Have you always been facing issues with part defects such as sink marks, warped parts, or uneven finishes? These problems interfere with production, raise scrap rate and jeopardize your bottom line. You are aware that the mold temperature is an art, not a science, but difficult to master. Getting a good partner who is able to produce a steady output is what you require and at CKMOLD we have mastered the art of temperature control into a fine art.

CKMOLD realizes maximum quality of part through the combination of superior thermal simulation in the design stage, high-precision Temperature Control Units (TCUs) and chillers, and effective cooling channel designs, such as conformal cooling. We uphold this attribute by strict real-time check using in-built sensors and strict maintenance regimes. This is the ultimate control of the mold temperature that is core to the elimination of defects and consistency, which is our philosophy of Mastering Molding Right.

Achieving this level of control isn’t about one magic trick. It’s about a complete system that combines deep understanding with the right technology and processes. It means answering the fundamental questions that business owners like Michael often ask when they’re trying to diagnose production issues. Let’s walk through these key questions to see how a systematic approach to temperature management leads to superior parts and a more profitable operation.

How Is the Quality of Molded Parts Ultimately Controlled?

You have sanctioned an ideal 3D model, yet the physical components rolling out of the plant are not in line with the specifications. Irregular dimensions and cosmetical defects cause headaches to your assembly staff and may end up disappointing your end-users. You require some molding process that is reproducible, predictable and constant. At CKMOLD, we develop quality control in all processes, which begins with the simplest and the most significant component of the whole process.

Four variables, including temperature of plastic, injection pressure and speed, cooling time, mold temperature, control the quality of molded components. Among these, the most significant one that can be used in controlling the final part dimensions, surface finish and internal stress are its mold temperature. With absolute control over the thermal profile of the mold, we can control the solidification of the plastic directly avoiding defects such as warpage, sink marks, and dimensional instability. This is the basis of a repeat, high quality process.

Many people think of quality control as something that happens at the end of the line, with an inspector checking finished parts. In reality, true quality is built into the process itself. You can’t inspect quality into a part; you have to manufacture it in. For injection molding, this means mastering the four pillars of process control. I’ve seen many companies, even experienced ones, focus too much on one pillar while neglecting another, leading to a constant struggle. They’re always adjusting one variable to compensate for another that’s out of control. The secret is to stabilize the most important pillar first, which is the mold temperature. Once the thermal foundation is solid, everything else becomes much easier to optimize and control.

The Four Pillars of Process Control

Think of these four elements as the legs of a table. If one is too short or unstable, the whole table wobbles.

| Pillar | Its Role in Molding | Impact of Poor Control |

|---|---|---|

| Material Temperature | Determines the plastic’s viscosity (flowability). | Too hot can degrade the material; too cold causes it to be too stiff to fill the mold (a "short shot"). |

| Injection Pressure & Speed | Pushes the molten plastic into the mold cavity. | Too much pressure causes "flash" (plastic leaking out); too little results in an incomplete part. |

| Cooling Time | The time the part spends in the mold to solidify. | Too short and the part will be soft and deform upon ejection; too long and it hurts productivity. |

| Mold Temperature | Controls the rate at which the part cools and solidifies. | This is the master variable that influences shrinkage, warpage, surface finish, and internal stress. |

By stabilizing the mold temperature, we create a consistent environment for the plastic. This allows us to set the other three parameters—melt temp, pressure, and time—to their optimal values and keep them there. This holistic view is the only way to achieve a truly robust and repeatable manufacturing process.

Benefits of using mold temperature controllers in injection molding

There are many main advantages of using mold temperature controllers in injection molding that enhance quality of products, efficiency of production, use of energy, and life of the mold:

Accurate Product Quality: Mold temperature controllers ensure the same and steady temperature in the mold which eliminates defects like shrinkages, warping and porosity. This gives molded parts dimensional stability and mechanical performance.

Faster Cycle Time: Using the close control of mold temperature, these controllers allow faster cooling or heating steps which means that the molding cycle becomes shorter and the throughput is increased.

Energy Efficiency: Proper management of temperature will avoid cases of overheating and help reduce energy wastage. Controllers dramatically decrease preheating and after-cooling durations, a benefit towards saving energy and also making operations more sustainable.

Increased Mold Life: Stable thermal control minimizes thermal stress, and helps to avoid damage of molds such as cracks or decay, which helps to maintain high levels of mold integrity and low maintenance expenses.

Improved Process Reliability: New controllers based on superior sensors and algorithms maintain the mold temperature in a narrow range that increases process repeatability and reducing production variability.

Complex Control Features: Most controllers have touchscreen displays, feature automation to make them user friendly and have safety features that safeguard equipment and operators.

The combination of these advantages streamlines the injection molding process and enhances the product consistency, minimizes downtime, and cuts the cost of operation.

What Factors Are Key to Maintaining a Stable Mold Temperature?

Your mold is reported to be running at the right temperature but you continue to notice some inconsistency in the outcome of each production run. The quality of parts appears to vary after a couple of hours of use and leads to unforeseen issues. This turmoil renders the operation of this unpredictable. The answer is to know and manage all the factors which affect the thermal condition of the mold, and establish an ideal balance.

