Do you want to utilize Thermoplastic Polyurethane (TPU) because of its incredible flexibility and strength yet you are wary of the molding process? TPU is tricky to many designers and engineers. They encounter issues such as parts that stick in the mold, uneven surface finish, or material degradation, which can stop production and cause costly material waste. You understand that the possibilities of TPU are enormous, yet it seems to be hard to make it right.

Injection molding of TPU is a controlled multi-step process that needs to be carefully controlled. It starts with the drying of the hygroscopic TPU pellets to eliminate all moisture. Then the material is melted in the barrel at a certain temperature, usually between 190 o C and 220 o C. The molten TPU is then injected into the mold cavity with high pressure and a controlled speed. Lastly, a certain holding pressure and cooling time is used to control shrinkage and make sure the part solidifies properly prior to ejection.

This overview is a good start, but to be able to fully master TPU and to prevent the most frequent pitfalls, we should dig deeper. All of those processes, drying, melting, injecting, and cooling, possess their critical parameters. The difference between a successful production run and a frustrating experience is the knowledge of the reasons behind each setting. We will simplify the whole process to make you feel confident about molding TPU.

Can TPU be injection molded?

Have you ever touched a product that has a hard but flexible rubber-like texture and thought to yourself that you could make something like this with the speed and efficiency of injection molding? You may think that such unique materials are manufactured slowly and in a specialized way, which restricts your design and production capacity. This can be a true obstacle in case you are attempting to innovate.

Thermoplastic Polyurethane (TPU) is ideal in injection molding, yes. It is a very versatile thermoplastic elastomer specially designed in this process. It can be molded into intricate components at the high speed and precision of typical injection molding because of its special property of melting into a liquid when heated and solidifying again into a strong solid when cooled. This is why it is a preferred option when a part requires the properties of rubber (elasticity) and plastic (processability) such as protective cases, industrial wheels, and seals.

Why TPU is such a star in the molding world boils down to its molecular structure. I would say it is like a chain composed of two types of links: hard and stiff links and soft and flexible links. The hard segments provide it strength, chemical resistance and its thermoplasticity (the capability to be melted and re-melted). The soft segments make it have that incredible elasticity and rubbery texture. Such a combination enables us to produce parts that are extremely hard and abrasion resistant, but can be bent and stretched without fracturing. This creates an enormous scope of applications that cannot be tackled by rigid plastics or conventional rubbers.

Why TPU is a Great Choice for Molding

By deciding to injection mold TPU, you are opening the door to a series of potent benefits that can take your product design and manufacturing process to the next level. It is not only a matter of making a flexible part, but a high performance part efficiently.

Here’s a breakdown of the key benefits:

| Advantage of Molding TPU | Description |

|---|---|

| Design Freedom | The fluid nature of molten TPU allows it to fill intricate and complex mold cavities, enabling detailed designs. |

| High Production Rate | You can leverage the speed of automated injection molding to produce thousands of consistent parts per day. |

| Exceptional Durability | Molded TPU parts have outstanding resistance to abrasion, tearing, oils, and many chemicals. |

| Overmolding Capability | TPU bonds exceptionally well to many rigid plastics (like PC, ABS, and Nylon), perfect for creating parts with soft grips. |

| Recyclability | As a thermoplastic, any production scrap or end-of-life parts can be reground and reprocessed, reducing waste. |

I recall one of the projects with a client making high-end power tools. They were having problems with the grips, which were constructed of a piece of rubber that had to be assembled manually. We converted to two shot overmolding where we would inject a hard ABS plastic to form the tool body, and then inject a layer of TPU to form the grip in the same mold. The outcome was an impeccably bonded, longer lasting grip and they reduced their assembly time to zero. That is the strength of shaping with TPU.

What is the processing of TPU material?

You are convinced to work with TPU, then. However, today you stand in front of an injection molding machine and can only wonder about suitable parameters. When you simply play the parameters of a standard plastic such as polypropylene, you will inevitably end up with a mess- Materials will drip out of the nozzle, parts will get caught irrevocably inside the mold, or there will be burn marks caused by overheating. This experimentation process is irritating and precious machine time and costly material is wasted.

Manufacturing TPU material in injection mold is an accurate four-step process. To remove splay and bubbles, first dry thoroughly, hygroscopic pellets. Second, Reheat TPU in the barrel at a given temperature profile, e.g. 190 o C to 220 o C with low back pressure. Third, pressure inject the material at a high pressure and moderate speed so that the material does not cause degradation when filling the cavity. Lastly, you need to pay extra attention to the cooling and holding process in order to adjust shrinkage and have the part solidify appropriately prior to it being ejected.

