High injection pressure is a nightmare for delicate inserts. Low-Pressure Molding (LPM) with Moldflow analysis provides a soft yet efficient way to safeguard your precious parts.

Low-Pressure Molding (LPM) uses Moldflow analysis to predict and maximize the injection of plastic melt into a mold at relatively low pressures. Material flow, heat, and pressure loss are modeled by the analysis. It helps engineers design effective molds and minimize defects, especially when handling fragile inserts, preserving component integrity and high-quality encapsulation.

It’s simple enough to recognize the benefits of low-pressure molding, but how does that translate to the application of simulation software? And what pressures are we even talking about, anyway? Let’s dive into the details of Moldflow analysis for LPM so you can unleash this mighty combination for your manufacturing needs.

What Kind of Pressures Are We Typically Talking About in Mold Flow Analysis?

Confused by the various pressures used in injection molding and what Moldflow truly predicts? Such confusion can make it difficult to interpret simulation results or to diagnose problems. Knowledge of average pressures is important to know how Moldflow will optimize the process, whether it’s conventional or low-pressure.

In traditional injection molding, "mold flow pressure" generally refers to the injection pressure required to pack the mold cavity, between 3,000 and 30,000 psi (or 20 and 200 MPa). Moldflow analysis calculates this fill pressure, packing pressure, and clamp tonnage. These calculations are important in the choice of machines and part quality.

When we are talking about pressure in injection molding, it is not just one number. There are several key pressures at work, for which Moldflow analysis can provide us with an appreciation of them all. When I started in a mold factory, the amount of pressure that was at work was mind-boggling. The equipment is robust for a reason.

Here’s the analysis:

- Pressure of injection: The primary pressure the machine screw exerts to force molten plastic into the mold cavity. It should be high enough to overcome flow resistance and fill the part within the given time. Moldflow predicts the peak injection pressure needed.

- Packing Pressure (or Holding Pressure): A second pressure is also applied when the mold is almost full. This "packs out" the part, forcing in more material to compensate for shrinkage as the plastic cools and hardens. This is necessary for dimensional accuracy and sink mark avoidance. Moldflow also optimizes this process.

- Clamp Pressure (or Tonnage): This is the pressure the molding machine puts down to keep the two halves of the mold securely closed against injection pressure. The mold will flash (plastic will escape) if the clamp force is not sufficient. Moldflow can determine the required clamp tonnage, and this is critical for fitting the right machine. For example, Jacky, our product designer, would need this data to ensure his parts could be made on equipment available.

Material viscosity (how fluid the material is), part complexity, wall thickness, and gate size all have an effect on these pressures. A heavy, simple part of low-viscosity material will need less pressure than a light, complex part of high-viscosity material.

So, What Makes Low-Pressure Injection Molding Different in Terms of Pressure?

Are you working with sensitive electronic components, sensors, or breakable inserts that cannot withstand regular molding pressures? Conventional injection molding can easily damage these components. Low-Pressure Molding (LPM) offers a specialized process that is ideal for these sensitive applications.

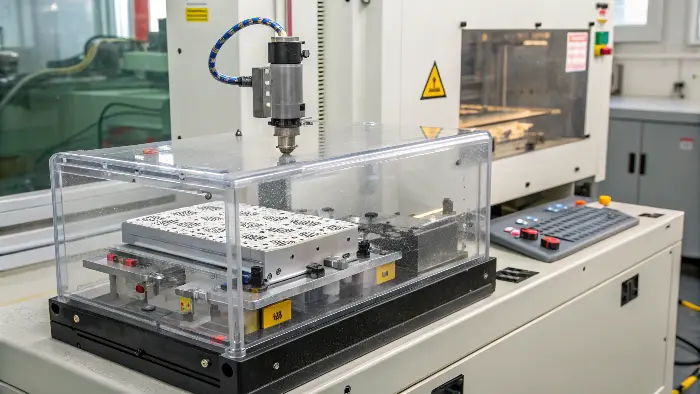

Low-Pressure Injection Molding (LPM) is achieved at very low pressures, typically between 1.5 and 40 bar (approximately 20 and 600 psi). Low-stress molding is ideal for encapsulation of delicate electronic components, PCBs, and connectors without damage. Moldflow analysis for LPM is to provide full fill and adequate adhesion at these low pressures.

The basic principle of LPM is gentle touch. Imagine it as a far lighter touch than the pressure of standard injection molding. I have seen LPM used wonderfully to encapsulate circuit boards, creating a waterproof and rugged seal without damaging any of the small components. That is where it truly excels. The pressures are significantly reduced because the materials involved, typically polyamide-based hot melts, are formulated to flow very freely at lower temperatures and pressures.

Most significant characteristics and benefits of LPM pressures:

- Pressure Range: As stated, we are referring to 1.5 to 40 bar (20-600 psi). This is merely a subset of pressures with conventional molding.

