in preventing weld lines. Residues like burned material, oil, dust, rust, or outdated release agents start to build up on the cavity walls, gates, runners, and vent areas when a mold is not thoroughly cleaned.

These impurities cause the material to split, slow down, or abruptly shift direction by interfering with the melt’s flow. The melt fronts meet at lower temperatures or with reduced velocity, which raises the likelihood of weak or highly visible weld lines on the finished object.

Regular mold cleaning can ensure that cavity surfaces are smooth and that plastic fills in uniformly without unnecessary interruptions. Even slight buildup on the cavity surface can create micro-barriers which force the melt to flow unevenly. A well-polished mold surface reduces friction, which reduces melt temperature loss and preserves flow rate, thus enhancing strength and improving aesthetics around the weld line area.

Clean and well-maintained vents also play a critical role. In the case of blocked or partially clogged vents, air is trapped inside the cavity to create backpressure and turbulence in the melt flow. These disturbances prevent the melt fronts from fully bonding, usually resulting in prominent weld lines or even burn marks. Regular cleaning of the vents ensures proper air release and smoother material convergence.

It also entails checking for worn gates, eroded runners, and misaligned mold halves. Worn gates can restrict flow, while misalignment causes different flow paths to meet improperly, both increasing weld line formation. By maintaining gating, runners, ejector pins, and alignment systems in good condition, the mold will deliver consistent flow patterns cycle after cycle.

A clean, well-maintained mold eliminates unnecessary flow resistance, prevents contamination, ensures proper venting, and supports optimal melt behavior. The combination of all these elements significantly reduces the formation of weld lines and improves the final product’s strength, surface finish, and overall quality.

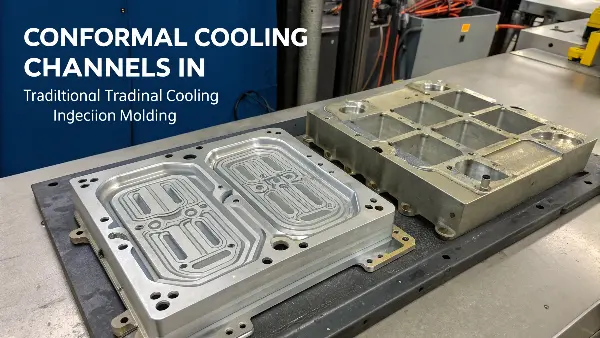

Can Conformal Cooling Channels Make a Difference with Weld Lines?

Have you ever struggled with parts that have complex shapes, deep ribs, or thin walls? These features often create hot spots and cold spots in the mold because traditional straight-drilled cooling lines can’t reach them effectively. This uneven temperature distribution is a major cause of weld lines and warpage, forcing you to compromise on part design or deal with high scrap rates. It’s a constant battle to achieve uniformity.

Yes, conformal cooling channels can make a significant difference. Unlike traditional cooling lines, which are straight, conformal channels are 3D-printed to follow the exact contours of the part’s surface. This allows for incredibly uniform and efficient cooling across the entire mold, eliminating the cold spots where weld lines tend to form. By maintaining a more consistent and higher overall mold temperature without hot spots, the melt fronts have a better chance to fuse properly, drastically reducing or eliminating weld lines.

The real magic of conformal cooling is its precision. It puts cooling exactly where you need it most. I worked on a medical device component with a very deep, narrow core. With traditional cooling, the tip of the core was always too hot, while the base was cold. This temperature difference caused a prominent weld line right where two flow fronts met. We redesigned the core with 3D-printed conformal cooling channels that spiraled up to the tip. The temperature variation dropped from 40°C to just 5°C across the core. The weld line problem was solved, and as a bonus, the cycle time was reduced by 30%.

How Conformal Cooling Provides Superior Control

The primary advantage of conformal cooling is its ability to maintain a consistent temperature across the entire surface of the mold cavity. This uniformity is what gives molders the power to tackle defects like weld lines head-on.

- Targeted Cooling: Channels can be designed to be closer to the surface in areas that tend to retain heat (hot spots) and further away in areas that cool too quickly. This levels out the temperature profile of the part as it solidifies. For weld lines, it means the area where melt fronts meet can be kept at an optimal temperature for fusion.

- Reduced Thermal Stress: Uniform cooling leads to less internal stress within the plastic part. This not only improves the strength of the weld line but also reduces the risk of warpage, a common side effect of uneven cooling.

- Enabling Higher Mold Temperatures: Because conformal cooling is so efficient, you can run the entire mold at a higher baseline temperature to improve weld line fusion without drastically extending the cooling time. Traditional cooling at the same temperature would lead to unacceptably long cycles.