The stable operating temperature is reliant on three main aspects and that includes the amount of heat input by the molten plastic, the efficiency of the cooling system design, and the effectiveness of the external Temperature Control Unit (TCU) or chiller. A balance has to be created whereby the cooling system absorbs the heat at the same rate that it is being supplied. Critical to this thermal equilibrium is the design of cooling channels, flow rate of coolant and responsiveness of the TCU.

The core concept here is achieving "thermal equilibrium." Imagine filling a bucket with a hole in the bottom. To keep the water level constant, the water flowing in must exactly match the water flowing out. It’s the same with a mold. With every shot, hot plastic injects a dose of thermal energy (heat). The cooling system’s job is to remove that exact amount of energy before the next shot. If it removes too little heat, the mold gets progressively hotter. If it removes too much, the mold gets colder. Neither is good. Our entire approach is designed to create and maintain this perfect balance throughout the entire production run.

Achieving Thermal Equilibrium

To achieve this balance, we have to engineer and control three distinct areas.

| Factor | What it Controls | CKMOLD’s Approach |

|---|---|---|

| Heat Input | The amount of thermal energy introduced with each cycle. This is determined by the material type, its melt temperature, and the volume of the part (shot size). | We analyze this during the Moldflow simulation phase to accurately predict the thermal load the mold will need to handle. |

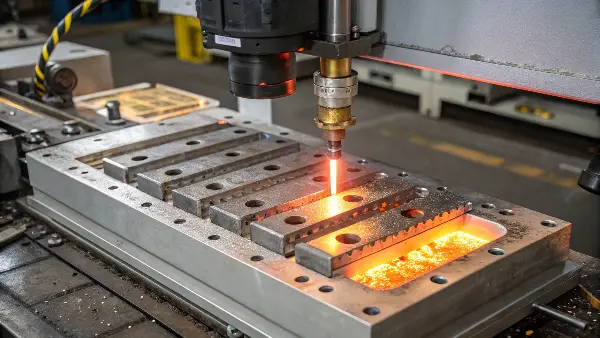

| Cooling Design | The mold’s internal ability to remove heat efficiently and evenly. This includes the layout, diameter, and proximity of cooling channels to the part cavity. | We use simulations to optimize the cooling circuit. We strategically place channels and use high-conductivity inserts (like beryllium copper) in hot spots. |

| External Equipment | The stability and capacity of the TCU or chiller that supplies the cooling fluid. This is the "engine" that drives the cooling process. | We use high-quality, properly sized TCUs that can provide a consistent temperature and flow rate, even under heavy, continuous use. |

A common mistake I see is when companies invest in a great mold but connect it to a cheap, undersized TCU. The TCU can’t keep up, and the mold temperature slowly climbs throughout the day, causing defects to appear in the afternoon that weren’t there in the morning. All three of these factors must be in harmony to ensure a stable, predictable process from the first part to the last.

Problems of High and Low Molding Temperatures.

Wrong temperature settings may cause a lot of problems. Elevated temperature may make the plastic break down or lose the properties they would want whereas low temperatures may lead to partial filling of the mold.

Problems with High Molding Temperature.

Uncontrolled high temperatures of mold may lead to material degradation and prolonged cycle time. Misadjustment in the temperature of the mould may result in many problems with products.

When the molding temperatures are high, serious flaws in the end product may arise, including warping, discoloration and a decrease in the mechanical property. These flaws have a great influence on the efficiency of production and performance of the product.

The integrity and quality of the final product are preserved by keeping the mold temperatures within the limits. Monitoring and readjustments will ensure that no high-temperature problems occur.

Low Molding temperature problems.

Low temperatures of molds cause low smoothness of surface finish. The surface gloss is elevated by high temperatures of molds, and reduced by low temperatures.

During low molding, the strength of products is lowered and weld lines also become more visible. The internal stress left may be above the elastic limit of the resin and the surface of the plastic part may have cracks.

Low temperature reduces melt flowability. This may come as a potential cause of partial filling of the mold. Proper temperature of molds brings about smooth, strong and flawless products.

How Can You Accurately Measure Mold Temperature?

According to your process sheet, the temperature of the mold will be 60 o C, and the parts you are receiving are of the type that were created in a mold that was running a lot hotter. Are you a measuring rod of the right thing? This is a typical, but expensive error of using the temperature setting on the control unit. The temperature at which you really need to be able to control the process is the temperature inside the mold itself, the steel.

