It can be intimidating to choose the proper high-performance plastic. You realize that it will need to handle the heat, but choosing the wrong one can lead to critical part failure, budgets being squandered, and important projects being put behind schedule. The following is a roadmap that dispels confusion by outlining fundamental differences between PEEK, PEI, and PPS. I can help choose the best material that will work for you by offering both performance as well as affordability.

Your number one priority will dictate your top-of-the-list best high-temperature plastic. PEEK provides ultimate performance, highest strength, wear resistance, and highest operating temperature (250°C) as needed for extreme aerospace or medical applications. PEI (Ultem) is a cost-saving option, offering very good strength, highest heat resistance (170°C), and great electrical insulating characteristics. PPS is in a category by itself in chemical resistance and dimensional stability, ideal for parts in extreme chemical environments such as pumps and valves.

Now that you have the quick overview, you’re probably wondering about the specifics. How do these materials really stack up against each other in real-world applications? Getting these details right is the key to a successful project. Let’s dive deeper into the comparisons that matter most to help you select the perfect high-performance plastic for your parts.

What is the difference between PEI Ultem and PEEK?

You require a high-temperature plastic, yet you are left trying to weigh PEEK against PEI in terms of pros and cons. The expense of PEEK is a big consideration, but you fear that PEI will be too weak for your purpose, leaving a risky performance compromise. I’ve seen countless customers struggle with this very issue. Knowing about their differences will reveal which of them is the wise solution to your project.

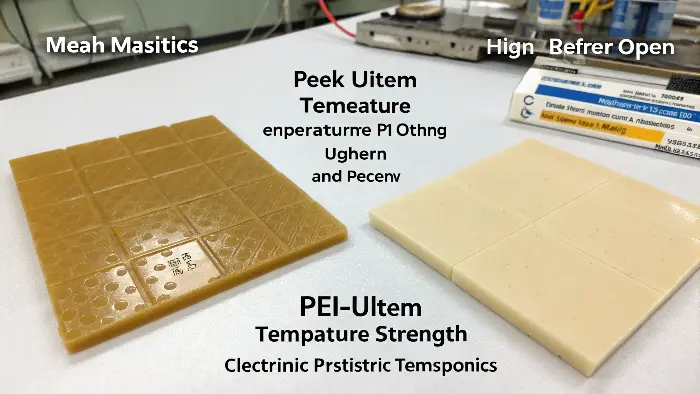

It mainly comes down to performance versus cost. PEEK enjoys greater mechanical strength, higher 250°C (482°F) continuous use, and higher general chemical resistance, but is more costly. PEI (Ultem) is a much less expensive offering that enjoys good heat stability to 170°C (340°F) and good dielectric strength. PEI (Ultem) is typically chosen in electrical insulations and medical components in which PEEK ultimate performance is not required.

To really get to the bottom of this, we need to look closer at what these differences mean for your final product. I always tell my clients to think about the "must-have" properties versus the "nice-to-have" ones. This is where you can find significant cost savings without sacrificing what truly matters.

Key Performance Metrics: PEEK vs. PEI

Let’s break down their performance using a simple table. This is the same approach I use when consulting with business owners like Michael, who need clear, actionable data.

| Property | PEEK (Polyetheretherketone) | PEI (Polyetherimide / Ultem) | What This Means For You |

|---|---|---|---|

| Continuous Use Temp. | ~250°C (482°F) | ~170°C (340°F) | PEEK can handle extreme heat. PEI is great for many hot applications, but not for the most severe environments. |

| Tensile Strength | ~90-100 MPa | ~85-105 MPa | They appear similar, but PEEK retains its strength much better at high temperatures. |

| Chemical Resistance | Excellent | Good | PEEK stands up to a wider range of harsh chemicals. PEI is good but can be attacked by certain solvents. |

| Sterilization Resistance | Excellent | Excellent | Both are fantastic for medical devices that need repeated autoclaving. PEI often wins here due to its lower cost. |

| Cost | Very High | Moderate | This is the biggest trade-off. PEEK can be 5 to 10 times more expensive than PEI. |

On one occasion, I approached a client who was building a new brand of reusable surgical instruments. At the beginning, they used PEEK everywhere. We decided to look at their requirements after which we understood that the cutting tips required the extreme hardness of PEEK and the wear resistance, but not the handles. The handles were merely required to be able to withstand steam sterilization and be powerful enough to be used normally. By replacing the handles with PEI, they were able to reduce the material bills of that component by more than 60% with no performance penalty. Such decision making is the type of intelligent decision making that distinguishes good projects from expensive projects.

