Having trouble with the color consistency of your plastic parts? Mismatched shades may weaken your brand’s identity and make customers reject costly lots, which delays your projects. It’s frustrating when your vision for that ‘exact’ color isn’t quite what comes out, ruining customer trust. Mastering the Pantone color matching process will ensure that every part you produce perfectly aligns with the standards you set for your brand, guaranteeing consistency and quality every single time.

Perfect Pantone color matching can only be achieved when a standardized color system is combined with thorough material and process control. Firstly, the correct Pantone Coated (C) or Uncoated (U) reference should be specified. Then, a color concentrate formulated in cooperation with a reliable masterbatch supplier for a particular plastic resin has to be used. Finally, injection molding parameters-temperature, pressure, and cooling time-should strictly be controlled because these variables can greatly alter the final color appearance.

Getting color right feels like it should be simple, but in the world of injection molding, it’s a complex dance of science and art. I’ve seen countless projects get derailed by something as seemingly basic as the wrong shade of blue. It’s not just about picking a color from a book; it’s about recreating that exact color in a physical, three-dimensional object made from a specific polymer. The journey from a designer’s screen to a finished part is filled with potential pitfalls that can alter a color’s appearance. But don’t worry, by breaking down the process, we can master it. Let’s dive into how you can ensure your brand colors remain true and consistent, part after part.

What are ways to add Pantone color to injection molded plastic, and what are its advantages and disadvantages?

Color addition to plastic materials in injection molding is possible in a number of ways depending on the accuracy, volume of production as well as cost required. Some of the most widely used methods are masterbatch colorants, machine hopper mixing and pre-formulated resins. All the techniques possess their own advantages and disadvantages that influence the color stability, elasticity and handling effectiveness.

Pre-Formulated Resins,

Pre-Formulated Resins or precolored or compounded resins are those materials that are already mixed with pigments by the supplier of resin. Before the polymer is pelletized into a final product, the colorant is compounded into the base polymer, and each pellet of the final product contains the same concentration of the colorant. The process, which provides excellent dispersion, color uniformity, and high durability, is based on the fact that the color is completely embedded in the plastic skeleton. It is great when there is a high volume of production and proper matching of colors is required accurately; particularly when it involves a brand of a color. Nevertheless, ready-made resins might be more costly because of the extra processing and they cannot also be colored during processing. They also take more time in lead times when tailor made shades should be made.

Masterbatch Colorants

Another option that manufacturers would prefer to have flexibility and cost-effectiveness is Masterbatch Colorants. A masterbatch is a concentrated blend of pigments and is only enclosed by a carrier resin that is compatible with the base polymer. It is combined with natural (uncolored) resin in a fixed proportion, usually 1-5% during the molding. The color is evenly spread because the material melts resulting in vivid and uniform colors. This technique gives easy color manipulation through interchange of the masterbatch concentration and is clean and safer to handle than liquid dyes. Nevertheless, masterbatch needs special attention from mixing and setting machines to prevent streaks or uneven dots. Minor changes in processing conditions may result in slight changes in the tone of the color, which makes it more appropriate for medium-scale and large-scale release.

Machine Hopper Mixing

Machine Hopper Mixing or dry blending or in-machine mixing is whereby colorants (either in the form of masterbatch pellets or powdered pigments) are added directly to the machine hopper. The resin and colorant combine when they are forced into the barrel, where the color can be dispersed throughout the melting process. It is a low-cost, fast, and adaptable process, which is useful when making small production batches, testing colors, or prototyping. It allows making changes effortlessly during the molding process and does not require the use of external mixing equipment. Nevertheless, it also has the lowest accuracy as compared to the other two techniques. Imprecise blending may create color streaks, irregular shading, or surface imperfections. Also, there is the risk of dust and contamination created by using dry pigments, which can also influence the quality of products.

Overall, pre-formulated resins offer the best accuracy in color and durability, masterbatch colorants have an adequate ratio of cost and operation and machine hopper mixing is ideal when the short run is needed or when the experiment might need to be finished within a short time. The option here is based on production size, cost and level of color accuracy that the final product needs to have.

Why is a Standardized Color System Like Pantone So Crucial for Brand Identity?

Ever tried to specify a color for a project only to have it come back looking completely different? You describe "corporate blue," but the supplier produces a shade that’s too light or has a purplish tint. This miscommunication leads to wasted time, materials, and money, and it can seriously compromise your brand’s visual identity. The Pantone Matching System (PMS) solves this problem by providing a universal, standardized language for color, ensuring absolute clarity for everyone involved.

