Are you having trouble assembling complex parts or searching for solutions to reinforce components and save costs? Most manufacturers struggle to assemble disparate materials in an optimal way. Insert molding provides a strong solution, simplifying production and improving product quality in a variety of markets.

Insert molding is a broad manufacturing process where two or more materials, typically a plastic and metal insert, are combined in a single, bonded component. The process reinforces parts, reduces assembly cost, and allows complex designs with greater precision. It’s employed extensively in the automotive, electronics, and medical industries for all these reasons.

This is not gluing two things together; this is creating a synergistic element where the whole is more than the sum of the parts. I’ve seen what it does to product development. If you want to know how this technology can specifically benefit some of the different areas, let’s talk about some of the primary applications.

How Does Insert Molding Drive Innovation in Automotive Components?

Automotive engineers worry all the time about minimizing vehicle weight, improving part strength, and making assembly easier. Traditional methods involve several steps and fasteners and add complexity and failure risk. Insert molding eliminates these issues outright by creating integrated, ruggedized parts.

Insert molding significantly improves the appearance of cars by allowing the production of lighter, stronger, and more reliable parts. It allows the combination of metal strength with plastic design flexibility, leading to improved performance, reduced assembly time, and manufacturing cost savings on complex car components like sensors, connectors, and structural parts.

When I first encountered insert molding in an automotive context, I was amazed by its efficiency. It’s not just about making a part; it’s about making a smarter part. Let’s look deeper into how this process is shaping the automotive landscape. We can see its impact in several key areas:

- Weight Reduction: With overmolding plastic over metal inserts, businesses are able to replace heavier, all-metal components. This is necessary to maximize fuel efficiency and vehicle performance. For example, structural housings or brackets can be reduced in weight but still achieve needed strength. I’ve seen projects where this alone drastically changed the final vehicle spec.

- Improved Resistance: The bond of insert molding is extremely strong. Parts are then better able to resist vibration, heat, and wear and tear – all common conditions of automobiles. Think of electric connectors or sensor covers that need to survive harsh under-hood conditions. The reliability benefit is usually sizable.

- Simplified Assembly: With the incorporation of threads, clips, or electrical contacts into the molded part itself, extra assembly steps are eliminated. Labor is saved, production is hastened, and the possibility of assembly errors is minimized. I have seen assembly lines become much more streamlined due to this direct integration.

Here’s a table summarizing some common automotive applications:

| Component Category | Examples | Key Benefits from Insert Molding |

|---|---|---|

| Electrical Systems | Connectors, sensors, wire harness components | Improved sealing, reduced size, enhanced conductivity |

| Structural Parts | Brackets, reinforcements, mounting points | Weight reduction, high strength-to-weight ratio |

| Interior Components | Knobs with metal grips, decorative trim | Enhanced aesthetics, improved tactile feel |

| Powertrain Parts | Bearing housings, fluid handling components | Wear resistance, precise tolerances |

The precision offered by insert molding is also vital for the complex geometries often found in modern automotive designs. It allows engineers to create parts that fit perfectly and perform reliably, which is a huge advantage in such a competitive industry.

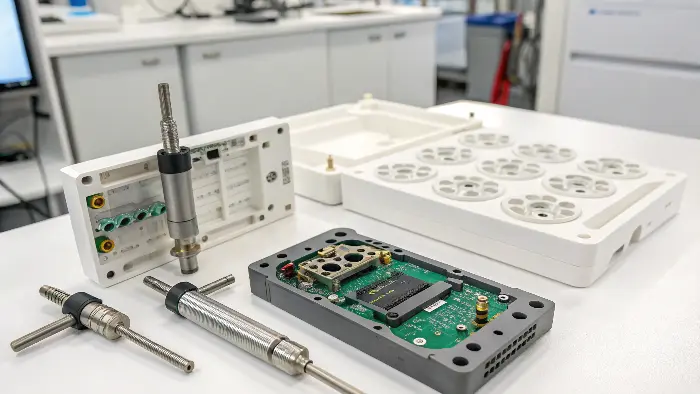

Types of Inserts in Insert Molding

Inserts used in insert molding are typically differentiated into two groups: mold inserts and part inserts

Mold Inserts

Mold inserts are usually metallic and are mounted on the mold. Mold inserts can be made of high-conductivity metals. This can affect temperature during injection. A mold insert is the core. Core mold components are included in core shift analysis. That is, we can simulate the way mold cores move and affect the thickness of the molded part. Common mold inserts are cores, ejector pins, and cooling channels.

