Are inconsistent part dimensions driving you crazy? Shrinkage issues lead to rejects, assembly problems, and wasted resources, undermining your precision goals. Let’s get it under control.

Mastering shrinkage involves understanding material behavior (like PVT), optimizing process parameters (pressure, temperature, time), and smart mold design (gating, cooling). It’s a balance achieved through systematic adjustments and data.

Shrinkage is an inherent part of injection molding, but excessive or uneven shrinkage causes major headaches. Understanding why it happens and how to manage it is fundamental to precision. Let’s dive into the specific actions you can take.

How Can You Reduce Shrinkage in Injection Molding?

Are your molded parts coming out too small or warped? Uncontrolled shrinkage often leads to dimensional failures and assembly headaches, costing you time and materials. There are ways to fight back.

Reduce shrinkage by increasing packing/holding pressure and time, lowering melt and mold temperatures (within limits), increasing injection speed, and optimizing gate/runner design for better pressure transmission.

!

Reducing shrinkage basically means packing more material into the mold cavity and allowing it to cool in a way that minimizes contraction. It sounds simple, but it involves balancing several process parameters. Let’s break down the key strategies:

Process Adjustments

- Packing/Holding Pressure & Time: This is your primary weapon. Higher packing pressure forces more material into the cavity to compensate for the volume reduction as the plastic cools. Longer holding time ensures the gate freezes before pressure drops, preventing backflow. Be careful, though – excessive pressure can cause flash or stress.

- Melt Temperature: Lowering the melt temperature reduces the total amount the plastic needs to cool (and thus shrink). However, lowering it too much increases viscosity, potentially causing short shots or requiring higher injection pressure. Find the sweet spot.

- Mold Temperature: A cooler mold solidifies the outer layers faster, potentially resisting further shrinkage of the core. But, too cold can cause flow issues, high stress, and poor surface finish. Uniform, controlled cooling is vital.

- Injection Speed: Faster injection often reduces shrinkage, especially in thin sections, by minimizing cooling during flow and allowing pressure to transmit more effectively. However, it can increase shear heating and potentially cause cosmetic defects.

Mold Design Factors

- Gate Size & Location: Larger gates allow for better packing pressure transmission deep into the cavity and for longer. Gates should be located to fill thicker sections first.

- Runner System: Efficient runners minimize pressure loss before the cavity.

-

Cooling Design: Uniform cooling prevents differential shrinkage, which causes warpage.

Here’s a quick reference table:Parameter Adjustment Effect on Shrinkage Potential Side Effects Increase Packing Pressure Decreases Flash, sticking, high stress Increase Holding Time Decreases Longer cycle time, gate wear Decrease Melt Temp Decreases Higher viscosity, short shots, stress Decrease Mold Temp Decreases Flow issues, poor surface, high stress Increase Injection Speed Decreases Shear burn, flash, gas traps I remember a project with thin-walled parts showing excessive sink marks (a type of shrinkage). Increasing the holding time slightly and optimizing the gate size made a huge difference by packing out those areas more effectively before the gate froze.

How Do You Calculate Shrinkage in Injection Molding?

Are you guessing shrinkage values for mold design? Incorrect estimates lead to costly mold modifications and production delays when parts don’t meet spec. You need a reliable calculation method.

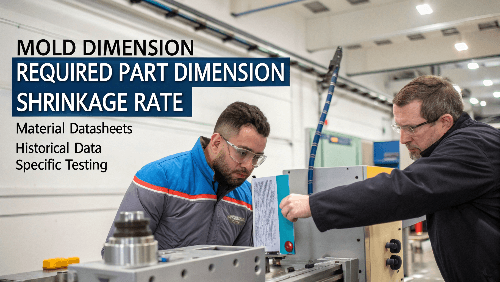

Calculate mold cavity dimensions using the formula: Mold Dimension = Required Part Dimension / (1 – Shrinkage Rate). Obtain the shrinkage rate from material datasheets, historical data, or specific testing.