The reason this is important is that it eliminates subjectivity in the color communication and supplies a single, verifiable standard. That means your signature red will look the same on your website, on your packaging, and on your injection-molded product. This, of course, is the basis for a consistent and recognizable brand identity, engendering customer trust and familiarity. It is the universal translator between design intent and manufacturing reality.

The power of a brand often lies in its immediate visual recognition, and color is a huge part of that. Think of Tiffany & Co. blue or Coca-Cola red. These colors are wedded to their brands. As a mold maker, I’ve learned that protecting this brand integrity is one of our most important jobs. Simply relying on digital color values like RGB or CMYK is a recipe for disaster in manufacturing. Those systems are designed for screens and print, not for physical objects. Plastic resins, textures, and lighting conditions all change how a color is perceived. Pantone provides the physical benchmark we need to get it right. It bridges the gap between the creative vision and the engineered product.

The Role of Pantone Color in Branding

Color isn’t just a decorative choice; it’s one of the core assets of your brand. It elicits emotions, imparts better recognition, and helps make you different from the competition. More often than not, it’s the color that a customer will first notice about a product when it catches their eye on a shelf. Consistent use of a specific Pantone shade reinforces brand identity. Deviation, no matter how slight in degree, can give customers the perception of decreased quality, or worse, a fraudulent product. Ensuring color accuracy is a direct investment into the perceived value and trustworthiness of your brand.

How Pantone Differs from Other Color Systems

It’s essential to understand why systems used in digital design or printing don’t translate directly to injection molding. Each system is designed for a different medium, and using the wrong one will lead to color mismatches.

| Color System | Primary Use | How it Works | Why it’s Not for Molding |

|---|---|---|---|

| RGB | Digital Screens | Additive: Mixes Red, Green, and Blue light to create colors. Black is the absence of light. | Physical objects don’t emit light; they reflect it. RGB values cannot predict how a colored plastic will look. |

| CMYK | Print Media | Subtractive: Mixes Cyan, Magenta, Yellow, and Black inks on paper. White is the absence of ink (the paper). | The process works with ink absorption on paper, which is completely different from how pigment is dispersed in a polymer base. |

| Pantone (PMS) | Manufacturing & Branding | Standardized Ink/Pigment Formulas: Provides specific formulas for creating solid colors. It’s a universal physical reference. | Designed for creating consistent color on physical substrates, making it the ideal standard for injection molding. |

Why Choose Pantone Match for Injection Molding Products and Other things to consider when picking a color?

Pantone match has been selected to be used in injection molding products because of the following reasons.

When selecting the colors to be used in injection molding products, the PantoneMatching System (PMS) colors are preferred to provide the opportunity of reproducing colors consistently and with accuracy in each point of production of the molded products.

Pantone has offered the universal color guide, thus allowing manufacturers, designers and clients to communicate precise shades without misunderstanding. This is more so with brand specific products like electronics, auto parts, or packaging where a minor color difference can influence brand recognition and product attractiveness. With a Pantone match a manufacturer can reproduce a color to a dot without regard to the type of resin or the location of the production, and reduce differences between the lighting conditions or pigment differences and human perception.

The other benefit of Pantone colors is that it is associated with better quality control. Having a standardized reference, you can use molded samples more closely to a specified Pantone chip, which means that mass production and prototype are the same in color. This minimizes possibilities of expensive reworking or customer dissatisfaction as a result of inappropriate matching of colors.

Also, Pantone matching gives you the opportunity to work more closely with your pigment suppliers because they can create masterbatches or pre-colored resins that can precisely match your standard color. Aesthetics and branding are highly important in such industries as consumer goods or medical equipment; such a high degree of accuracy can greatly influence the marketability of the product.

Other Things to Consider When Picking a Color for Your Injection Molding Products

There are other considerations that one should make when selecting a color in their injection molding products.

Although color matching is a crucial factor, there are other factors that determine the way your final molded product will look.

- To start with, the resin type is involved in a significant role- the various types of polymers (such as ABS, polypropylene, or nylon) have varying amounts of natural transparency, gloss, and absorption of pigments. Pantone color, which has been reshaped in two moulds can appear marginally different in one of the resins.

- Second, the surface texture and finish affect the perception of color. A smooth surface reflects more light, causing the color to be brighter, whereas a textured or matte cover can dull it. Always screen molded samples in the same light conditions your product will stand in since color may change in a fluorescent, daylight or warm light.

