You’ve designed the perfect part, but the finished products are flawed. Defects like sink marks, flash, and warping are ruining your production run, wasting time, material, and money. It’s frustrating when you know the design is solid, but the process itself is failing. You need a clear way to diagnose and fix these problems at their root, and very often, that root is temperature.

Balancing melt and mold temperatures is the key to correcting most injection molding defects related to temperature. Sink marks and voids: reduce temperatures and increase holding pressure. Flash: reduce temperatures to increase viscosity. Short shots: increase temperature to improve flow. Warping: uniform mold cooling, vary temperatures to minimize stress. A disciplined, systematic approach to temperature will be your strongest ally in producing perfect parts, shot after shot.

I’ve spent years on the factory floor and seen how a few degrees can make the difference between a perfect batch and a pile of scrap. It’s a delicate dance between heat, pressure, and time. Mastering this balance is what separates beginners from seasoned pros. It’s not just about turning dials; it’s about understanding what’s happening inside the mold when you do. Let’s walk through some of the most common defects and look at how precise temperature control can solve them, turning frustration into success.

What Causes Sink Marks and Voids, and How Can Temperature Control Fix Them?

You’ve designed the perfect part, but the finished products are flawed. Defects like sink marks, flash, and warping are ruining your production run, wasting time, material, and money. It’s frustrating when you know the design is solid, but the process itself is failing. You need a clear way to diagnose and fix these problems at their root, and very often, that root is temperature.

Balancing melt and mold temperatures is the key to correcting most injection molding defects related to temperature. Sink marks and voids: reduce temperatures and increase holding pressure. Flash: reduce temperatures to increase viscosity. Short shots: increase temperature to improve flow. Warping: uniform mold cooling, vary temperatures to minimize stress. A disciplined, systematic approach to temperature will be your strongest ally in producing perfect parts, shot after shot.

I remember working on a project for a client who made thick-walled electronic enclosures. The parts looked perfect coming out of the mold, but after a few hours, ugly sink marks would appear right over the thickest sections. The team was getting frustrated. The problem was that the outside of the part was solidifying while the inside was still molten. As the molten core finally cooled and shrank, it pulled the solidified surface inward. We had to rethink our entire temperature strategy. It’s a common story, and understanding the "why" behind it is the first step. Let’s dig deeper into how to tackle this problem head-on by controlling the heat.

A Deeper Look at Shrinkage and Temperature

At its core, the formation of sink marks and voids is a story about volume change. Plastic shrinks as it cools from a molten state to a solid state. When a part has sections of varying thickness, this process becomes uneven.

- Thick Sections Cool Slower: The outer surface of a thick section cools first and solidifies, forming a skin. The inside, however, remains molten for longer.

- The Pull of Shrinkage: As this molten core finally cools, it shrinks. Since the outer skin is already solid, the core pulls this skin inward, creating a depression on the surface—a sink mark. If the skin is too rigid to be pulled in, the shrinking core will pull away from itself, creating an empty space inside the part—a void.

So, how do we use temperature and pressure to fight this natural tendency?

Four Key Parameters to Adjust

Controlling this process requires adjusting several interconnected settings. It’s not just about one dial; it’s about finding the right balance across the board.

-

Lower Melt Temperature: A very high melt temperature means the plastic has more heat to lose. This leads to a greater overall shrinkage. By reducing the melt temperature to the lower end of the material’s recommended range, you reduce the total amount of shrinkage that will occur. The plastic enters the mold closer to its solid-state, so there’s less volume change during cooling.

-

Lower Mold Temperature: A hot mold keeps the plastic molten for longer, especially in thick sections. This extends the time for the troublesome shrinkage to happen. By lowering the mold temperature, you encourage the entire part to solidify more quickly and uniformly. This gives the molten core less time to pull the surface inward.

-

Increase Holding Pressure and Time: After the initial injection, holding pressure (or packing pressure) forces more material into the mold cavity. This helps to compensate for the material volume lost to shrinkage. Increasing both the pressure and the duration of this holding phase ensures that as the core shrinks, there is extra material being pushed in to fill the potential sink or void.

