Have you ever gotten a shipment of plastic components that just didn’t quite fit, or broke under stress? This most commonly is the result of a lack of precision in the molding process, which costs you money and time. Precision molding services provide the solution, making your parts accurate to specs every time.

Precision molding services are preferred since they yield high-quality, consistent, and dependable plastic parts that are accurate to close tolerances. Such accuracy is extremely crucial for complex assemblies, functional functionality, and overall product integrity, eventually saving money by reducing defects and enhancing efficiency.

Discover why precision is so highly sought after by starting out with an introduction to the molding process itself and why precision is so vital. If you’d like to improve the quality of your product and reduce manufacturing frustrations, learning the details of precision molding is a good place to start. Let’s have a closer look at this to see just why these services are so invaluable.

What are the processes of molding?

Have you ever thought about how those complicated plastic components on your daily gadgets are produced? It seems like magic, but it is a process. Without these steps, confusion is created when communicating designs or repairing problems. Understanding the fundamentals of molding makes everyone on the same page.

The fundamental injection molding process involves a number of main steps: clamping the mold, injecting molten plastic material into the mold cavity, cooling and solidifying the material, and finally, ejecting the finished part. Each of these steps must be treated with caution to result in the best output.

The journey of a plastic part, from raw material to finished product, is very fascinating. When I was first working in a mold factory, seeing these machines operate was like viewing a sophisticated dance. It begins with the clamping stage. During this stage, the two mold halves are locked tightly by a powerful clamping unit. This pressure is beneficial in pushing back against the pressure of the plastic being injected in liquid form, to prevent leakage or "flash."

And then there is injection. The plastic pellets are charged into an injection machine, melted by friction and heat from a reciprocating screw, and then forcefully injected into the closed mold cavity. The rate and pressure of this injection are critical parameters. Too little, and you have a short shot part (a "short shot"); too much, and you can ruin the mold or create flash.

Then, after the cavity is filled, comes the cooling stage. The plastic material solidifies as it cools and takes on the shape of the mold. Cooling time is a function of plastic material, part thickness, and mold temperature. This is typically the longest stage of the cycle, and optimization is key to efficient manufacturing. I’ve worked on many projects where modifying the designs of cooling channels in the mold had a significant effect on cycle time.

And then there’s ejection. After the part has cooled sufficiently, the mold opens and an ejection system (often pins or plates) pushes the hardened part out of the cavity. The part falls onto a conveyor or is grabbed by a robotic arm. The machine is then ready to start the next cycle. Knowing these basic steps is the first step to knowing why precision at every step is the big deal that it is.

| Stage | Description | Key Considerations |

|---|---|---|

| Clamping | Securing the two mold halves together. | Clamping force, mold alignment |

| Injection | Forcing molten plastic into the mold cavity. | Injection pressure, speed, temperature |

| Cooling | Allowing the plastic to solidify within the mold. | Cooling time, mold temperature |

| Ejection | Removing the finished part from the mold. | Ejection force, part design |

This systematic approach ensures that parts can be produced repeatedly and efficiently.

Why is precision important in injection molding?

Imagine constructing a product where the plastic components just don’t quite fit. This frustrating exercise most likely means that there is not sufficient accuracy in the molding. When components are not manufactured to exact specifications, it can lead to functional failures, assembly problems, and added expense.

Precision injection molding is important since it enables parts to be within precise design specifications and tight tolerances. Precision is important to guarantee correct fit, form, and function of parts, especially in complex assemblies, leading to better product quality and reduced scrap.

When we’re talking about precision injection molding, we’re talking about making parts that are always precise, to very close tolerances. I’ve learned after all these years in business that "close enough" is never good enough, especially for high-usage applications. The first big reason precision is so essential is part functionality. If a gear, a snap-fit, or a sealing surface isn’t molded to the right dimensions, it won’t perform like it was designed. This can lead to product recalls or field failures, and that is a nightmare for any company.

