Struggling to find a material that’s tough yet flexible for your new gadget or medical tool? Traditional plastics too rigid, silicones too weak? TPU injection molding offers that perfect blend.

TPU injection molding is revolutionizing consumer electronics with protective cases and flexible cables, and medical devices with biocompatible catheters and wearables, thanks to its unique combination of durability, flexibility, and ease of processing.

You’ve probably held TPU in your hands countless times without even realizing it – that grippy phone case, the soft-touch buttons on your remote, or even parts of the smartwatch on your wrist. This stuff is incredibly versatile! I’ve seen firsthand how its unique properties are pushing the boundaries of what’s possible in product design, especially in fast-moving sectors like consumer electronics and medical tech. It’s not just about making things; it’s about making them better, more user-friendly, and often more durable. So, let’s dive into some of the cool ways TPU is making a real impact.

What are the Applications of TPU, Generally Speaking?

Ever wondered what makes that phone case so durable yet flexible, or that watch strap so comfortable? Chances are, it’s TPU, but its uses go far beyond these everyday items. It’s a real workhorse.

TPU finds applications across numerous industries due to its elasticity, abrasion resistance, and chemical inertness. Common uses include automotive parts, footwear, sporting goods, industrial components, and, as we’ll explore, consumer electronics and medical devices.

TPU, or Thermoplastic Polyurethane, is a real chameleon in the world of plastics. I often describe it to clients like Michael as a bridge material – it beautifully spans the gap between flexible rubbers and rigid plastics. This "best of both worlds" characteristic is why its application list is so darn long and varied. Think about it: in the automotive world, I’ve seen it used for interior components like dashboard elements, gear shift knobs, and those little anti-vibration pads because it dampens noise and withstands wear and tear. It just makes cars feel a bit more premium, a bit quieter. Then you hop over to footwear – those comfy, durable soles on your running shoes? Very often TPU, prized for its cushioning and rebound. My own running shoes have TPU elements, and they’ve lasted ages! Sporting goods are another big one: think ski boot shells, protective gear, even the bladders in soccer balls. It’s tough, it’s resilient, it can handle impacts. And in general industrial applications, it’s everywhere: seals, gaskets, drive belts, caster wheels, animal ear tags (yes, really!). Why? Because it resists oils, greases, and abrasion like a champ. This versatility stems from its tunable nature; by changing the chemistry, you can get TPUs that are super soft and stretchy, or quite firm and tough. This adaptability is what makes it such a go-to material for designers and engineers looking to solve specific challenges. It’s not just a material; it’s a problem-solver. I remember working on a project for caster wheels for heavy-duty industrial carts. The client needed something that wouldn’t mark floors but could still carry a heavy load. TPU was the perfect fit. It’s that kind of practical problem-solving that gets me excited about materials.

What is TPU in Electronics, and How is it Changing the Game?

Tired of bulky, fragile electronic gadgets? What if your devices could be sleeker, tougher, and more comfortable to hold, all thanks to one amazing material? This is where TPU really starts to shine for consumers.

In electronics, TPU is prized for its shock absorption, grip, and durability. It’s commonly injection molded into protective cases, cable jacketing, flexible connectors, soft-touch overmolds for buttons and grips, and wearable device components.

When it comes to consumer electronics, TPU has been a real game-changer. I mean, just look at the smartphone in your pocket. That protective case? High chance it’s TPU. And for good reason! It offers fantastic shock absorption. I remember one client, Michael, who was developing a ruggedized tablet for field technicians. We went with a TPU overmold design, and the drop test results were phenomenal. The stuff just eats up impact energy, it’s like a tiny bodyguard for your expensive tech. Beyond cases, think about cables – USB cables, headphone wires. The outer jacket is often TPU because it’s flexible, resists kinking and abrasion (how many Apple cables have you seen fray near the connector? Better TPU jacketing helps prevent that!), and can be made in vibrant colors. I’ve seen some really innovative uses in flexible connectors and strain reliefs, preventing those annoying cable breakages right at the plug. And then there’s the "soft-touch" feel. That grippy, slightly rubbery texture on remote controls, game controllers, or power tool handles? Often, that’s TPU overmolded onto a rigid plastic frame. It adds a premium feel and improves ergonomics. It just feels good in your hand, you know? For wearables – smartwatches, fitness trackers – TPU is a star. It’s skin-friendly (many grades are biocompatible, which we’ll touch on more), comfortable for long wear, sweat-resistant, and durable enough for daily activity. We’ve used it for watch straps, housings, and even flexible circuit enclosures. It’s the material that helps electronics survive our often-clumsy daily lives. The design possibilities are huge, especially with injection molding allowing for complex shapes and integrated features. It’s not just about protection; it’s about enhancing the user experience, making gadgets tougher and nicer to use.

What are the Medical Applications of TPU, and Why is it Trusted?

Need medical device components that are safe, flexible, and can withstand sterilization? Finding materials that meet stringent medical standards can be a real headache for device designers. This isn’t just about looking good; it’s about patient safety.