- Third, take into consideration production variables, including melt temperature, cycle time and cooling rate. Such processing conditions may slightly change the behavior of pigments leading to slight changes in hue. Thus, repeatability is best achieved by keeping machines in constant settings.

- Finally, consider functional and environmental needs – e.g. UV stability, chemical resistance or food-contact safety. Certain pigments can be destroyed by sunlight or can intermix with some additives, and therefore, to achieve durability and compliance, it is best to select the colorants designed to work with your application.

To conclude, though Pantone color matching provides a reliable base to guarantee uniformity in colors in injection molding, it is also necessary to think about compatibility of resins, surface finish, processing stability, and performance to final appearance to have the ideal end product appearance.

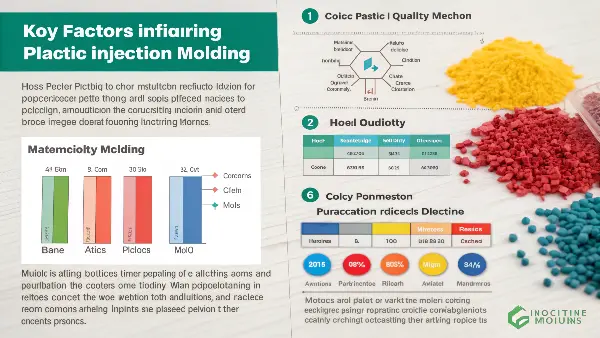

What Key Factors Influence Color Matching in Plastic Injection Molding?

You’ve specified the exact Pantone color and your masterbatch is ready. So, you’re all set, right? Unfortunately, it’s not that simple. Many product designers are surprised when the first molded parts come out looking different from the color plaque they approved. The final color is a result of a complex interplay between material, colorant, and the molding process itself. Ignoring any of these factors may lead to serious color shifts and inconsistent results.

The most important factors affecting the color matching of plastics are the base resin, quality/carrier of the color masterbatch, and injection molding processing parameters. The resin’s natural color, clarity, and heat stability could change the shade. The masterbatch must be compatible with the base resin. Finally, conditions of processing such as melt temperature, injection speed, and cooling rate directly affect the dispersion of pigments and the reflection of light from the surface, changing the perception of color.

I recall a project from many years ago when we were molding a part in ABS plastic, Pantone 293 C. It was one of those projects where the client was very particular about color. The first test shots looked a little darker and more subdued than the reference chip. We checked the masterbatch; it was perfect. The problem? The particular grade of ABS we were using had a slight yellowish tint to the natural material. In the raw pellet, it was all but unnoticeable, but it was enough to distort the bright blue. We had to switch to a "water-clear" grade of ABS to hit the target. The valuable lesson I learned here is that the base resin is not a blank canvas, but an active ingredient in the final color equation.

The Impact of the Base Polymer

The plastic resin you choose is the foundation of your part, and its properties will heavily influence the final color.

- Natural Color: Polymers are rarely perfectly clear or neutral white. ABS can be yellowish, nylon can be beige, and polypropylene can be milky. This inherent color of the resin will mix with the colorant, shifting the final shade. For bright, pure colors, you need a resin with high clarity and minimal natural tint.

- Opacity vs. Transparency: A transparent polymer like polycarbonate will render colors differently than an opaque one like ABS. The way light passes through or reflects off the material is fundamental to its color appearance.

- Melt Flow Index (MFI): Different grades of the same polymer can have different MFI values. A higher MFI (easier flow) can sometimes lead to better pigment dispersion, resulting in a more uniform and intense color.

The Science of Color Masterbatch

The masterbatch is the concentrated mixture of pigments and/or additives encapsulated during a heat process into a carrier resin. The quality of this component is non-negotiable.

- Pigment Choice: Not all pigments are created equal. Some are more heat-stable than others. If a pigment degrades at the resin’s processing temperature, the color will change. Lightfastness is also key; some pigments fade when exposed to UV light.

- Carrier Resin Compatibility: The carrier resin in the masterbatch must be compatible with the base resin of your part. An incompatible carrier can lead to poor dispersion, streaks, and even structural weaknesses in the final product. Always ensure the masterbatch supplier knows your exact base resin.

- Let-Down Ratio (LDR): This is the ratio of masterbatch to natural resin. A typical LDR is between 1% and 4%. Any inconsistency in this ratio, whether due to poor mixing or an inaccurate dosing machine, will cause color variations from shot to shot.

The Role of Processing Conditions

The injection molding machine is where all the ingredients come together. How you run the process can make or break your color matching.