Part Inserts

Part inserts are items inserted into the mold prior to the injection stage. They are forced out with the completed part. Part inserts may be metal or plastic. Each new shot takes a new part insert. You can define the initial temperature and mold contact time prior to injection. Typical examples include threaded inserts, pins, and bushings.

Why is Insert Molding a Game-Changer for Electronic Devices?

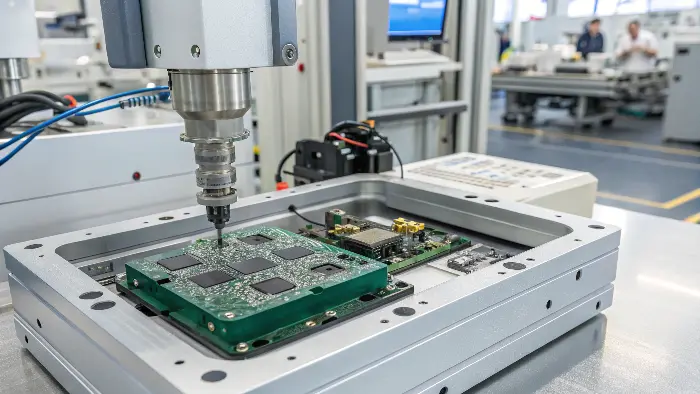

Designing small, durable electronic products is especially challenging. Components must be compact, lightweight, and even isolated from environmental conditions, yet must carry electricity and dissipate heat. Conventional assembly can be cumbersome and less reliable, resulting in possible reliability problems. Insert molding offers a simple and efficient answer to these multifaceted demands.

Insert molding revolutionizes the production of electronics by enabling the production of small, highly integrated, and reliable devices. Insert molding ensures the safe encapsulation of sensitive electronic components, provides electrical insulation or conductivity as needed, and accommodates complex geometries, leading to smaller, more reliable, and lower-cost consumer and industrial electronic products.

The miniaturization trend in electronics wouldn’t be where it is today without processes like insert molding. I’ve seen how it allows designers to pack more functionality into smaller spaces, which is what consumers demand. Let’s explore the specific advantages it brings to the electronics industry. The benefits are quite significant:

- Miniaturization and Integration: Insert molding allows in-molding insertion of pins, contacts, circuits, and even small PCBs into a plastic housing. This does away with the need for independent connectors and fasteners, making the products much smaller and more integrated. Think about your laptop or smartphone connectors – some smartphones and laptops use this technology.

- Increased Protection and Life: Encapsulation of electronics using plastic protects the electronics from dust, water, shock, and vibration. It is necessary for handheld and ruggedized applications. I recall a project where insert molding increased the life of an outdoor sensor considerably by merely increasing protection.

- Improved Electrical Performance: The process can be employed to form precise electrical paths or insulation barriers. The metal inserts can be used as grounds, shields, or conductors, and the plastic as insulation. Such precision is needed in high-performance electronics where signal integrity is of the utmost importance.

- Cost-Effectiveness: Insert molding is cost-effective on a grand scale by integrating multiple manufacturing and assembly processes into one. Labor cost is saved and waste material is minimized. High repeatability also equates to fewer defects, and that’s always a benefit to the bottom line.

Here’s how insert molding is applied in various electronic devices:

| Device Type | Examples of Insert Molded Parts | Key Advantages |

|---|---|---|

| Connectors | USB ports, audio jacks, power connectors | Robustness, precise pin alignment, sealing |

| Switches & Buttons | Encased switches, buttons with integrated contacts | Tactile feel, durability, protection from elements |

| Sensors | Encapsulated sensor elements, integrated mounting features | Protection, miniaturization, stable performance |

| Housings | Casings with embedded antennas, threaded inserts for assembly | EMI shielding, structural integrity, ease of assembly |

The ability to achieve tight tolerances and complex shapes makes insert molding ideal for the sophisticated designs required in modern electronics. It’s a key enabler for innovation in this fast-paced industry, allowing for designs that were previously impossible or too expensive to produce.