Predicting shrinkage accurately is crucial for designing molds that produce dimensionally correct parts right from the start. While complex simulation software provides the most accurate prediction, a basic calculation is essential for initial design and feasibility checks.The Basic Formula

The fundamental relationship is straightforward:

Mold Cavity Dimension = Desired Part Dimension / (1 - S)

Where ‘S’ is the anticipated shrinkage rate (expressed as a decimal, e.g., 0.006 for 0.6%).

This formula accounts for the fact that the mold cavity must be larger than the final part to compensate for the material’s contraction upon cooling.Finding the Shrinkage Rate (S)

This is the critical input, and it’s influenced by several factors:

- Material Type: This is the biggest factor. Semi-crystalline plastics (like PP, PE, Nylon) generally shrink much more than amorphous plastics (like ABS, PC, PS). Material datasheets provide a range of potential shrinkage values (e.g., 0.004-0.007 in/in or mm/mm).

- Processing Conditions: Melt/mold temperatures, packing pressure, and cooling time significantly affect the final shrinkage. Higher packing reduces shrinkage; higher temperatures often increase it.

- Part Geometry: Wall thickness plays a huge role. Thicker sections cool slower and shrink more. Fiber fillers in reinforced plastics reduce shrinkage, but orientation effects can cause different shrinkage rates along flow vs. cross-flow directions.

Practical Application

- Datasheet Range: Start with the supplier’s datasheet range for the specific grade of plastic.

- Consider Conditions: Adjust your estimate within that range based on your expected processing conditions and part thickness. For high packing and cool molds, aim for the lower end; for low packing and hot molds, aim for the higher end.

- Flow vs. Cross-Flow: For fiber-filled materials, use different rates if critical tolerances exist in different directions. Shrinkage is typically lower along the direction of polymer/fiber orientation (flow direction).

-

Experience & Testing: Your own historical data with similar parts and materials is invaluable. For critical dimensions, molding trials with a prototype tool or insert might be necessary to pinpoint the exact shrinkage. Factor Typical Impact on Shrinkage Rate Example Adjustment Direction Material High (Semi-crystalline > Amorphous) Use specific datasheet range Packing Pressure Moderate (Higher P = Lower S) Estimate lower S for high pack Melt/Mold Temp Moderate (Higher T = Higher S*) Estimate higher S for hot process Wall Thickness Moderate (Thicker = Higher S) Estimate higher S for thick areas Fillers (Fibers) High (Lower S, Anisotropic) Use lower S, check flow direction Note: Higher temps cause more thermal contraction, but lower viscosity can sometimes allow better packing, slightly complicating the effect.

Getting the shrinkage calculation right saves enormous headaches later. I always advise clients to use the middle of the datasheet range as a starting point, then adjust based on part thickness and intended processing.How Do You Control Shrinkage in ABS Plastic?

Is inconsistent shrinkage in your ABS parts causing problems? Acrylonitrile Butadiene Styrene (ABS) is common, but controlling its dimensions requires specific attention to its properties and processing needs. Let’s fine-tune your ABS process.

Control ABS shrinkage by using moderate melt (220-250°C) and mold (50-80°C) temperatures, ensuring adequate packing pressure and time, consistent material drying (crucial!), and uniform mold cooling.

ABS is an amorphous thermoplastic, meaning it doesn’t have a sharp melting point and generally exhibits lower, more predictable shrinkage compared to semi-crystalline materials. However, achieving tight tolerances still requires careful control.Key Considerations for ABS

- Moisture Sensitivity: ABS is hygroscopic, meaning it readily absorbs moisture from the air. Processing damp ABS causes splay marks, weakened properties, and inconsistent shrinkage. Proper drying (typically 2-4 hours at 80-90°C, check datasheet) is non-negotiable for precision work. I’ve seen seemingly random shrinkage issues disappear just by enforcing strict drying protocols.

- Thermal Properties: ABS has a relatively wide processing window. Sticking to the middle of the recommended temperature ranges usually provides the best balance between flowability and stability.