- Melt Temperature: Too high a temperature can burn the pigments or the resin itself, causing discoloration (often a yellowish or brownish tint). Too low a temperature can result in poor pigment dispersion, leading to streaks or a faded look.

- Injection Speed and Pressure: These parameters affect how the polymer molecules and pigment particles align within the mold. This can influence the part’s gloss level, which in turn changes how the color is perceived.

- Residence Time: The amount of time the plastic spends inside the heated barrel before injection is critical. Longer residence times increase the risk of thermal degradation and color shifts.

What Are the Common Pitfalls in Pantone Matching and How Do You Avoid Them?

But even when a process is well-defined, things can go wrong. I’ve seen teams spend weeks chasing a color issue, only to find that the root cause was something simple that was overlooked. Knowing some of these common pitfalls beforehand could save you immense frustration, time, and money. From discrepancies in gloss to issues with lighting, being aware of these challenges becomes the first step to crafting a robust and repeatable color-matching strategy.

Common pitfalls include mismatched surface texture between the sample and final part, colors being evaluated under different lighting, and metamerism (when colors are a match under one light source and not under another). To avoid these, allow the texture on your color approval plaque to be similar to the texture of the final part. Always use a standardized light box for color evaluations, such as D65, and always check color matches under different light sources to catch any metameric issues early.

One of the most memorable challenges I dealt with was a client rejecting a batch of gray parts we’d made. In our quality lab, under our D65 light source, they were a perfect match to the Pantone chip. But the client reviewed them in their office, which had warm, fluorescent lighting, and to them, the parts looked greenish. It was a classic case of metamerism: the parts were not technically "wrong," but they were wrong for the client’s viewing environment. We had to reformulate the masterbatch using different pigments to create a match that was stable across various light sources. Nowadays, checking all critical color matches under at least three different light sources is a standard part of our process: daylight (D65), office light (CWF), and incandescent (A).

The Texture and Gloss Effect

The texture of a surface dramatically changes how it reflects light, and therefore, how its color is perceived.

- The Problem: A high-gloss, smooth surface will reflect light directly, making colors appear darker and more saturated. A matte, textured surface will scatter light, making the same color appear lighter and less saturated. If you approve a color on a high-gloss plaque but the final part has a textured finish (like one created by EDM or chemical etching), the colors will not match.

- The Solution: Always, and I mean always, create your color approval samples using plaques that have the exact same surface finish as your final production part. If the part has multiple textures, your plaque should too. This ensures that what you approve is what you will get.

The Lighting and Metamerism Trap

Human eyes perceive color based on the light that reflects off an object and enters our eyes. Change the light, and you change the color.

- The Problem: Metamerism occurs when two colors appear to match under one lighting condition but not another. This happens because the objects are reflecting different wavelengths of light, but these different combinations happen to stimulate the eye in the same way under a specific light source. Moving to a different light source (e.g., from daylight to fluorescent office lighting) breaks this illusion.

- The Solution: Use a standardized light box for all official color evaluations. These boxes can simulate various lighting conditions like daylight (D65), cool white fluorescent (CWF), and incandescent (Inc A). Check and approve your colors under all potential end-use lighting environments to ensure a stable match.

Other Hidden Variables

Several other factors can trip you up if you’re not careful.

| Pitfall | Why it Happens | How to Prevent It |

|---|---|---|

| Wall Thickness Variation | Thicker sections of a part cool slower and can appear darker or have a different gloss level than thinner sections. | Design parts with uniform wall thickness wherever possible. If variations are unavoidable, evaluate the color in all sections of the part, not just one spot. |

| Use of Recycled Material | Regrind or recycled material has been through at least one heat cycle, which can degrade it and alter its base color, affecting the final shade. | For color-critical applications, use 100% virgin resin. If regrind must be used, establish a strict, consistent percentage and perform extensive testing to ensure color stability. |

| Mold Contamination | Traces of a previous colorant left in the molding machine barrel or hot runner system can bleed into the new color, causing streaks or shifts. | Implement rigorous purging procedures when changing colors. Use a commercial purging compound to thoroughly clean the barrel and screw between runs. |

Conclusion

Perfect Pantone injection molding color matching is not an accident; it’s a process of design and discipline. By understanding the importance of Pantone, being fully in control of the material and masterbatch quality, and following strict process parameters, the element of guesswork will be taken out to ensure that your brand’s colors are always accurately represented. This commitment to consistency protects your brand identity and delivers the quality your customers expect.