-

Lower Injection Speed: High-speed injection can introduce excessive shear heat. This is heat generated by the friction of the plastic molecules rubbing against each other and the mold walls. This extra heat adds to the overall temperature problem, making the melt hotter than your setting indicates. By slowing the injection speed, you reduce shear heat, helping the plastic cool more predictably.

Here is a simple troubleshooting table:

| Parameter | Adjustment for Sink/Voids | Reason |

|---|---|---|

| Melt Temperature | Lower | Reduces the total thermal energy in the plastic, leading to less overall shrinkage. |

| Mold Temperature | Lower | Promotes faster and more uniform solidification, preventing the core from pulling in the outer skin. |

| Holding Pressure | Increase | Packs more material into the cavity to compensate for volume loss during cooling. |

| Holding Time | Increase | Allows the packing pressure to be effective for a longer period, especially while the gate is freezing. |

| Injection Speed | Lower | Reduces frictional shear heating, preventing the melt from becoming unnecessarily hot. |

By carefully working through these parameters, you can systematically eliminate sink marks and voids. Start with small adjustments and observe the results. This methodical approach will help you pinpoint the perfect settings for a flawless part.

What Are the Flow Lines Injection Molding?

Flow lines are streaks observed, wavy or lines formed on the surface of a sculpted plastic piece. They tend to look as slightly varied tones of color and take the path in which the flowing plastic took in the cavity of the mold.

They do not generally have an impact on the strength of the part, although they cause the look of a poor product, particularly on glossy or cosmetic parts.

Main Causes of Flow Lines

Low Melt Temperature

Unless the plastic is heated sufficiently, the substance becomes thick and does not easily flow. This results in visible flow paths since the resin hardens prematurely.

Decelerating Injection rate or Pressure.

In cases where the injection rate is too slow the melt line will not fill the cavity uniformly but crawls within it. The result of this slow motion is streaks.

Mold Temperature Too Low

Cold mold makes the resin to cool too fast. The surface begins to solidify prior to the cavity being completely packed leading to flow marks.

The abrupt alterations in Wall Thickness.

The transition between thick and thin layers compel the melt to decelerate or accelerate suddenly to leave visible lines in the flow direction.

Gate Issues

Poorly designed gates, such as small gate size, wrong position of the gate or blocked gates, may cause disproportionate or slow flow of the melt.

Incorrect Venting

Due to poor venting, there is resistance within the cavity, which slows down flow leaving visible marks.

How to Prevent Flow Lines

Increase Melt Temperature

Increased melt temperature enhances the fluidity of resin and enables an easier flow reducing streaks.

Raise Mold Temperature

A warmer mold prevents the melt to cool at an early stage to bring up an even finish on the surface.

Enhance Injection Rate and Pressure

An accelerated injection will be used to fill the cavity before some of the flow freezes to maintain the flow marks.

Keep Wall Thickness even.

Do not have extreme changes of thickness. In case of necessity, redesign flow paths in order to decrease flow hesitation.

Proper Drying of Material

Wipe dry hygroscopic plastics to the suggested moisture content and then process.

Improve Venting

Proper vent slots and air relief are used so that the plastic does not have back-pressure or air traps.

Are Your Parts Flashing or Coming Out as Short Shots?

You open the mold, and sure enough, there is one of two frustrating outcomes: either the part is incomplete, with sections missing-a "short shot"-or there’s a thin, unwanted layer of plastic seeping out of the parting line-"flash." Both are classic molding defects that bring production to a grinding halt. Short shots mean scrapped parts; flash means costly manual trimming and a poor-quality finish. You’re either using too little material or too much, or so it seems. More often than not, it’s actually all about flow.

Flash and short shots are two sides of the same coin and usually related to temperature and viscosity: when the plastic is too fluid because of high temperatures, it flashes out of the mold cavity. When the plastic is too stiff because of low temperatures, it will solidify before filling the mold cavity completely-a condition known as short shots. The solution involves determining the optimum material processing temperature, increasing it to eliminate short shots and decreasing it to eliminate flash.

