Thinking about a career in injection molding1 but unsure where to begin? The industry keeps evolving, making it hard to know the right path. Let me guide you through starting strong in 2025.

Starting a career in injection molding in 2025 requires building strong foundational knowledge, gaining practical skills2 (hands-on or through simulation), specializing in an area like design or processing, and continuously learning about new technologies and materials.

It sounds straightforward, but there’s more to consider for building a successful, long-term career. The industry has specific demands and exciting opportunities if you approach it correctly. Let’s break down what you need to know.

What is the future of injection molding?

Worried if injection molding has a future with new tech emerging? Constant change can make job security feel uncertain. Understanding trends helps you position yourself for success.

The future of injection molding looks bright, driven by automation, smart manufacturing (Industry 4.03), advanced materials, increased sustainability focus, and demand from key sectors like automotive, medical, and packaging.

Let’s dive deeper into these future directions. The industry isn’t static; it’s constantly adapting. We’re seeing huge pushes toward sustainability. This means using more recycled or bio-based plastics, designing for easier disassembly and recycling, and optimizing processes to use less energy. Companies need people who understand these principles. Automation and Robotics4 are also playing a bigger role. Machines can run longer with less direct supervision, and robots handle part removal and secondary operations. This doesn’t always mean fewer jobs, but jobs that require different skills – programming, maintenance, and system oversight. Industry 4.0 concepts, like sensors in molds and machines collecting data, are becoming more common. This data helps optimize production in real-time, predict maintenance needs, and improve quality control. People who can analyze this data will be valuable. Advanced Materials continue to emerge, offering new properties for demanding applications. Think lighter, stronger plastics for cars or biocompatible materials for medical devices. Expertise in processing these new materials is crucial. Based on my experience, the core principles remain, but adapting to these technological shifts is key for anyone wanting a lasting career.

Is injection molding a good career?

Considering injection molding but wonder if it’s a stable or rewarding path? Some see it as just factory work, missing the diverse opportunities. Let’s explore if it’s a good fit.

Yes, injection molding offers a good career path with stable demand5 across various industries, diverse roles (design, processing, maintenance, quality), opportunities for skill development, and the satisfaction of making tangible products.

Let’s look at why it can be a great choice. First, demand is consistent. Plastics are essential in countless products, from medical devices and electronics to cars and consumer goods. This creates job security. Second, there’s a variety of roles. You could be a mold designer like Jacky, a process technician setting up machines, a quality control inspector, a maintenance engineer keeping things running, or even move into management or sales. Third, it requires real skills. Understanding materials, process parameters, mold design, and troubleshooting requires continuous learning and offers a path for advancement. As my insight suggests, if you have specialized knowledge and can solve real problems for a company, you will thrive. I found my own success by building expertise and helping clients. It’s rewarding to see a product go from concept to reality because of your input. Challenges exist, like tight deadlines or the need for precision, but overcoming them builds valuable experience. It’s a field where practical knowledge truly matters. If you enjoy problem-solving and making things, it can be very fulfilling.

What is the injection molding market forecast?

Need solid data before committing to this career path? Market trends influence job availability and company growth. Knowing the forecast helps you make informed decisions.