Second, precision is important to assembly. Modern products are more likely to be made up of many interrelated pieces. One piece being off by even a little can lead to a domino effect of fit issues. I remember one customer who had terrible assembly line slowdowns just because their molded casings weren’t accurate. Once we helped them get tighter tolerances, their assembly process smoothed out big time. This has a direct effect on production rate and labor expense.

Another critical aspect is material waste and cost. Imprecise molding often leads to a higher number of rejected parts. Each reject means wasted material, wasted machine time, and wasted energy. Precision helps minimize these defects, leading to more efficient use of resources and lower overall production costs.

Lastly, accuracy also applies to the mold performance and longevity. A well-designed and machined mold, combined with a well-controlled molding process, will deliver repeatable parts for a longer period of time. When the process parameters are not accurate, it will cause faster wear and tear on the mold. At CKMOLD, we always state that an investment in a precision mold and process will reap rewards in the long term by delivering consistent quality and minimizing downstream issues. It’s doing it right, each and every time.

Key Areas Benefiting from Precision:

- Dimensional Accuracy: Ensuring parts match the CAD model.

- Tight Tolerances: Meeting strict dimensional limits.

- Repeatability: Producing identical parts across large production runs.

- Surface Finish: Achieving the desired texture and appearance.

Precision isn’t just a buzzword; it’s a fundamental requirement for high-quality manufacturing.

Process optimization of injection molding is necessary to prevent defects and produce high-quality parts.

The 8 Parameters of Injection Molding Process Optimization to Prevent Defects

The 8 parameters of injection molding process optimization to prevent defects are as follows for better understanding:

-

Injection Pressure: Controls pressure pushing molten plastic into the mold. Inaccurate pressure can lead to short shot (incomplete filling) or too much flash. Balance to fill rate and avoid stress in the part.

-

Injection Rate: Regulates the rate at which material is injected. Too rapid causes burn marks or air pockets; too slow causes short shots or substandard surface finish. Regulate according to part shape and material.

-

Mold Temperature: Affects material flow, cooling rate, and surface finish. Incorrect temperatures may result in warping, sink marks, or poor dimension accuracy. Utilize stable mold temperature suitable to material.

-

Melt Temperature: Molten plastic temperature. Too high will degrade the material, causing discoloration or poor parts; too low will result in incomplete fill or poor bonding. Optimize to material specifications.

-

Cooling Time: Affects the duration of the part within the mold to harden. Inadequate cooling may result in warping or sink marks, while too much time minimizes efficiency. Calculated based on part thickness and material.

-

Pressure and Time Holding: Applied following first injection to pack out the mold and compensate for material shrinkage. Miscalibrated settings will yield sink marks, voids, or out-of-dimension. Calibrate to ensure the part density is proper.

-

Clamp Force: Force closing the mold throughout injection. Too low will develop flash or mold opening; too high will destroy the mold. Set to equal the expected part area and material pressure.

-

Back Pressure and Screw Speed: Controls the plasticizing process in the barrel. Low levels may result in unstable melt quality, air entrapment, or material degradation. Optimize for stable melt and minimum defects.

Through effective control of these parameters, manufacturers can reduce common defects like short shots, flash, warping, sink marks, voids, and surface defects and create quality injection-molded parts.

What are the defects of injection molding?

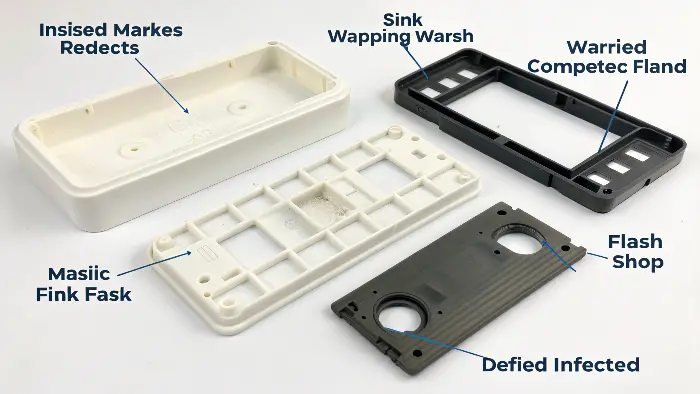

Do you ever notice blemishes on a plastic part, like uncharacteristic marks, warping, or absent shapes? These are common injection molding defects. Not only are these blemishes not pleasing to the eye, but they can also compromise the part’s strength and function, leading to costly rejections and production downtime.