I once had a rush job for a series of small, intricate clips. The thin walls were a real challenge. Initially, we kept getting short shots because the plastic was freezing before it could fill the tiny features. So, we started gradually increasing the barrel temperature. But we went a little too far, and suddenly, we had flash on every single part. It was a perfect lesson in how a few degrees can swing the process from one problem to its complete opposite. It’s all about finding that "just right" window.

Understanding the Role of Viscosity

The key concept linking temperature to both flash and short shots is viscosity. Think of viscosity as the thickness or resistance to flow of the molten plastic.

- High Temperature = Low Viscosity: When you heat the plastic, it becomes thinner and flows more easily, like warming up honey.

- Low Temperature = High Viscosity: When the plastic is cooler, it becomes thicker and more sluggish, like honey straight from the fridge.

Your goal is to achieve a viscosity that is low enough for the plastic to flow easily and fill every corner of your mold, but high enough that it doesn’t escape through tiny gaps in the parting line under pressure.

Troubleshooting Flash: When the Plastic is Too Runny

Flash is a sign that the melt is too fluid and the clamping force isn’t enough to contain it. While mechanical issues like a worn-out mold can be a cause, temperature is the first process parameter you should check.

- Primary Culprit: High Melt Temperature: If your barrel temperature is too high, the plastic’s viscosity will be too low. It acts more like water than paste, and the injection pressure can easily force it out of the mold’s parting line. Solution: Gradually lower the melt temperature. Do this in small increments (e.g., 5°C or 10°F) until the flashing stops, but be careful not to lower it so much that you cause a short shot.

- Secondary Culprit: High Mold Temperature: A hot mold prevents the plastic from solidifying near the parting line. This keeps it fluid for longer, giving it more opportunity to flash. Solution: Lower the mold temperature. This will help the "skin" of the plastic freeze faster upon contact with the mold surface, sealing the cavity.

Troubleshooting Short Shots: When the Plastic is Too Stiff

A short shot is the opposite problem. The plastic doesn’t reach the end of the mold cavity before it solidifies. The part comes out incomplete.

- Primary Culprit: Low Melt Temperature: If the melt is too cool, its viscosity is too high. It’s too sluggish to travel through the entire mold, especially if the part has long flow paths or thin walls. The plastic freezes mid-journey. Solution: Gradually increase the melt temperature. This will lower the viscosity and improve its ability to flow. Again, make small, controlled adjustments.

- Secondary Culprit: Low Mold Temperature: If the mold itself is too cold, it will suck the heat out of the plastic too quickly. This premature cooling can cause the flow front to solidify before the mold is full. Solution: Increase the mold temperature. This keeps the mold walls from "freezing" the plastic on contact, allowing it to flow further.

Here is a comparative table to guide your adjustments:

| Defect | Primary Temperature Cause | Secondary Temperature Cause | Solution |

|---|---|---|---|

| Flash | Melt Temperature Too High | Mold Temperature Too High | 1. Lower Melt Temperature 2. Lower Mold Temperature |

| Short Shot | Melt Temperature Too Low | Mold Temperature Too Low | 1. Increase Melt Temperature 2. Increase Mold Temperature 3. Consider increasing injection speed |

By viewing flash and short shots as opposite ends of a temperature spectrum, you can troubleshoot more effectively. Adjusting your temperatures methodically will help you find that perfect processing window where the plastic flows exactly as it should.

Top Common Injection Molding Defects in Plastic Molding Caused by Temperature Issues & How to Fix Them

One of the most important aspects of the injection molding is temperature control. The plastic will not flow, cool, or solidify as it was meant to when the melt, mold, or cooling temperatures are not properly set. This results in the detectable defects, dimensional variability, and increased rate of rejection. The three most prevalent defects in molding that are directly related to temperature issues- and the way to correct them are listed below.

Delamination

Delamination is a flaw of injection molding in which a component has layer separation or surface splitting, which may take the form of flakes, peeling or voids. This happens when the material does not bond well in the molding process and this may adversely influence the strength and look of the piece.