Applications of High-Temperature Plastics

Plastics with high temperature are highly applied in industrial sectors in which the traditional polymers do not succeed because of heat, chemical influence, or mechanical pressure. These plastic materials, containing PEEK, PPS, PSU, PI and LCP, have the benefit of preserving their structural integrity and performance up to constant operating temperatures exceeding 150 °C. Their distinct strength, thermal stability, and chemical resistance features make them a perfect product in challenging applications in aerospace, automotive, electronics, medical, and industrial applications.

Use in the Aerospace Industry

High-temperature plastics are also used in place of metals in the aerospace industry to decrease weight without affecting structural integrity and reliability. They are commonly employed in parts like brackets, housings, cable insulation, and connectors, which require operating under extreme temperatures and require resistance to jet fuel or hydraulic fluid. Their lightweight also contributes to their fuel efficiency, which is essential to both aircraft and spacecraft.

The Car Industry

The car industry depends on such materials a great deal, where it is used in under-the-hood components which it are regularly subjected to heat, petroleum, and wear and tear. Fuel system components, engine housings, transmission parts, gaskets and seals are made using high-performance plastics. They assist manufacturers in complying with increased standards of emissions and making their vehicles more efficient by substituting heavy metals with lightweight and durable alternatives.

Electronics and Electrical Industries

High-temperature plastics also have a lot to offer to electronics and electrical industries. Their high dielectric characteristics and thermal resistance are suitable in connectors, circuit boards, insulators, and microcomponents in smartphones, computers and high-end communication devices. Other types of material, such as LCP, are especially appreciated when it comes to precision-molded connectors that are required to operate at a high temperature level.

In the Healthcare Industry

In the healthcare industry, devices and instruments that undergo many sterilization processes are best made of high-temperature plastics. Surgical instruments, endoscopic equipment and dental equipment are fabricated out of materials like PEEK and PPSU as they can withstand high-pressure steam sterilization without compromising mechanical and chemical properties. They are also biocompatible, making them suitable for implants and long-term medical use.

Industrial Applications

Pump components, seals, bearings and valves are industrial applications that are subjected to aggressive chemicals, friction and heat. The high-temperature plastics are reliable and minimize the maintenance in highly challenging environments, like chemical processing plants, oil and gas equipment, and food production machinery. They are indispensable in enhancing efficiency and safety because of their resistance to wear and operation in harsh conditions.

So we can say that high-temperature plastics are versatile and can be utilized in a wide range of high-performance applications to substitute metals in cases of lightweight and durability combined with thermal stability. With the ever-increasing need for materials capable of surviving in more severe conditions in industries and allowing the creation of more sustainable and efficient designs, the utilization of high-temperature plastics is likely to grow further.

What is the difference between PPS and PEEK plastic?

You may be comparing PPS and PEEK spec sheets and noticing two materials that both claim high-temperature performance. It’s a confusing similarity. Making the wrong choice could cause your parts to warp after being subjected to a particular chemical or not have sufficient raw power to withstand a mechanical application, resulting in costly in-the-field failures. Let’s compare their respective strengths so that you’ll understand exactly how PPS’s stability excels and PEEK’s strength is called upon.

Mechanical strength against chemical resistance and price is the key distinction. PEEK is much stronger, more tough, and higher-temperature operating. PPS, although not as strong as PEEK, displays outstanding chemical resistance, particularly against aggressive chemicals and acids, and superior dimensional stability at a reduced price. PPS is usually the ideal selection for fluid handling parts in chemical or vehicular applications.

The choice between these two powerful materials almost always comes down to the specific environment your part will live in. Is it a battlefield of mechanical stress or a bath of harsh chemicals? Answering that question is the first step. Let’s dig into the details that will help you decide.

Application-Specific Differences: PPS vs. PEEK

Think of PEEK as a heavyweight boxing champion—incredibly strong and tough. Think of PPS as a master swordsman—precise, stable, and resilient in its own way. They are both experts, but in different fighting styles.

| Property | PEEK (Polyetheretherketone) | PPS (Polyphenylene Sulfide) | What This Means For You |

|---|---|---|---|

| Mechanical Strength | Superior | Good (often glass-filled) | Unfilled PEEK is much stronger and tougher than unfilled PPS. Glass-filled PPS closes the gap but can be more brittle. |

| Chemical Resistance | Excellent | Exceptional | PPS has virtually no known solvents below 200°C. It’s a champion against automotive fluids and strong acids. |

| Dimensional Stability | Very Good | Exceptional | PPS has very low moisture absorption and a low coefficient of thermal expansion, meaning it holds its shape extremely well. |

| Wear Resistance | Excellent | Good | Bearing-grade PEEK (with carbon fiber, PTFE, and graphite) is one of the best wear-resistant plastics available. |

| Cost | Very High | Low to Moderate | PPS is significantly more affordable than PEEK, making it a great value proposition for the right applications. |

A client came to me a few years ago with a mold of a fuel pump housing. They were initially designed to use PEEK since they required resistance to high temperatures. Nevertheless, they were not really worried about mechanical loading but were always exposed to aggressive fuel additives. Instead, I proposed a cost-benefit analysis of using a 40% glass-filled PPS. The PPS provided adequate heat resistance to the application and better resistance to all the chemicals in the fuel. The switch provided them with an environmentally appropriate part and reduced their material costs by almost 75 percent. That’s a huge win.