Injection molding defects are defects or imperfections of the molded parts, e.g., flash, warping, burn marks, short shots, and sink marks. These faults are the result of defects in mold design, material, processing parameters, or equipment, with an effect on part quality and performance.

Identification of most prevalent defects is basic to any plastic part designer or producer. It’s helpful in debugging, but even more helpful in making sure that these defects don’t occur in the first place. I’ve had my own set of defects in all these years, and each one of them has a story to tell about what might have gone wrong along the way.

One of the most common flaws is sink marks. These are tiny craters or depressions on the surface of a thicker part cross-section. They happen because the material in the interior contracts and cools faster than the already solidified surface. Good part design, i.e., not too thick sections, and correct adjustment of the packing pressure can be the remedy.

Warping is another headache. That’s when a piece warps or curves away from its intended shape as it cools. Typically it happens due to uneven cooling, internal stresses from poor design, or improper material. I recall one project where a large flat piece was constantly warping; we redid the cooling channels in the mold and altered processing temperatures to fix it.

And lastly, flash, a thin excess plastic which seeps out of the mold cavity, usually along the parting line or around the ejector pins. It usually indicates mold is not closing shut enough, injection pressure is too high, or mold is worn.

A short shot is when molten plastic does not fill the mold cavity and therefore the part comes up short. It may be caused by insufficient material, lower injection pressure or rate, or plugged gates.

Finally, burn marks are discolorations, usually black or brown, on the part surface due to air being trapped and being heated to carbonize the plastic. Venting inside the mold is critical in preventing this.

Here’s a quick look at some common defects and their typical causes:

| Defect | Description | Common Causes |

|---|---|---|

| Sink Marks | Depressions on the surface | Thick sections, insufficient packing pressure, high melt temperature |

| Warping | Distortion from intended shape | Uneven cooling, internal stresses, incorrect material |

| Flash | Excess material on part edges | Low clamp force, high injection pressure, worn mold |

| Short Shot | Incomplete part | Insufficient material, low injection pressure/speed, blocked gates |

| Burn Marks | Discoloration due to overheating | Trapped air, excessive injection speed, high melt temperature |

Addressing these defects requires a good understanding of material properties, mold design principles, and process control. This is where precision truly shines, as a well-controlled, precise process minimizes these issues.

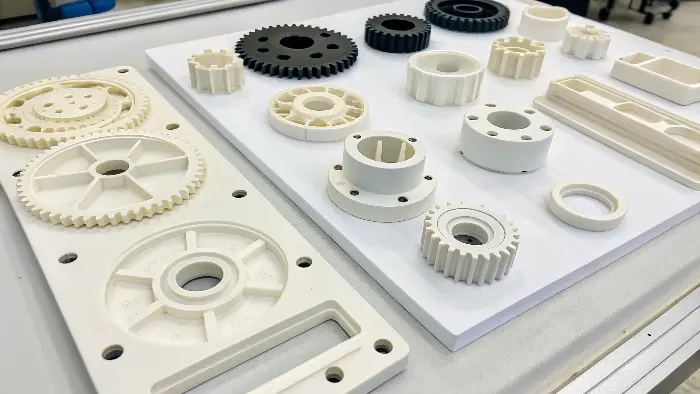

Industries Served by Precision Molding

Precision molding, including operations such as injection molding, insert molding, and overmolding, is applied in a wide range of industries due to its ability to produce high-precision, complex, and robust parts. Key industries include:

Automotive:

Produces precise parts like connectors, sensors, knobs, and interior components, using plastics with metal inserts to provide function and durability.

Electronics:

Produces complex components such as connectors, enclosures, and components on printed circuit boards, providing insulation and accurate tolerances for repeatable performance.

Aerospace:

Offers lighter yet robust pieces like brackets, fittings, and housings, typically made from high-performance materials like PEEK for harsh environments.