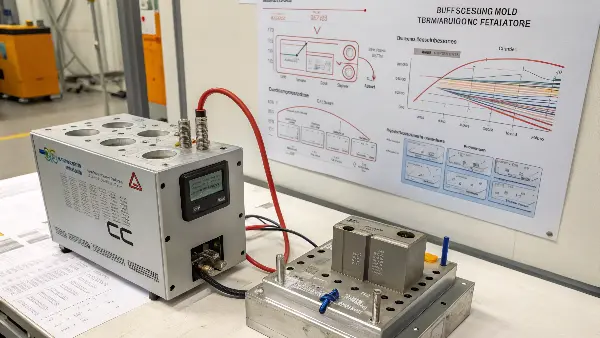

The temperature of the mold is measured at the thermocouples built into the mold steel preferably as near the cavity surface as is convenient. Surface pyrometers may offer a spot check but embedded thermocouples offer real-time and instantaneous information in the most sensitive locations. This information is sent back to TCU and the controller of the molding machine enabling the actual steel temperature, and not the temperature of the coolant fluid, to be tightly controlled in a closed-loop manner.

It’s vital to understand the difference between measuring the process fluid (the water or oil) and measuring the mold steel. The fluid temperature is an input to the system, but the steel temperature is the result. It’s the steel temperature that the plastic "feels" as it solidifies. Measuring the fluid tells you what the TCU is trying to do, but measuring the steel tells you what is actually happening. At CKMOLD, we insist on measuring what is actually happening because that is the only path to true process control.

Methods of Measurement: From Simple to Precise

There are a few common ways to measure temperature, each with its own pros and cons.

| Measurement Method | Accuracy | Use Case | Control Level |

|---|---|---|---|

| TCU Display | Low | Monitoring the external controller’s setting. | Indirect. It doesn’t account for heat loss in hoses or inefficient flow in the mold. |

| Surface Pyrometer (IR Gun) | Medium | Quick spot checks on the mold surface when it’s open. Good for troubleshooting. | None. It’s a manual check, not part of a closed-loop control system. |

| Embedded Thermocouple | High | Provides continuous, real-time measurement of the steel temperature for active process control. | Direct and Closed-Loop. This is the gold standard for high-precision molding. |

An embedded thermocouple is a simple and robust sensor that we place strategically by drilling a small hole into the mold plate, getting the sensor tip as close as possible to a critical feature of the part. This provides a direct, live reading of the steel temperature in that area. This data can then be used by the molding machine to make micro-adjustments to the process, ensuring the temperature stays locked in. For any project where consistency and quality are paramount, like the electronics housings my client Michael produces, we consider embedded thermocouples to be essential, not optional.

In a Hot Runner Mold, What’s the Hardest Area to Control Thermally?

Hot runner systems are an alternative that offer reduced wastage and shorter cycles, yet it presents large engineering problem. One of the halves of the mold must remain very hot so that the plastic remains molten, and this must only be a few millimeters from the main cavity which must be actively cooled. Motivated by such vigorous thermal struggles can be a host of annoying issues, such as unsightly gate tracks to material wastage. What is the way of this fine balancing of thermals?

The gate area is the most sensitive and challenging area to control the temperature in the hot runner mold. This is where the hot runner nozzle, which may reach above 2006 C, gets in contact with the cooled cavity steel, which may be at 60 C. This forms a high thermal gradient. Lack of control in this case causes stringing, drooling or a frozen gate. It needs a well-planned insulating air space, specific nozzle tip materials and a special cooling circuit immediately surrounding the gate to separate the heat and provide a clean separation of the part.

This specific spot is what I call the "thermal battleground." You have two opposing missions in the same tiny space. The hot runner nozzle’s job is to deliver perfectly molten plastic right to the part. The cavity’s job is to cool that plastic down so it becomes a solid part. The point where they meet—the gate—is where the battle is won or lost. If you don’t control this interface perfectly, the entire system fails. You end up with cosmetic defects on the part or, even worse, production stoppages. Mastering this area is a true test of a mold maker’s expertise.

Managing the Thermal Battleground at the Gate

If the temperature at the gate is not perfectly managed, a number of specific defects will occur.

- Gate Freeze-Off: If the cooled mold steals too much heat from the nozzle tip, the plastic will solidify and block the gate, preventing the next part from filling correctly.

- Drooling or Stringing: If the gate area is too hot, the plastic won’t freeze off cleanly when the part is formed. Instead, it leaves a long "string" or a "drool" of plastic on the part, which is a major cosmetic flaw.

- Material Degradation: If the plastic sits at a very high temperature in the gate area for too long, it can begin to burn or degrade, causing black specks in the final part.

To win this battle, we use a three-pronged strategy. First, we design a very precise insulating air gap between the hot nozzle and the cool mold plate. Second, we select advanced nozzle tips made of special alloys that are engineered for specific thermal performance. Finally, and most importantly, we design a separate, highly efficient cooling channel that runs directly around the gate area. This dedicated circuit acts as a thermal barrier, aggressively removing any excess heat that leaks from the nozzle, ensuring the gate functions perfectly cycle after cycle.

Conclusion

The best quality parts are not a fortuitous occurrence. It is the direct consequence of a profound knowledge and accurate control of mold temperature. This is done with an all round system that begins with advanced simulation, applies the appropriate technology, measures what matters and to solve complicated issues such as hot runner control. This is the overall strategy of making us at CKMOLD justify our slogan, Master Molding Right, which provides our clients with tranquility and high quality outcomes always.