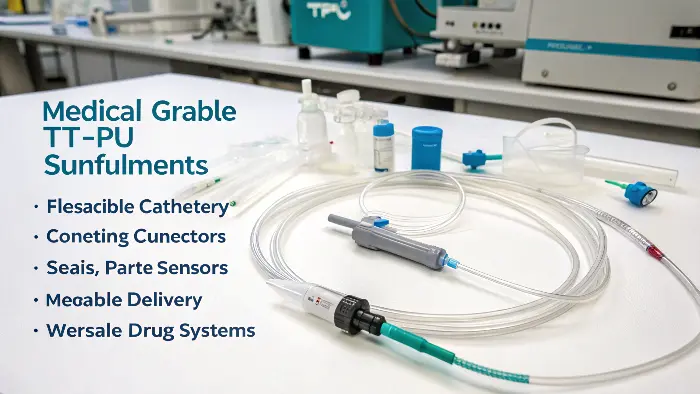

Medical-grade TPUs are widely used for catheters, tubing, connectors, seals, and components in drug delivery systems and wearable medical sensors due to their biocompatibility, flexibility, chemical resistance, and sterilizability.

The medical field is where TPU’s reliability and safety really shine. I’ve worked on several medical device projects, and the stringent requirements always make material selection critical. You can’t mess around when people’s health is on the line. Medical-grade TPUs have become a go-to for so many applications because they tick a lot of boxes. Biocompatibility is a big one – these materials are tested to ensure they don’t cause adverse reactions when in contact with bodily fluids or tissues. This makes them suitable for things like catheters and medical tubing that go inside the body. Their flexibility is another huge plus. Think about a catheter; it needs to be flexible enough to navigate through delicate blood vessels but also have enough "pushability" so the doctor can guide it. TPU can be formulated to achieve that perfect balance. I recall a project involving a new type of feeding tube; TPU provided the right combination of softness for patient comfort and kink resistance for reliable delivery – nothing worse than a tube kinking up! Connectors and luers in IV sets or dialysis equipment also benefit from TPU’s excellent sealing ability and chemical resistance to various medical fluids and cleaning agents. And it can be sterilized! Many TPU grades can withstand common sterilization methods like ethylene oxide (EtO), gamma radiation, or even autoclaving (steam sterilization) in some cases, which is essential for reusable devices or ensuring single-use items are sterile. We’re also seeing it more in drug delivery systems and as housings or flexible components in wearable medical sensors – things that monitor vital signs or dispense medication. Its durability means these devices can last, and its flexibility allows them to conform to the body comfortably. It’s a material that truly helps improve patient care, and that’s something I find very rewarding.

What are the Applications of Injection Molding, Especially with TPU in Mind?

Got a complex part design for your electronic or medical device? Wondering how to mass-produce it efficiently and consistently, especially with a flexible material like TPU? That’s where the magic of injection molding comes in.

Injection molding is a versatile manufacturing process used to produce a vast range of parts, from tiny components to large housings. With TPU, it enables the creation of intricate, flexible, and durable parts with high precision and repeatability.

Injection molding itself is a workhorse process, and when you pair it with a material like TPU, you unlock some serious manufacturing power. I’ve been around injection molding machines for a long time, and their ability to churn out identical parts, sometimes millions of them, with incredible precision is still impressive. Think about it: almost every plastic item you see has likely been injection molded. Car dashboards, LEGO bricks (a classic example of precision!), bottle caps, an incredible array of consumer electronics casings, and, of course, medical device components. Why is it so popular? High volume, low cost per part (once the mold is made, and that’s a big "once" because molds are an investment), complex geometries are achievable, and you get excellent repeatability. When you throw TPU into this mix, it gets even more interesting. Because TPU is a thermoplastic, it can be melted, injected, and solidified repeatedly. This makes it perfect for injection molding. For Michael’s consumer electronics components, injection molding allows us to create intricate features like button actuators, living hinges (though you have to be careful with very soft TPUs for these), and precise overmolds onto other plastic or metal parts. Imagine trying to make a million phone cases with perfect cutouts and a consistent soft-touch feel by hand – impossible! Injection molding makes it routine, almost boringly efficient, which is exactly what you want in mass production. For medical devices, the precision and cleanliness of injection molding are paramount. We can mold very fine details needed for luer locks on catheters or precise sealing surfaces. The process can also be highly automated, reducing human handling, which is a plus in cleanroom environments. The combination of TPU’s flexible yet tough nature with the efficiency and precision of injection molding is why we see it taking off in these demanding industries. It allows designers to dream up complex, functional parts that can actually be made affordably and reliably. It bridges that gap between a great idea and a real product in your hand.

Conclusion

TPU injection molding is not just a trend; it’s a powerful solution. It enables innovative, durable, and user-friendly products in electronics and medical fields, changing how we interact with technology and healthcare for the better.