Here’s a direct comparison to highlight the benefits:

| Feature | Traditional Cooling (Straight-Drilled) | Conformal Cooling (3D Printed) |

|---|---|---|

| Channel Design | Restricted to straight lines | Follows part geometry |

| Temperature Uniformity | Poor, leads to hot and cold spots | Excellent, highly uniform surface temp |

| Weld Line Control | Limited, often a problem area | Superior, eliminates cold spots for better fusion |

| Cycle Time | Can be long due to inefficient cooling | Often reduced by 20-50% |

| Initial Cost | Low | High, requires 3D metal printing |

While the initial investment is higher, the long-term gains in quality, reduced scrap, and faster cycle times make conformal cooling a game-changing technology for complex parts where weld lines are a persistent problem.

How Do You Choose the Right Temperature Control Technique for Your Project?

You’ve learned about powerful techniques like RHCM and conformal cooling, but now you face a critical question: which one is right for your specific needs? Investing in the wrong technology could be a costly mistake, while sticking with traditional methods might mean continuing to struggle with weld lines. It’s easy to feel overwhelmed by the options, unsure of which path will provide the best return on investment for your manufacturing operation.

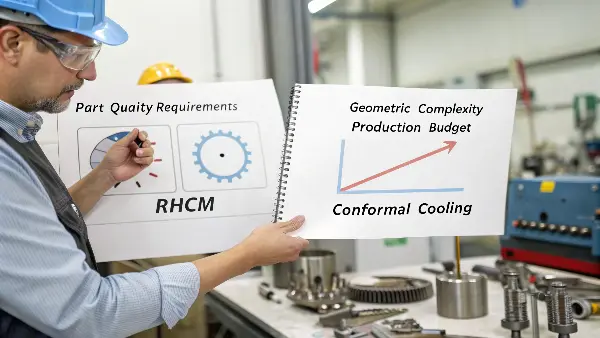

Choosing the right technique depends on three key factors: your part’s quality requirements, its geometric complexity, and your production budget. For parts requiring a flawless, high-gloss cosmetic surface, Rapid Heating and Cooling (RHCM) is often the best choice. For parts with complex shapes, deep features, or uneven wall thicknesses where warpage is also a concern, conformal cooling provides superior temperature uniformity. For less critical parts, optimizing traditional heating and cooling may be sufficient.

Making the right decision requires a practical look at your project’s goals. I always advise my clients to start with the end product. "What does the customer absolutely need this part to be?" I ask. If it’s a front-facing component on a luxury product, the visual perfection from RHCM is worth the investment. If it’s a complex internal component where structural integrity and dimensional stability are paramount, conformal cooling is the clear winner. There is no one-size-fits-all answer; the right choice is the one that solves your specific problem most effectively and economically.

A Practical Decision-Making Framework

To make an informed choice, you need to weigh the technical capabilities of each method against your project constraints. Let’s break it down into a structured comparison to help guide your decision.

- Define Your Primary Goal: Are you trying to solve a cosmetic issue (visible weld lines) or a structural one (weakness, warpage)? RHCM excels at surface aesthetics. Conformal cooling excels at overall thermal management, which improves both structural and cosmetic issues, especially in complex parts.

- Analyze Your Part Geometry: Is your part relatively simple, or does it have deep ribs, sharp corners, and varying thicknesses? The more complex the geometry, the more benefit you will see from conformal cooling’s ability to provide uniform temperature control.

- Consider Your Budget and Volume: RHCM and conformal cooling represent a significant initial investment in mold design and equipment. You must evaluate if the improved quality and potential cycle time reduction justify the cost. For high-volume production of premium parts, the ROI is often very clear. For lower-volume or less critical applications, it may be more cost-effective to first optimize conventional methods.

This table provides a quick guide to help you match the technology to the application:

| Scenario / Requirement | Best Fit Technology | Why? |

|---|---|---|

| Flawless, "Class A" surface finish | Rapid Heating & Cooling (RHCM) | Heats the surface above the melt’s glass transition temp, erasing flow marks. |

| Complex part with warpage issues | Conformal Cooling | Provides uniform cooling to reduce thermal stress and dimensional instability. |

| Both high surface quality and complex geometry | Combination of RHCM & Conformal Cooling | The ultimate solution for achieving perfect parts with challenging designs. |

| Budget-conscious project with moderate complexity | Optimized Conventional Cooling | Use thermal analysis (MFA) to place standard circuits more effectively. |

By carefully considering these factors, you can move from feeling uncertain to making a strategic decision that will enhance your product quality and strengthen your competitive advantage.

Conclusion

In the end, eliminating weld lines comes down to controlling temperature at the precise moment molten plastic fronts meet. By leveraging advanced techniques like RHCM for perfect surfaces or conformal cooling for uniform thermal management, you can overcome this persistent challenge. These methods give you the power to produce stronger, more visually appealing parts, moving beyond frustrating defects to achieve manufacturing excellence.