Is PEEK the strongest plastic?

You’ve heard it too often in the trade: "If it must be strong, use PEEK." The name beckons so many to summon it in every challenging application. But cost can rapidly drive up your price, and "strongest" isn’t even a correct engineering term. You’ll over-design your part and pay more for performance that you never did require in the first place. Let’s take a clear definition of what "strongest" really is in the plastic trade and determine whether PEEK even deserves that appellation.

Despite being among the stiffest and strongest thermoplastics available, it is not correct to refer to PEEK as the "strongest plastic." Strength lies in PEEK’s remarkable capability of retaining its superior mechanical properties—intrinsic strength, endurance resistance, and toughness—within exceedingly broad temperatures and in adverse chemical surroundings. Another reinforced polymer may possess higher strength in one parameter at ambient temperature, yet none can equal PEEK’s across-the-board performance in adverse conditions.

When an engineer or client asks me for the "strongest" material, my first question is always, "Strong in what way?" The answer dictates whether PEEK is the right choice or simply an expensive one. Let’s clarify what strength means for your parts.

What Does "Strong" Mean for a Plastic?

"Strength" doesn’t even qualify as a value. It’s an aggregate of many different properties that inform us about what a material will do under stress. For a businessman like Michael, it’s good to understand them in order to not overpay.

-

Tensile Strength: Tensile strength means to resist being stretched apart. This is significant in parts that are under tension, like in a fastener or in a cable component.

-

Flexural Strength: This measures how much bending a material can withstand. This is important in structural support, levers, or in beams.

-

Impact Strength: That’s toughness. That’s absorbing a sudden impact or blow without cracking up or breaking. Consider a power tool housing that could be dropped.

-

Fatigue Strength: The strength to resist repeated loading as well as unloading. It’s particularly important in moving parts such as gears or vibrating parts such as pistons.

PEEK’s Place in the Hierarchy

PEEK’s superpower is more than having big numbers in these areas; it’s holding big numbers when it gets tough. While many plastics are stiff at ambient temperatures, their performance plunges over a precipice as soon as it warms up or as soon as it encounters chemicals. PEEK, by contrast, holds onto its outstanding strength, stiffness, and toughness at 250°C (482°F).

This is why PEEK is king in aerospace, wherein a component must be as lightweight as possible, yet also must withstand extreme tempo variations as well as mechanical stress. In medical implants, it also reigns supreme, as it must survive in the human body (a chemically harsh environment) under constant load, decades at a time. Is PEEK then the strongest, then? In high-stress, high-temperature, chemically aggressive situations, it is perhaps the best and therefore "strongest" choice. But if your component only must support high tensile strength at normal temperatures, then perhaps there is a different material that will do the trick at a fraction of the cost.

How to Choose and Design for High-Performance Plastics in Injection Molding?

High-performance plastics are engineering materials that were designed to possess high-performance properties which are superior to the normal polymers. They are well known to be resistant to high temperatures exceeding 150 °C, provide high mechanical strength, are resistant to chemicals, and their dimensions remain constant in harsh conditions. They can also insulate or conduct electricity depending on the usage. PEEK, PPS, PSU, PI,and LCP are some common examples that are commonly used in aerospace, automotive, electronics, and medical applications.

When selecting a high-performance plastic to be used in injection molding, one ought to consider the operating conditions of the end product. The first factor is usually the temperature resistance, so that the plastic can bear the necessary working environment. Tensile strength, stiffness, and impact resistance are also mechanical properties that contribute largely. When the parts will be subjected to oils, fuels or cleaning agents, then chemical resistance will be an important factor, but in cases where moving parts are needed, then materials with low wear and friction, such as PEEK or PTFE-filled blends, may be required.

When using high-performance plastics, design is a matter of attention. Even wall thickness can prevent warpage or voids, and draft angles of 1-2 degrees are preferred to allow easy ejection of the part out of the mold without harming such precision features. It is possible to add strength without adding wall thickness by the use of ribs and bosses, and the placement of the gates needs to be optimized to prevent the placement of weld lines in sensitive areas.