- Melt Temp: 220-250°C (430-480°F). Too low increases viscosity and stress; too high risks degradation.

- Mold Temp: 50-80°C (120-175°F). A warmer mold improves surface finish and reduces molded-in stress (which can affect post-mold dimensions) but slightly increases shrinkage and cycle time. Uniformity is key.

- Packing: Like most plastics, ABS benefits from sufficient packing pressure and time to compensate for volume reduction during cooling. Because it’s amorphous, the transition from molten to solid is more gradual, so holding pressure remains effective for longer compared to some crystalline materials.

- Cooling: Ensure cooling channels are designed for uniformity across the part geometry to prevent differential shrinkage and warpage.

Parameter Guidelines for ABS Shrinkage Control

Parameter Typical Range/Target Reason for Precision Control Drying 2-4 hrs @ 80-90°C Prevents hydrolysis, stabilizes melt viscosity Melt Temperature 220-250°C (430-480°F) Balances flow and degradation, affects shrinkage Mold Temperature 50-80°C (120-175°F) Affects cooling rate, stress, surface, shrinkage Packing Pressure Moderate to High Compensates for volume contraction Holding Time Sufficient to freeze gate Ensures packing effectiveness Cooling Time Consistent, adequate Ensures part stability before ejection When molding tight-tolerance ABS parts, consistency is paramount. Ensure your drying is spot-on, keep temperatures stable, and apply enough packing pressure. We once had an issue with mating ABS parts having inconsistent fit; stabilizing the mold temperature using a high-quality thermolator was the final piece of the puzzle.

How Might You Increase Shrinkage in Polypropylene?

Do you actually need more shrinkage in your Polypropylene parts? While usually undesirable, specific situations like insert molding or achieving a certain fit might require maximizing PP’s natural tendency to shrink.

Increase Polypropylene (PP) shrinkage by using higher melt and mold temperatures, reducing packing pressure and/or time, slowing injection speed, and allowing for longer, slower cooling cycles.

This sounds counter-intuitive, as we usually fight against shrinkage. However, Polypropylene (PP), a semi-crystalline material, has inherently high shrinkage. If a design relies on this shrinkage (e.g., to tightly grip an insert after cooling), or if previous molds were overcompensated, you might need to encourage it. This involves doing the opposite of shrinkage reduction techniques.Factors Encouraging PP Shrinkage

- Material Structure: PP’s semi-crystalline nature means its polymer chains organize into dense crystalline structures upon cooling, leading to significant volume reduction (high shrinkage). Slower cooling allows more time for crystals to form and grow, maximizing this effect.

- Higher Temperatures:

- Melt Temperature: Higher melt temps mean the plastic starts cooling from a higher point, undergoing more total thermal contraction. It also lowers viscosity, potentially hindering effective packing pressure transmission if not managed carefully.

- Mold Temperature: A hotter mold allows the PP to cool more slowly, promoting crystal growth and thus increasing overall shrinkage.

- Lower Packing: Reducing packing pressure or holding time allows the material to contract more freely as it cools, without being forced to retain volume by external pressure. This directly increases observed shrinkage.

- Slower Injection Speed: This allows the material to cool slightly more during filling, potentially promoting earlier crystallization and reducing the effectiveness of subsequent packing.

Parameter Adjustments to Increase PP Shrinkage

Parameter Adjustment Effect on Shrinkage Reason Increase Melt Temp Increases More total thermal contraction Increase Mold Temp Increases Slower cooling, promotes crystallization Decrease Packing Pressure Increases Less compensation for volume loss Decrease Holding Time Increases Less compensation before gate freeze-off Decrease Injection Speed May Increase More cooling during fill, less effective pack Extend Cooling Time May Increase Allows more complete crystallization/cooling It’s crucial to understand why you need more shrinkage. This approach is generally not standard practice. I encountered a situation once where a client needed PP components to shrink tightly onto metal inserts. We carefully increased the mold temperature and slightly reduced holding time, compared to a standard setup, to achieve the required grip force after cooling, essentially maximizing the natural shrinkage. Proceed with caution and thorough testing when intentionally increasing shrinkage.

