Overwhelmed by ABS options? Choosing the wrong grade means project delays and cost overruns. We simplify ABS selection, ensuring your project’s success from the start.

Selecting the right ABS grade involves understanding your project’s specific requirements for impact strength, heat resistance, flow characteristics, and any special properties like flame retardancy or electroplating suitability. Matching these to available ABS grades is key.

Picking the right type of ABS plastic for your injection molding project can feel a bit like navigating a maze, right? There are so many options, and each one seems to have its own set of pros and cons. I get it. At CKMOLD, we’ve guided countless clients, much like Michael who’s always aiming for that perfect balance of quality and cost for his consumer electronics components, through this very process. The good news is, it’s not as daunting as it seems once you break it down. Let’s dive into how you can make the best choice and truly "Master Molding Right."

What Makes ABS Such a Popular Choice for Injection Molding Anyway?

Ever wondered why so many products, from LEGO bricks to car dashboards, are made from ABS? It’s no accident! This material’s versatility often makes it a go-to for manufacturers.

ABS (Acrylonitrile Butadiene Styrene) is popular due to its balanced combination of toughness, impact resistance, good processability, dimensional stability, and affordability. It also offers good chemical resistance and can be easily colored or electroplated.

ABS is one of those workhorse materials in the plastics world, and for good reason. I’ve seen it used in an incredible range of applications over the years. When I think about why it’s so popular, a few key things always come to mind. First, it’s tough. The "B" in ABS stands for Butadiene, which is a rubbery component. This gives ABS excellent impact resistance, much better than, say, general-purpose polystyrene. This means parts made from ABS can take a bit of a knock without shattering, which is a huge plus for consumer products that might get dropped or bumped around. I remember a client, similar to Michael, who was developing a new handheld device. They initially considered a different plastic, but after some impact testing, we switched to a high-impact ABS grade, and it made all the difference in durability.

Then there’s its processability. ABS generally flows well in the mold, making it suitable for relatively complex geometries. It’s not overly sensitive to processing conditions, which makes it a bit more forgiving for molders. This ease of molding often translates to faster cycle times and lower manufacturing costs – something every business owner appreciates.

Here’s a quick rundown of its star qualities:

- Good Mechanical Properties: A nice balance of strength, stiffness, and toughness.

- Dimensional Stability: Parts hold their shape well after molding.

- Surface Finish: Can achieve a very good, glossy surface finish.

- Chemical Resistance: Holds up well against many common chemicals, oils, and acids.

- Ease of Secondary Operations: It can be easily painted, glued, machined, and, importantly for many consumer electronics, electroplated. That shiny chrome look on many plastic parts? Often, it’s plated ABS.

It’s this all-around capability that makes ABS a default choice for so many injection molding projects. It hits a sweet spot between performance and cost.How Do Different ABS Grades Actually Vary in Properties?

You know ABS is versatile, but "ABS" isn’t just one thing, right? There’s a whole family of grades, and picking the wrong one can lead to parts failing under stress or heat.

ABS grades vary significantly in impact strength (from medium to very high), heat deflection temperature, flow rate (for easy molding of thin walls or complex parts), flame retardancy (UL94 ratings), and suitability for electroplating or UV resistance.

Dive deeper Paragraph:

This is where things get interesting – and where making the right choice really matters. Saying "I need ABS" is like saying "I need a car." Okay, but what kind of car? A sports car, an SUV, a pickup truck? ABS grades are tailored for different performance needs. At CKMOLD, we always start by asking about the end-use application.

Let’s break down some common variations:

- General Purpose ABS: This is your standard, all-around performer. Good balance of impact strength and stiffness, easy to process. Think enclosures, housings, and everyday items.

- High Impact ABS: As the name suggests, these grades are formulated for increased toughness. The butadiene content is typically higher. Ideal for parts that might experience drops or impacts, like tool housings or certain toy components. We once helped a client making protective casings for portable electronics switch to a high-impact ABS, and it drastically reduced field failures.