So, let us go through this step by step. The trick to a repeatable and smooth process is making sure you have these details correct. It is somewhat like a recipe, by mistake omitting an ingredient or miscalculating temperatures, the end product will not taste the same as you think it should.

Stage 1: Material Drying

This is where failures begin most often, and this is the critical step. TPU is "hygroscopic," and it likes to take up water in the atmosphere. If you’re attempting to form damp TPU, the water turns to steam in the hot barrel and creates defects like splay marks, bubbles, and occasionally part brittleness.

- Action: Dry the TPU pellets in a desiccant dryer for 2-4 hours at 80°C – 110°C (176°F – 230°F). Always check the data sheet of the respective grade for the precise instruction. The final moisture content should be below 0.05%.

Stage 2: Melting and Plasticizing

Here we transform the solid pellets into a uniform molten liquid.

- Temperature: Apply a decreasing temperature profile. For example: Nozzle: 210°C, Front: 210°C, Middle: 190°C, Rear: 180°C. This avoids overheating at the feed throat.

- Back Pressure: Low (e.g., 5-15 bar). TPU can be shear heat sensitive. High back pressure can cause degradation of the material before it is injected.

- Screw: A compression ratio of 2.5:1 to 3:1 is sufficient for a general-purpose screw.

Stage 3: Injection and Packing

This is where we form the part.

- Injection Pressure: TPU is highly viscous (thick) and therefore requires high injection pressure to push it into all the details of the mold cavity.

- Injection Speed: A midrange to slow speed is generally best. Too fast, and you can shear burn it; too slow, and the material can cool before filling the mold.

- Holding Pressure: There must be a holding time that is long, as well as sufficient pressure to pack out the part and offset TPU’s relatively high shrink rate.

Stage 4: Cooling and Ejection

- Temperature of Mold: A temperature in the mold of 20°C to 40°C (68°F – 104°F) is normal. Higher mold temperature results in a better surface finish but at the expense of increased cycle time and part adhesion

.* Ejection: TPU parts can be tacky and flexible when warm. Ensure your mold contains adequate draft angles (a minimum of 3-5 degrees) and a smooth, polished surface to facilitate ejection.

What are the Benefits of Thermoplastic Urethanes (TPU)?

TPUs provide ten primary benefits for injection molded products.

Elasticity: TPUs are very elastic, so they can be stretched and will revert back to their original position.

Toughness: TPUs are durable and resistant to wear and tear, even in harsh environments.

Chemical resistance: TPUs are resistant to a broad array of chemicals and can be employed in severe environments.

Low-temperature flexibility: TPUs are capable of retaining their flexibility in low temperatures and can endure cold conditions.

Abrasion resistance: TPUs are highly abrasion-resistant. They’re perfect when there’s friction.

Hydrophobic: TPUs are hydrophobic, i.e., they repel the uptake of water. This property makes them ideal for applications in wet or humid environments.

Excellent electrical insulation: TPUs are electrically insulating. Hence, they’re utilized in electrical and electronics applications.

Biocompatibility: Certain grades of TPU are biocompatible, i.e., they’re compatible with living tissues and can be used in medical and dental applications.

TPU has different properties according to material grade. That’s why you require an ally who will assist you in material selection and overcome processing issues.

What are the Disadvantages of Thermoplastic Urethanes (TPU)?

There are some disadvantages of injection-molded TPUs.

Processing: TPU may be more challenging to process than other materials, including typical varieties of thermoplastics.

Cost: Due to their intricate make-up and processing demands, TPU may cost more to purchase and utilize than other thermoplastics.

Sensitivity to moisture: certain TPU are moisture absorbent, which can influence physical characteristics like dimensional stability, mechanical strength, and electrical insulation.

Chemical resistance: TPUs are resistant to many types of chemicals, but they are susceptible to some solvents, like ketones and esters.

Aging: TPUs will age with time, resulting in a loss of mechanical strength, elasticity, and other physical properties.

Surface finish: TPUs possess a matte surface finish, which is not ideal for use in applications needing glossy finish.

Remember that these drawbacks can be eliminated or reduced through the right processing, formulation, and selection of the correct TPU grade.