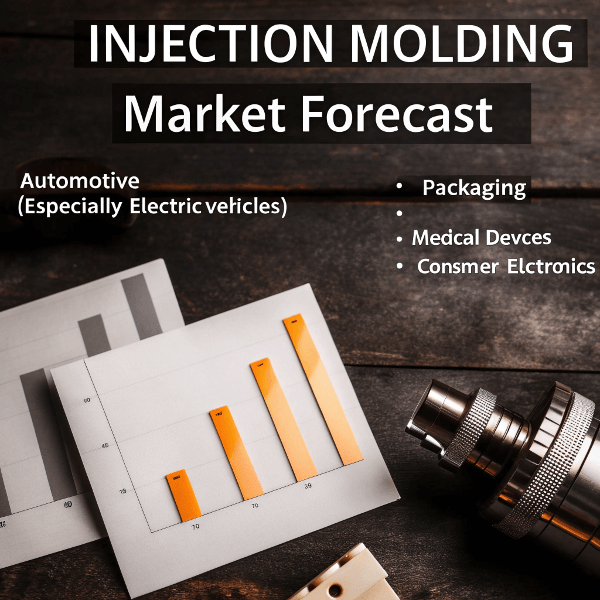

Market forecasts predict steady growth for the global injection molding industry6. Key drivers include increasing demand from automotive (especially EVs), packaging, medical devices, and consumer electronics sectors worldwide.

Let’s examine the numbers and drivers more closely. Market research reports consistently show the global injection molding market expanding. While exact figures vary slightly between reports, most project a Compound Annual Growth Rate (CAGR) of around 4-5% over the next five to seven years. This translates to a market value expected to surpass hundreds of billions of dollars globally.

What’s fueling this growth?

- Automotive: Cars use many injection-molded parts (bumpers, dashboards, interior trim). The shift to Electric Vehicles (EVs) introduces new needs for lightweight components and specialized housings for batteries and electronics.

- Packaging: Demand for durable, lightweight, and often complex plastic packaging for food, beverages, cosmetics, and pharmaceuticals continues to rise. Sustainability concerns are also driving innovation here.

- Medical: An aging global population and advancements in healthcare increase demand for disposable medical devices, diagnostic tools, and drug delivery systems, many made by injection molding.

- Consumer Electronics: Phones, laptops, appliances – they all rely heavily on precisely molded plastic casings and components.

Regionally, Asia-Pacific often leads in market share due to its manufacturing base, but North America and Europe remain significant markets with strong growth in high-value applications. This positive outlook suggests continued demand for skilled professionals in the field.Is injection molding profitable?

Thinking about the business side or how company health impacts careers? Profitability drives investment in technology and people. Understanding the financial side gives context to your career.

Yes, injection molding can be highly profitable, but it depends heavily on efficiency, mold quality, automation levels, production volume, material management, and targeting the right markets or niches.

Let’s break down what makes an injection molding operation profitable. High initial investment is required for machines and especially molds, which can be very expensive. So, achieving profitability relies on maximizing the return on that investment. Efficiency is paramount. This means fast cycle times, low scrap rates, and minimal downtime. Good process control and well-maintained machinery are essential. Mold design and quality directly impact efficiency and part quality. A well-designed mold runs faster and produces better parts, reducing costs. Automation helps reduce labor costs and increase consistency, especially for high-volume production. Material costs are a significant factor. Efficient purchasing and minimizing waste are crucial. Production volume7 plays a big role; the process is designed for mass production, so higher volumes generally lead to lower per-part costs. Expertise, as I mentioned in my insights, is vital. Skilled designers, process engineers, and technicians who can optimize setups, troubleshoot problems quickly, and ensure quality contribute directly to the bottom line. Companies that focus on high-value niches (like medical or aerospace) or possess specialized capabilities often achieve higher profit margins. Understanding these factors helps you see where your skills contribute most to a company’s success.

Conclusion

Starting an injection molding career in 2025 offers solid prospects. Success hinges on building expertise, embracing new technology, and finding where your specific strengths can solve problems and add value.

-

Explore this link to discover various career paths and opportunities in the injection molding industry, helping you make informed decisions for your future. ↩

-

This resource will provide insights on acquiring essential practical skills in injection molding, crucial for your career success. ↩

-

Learn about Industry 4.0’s role in injection molding and how data analytics is becoming essential for success. ↩

-

Discover how automation is changing job roles in injection molding and what skills are now in demand. ↩

-

Understanding the stable demand for injection molding can help you gauge job security and growth potential in this field. ↩

-

Understanding the latest trends in the injection molding industry can help you make informed career decisions and identify growth opportunities. ↩

-

Learning about production volume’s impact can guide you in optimizing operations for better profit margins. ↩