Are your high-precision molded parts failing to meet tight tolerances due to unpredictable shrinkage? This leads to costly rework and delays. Discover CKMOLD’s meticulous approach to ensuring your parts are perfect.

CKMOLD ensures precise shrinkage compensation1 by combining rigorous material testing2, advanced simulation, and empirical data from actual molding trials. We calculate mold adjustments3 by analyzing material properties, part geometry, and specific processing conditions.

Transition Paragraph:

When I first started in this industry, grappling with shrinkage was one of the biggest learning curves. You’d design a mold perfectly to spec, only to find the parts were consistently undersized. For a designer like Jacky, who works with components needing exact fits, this isn’t just an annoyance; it’s a critical failure. At CKMOLD, we’ve spent years refining our methods because we know that "close enough" is never good enough for high-precision applications. It’s not just about a formula; it’s about a comprehensive understanding of how materials behave under real-world molding conditions. Let’s delve into how we tackle this complex challenge head-on.

What is shrinkage and warpage?

Confused by parts that are not only the wrong size but also twisted out of shape? Shrinkage and warpage can turn your components into unusable scrap, impacting timelines and costs.

Shrinkage is the volumetric reduction a plastic part undergoes as it cools from melt temperature to ambient temperature. Warpage is the dimensional distortion or bending of a part, often caused by uneven shrinkage rates or internal stresses.

| Dive deeper Paragraph: Shrinkage and warpage are two common headaches in injection molding. They are related, but not quite the same thing. Think of shrinkage as the material getting smaller overall. When molten plastic is injected into the mold, it’s hot and expanded. As it cools down to room temperature, the polymer chains pack closer together. The whole part reduces in volume. This is a natural, unavoidable physical process for almost all plastics. The amount it shrinks depends on the material type, additives, and processing conditions. Warpage, on the other hand, is when the part doesn’t just get smaller. It also twists, bends, or distorts from its intended shape. This usually happens because the shrinkage isn’t uniform across the part. Imagine one section of the part cooling and shrinking much faster than another. This difference creates internal stresses. If these stresses are strong enough, they will pull and push the part out of shape as it solidifies. So, while all parts shrink, not all parts warp. Warpage is essentially a symptom of differential shrinkage or poorly managed internal stresses. For Jacky, designing a thin-walled electronic enclosure, understanding this difference is vital. Uniform shrinkage might be manageable by adjusting mold dimensions. But warpage can make the part completely unusable for assembly. Key factors influencing these are: |

Factor | Effect on Shrinkage | Effect on Warpage |

|---|---|---|---|

| Material Type | Varies (e.g., crystalline > amorphous) | Can increase if non-uniform | |

| Wall Thickness | Thicker sections may shrink more | Differential shrinkage if varied | |

| Mold Temperature | Higher temp can increase post-shrinkage | Uneven cooling leads to warpage | |

| Packing Pressure | Higher pressure reduces shrinkage | Can induce stress if not uniform | |

| Fiber Orientation | Anisotropic (directional) shrinkage | Can cause significant warpage | |

| Gate Location | Affects flow and packing distribution | Poor location can increase stress/warpage |

At CKMOLD, we focus on predicting both to ensure dimensional stability and part integrity from the outset.

How to calculate shrinkage in mold?

Do your mold designs consistently miss the mark, resulting in undersized parts? Relying on generic datasheet values for shrinkage can lead to expensive mold rework and production delays.

To calculate shrinkage for a mold, use the formula: Mold Dimension = Part Dimension / (1 – Shrinkage Rate). The shrinkage rate is determined from material datasheets, empirical testing, or simulation, expressed as a decimal (e.g., 0.005 for 0.5%).

Dive deeper Paragraph:

Calculating the right amount of shrinkage compensation for a mold is more than just plugging a number into a formula. It is a science and an art. The basic idea is straightforward. If you know your plastic part needs to be a certain size, and you know the plastic will shrink by a certain percentage, you need to make the mold cavity bigger by that percentage. The formula we start with is Mold Dimension = Desired Part Dimension / (1 - Shrinkage Rate).