The high-performance plastics tend to shrink less, so it is easier to achieve tight tolerances, although what is critical is the precision of the mold. Also, since these plastics may need more mold temperatures, the design of cooling system must be optimized to regulate the time of cycles and ensure the quality of parts.

High-performance plastics are customizable and suitable for high-performance applications in most industries because of their unique properties. They are applied in aerospace to form lightweight but heat-resistant brackets and connectors. They are used in fuel system components and other under-the-hood components, which are vulnerable to heat and chemicals, by automotive manufacturers.

These materials are used as connectors, insulators and circuit housings in electronics and are found to be useful in the medical industry due to their sterilization resistance, making them useful as surgical tools and housings. Industrial machinery also has a beneficiary with parts such as bearings, seals, and pump parts, which also require durability and resilience to chemicals.

What is the temperature range for Ultem PEI?

You’re considering PEI (Ultem) because it’s such a great value proposition, balancing cost and performance, but you’re not so sure about its thermal limitations. If you overestimate this, your parts will soften, warp, or completely fail in service, which can cost you in terms of product recall as well as real damage to your reputation. Let’s get extremely clear about what PEI’s exact temperature range is so that you can work with it without reservation in the correct application.

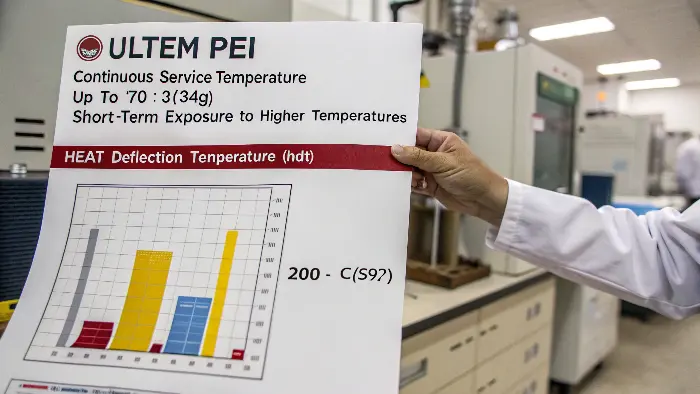

Its service temperature is up to 170°C (340°F) continuously. Short-term higher temperatures may be accommodated, yet inasmuch as parts requiring long-term maintenance of structural integrity must abide by this figure, this is paramount. The Heat Deflection Temperature (HDT) of this PEI is about 200°C (392°F) such that it will resist buckling under load at that value. Based on this, it is particularly suitable in cases needing steam sterilization or in hot environments.

Understanding the temperature ratings on a data sheet is crucial. They aren’t just numbers; they tell a story about where a material can thrive and where it will fail. Let’s translate these technical terms into practical knowledge you can use.

Understanding Key Thermal Properties

When you look at a material data sheet for PEI, you’ll see a few different temperature values. Here’s what they actually mean for your project.

- Continuous Service Temperature (CST): The CST is key to long-term performance. CST is defined as that maximum, steady-state temperature a material can endure continuously, 24/7, for thousands of hours without substantial property loss. The CST of PEI is 170°C (340°F).

- Heat Deflection Temperature (HDT): This measures how the material will behave under load at high temperatures. This is the temperature at which a test bar will bend a preselected amount under a preselected load. For PEI, this is in the 200°C (392°F) range. This value is of critical importance to injection molders as well as to parts that must maintain their shape under stress at high temperatures.

- Glass Transition Temperature (Tg): The point at which the material transitions from a hard, glassy to a softer, more rubber-like state. PEI’s Tg is about 217°C (422°F). The material subsequently loses structural stiffness much more quickly above this temperature.

Practical Applications Within PEI’s Temperature Range

So what does this mean in real life? What it means is PEI is a great option for a wide variety of "hot" applications. I had one customer, a medical device manufacturer, that was developing reusable sterilization trays. The trays needed to be strong and could be subjected to repeated use in a steam-based autoclave, which typically operates at 121°C to 134°C. PEI was ideal. The PEI performed beautifully under the heat and steam, was robust enough to safeguard delicate instrumentation, and cost much, much less than PEEK.

It is also heavily used in under-the-hood car sensors and connectors. The products get hot by virtue of being under the hood, but don’t usually encounter PEI’s service temperature at steady-state. PEI provides such types of applications with required heat resistance, chemical resistance against such car engine fluids, plus excellent electric insulation, in one low-cost package.

Conclusion

When it comes to high-performance plastic, there is no "best" in absolute terms, only "best" in your particular application. PEEK is the ultimate extreme strength and heat performer, PEI is your cost-effective workhorse in electrical and medical grades, and PPS is the undisputed king of chemical stability and resistance. Knowing these fundamental differences gives you what it takes to make more astute, more cost-effective choices that yield successful, reliable, and profitable products.