Cause:

Delamination can occur due to a number of reasons. The reason is often moisture in the material, particularly plastics such as ABS, PC, or PA, whereby the layers are separated by trapped steam during injection. Poor or contaminated resin also leads to poor bonding and lack of enough melt temperature can leave the plastic not well fused. Weak layer adhesion and delamination may be caused by turbulence caused by high injection speed, pressure or improper drying of hygroscopic plastics, poor mixing of colors or additives.

How to Fix It:

Delamination can be prevented by close attention to the molding process.

- The correct drying of resin will avoid the separation of layers due to moisture and clean and good-quality material will avoid contamination.

- The maximization of melt temperature and regulation of speed and pressure of injection minimizes turbulence, as well as enhances the bonding of layers. Even mixing of additives or colors and keeping mold temperature constant also contributes to creation of strong parts that are free of defects.

Burn Marks

Cause:

Burn marks are dark and charred streaks produced by the overheated air or resin. Although it is primarily triggered by trapped air, temperature increases immensely. The air pocket is heated to high temperature of burning by high melt temperature, or very high injection speeds. High temperature of molds also leads to a high possibility of scorching during filling.

How to Fix It:

- Limit Melt temperature to reduce melting material friction and heat production.

- Reduce the rate of injection so that trapped air has time to escape.

- Venting should be increased towards the end of the flow path.

- Keep the mold temperature low to ensure that there is low concentration of heat.

- Tilting gates to achieve better flow and reduced compression of air bubbles.

Jetting-one of the Common Injection Molding Defects

Cause:

Jetting is either in form of snake like lines or irregular streaks on the surface which are rough. The defect may be frequent when the melt temperature is too low and the resin will solidify before being completely mixed with the rest of the melt. It may also happen when the surface on which the mold is deposited is excessively cold, and as such, the polymer will freeze as soon as it comes in contact with it. The problem of temperature decreases the flow capacity of the melt and it ends up shooting through the cavity rather than filling uniformly.

How to Fix It:

- Raise the temperature of melting to enhance the flow properties of the polymer.

- Increase the temperature of molding materials to avoid early freezing of the material.

- Slow down injection rate to permit more layered application.

- Change the design of gates (e.g. larger gate size or other angle) to direct material to flow.

- Make sure that the melt moves into the cavity in controlled, laminar fashion, rather than projecting forward.

The vast majority of injection molding failures can be related to wrong temperature setting. With a close balance between melt temperature, mold temperature and cooling uniformity, manufacturers can remove such significant problems as delamination , burn marks and jetting to achieve better surface quality, further dimensional accuracy and reduced scrap.

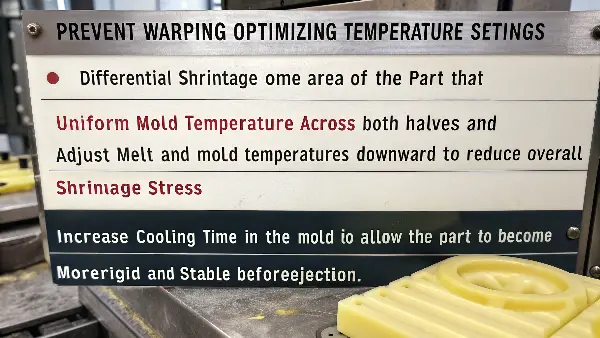

How Can You Prevent Warping by Optimizing Your Temperature Settings?

There’s nothing more defeating than molding a part that looks perfect initially, only to see it twist and distort as it cools. This is warping, and it can render a part useless, especially if it needs to fit precisely with other components. Warping is evidence that internal stresses built up during the molding process are being released unevenly. In most instances, this stems from temperature differences and cooling rates.

Warping is due to differential shrinkage, which means one area of the part is shrinking more or faster than another. The principal solution is control of your cooling process. Ensure your mold temperature is uniform across both halves and all sections. Reducing the melt and mold temperatures down will help decrease the overall shrink stress. Also, allowing increased cooling time in the mold enables the part to become more rigid and stable prior to being ejected into open air.