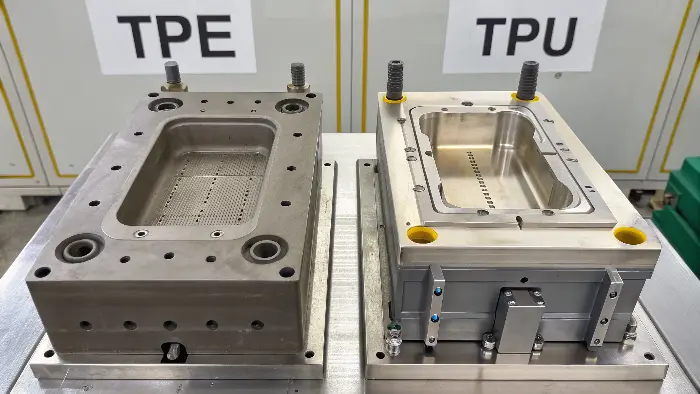

What is the difference between TPE and TPU injection molding?

When it comes to flexible materials, TPE and TPU are those that people commonly talk about in one breath, which is why it is not challenging to mix them up. The wrong one or setting the wrong process parameters can produce a part that will fail in the field or doesn t have the right feel. This blurring can result in you choosing a high-cost, over-engineered material (TPU) or one that is too fragile to be suitable to your use (TPE).

The main difference between injection molding TPE and TPU is in the properties of materials and the obtained parameters of the process. TPU TPEs are a special type of TPEs being harder, stronger and more abrasion resistant. It therefore needs increased processing temperatures (190-220 o C) and pressures. TPE deals with a wider, less demanding spectrum of materials and they tend to run at lower temperatures (160-200 o C). Most importantly, TPU is always subject to intense drying and most TPE grades are not, thus requiring more involved processing.

Heuristic: think of it like this: TPE (Thermoplastic Elastomer) is the general family name, in this case, the equivalent of fruit. TPU (Thermoplastic Polyurethane) is a particular type of that family, such asapple. Although everything that is an apple is a fruit, no everything which is a fruit is an apple. In much the same vein, every TPU is a TPE, not every TPE is a TPU. This is an important difference when you are at the machine. I have watched entire teams spend hours trying to run a difficult TPU grade on the gentle settings they would use to run a TPE that is good until they end up with undershot and unmelted material.

Head-to-Head: TPE vs. TPU

To make the right choice for your project, you need to compare them directly. Here is a table that breaks down the key differences in both material properties and processing needs:

| Feature | Thermoplastic Elastomer (TPE) | Thermoplastic Polyurethane (TPU) |

|---|---|---|

| Hardness | Very soft to semi-rigid (20 Shore A – 90 Shore A) | Semi-rigid to very hard (60 Shore A – 75 Shore D) |

| Durability | Good flexibility, lower tear & abrasion resistance | Excellent abrasion, tear, and chemical resistance |

| Processing Temp | Lower (160°C – 200°C) | Higher (190°C – 220°C) |

| Drying | Some grades don’t require it | Mandatory and critical for part quality |

| Viscosity | Lower, flows more easily (can cause flash) | Higher, requires more injection pressure (can stick) |

| Cost | Generally lower | Generally higher |

| Applications | Soft-touch grips, seals, flexible toys, medical tubing | Caster wheels, phone cases, power tool parts, hoses |

Then it is just a matter of choice depending on application requirements. A TPE will provide the best possible chance of your application when you require super-soft and comfortable grip with a toothbrush and price is a significant consideration. However, when designing a caster wheel to be used by a heavy duty industrial cart that will continuously be put under abrasion pressure and heavy loads, the toughness and durability of TPU cannot be ignored. Knowing these differences will make you choose the appropriate material and know how to process it in the first place.

Uses for Molded TPU Parts

Thermoplastic Polyurethane (TPU) molded parts are extensively used for their special blend of abrasion, chemical, and durability along with flexibility, making them suitable for a variety of applications in numerous industries.

Principal Applications of Molded TPU Parts

Automotive Sector: Interior trim, door panel, handles, instrument panel, protective underbody components, airbag covers, and elastic components where TPU’s durability, flexibility, and oil and chemical resistance are appreciated.

Medical Devices: Materials like catheters, surgical instruments, orthopedic supports, prosthetic components, and wearable medical devices that need biocompatibility, chemical resistance, and safety.

Consumer Electronics: Protective and shock-absorbing enclosures, flexible parts, wire coatings, and handles for handheld units.

Footwear: Hardwearing and flexible shoe midsoles and soles, combining shock absorption and abrasion resistance.

Sports Equipment: Protective gear, helmets, padding, and inflatables requiring impact resistance and flexibility.

Industrial Uses: Conveyor belts, seals, gaskets, rollers, wheels, and pulleys that require wear resistance and chemical inertness.