- Material Properties: LPM typically utilizes thermoplastic materials like polyamides (hot melts) with extremely low molten viscosity. They flow like honey in contrast to thick paste and therefore require less force to transport.

- Purpose: The primary purpose is generally encapsulation – inserting an object into a shielding cover. Such is the case for PCBs, sensors, connectors, and medical devices.

- Gentle on Inserts: The low pressure prevents fragile wires, solder joints, and sensitive components from being crushed, displaced, or damaged throughout the molding process.

- Less Tooling: Since the pressures are low, LPM molds may be constructed from less-hardened materials such as aluminum rather than hardened steel. This can result in quicker tool development and less expensive tools. I have assisted clients in deploying LPM processes where the tool investment is considerably lower than a comparable high-pressure mold.

- Role of Moldflow: Simulation is crucial even at low pressure. It ensures the material flows over every small detail on the insert, has good bond strength, prevents air entrapment, and controls the thermal factor, because the heat from the molten material can also impact delicate components.

LPM is a specialty item, but for the proper applications, it’s a highly effective but gentle manufacturing process.

The Relationship Between Mold Flow Analysis and DFM

DFM or Design for Manufacture is a manufacturing-led design approach that involves the manufacturability and cost-effectiveness of manufacture to be considered at the initial stages of product design. DFM encompasses the entire process of product development, from conceptual design to detailed design, process planning, and production manufacturing.

In the manufacturing of plastic parts (e.g., automotive, aerospace, medical, equipment, consumer goods, electronics, personal care, and most others), DFM usage in mold design is also necessary. By using DFM, designers can examine and enhance product designs to make them easier to manufacture. This includes examining manufacturability, determining the most appropriate manufacturing processes, and enhancing product designs to reduce manufacturing complexity and expense.

Summarily, mold flow analysis and DFM are both key methods in mold designing and production in the automotive manufacturing sector. They complement one another and can effectively improve the quality and productivity of production of the molds and reduce the production costs.

How Can You Actively Reduce Pressure Requirements Using Moldflow Analysis?

Are high injection pressures causing issues like high clamp tonnage requirements, material degradation, or other mold wear? These can make costs rise and efficiency fall. Moldflow analysis isn’t only useful for pressure forecasting, but for actually determining how to reduce it.

Moldflow analysis conserves injection pressure by allowing you to computer-model and optimize various design and process parameters. Some of the key approaches are gate size increases, runner system design for lower resistance, wall thickness additions where practical, lower viscosity materials, and adjustments to processing conditions like melt temperature or fill rate. These can be experimented with in the computer to find the most favorable combination.

Pressure reduction is most often a number one priority when optimizing processes and designing molds. It can lead to a more consistent process, less mold and machine stress, and even better part quality in some cases. I had one customer who had severe problems with a production mold that needed to run under really high pressures, which was generating a lot of flash and high scrap. We modeled lowering that pressure with Moldflow.

Following are some good ways you can experiment with Moldflow:

-

Gate Optimization:

- Size: Expanding the cross-sectional gate size reduces flow resistance. Moldflow can show the effect of gate size variation on pressure.

- Location: Placing gates in strategic locations can reduce flow path lengths and equalize filling, saving the total pressure demanded.

- Type: Some types of gates naturally offer less resistance than others.

- Number: Larger pieces benefit from having more than one gate since it can significantly reduce the pressure required from any individual gate and improve filling.

-

Runner System Design:

- Size: Large diameter runners reduce pressure drop but use more material. Moldflow helps to identify the best balance.

- Length: Shorter runners mean shorter travel distance for the plastic and hence lower pressure loss.

- Arrangement: A balanced runner system provides all the cavities (in a multi-cavity mold) with nearly the same pressures.

-

Wall Thickness (Part Design):

- Raising the nominal wall thickness of a part will allow for plastic flow, hence decreasing pressure. Thin sections can be detected as the cause of abnormal pressure drops by using Moldflow. Jacky, for example, could utilize it to detect whether an extra very small increase in a vital wall section would make molding easier.

-

Material Selection:

- Selecting a material grade with higher melt flow rate (MFR) or lower viscosity will automatically use lower pressure to fill the mold. Moldflow’s material database is used here.

-

Processing Conditions:

- Melt Temperature: Increasing melt temperature (within material parameters) reduces pressure and viscosity. Mold Temperature: A warmer mold will maintain the plastic molten for longer, facilitating flow, but will also retard the cycle time. Injection Speed: Sometimes, a slower fill at a more controlled rate can reduce peak pressure, but this is balanced to cycle time and potential premature freezing. For my client, Moldflow was able to show them that combining the action of slightly opening the gates along with runner balancing optimization reduced the injection pressure required significantly, eliminated their flash problem and stabilized their process.

Which Process Is Better for You: Low Pressure Molding or Injection Molding?

The cost, functionality, and quality of the final product can all be greatly impacted by the molding technique used for producing plastic parts or encapsulating components. Despite their apparent similarities, two popular processes—injection molding and low pressure molding—have distinct uses. Knowing how they differ can make it easier to choose the one that works best for your particular application.