I recall a project involving large, flat panels for a housing unit. They came out of the press looking perfectly flat, but by the time they reached the assembly line, they were bowed like a banana. We discovered that one side of the mold had a cooling channel that was slightly less effective than the others. This tiny difference in temperature was causing one side of the panel to shrink and solidify at a different rate, building up immense internal stress that was released the moment the part was ejected. Resolving warping is all about achieving balance.

The Science of Stress and Warping

Warping is the physical result of internal stresses. These stresses are created when different parts of the component cool and shrink at different rates. When the hot, flexible part is ejected from the mold, these stresses pull and push against each other, causing the part to bend and distort as it settles into its final, stable form.

- Differential Cooling: This is the number one cause. If one side of the mold is cooler than the other, that side of the plastic part will cool and shrink faster. The warmer side is still larger and more pliable. This difference creates a bending force. This is common in parts with uniform thickness but non-uniform cooling.

- Differential Shrinkage: This is related to part geometry. Thicker sections cool much slower than thinner sections. The thin sections shrink and lock into place while the thick sections are still cooling and shrinking. This creates stress at the transition points, often causing distortion.

A Temperature-Based Strategy to Eliminate Warping

Fixing warping requires a holistic look at your entire temperature profile, from the melt to the post-ejection cooling.

1. Achieve Uniform Mold Temperature

This is the most critical factor. The temperature across the entire surface of the mold cavity should be as consistent as possible.

- Check Your Cooling Channels: Ensure all cooling channels are open and flowing correctly. A clogged or poorly designed channel can create hot spots on the mold surface.

- Measure Mold Surface Temperature: Use a pyrometer to check the temperature on both the core and cavity sides of the mold. If there’s a significant difference (more than 5-10°C), you’ve found a likely cause of your warping. Adjust the flow rate or temperature of the cooling water to balance them out.

2. Optimize Melt and Mold Temperatures

Lowering temperatures generally reduces stress by minimizing the total amount of shrinkage.

- Lower Melt Temperature: A hotter melt leads to more shrinkage, which creates more potential for internal stress. Bringing the melt temperature down reduces the overall magnitude of this shrinkage.

- Lower Mold Temperature: While this seems counterintuitive to the point about differential cooling, a lower overall mold temperature can help "lock" the part into its intended shape more quickly, provided the cooling is uniform. However, for some crystalline materials like Nylon or PP, a higher mold temperature can sometimes help reduce warping by allowing stresses to relax and anneal out before the part fully solidifies. This requires careful testing.

3. Extend Cooling Time

Don’t be in a rush to eject the part.

- Increase Cooling Time: Leaving the part in the mold for longer allows it to cool more completely and become more rigid. A rigid, stable part is less likely to distort from internal stresses when it’s ejected. While this can increase cycle time, it’s often a necessary trade-off for producing a dimensionally stable part.

This table summarizes the strategic temperature adjustments for combating warping:

| Strategy | Action | Why It Works |

|---|---|---|

| Ensure Uniform Cooling | Verify all cooling channels are working. Measure and balance mold halves. | Eliminates differential cooling, the primary cause of stress buildup. |

| Reduce Overall Shrinkage | Lower the melt temperature. | Less total shrinkage means less potential for stress to develop. |

| Adjust Solidification Rate | Carefully adjust mold temperature (often lower, sometimes higher). | Controls how fast the part sets. A uniform, controlled rate minimizes stress. |

| Stabilize the Part | Increase the cooling time inside the mold. | Allows the part to become strong enough to resist distorting forces upon ejection. |

By methodically addressing these temperature-related factors, you can tame the internal stresses that cause warping and produce parts that are flat, true, and dimensionally accurate every time.

Conclusion

The whole science behind injection molding is managing the process variables; temperature is usually the most critical. Understanding how melt and mold temperatures relate to plastic behavior gives you a systematic way to solve some common defects, such as sink marks and warping from uneven cooling or flash and short shots due to viscosity changes. In every case, a methodical approach to temperature management leads to better, more consistent parts.