Sophisticated TPU Molding Applications

Insert and overmolding enable TPU to be combined with another material for ergonomic grips, seals, and cushioned surfaces.

Two-shot molding allows multi-colored and multi-material parts for improved functionality and aesthetics.

Micro-molding creates detailed, small-sized TPU components for applications in precision medical and electronic industries.

These characteristics render molded TPU parts ideal for tough, elastic, and accurate components in the automotive, medical, electronics, footwear, sports, and industrial industries.

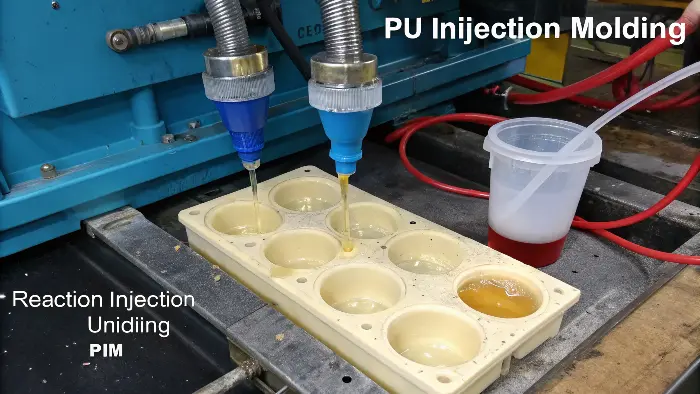

What is the process of PU injection molding?

You frequently find reference to the abbreviations PU or TPU and they are often spoken in the way that they are interchangeable. This is highly confusing. Do they comprise the same substance? Is it moulded in the same way? This is not merely a question of terms; the wrong use can cause potentially serious errors, such as attempting to inject a thermoset liquid into an ordinary thermoplastic injection molding press that can destroy your tools and create a fiasco of massive and unobtrusive proportion.

Although TPU belongs to the PU, the processes of their common molding are essentially different. TPU injection molding is a thermoplastic process through which a solid pellet is melted and injected to cool. Conversely, PU injection molding generally means Reaction Injection Molding (RIM). RIM is a thermoset in which polyol and isocyanate that are liquids at room temperature are coupled with each other and then injected into a mold. They react to form a solid cross-linked component within the mold in a chemical reaction that precludes remelting.

This is among the more significant differences you need to appreciate in the polymers world. I prefer talking with a simple analogy: TPU = water. And onto it you can form ice (a solid part) melt it back into water (molten plastic), and resolidify it. It is a physical change which is reversible. Conventional PU molding (RIM) is cake baking. The liquid ingredients are also mixed (flour, eggs, sugar), put in a pan (the mold), and baked. This heating triggers the chemical process in which the liquid batter is transformed into a solid cake. It is impossible to reverse back to the liquid ingredients of the cake. It performs a one-way chemical reaction.

Thermoplastic vs. Thermoset: The Core Difference

This fundamental difference between a physical change (TPU) and a chemical change (RIM PU) leads to completely different manufacturing setups, capabilities, and outcomes.

Here’s a table comparing the two processes:

| Feature | TPU Injection Molding (Thermoplastic) | PU Reaction Injection Molding (RIM) (Thermoset) |

|---|---|---|

| Material Form | Solid pellets | Two or more liquid components |

| Process | Melt, inject, cool, solidify | Mix liquids, inject, chemically react (cure), solidify |

| Pressures | High injection pressure (10,000+ psi) | Low injection pressure (around 100 psi) |

| Tooling | Requires high-strength steel molds | Lighter-duty molds (e.g., aluminum, even composites) |

| Cycle Times | Generally faster (30-90 seconds) | Generally slower due to cure time (1-5+ minutes) |

| Recyclability | Yes, can be reground and reused | No, cannot be remelted or recycled |

| Part Size | Best for small to medium-sized parts | Excellent for very large, complex parts (e.g., car bumpers) |

So, it is important to clarify that person means when she describes himself as injection molding PU. Are they forming thermoplastic PU (TPU) pellets in common injection molder or liquid thermosets with RIM? Being aware of this distinction will spare you very expensive misunderstanding and will enable you to speak the language of polymer processing like its native speaker.

Conclusion

TPU is a fantastic material with the potential of sole combination of rigidity and flexibility that demand a certain way of injection molding in order to reveal all its possibilities. It is not only another plastic. You can overcome its challenges by adopting a systematic approach, and this includes requiring the drying of all the materials, highly specific temperature profile, and controlled pressures. You will be a better designer with a better knowledge of how the process is different to that of the broader TPE family and a distinct thermoset PU process.