Industrial:

Provides durable components like gears, bearings, and housings for equipment that uses wear and chemical-resistant material.

Packaging:

Makes containers, closures, and caps of high accuracy, typically of food-grade or chemical-resistant material for reliability and safety.

Material flexibility, tight tolerances, and ability to merge multiple parts comprise precision molding’s properties that cannot be replaced in these industries.

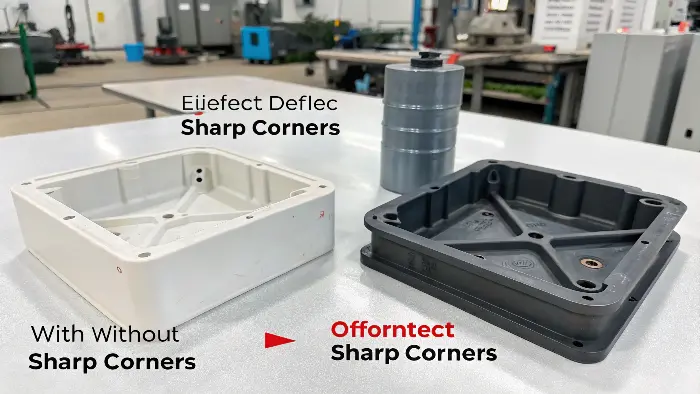

Why sharp corners must be avoided in injection molding?

When producing plastic components, it would be simple to think of having sharp internal or external corners for appearance or function. Sharp characteristics, though, are major problems in molding and for the integrity of the final product. Forgetting this can lead to brittle components, molding problems, and extra expense.

Sharp corners must be avoided in injection molding because they induce stress concentrations, obstruct smooth melt flow, lead to cooling issues, and cause mold filling and part ejection problems. This results in weaker parts, defects, and increased mold wear.

Discuss further Paragraph:

Trust me, from what I have learned of mold design and manufacturing, sharp corners are a source of trouble. One of the biggest issues is stress concentration. Think of it like a river taking a sharp bend – the water erodes the bank more severely there. Similarly, if a plastic part with sharp internal corners is stressed, the stress is concentrated at the corner, leading the part to be much more susceptible to crack or break at that point. I’ve seen countless parts fail prematurely simply because a tiny radius was overlooked in the design.

Sharp corners also affect the manner in which the plastic that has melted fills the mold cavity. Plastic does not want to enter small, sharp spaces. This will cause short shots (incomplete fill) or require very high injection pressure, and this will cause other problems like flash or mold stress. Rounded corners, or radii, permit the plastic to flow more easily and more evenly, with a greater likelihood of complete fill with less stress.

Cooling is also a problem. Sharp exterior corners cool much faster than the material. Sharp interior corners cool more slowly. This uneven cooling may lead to warping and internal stresses in the part. Radii will promote more uniform cooling, leading to a more stable and dimensionally accurate part.

Also, sharp corners on the mold (resulting in sharp corners on the part) are more susceptible to wear and damage. Sharp corners are also more likely to lead to part ejection problems, which may cause scuff marks or even breakage of the part upon ejection. Sharp corners are harder and more expensive to machine in a steel mold than rounded corners.

As a rule in general, we always suggest that designers place generous radii on internal and external corners. A minimum of 0.5mm is usual, but ideally it should be at least 0.5 times the nominal wall thickness. This one simple design consideration makes a big difference in part strength, moldability, and overall product quality. It’s the little things that count.

Impact of Sharp Corners:

- Stress Concentration: Leads to weaker parts prone to failure.

- Melt Flow Issues: Can cause incomplete fills or require higher pressures.

- Cooling Problems: Results in uneven cooling, warping, and internal stress.

- Mold Wear & Ejection: Harder to machine, wears faster, and complicates part ejection.

Adding radii is a fundamental principle of good design for injection molding.

Conclusion

Precision molding services are highly appealing because they ensure parts are made right the first time. Achieving this precision requires knowledge of the molding process, the value of accuracy, typical flaws, and design best practices like avoiding sharp edges. This ultimately leads to better products, reduced waste, and more efficient manufacturing.