So, if Jacky needs a part to be 100mm long, and the material’s shrinkage rate (S) is 0.5% (or 0.005 as a decimal), the mold dimension (Dm) would be D<sub>m</sub> = 100mm / (1 - 0.005) = 100mm / 0.995 ≈ 100.5025mm.

But here’s where it gets tricky. That "Shrinkage Rate" isn’t a single, fixed number. It’s influenced by many things:

- Material Type: Amorphous materials like ABS or PC generally shrink less and more uniformly than semi-crystalline materials like PP or Nylon. Semi-crystalline materials have more complex shrinkage due to their ordered molecular structure.

- Additives: Fillers like glass fibers or talc typically reduce shrinkage. They add bulk that doesn’t shrink as much as the base polymer.

- Processing Conditions: Melt temperature, mold temperature, injection pressure, packing pressure, and cooling time all play significant roles.

- Part Geometry: Wall thickness is a big one. Thicker sections cool slower and can shrink differently, and often more, than thin sections.

- Flow Direction: For fiber-filled materials, shrinkage is often less in the direction of material flow and more in the direction transverse (perpendicular) to flow. This anisotropy is crucial to consider.

At CKMOLD, we start with material datasheet values. But we always cross-reference with our extensive historical data from similar parts and materials. For truly high-precision molds, we often recommend running mold flow simulations. This software can predict how the plastic will flow, cool, and shrink. It takes into account the specific part geometry and processing parameters. We might even mold test plaques or a prototype cavity to get empirical shrinkage data for the exact material batch and conditions. It is an iterative process. I remember a project with a very tight tolerance part made from PBT with 30% glass fiber. The initial datasheet shrinkage was a range. We narrowed it down with simulation and then fine-tuned it after the first trial shots. This meticulous approach saved a lot of steel adjustments and time.What is the projected area in injection molding?

Unsure how much clamping force your mold truly needs? Underestimating clamping force leads to flash and part defects. Overestimating wastes energy and can damage the mold or machine.

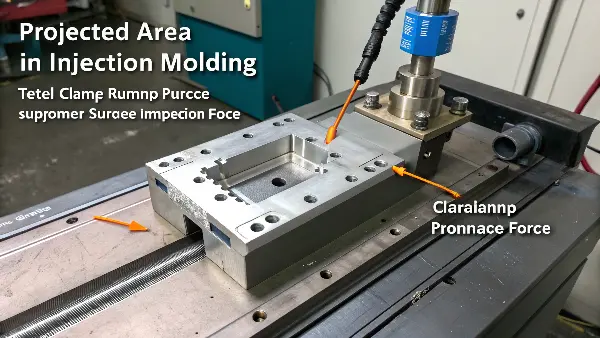

The projected area in injection molding is the total surface area of the part, including runners, as viewed from the direction of the clamp force (perpendicular to the parting line). It’s used to calculate the minimum required clamping force.

Dive deeper Paragraph:

Projected area is a fundamental concept in injection molding. It is directly tied to the forces at play inside the mold. When molten plastic is injected under high pressure, it pushes against all surfaces of the mold cavity. This pressure tries to force the two halves of the mold apart. The injection molding machine’s clamping unit must provide enough force to counteract this. It must keep the mold securely closed.

To calculate this required clamping force, you need to know the projected area. Imagine looking at your part and its runner system straight down the parting line. It is as if you’re shining a light from behind it and seeing its shadow. The area of that shadow is essentially the projected area. More formally, it’s the sum of all the surface areas of the part cavities and runner system that are perpendicular to the clamping direction.

The formula to estimate clamping force (F) is: F (tons) = (P * A) / K, where P is the average cavity pressure (psi or N/mm²), A is the projected area (square inches or mm²), and K is a constant (2000 for US tons from psi and sq.in, or a conversion factor for metric units). For example, if Jacky’s part plus runner has a projected area of 23.25 square inches (150 cm²) and the average cavity pressure for the material is 5800 psi (40 N/mm²), then the force trying to open the mold is significant. He’d need to ensure the machine’s clamping tonnage is sufficient, typically by adding a safety factor of 10-20%.