How Insert Molding Drives Innovation in Manufacturing and Industrial Sectors?

Like molding, through which metal or other inserts are mixed with plastic in one molding process, encourages innovation within manufacturing and industrial sectors by:

Advanced Designs:

Enabling complex, hybrid parts with metal strength and plastic flexibility, like heavy-duty connectors or small sensor housings.

Enhanced Performance:

Enhances part strength and environmental resistance, ideal for heavy-duty industrial components.

Streamlined Manufacturing:

Removes assembly processes and enables automation, conserving money and increasing efficiency for mass production.

Cost Efficiency:

Saves material scrap and tooling expense by integrating features into one part.

Customization:

Allows the delivery of tailored material combinations for defined applications, i.e., aerospace fitting or medical device components.

Sustainability:

Promotes light, green designs with lower material and energy consumption in the vehicle sector.

Applications:

- Spurs automation (robotic parts)

- Electronics (embedded circuits) Long-lasting machinery parts (gears, handles)

Insert molding encourages innovation through denser, lighter, cost-effective, and custom-made components, which lead to industrial application performance and efficiency improvement.

What Makes Insert Molding Indispensable for Medical Device Manufacturing?

The medical device industry demands the ultimate level of precision, biocompatibility, and reliability. The components are often required to be sterile, one-time use, or reusable and capable of being sterilized multiple times, with all important life functions completed. Meeting these demanding demands through conventional processes can be challenging, costly, and create potential points of failure. Insert molding offers a sophisticated solution.

Insert molding is a significant aspect of medical devices since it can produce highly precise, sterile, and biocompatible parts by encasing material like metal cannulas or electronics within a polymer body in a safe manner. This enhances the performance of the device, patient safety, and the ability to make complex, single-use, or sterilizable medical instruments and implants.

Where medical use is concerned, there simply isn’t room for error. I’ve had projects where the precision and reliability provided by insert molding were absolutely imperative to patient safety and the function of the device. Product integrity is everything. Let’s talk about why this process is so important in medicine. The reasons are irresistible:

- Sterilization and Biocompatibility: Insert molding medical-grade plastics can be selected for biocompatibility and resistance to a number of methods of sterilization (e.g., gamma radiation, autoclave, EtO). The absence of crevices where bacteria can live, a significant problem, is also removed through smooth insert integration.

- Increased Functionality and Miniaturization: Insert molding enables the creation of complex medical devices with integral features. Surgical instruments, for instance, can have metal tips or blades safely molded into ergonomic plastic grips. Catheters, too, can have metal guide wires or sensor elements, which increase their functionality.

- Enhanced Safety and Reliability: By creating a strong, monolithic bond between materials, insert molding inhibits parts from being displaced, a point of major concern for implant devices or instruments inserted into the body. I remember one situation where a modification to insert molding for a catheter component reduced failure rates significantly and improved patient care.

- Single-Time Cost-Effectiveness: Insert molding has the potential to lower the assembly cost of disposable medical devices and provide uniform quality, thus becoming cost-effective. This becomes more relevant in the medical field in order to keep costs low while ensuring quality is high.

Here are some examples of insert molding in medical devices:

| Device Category | Examples | Key Benefits |

|---|---|---|

| Surgical Instruments | Scalpel handles, forceps with inserts, trocars, dental tools | Ergonomics, sterility, secure attachment of functional metal parts |

| Catheters & Tubing | Catheters with radiopaque markers or guide wires, Luer lock connectors | Biocompatibility, precise dimensions, integration of functional elements |

| Diagnostic Devices | Housings for sensors, components for blood glucose meters | Hermetic sealing, protection of electronics, biocompatible surfaces |

| Implants | Orthopedic implants with specific surface features, dental implants | Biocompatibility, secure fixation, integration of different materials |

The accuracy of insert molding places medical devices within tight dimensional tolerances, which is necessary for function and for patient outcomes. It’s a technology that really does improve healthcare by allowing for safer, more efficient, and frequently cost-saving medical solutions.

Conclusion

Insert molding is a powerful and versatile manufacturing technique. It helps create stronger, more precise, and cost-effective components by combining different materials seamlessly. From automotive to electronics and medical devices, its applications are vast, driving innovation and efficiency across many industries.