- High Heat ABS (or Heat Resistant ABS): These grades can withstand higher operating temperatures without deforming. They achieve this through modifications in the acrylonitrile or styrene content, or by adding heat stabilizers. Think automotive interior parts (dashboards, vents) that sit in the sun, or housings for electronics that generate some heat.

- Flame Retardant ABS: Crucial for many electronic and electrical applications where fire safety is a concern. These grades contain additives that help them self-extinguish or resist ignition, often meeting specific UL94 flammability ratings (like V-0, V-1, V-2). This is a big one for Michael’s industry – consumer electronics often have strict flammability requirements.

- Electroplating Grade ABS: This is a special type of ABS designed to provide excellent adhesion for metallic coatings. The surface chemistry is optimized for the plating process. You see this in decorative automotive trim, bathroom fixtures, and shiny bits on appliances.

- High Flow ABS: For parts with very thin walls or long, complex flow paths, a high-flow grade makes molding easier. It has a lower viscosity, allowing the molten plastic to fill the mold cavity more readily.

Understanding these differences is the first step. It’s not just about picking an ABS; it’s about picking the right ABS for the job. This is where our experience at CKMOLD really helps our clients nail their material selection.What Key Factors Should I Consider When Matching an ABS Grade to My Project’s Needs?

Feeling lost trying to connect your product’s demands with the right ABS grade? Prioritizing the wrong factor can mean a subpar product or unnecessary costs. You need a clear path.

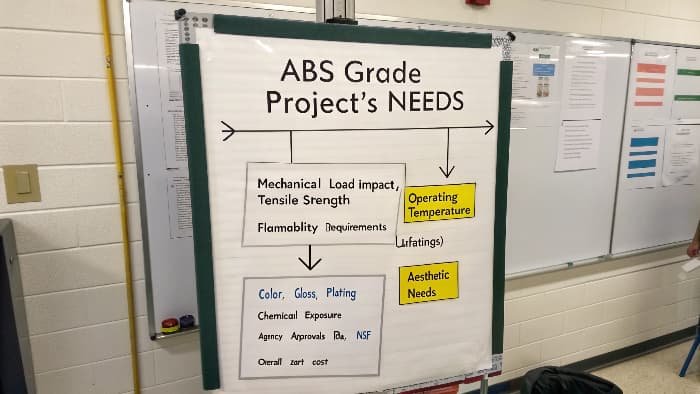

Key factors include: mechanical load (impact, tensile strength), operating temperature, flammability requirements (UL ratings), aesthetic needs (color, gloss, plating), chemical exposure, agency approvals (FDA, NSF), and overall part cost.

Dive deeper Paragraph:

Alright, so you know there are different ABS grades. Now, how do you connect the dots between what your part needs to do and the specific grade that will deliver? This is where we put on our detective hats. I always tell Michael, let’s list out the non-negotiables for your component.

Here’s a mental checklist I often run through with clients:

- Mechanical Performance: What kind of stresses will this part see?

- Impact: Will it be dropped? Hit? (Consider High Impact ABS)

- Tensile/Flexural Strength: Does it need to bear a load or resist bending? (Most general-purpose grades are decent, but some offer higher stiffness).

- Fatigue: Will it undergo repeated stress cycles?

- Thermal Environment: What temperatures will it experience?

- Maximum Operating Temperature: Will it be near a heat source or in a hot environment like a car dashboard? (Look at High Heat ABS grades, check their Heat Deflection Temperature or HDT).

- Minimum Temperature: Will it get very cold? (Some plastics become brittle at low temps, though ABS is generally decent).

- Regulatory & Safety Requirements: This is huge, especially for electronics.

- Flammability: Does it need to meet specific UL94 ratings (e.g., V-0, V-1, V-2, HB)? (Mandatory for Flame Retardant ABS if needed).

- Food Contact/Medical: Does it need to be FDA compliant or USP Class VI? (Specialty grades exist, though less common for general ABS).

- Aesthetics & Finishing: What does it need to look like?

- Color: ABS takes color very well. Custom colors are easy.

- Surface Finish: Glossy? Matte? (Mold finish plays a big role here, but material choice can influence).

- Electroplating/Painting: Does it need a metallic finish or a specific paint job? (Plating Grade ABS is essential for good adhesion).