Why does this relate to shrinkage compensation? An improperly clamped mold can lead to issues. If the clamp force is too low, the mold can flash. Flash is when plastic seeps out at the parting line. This flash can affect final part dimensions. It also indicates an unstable process, making consistent shrinkage hard to achieve. If the mold "breathes" (slightly opens and closes) during injection due to insufficient clamp, the effective cavity volume changes. Thus, the part dimensions and shrinkage become unpredictable. So, accurate projected area calculation ensures a stable process. This is a prerequisite for achieving predictable shrinkage and part quality. I’ve seen molds where flash was a constant issue. It often boiled down to underestimating the true projected area, especially with complex multi-cavity layouts or extensive runner systems.

What is the formula for injection pressure?

Guessing injection pressures and getting inconsistent part quality? Incorrect injection pressure leads to short shots, flash, or high internal stresses. All these impact part dimensions and shrinkage.

There isn’t one simple formula for injection pressure; it’s determined by material viscosity, flow length, wall thickness, gate size, and melt/mold temperatures. It’s typically set empirically and optimized during process development.

Dive deeper Paragraph:

Unlike a neat mathematical equation for something like clamping force, there isn’t a single, universal "formula" to calculate the exact ideal injection pressure before you start molding. It’s more of a target. This target is found through a combination of experience, material data, simulation, and systematic process optimization on the machine.

Injection pressure is the force exerted by the screw or ram to push the molten plastic into the mold cavity. It needs to be high enough to overcome all the resistances the plastic encounters during its journey. These resistances include:

- Material Viscosity: Thicker, more viscous materials (like high molecular weight polymers or heavily filled compounds) need higher pressure to flow.

- Flow Path Length & Thickness: Longer flow paths and thinner wall sections create more resistance, requiring more pressure. Think of trying to push honey through a long, thin straw versus a short, wide one.

- Gate Size & Type: Smaller gates restrict flow and necessitate higher pressure to fill the part adequately.

- Melt & Mold Temperatures: Colder melt or a colder mold increases the plastic’s viscosity, thus needing higher injection pressure.

- Venting: Poor mold venting can trap air. This trapped air creates back pressure that the injection pressure must overcome.

While there’s no direct calculation formula for the pressure setting itself, machine software and advanced mold flow simulations can predict required pressures based on these inputs. In practice, injection pressure is typically set and controlled in two main stages on the molding machine:- Filling Phase Pressure (Boost Pressure): This is the initial high pressure used to fill the cavity quickly (e.g., 95-99% full) before the plastic freezes off at the gate or thin sections.

- Packing/Holding Phase Pressure: Applied after the cavity is mostly full, this pressure (often lower than boost) packs additional material into the cavity. This compensates for shrinkage as the plastic cools and solidifies. This phase is crucial for minimizing voids, sink marks, and directly impacts the final part dimensions and the effectiveness of shrinkage compensation.

For Jacky, understanding these phases is key. If the packing pressure is too low, the part will show more shrinkage and potential sink marks. If it’s too high, it can lead to flash, overpacking (which can cause parts to stick or have high internal stresses), or even damage the mold. We at CKMOLD typically start with material supplier recommendations. Then, we meticulously fine-tune the pressures on the machine, carefully monitoring part weight, critical dimensions, and visual quality. I always tell my team, "Listen to the plastic, watch the process." The machine’s pressure readings and the resulting parts tell you a detailed story about what’s happening inside the mold.Conclusion

CKMOLD’s precision in shrinkage compensation stems from a deep understanding of material behavior and meticulous calculation. We adapt to real-world process variables, ensuring high-quality, dimensionally accurate parts every time.

-

Understanding shrinkage compensation is crucial for achieving high precision in molded parts, ensuring quality and reducing rework. ↩

-

Material testing is essential for ensuring the right properties are achieved, leading to better product quality and performance. ↩

-

Learning about mold adjustments can help you optimize your designs and improve the accuracy of your molded parts. ↩