What Fundamentally Causes Shrinkage in Injection Moulding?

Confused about why plastic parts shrink in the first place? Misunderstanding the root causes makes it difficult to effectively counteract or control shrinkage, leading to guesswork. Let’s clarify the underlying physics.

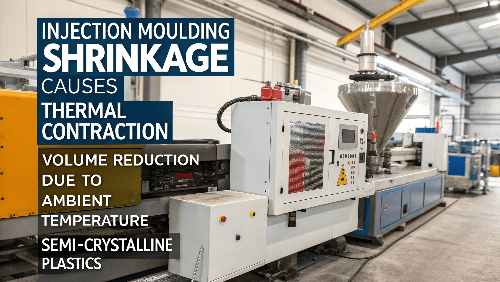

Shrinkage is primarily caused by the material’s thermal contraction as it cools from processing temperatures to ambient temperature, plus volume reduction due to phase changes (like crystallization in semi-crystalline plastics).

Shrinkage isn’t just one phenomenon; it’s the result of combined physical changes the plastic undergoes during the molding cycle. Understanding these mechanisms is key to predicting and controlling it.Thermal Contraction

This is the most basic cause, applicable to all materials. As materials cool, their density increases, meaning the same mass occupies less volume.

- Mechanism: Molecules vibrate less vigorously at lower temperatures, allowing them to pack closer together.

- Magnitude: The amount of contraction is related to the coefficient of thermal expansion (CTE) of the plastic and the total temperature change (from melt/solidification temp to room temp). Plastics generally have much higher CTEs than metals like mold steel.

Phase Change / Crystallization Shrinkage (Semi-crystalline Plastics)

This is a major contributor to shrinkage in materials like PP, PE, Nylon, and POM.

- Mechanism: As these materials cool below their melting point, polymer chains transition from a random, amorphous arrangement to highly ordered, densely packed crystalline structures. This ordering process significantly reduces volume. Amorphous plastics (ABS, PC, PS) lack this crystalline structure and thus exhibit lower overall shrinkage.

- Factors: The degree of crystallinity (and thus shrinkage) is influenced by cooling rate. Slower cooling allows more time for crystals to form, increasing shrinkage.

Pressure-Volume-Temperature (PVT) Relationship

The state of the plastic (its specific volume or density) depends on pressure, volume, and temperature. PVT diagrams illustrate this complex relationship.

- Impact: During the packing phase, high pressure compresses the molten plastic, forcing more material into the cavity. As the part cools and pressure decays (especially after the gate freezes), the material expands slightly due to pressure release but contracts significantly more due to cooling and crystallization. Effective packing aims to offset as much of this natural contraction as possible.

Other Influencing Factors

- Part Geometry: Thicker sections cool slower, allowing more time for molecular relaxation and/or crystallization, leading to higher shrinkage locally.

- Mold Constraint: The mold itself restricts shrinkage while the part is inside. Once ejected, the part may continue to shrink or warp as internal stresses relax (post-mold shrinkage).

-

Orientation: Flow direction can align polymer chains and fillers (if present), leading to different shrinkage rates parallel versus perpendicular to flow. Cause Description Affected Materials Key Influences Thermal Contraction Volume reduction due to cooling All Plastics Temperature change, CTE Crystallization Volume reduction from polymer chain ordering into crystals Semi-crystalline Cooling rate, Temperature Pressure Compensation Packing pressure offsets contraction until gate freeze All Plastics Packing Pressure, Time Geometric Constraints Thickness variations cause differential cooling/shrinkage All Plastics Part design, Cooling layout Understanding these root causes helps explain why certain process adjustments work. Reducing temperature lowers thermal contraction, while increasing packing pressure counteracts both thermal and crystallization effects before the gate freezes. It’s all connected.

Conclusion

Effectively managing shrinkage requires understanding its causes (thermal, crystallization) and manipulating material choice, mold design (cooling, gates), and process parameters (pressure, temperature, time) for consistent, precise parts.