What is Injection Molding?

A high-pressure manufacturing technique called injection molding is used to create intricate, large-volume plastic components. Pellets of thermoplastic are melted, and the molten substance is then injected into a precisely crafted mold cavity. The completed part is released from the mold once it has cooled and solidified.

Low pressure molding: what is it?

Using thermoplastic adhesives like polyamides, low pressure molding is a kinder method to encase sensitive electronics and components. Low pressure molding, as opposed to injection molding, prioritizes sealing and protection above producing intricate outside components.

Which One Is Best for You?

Your application will determine whether to use low pressure molding or injection molding. Injection molding is the recommended technique for producing large quantities of intricate, robust plastic components. Low pressure molding is a better option if you require a quick, safe, and low-stress procedure for fragile devices.

Contact with a knowledgeable molding service provider to help you select the best choice. Making an educated decision at the outset can help save money, effort, and guarantee product dependability over time.

Which Mold Flow Analysis Software Can Best Handle These Pressure Simulations?

Are you inquiring about which software can handle the best simulation of pressures with precision, especially for niche processes like Low-Pressure Molding? Selecting the right tool is critical in order to deliver precise results. Thankfully, the majority of high-end software packages can do the job.

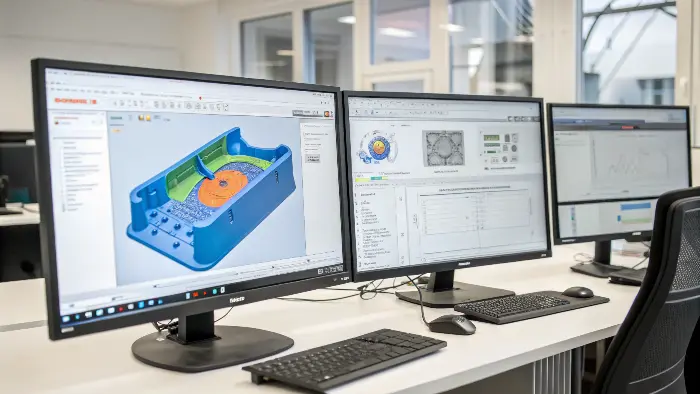

Market leading mold flow analysis software like Autodesk Moldflow, Moldex3D, and SOLIDWORKS Plastics all can simulate injection pressures of Low-Pressure Molding with good accuracy. It is a question of having good material data (specifically rheology and PVT for LPM materials) and correctly setting the low-pressure process parameters in the mold flow software. The "best" answer quite frequently is a question of individual needs and workflow conditions."

As far as the pressure levels of both high and low, the solver accuracy of the software and, above all, the material database are most important. I have worked with many different packages throughout the years and, naturally, each has their advantage.

- Autodesk Moldflow: It is generally regarded as industry standard. Moldflow has very advanced solvers and an enormous material database. It’s excellent for accurate pressure analysis, packing analysis, and clamp tonnage prediction. For LPM, if you have good material characterization data for your specific hot melt, Moldflow can provide very accurate simulations. Its ability to model the entire feed system and cooling is also advantageous.

- Moldex3D: It’s another advanced simulation software with a strong reputation for its superb 3D meshing and highly accurate results. It’s especially good at simulating highly complex flow behavior and heat characteristics. Moldex3D’s also highly capable at simulating LPM, provided the particular material properties are well defined. Its careful pressure drop analysis through complex geometries is a major strength.

- SOLIDWORKS Plastics: For designers like Jacky, who are already in the SOLIDWORKS environment, it is a more integrated and typically more convenient option. It does not offer the depths of the specialty stand-alone packages for every specialized situation, but it’s very capable for a wide range of pressure analyses, like finding high-pressure areas and checking design changes. For LPM, its accessibility can serve as a suitable substitute for initial evaluations.

The secret to proper LPM simulation in any of the said computer programs is the material data. Materials employed in LPM, i.e., polyamides or other hot melts, have certain flow behavior at reduced temperatures and shear rates. You have

-

Duplicate rheological data (viscosity vs. shear rate at conditions of interest).

-

Proper thermal properties (specific heat, thermal conductivity).

-

PVT data if warpage or precise shrinkage is a concern, though for simple encapsulation flow and temperature might be of major concern. Most material suppliers to LPM provide this data, or laboratory testing will generate it. My experience has been that if the input data are of high quality, all of these leading packages are able to deliver valuable insights into optimizing both low-pressure and conventional molding processes.

Conclusion

Moldflow analysis for Low-Pressure Molding is a crucial technique for safely encapsulating delicate components. By simulating the gentle flow of specialized materials at low pressures, it helps engineers optimize mold design and processing parameters. This ensures complete fill, good adhesion, and the integrity of fragile inserts, leading to higher quality products and efficient manufacturing in sensitive applications.