- Chemical Resistance: Will it come into contact with specific chemicals, oils, or solvents? (ABS has good general resistance, but always check against specific agents).

- Cost: While performance is key, budget always matters. More specialized grades (e.g., high heat, flame retardant) often cost more than general-purpose ones. It’s about finding the best value, not just the cheapest option.

By systematically going through these factors, we can narrow down the choices and pinpoint the ABS grade that offers the optimal blend of performance and cost-effectiveness for your specific injection molding project. It’s a collaborative process, and that’s how we ensure success.Are There Common Mistakes to Avoid When Choosing an ABS Grade?

Worried about making a costly error in your ABS selection? A simple oversight can lead to production nightmares, failed parts, or even safety issues. Knowing the pitfalls is key to avoiding them.

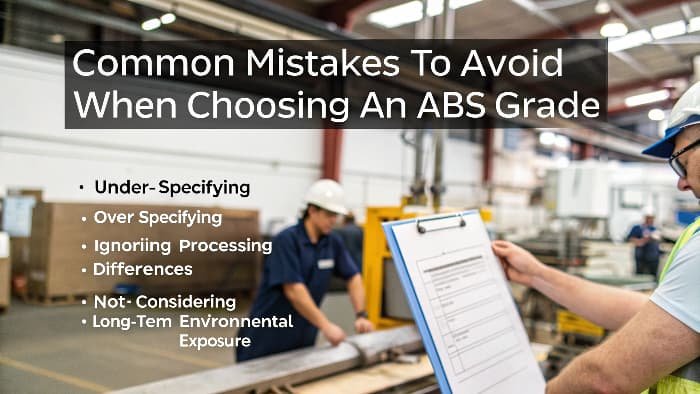

Common mistakes include under-specifying (e.g., choosing a general-purpose grade for a high-heat application), over-specifying (paying for properties you don’t need), ignoring processing differences between grades, or not considering long-term environmental exposure (like UV light).

Dive deeper Paragraph:

Oh, absolutely! Over my years in the mold and plastics industry, I’ve seen a few recurring slip-ups when it comes to selecting ABS. It’s easy to do, especially if you’re not deep in the material science weeds every day. Helping clients like Michael sidestep these is a big part of what we do at CKMOLD.

One common mistake is under-specifying. This happens when a less robust or lower-temperature grade is chosen for an application that really demands more. For example, using a general-purpose ABS for an enclosure that sits next to a heat-generating component. The part might look fine initially, but over time it could warp or soften. I remember a case where a client’s product was failing in warmer climates; they’d used a standard ABS instead of a heat-resistant one to save a few cents per part. That small saving ended up costing them a lot more in warranty claims.

Conversely, there’s over-specifying. This is where you pick a high-performance, and usually more expensive, grade when a standard one would have done the job perfectly. Maybe you choose a UL94 V-0 flame retardant ABS for a part that only needs to meet HB, or a super high-impact grade for something that will sit untouched on a desk. You’re essentially paying for performance you don’t need. It’s about finding that sweet spot.

Another one is ignoring processing nuances. Different ABS grades can have different melt flow rates (MFR) or recommended processing temperatures. If your mold is designed for a high-flow material and you switch to a stiffer, lower-flow grade without adjusting process parameters or even tool design, you can run into molding problems like short shots or high stress in parts.

Finally, not considering the full lifecycle or environmental exposure. For example, standard ABS isn’t great with long-term outdoor UV exposure; it can yellow and become brittle. If your part is going to be outside, you either need a UV-stabilized ABS grade, or you should consider a different material altogether (like ASA, which is like ABS’s weather-resistant cousin).

My advice? Always talk to your molder or a material expert. Provide as much detail as possible about your application. It’s much cheaper to spend a little extra time on material selection upfront than to deal with problems down the line. That’s the CKMOLD way – proactive and thorough.

Conclusion

Selecting the right ABS grade is crucial for your injection molding project’s success. By understanding your needs and the available grades, you can ensure optimal performance, quality, and cost-effectiveness. CKMOLD is here to guide you.